How Stamped Steel Control Arms Affect Fuel Efficiency

TL;DR

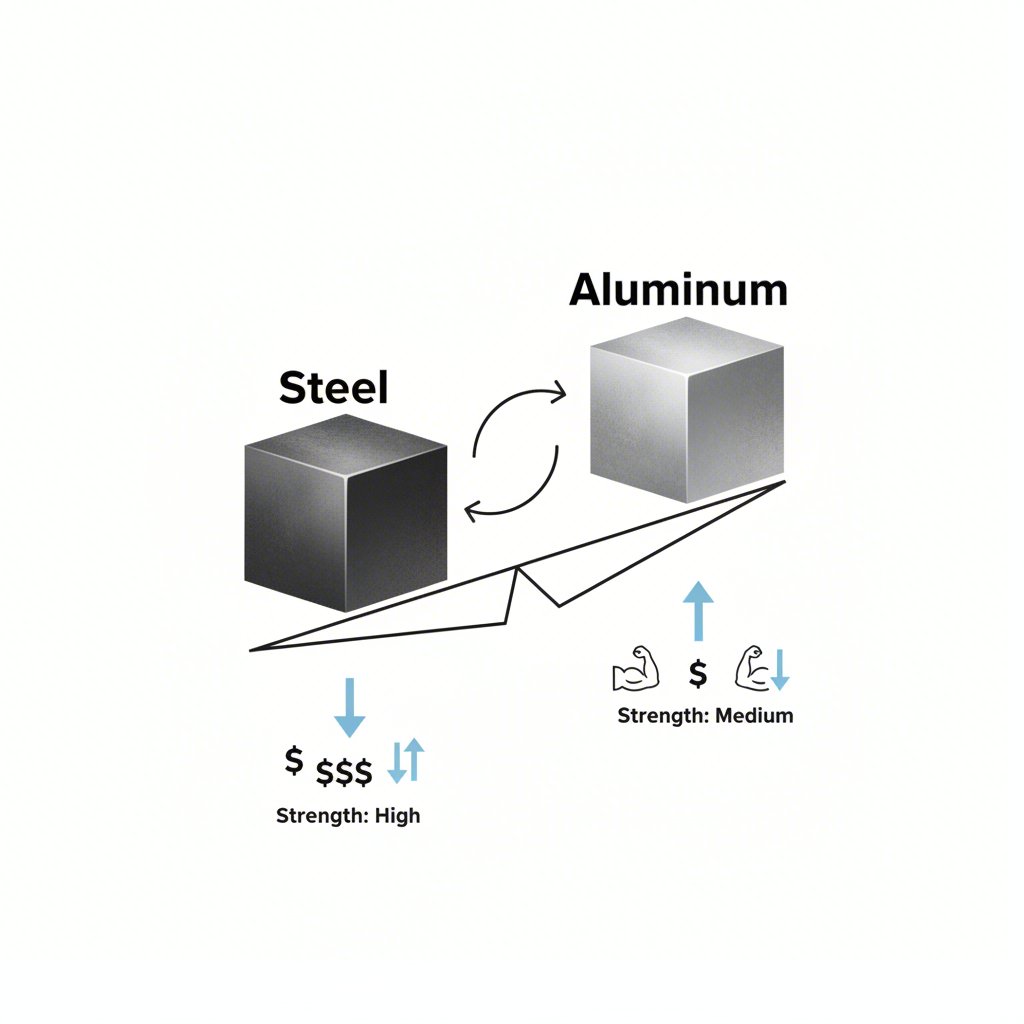

Stamped steel control arms typically have a negative impact on fuel efficiency because they are heavier than alternatives like cast aluminum. Reducing a vehicle's overall weight is a key strategy for improving miles per gallon (MPG), making lighter components a significant factor. The choice between steel and aluminum involves a direct trade-off: steel offers lower cost and high durability, while aluminum provides significant weight savings for better fuel economy and handling at a higher price point.

The Core Principle: How Vehicle Weight Affects Fuel Economy

At the heart of the discussion about control arms and fuel efficiency is a fundamental concept in automotive engineering: lightweighting. This strategy involves reducing the overall mass of a vehicle to decrease the energy required to accelerate and maintain speed, which directly translates to better fuel economy. According to the Union of Concerned Scientists, this principle is a cornerstone of meeting modern efficiency standards. Classical physics dictates that less mass requires less force to move, resulting in fewer greenhouse gas emissions and more miles per gallon.

This principle applies directly to every component, including those in the suspension system. Control arms, which connect the vehicle's chassis to the wheel hub, are a critical part of what is known as "unsprung mass." This refers to the weight of all components not supported by the suspension springs (tires, wheels, brakes, and control arms). Reducing unsprung mass is particularly beneficial, as it not only contributes to overall weight reduction but also improves handling and ride quality. Lighter components allow the suspension to react more quickly to road imperfections, keeping the tires in better contact with the surface for enhanced stability and traction.

While factors like aerodynamics and engine technology play huge roles, component weight is a tangible factor that engineers and even car owners can influence. For every 220 pounds of weight removed from a vehicle, experts estimate a potential 3-5% improvement in fuel efficiency. Therefore, when choosing replacement parts like control arms, the material and its corresponding weight become crucial considerations for anyone looking to optimize their vehicle's performance and running costs.

Stamped Steel vs. Aluminum Control Arms: A Detailed Comparison

When evaluating control arms, the two most common materials you'll encounter are stamped steel and cast aluminum, each with a distinct set of characteristics. The decision between them often comes down to balancing cost, durability, and performance goals, especially concerning fuel efficiency. Stamped steel has long been the traditional choice for many manufacturers due to its strength and low production cost, making it a reliable and budget-friendly option. However, its primary drawback is its weight.

In contrast, aluminum control arms have become increasingly popular, particularly in performance and newer vehicles where efficiency is a priority. As noted in a comparison by Metrix Premium Parts, aluminum is significantly lighter than steel. This weight reduction decreases the vehicle's unsprung mass, leading to improved suspension responsiveness, better handling, and, most importantly, enhanced fuel economy. Aluminum also boasts natural corrosion resistance, a significant advantage over steel, which can be prone to rust in damp climates unless properly coated.

However, these benefits come at a price. Aluminum is generally more expensive than steel, both in raw material cost and manufacturing. While steel is known for its rugged durability and ability to withstand heavy impacts, making it suitable for trucks and heavy-duty applications, aluminum may be more susceptible to damage under extreme stress. The choice ultimately depends on your specific needs: steel for cost-effectiveness and raw strength, and aluminum for lightweight performance and efficiency gains.

To simplify the decision-making process, here is a direct comparison of the key attributes of each material:

| Feature | Stamped Steel | Cast Aluminum |

|---|---|---|

| Weight | Heavier, which can negatively impact fuel efficiency. | Significantly lighter, improving fuel efficiency and handling. |

| Cost | Generally less expensive and more cost-effective. | Higher material and manufacturing costs. |

| Strength & Durability | Very strong and durable, suitable for heavy-duty use. | Strong, but may be more prone to damage from extreme impact. |

| Corrosion Resistance | Susceptible to rust if protective coatings are compromised. | Naturally resistant to corrosion. |

| Impact on Handling | Heavier weight can lead to less responsive handling. | Reduced unsprung mass improves traction and cornering. |

Beyond Material: The Role of Manufacturing in Performance

While the choice between steel and aluminum is critical, the manufacturing process—stamping, casting, or forging—adds another layer of complexity and has a significant impact on a control arm's final performance. Understanding these methods is key to appreciating the engineering trade-offs that automakers and parts manufacturers make. Each technique imparts different properties to the final product, affecting everything from strength-to-weight ratio to cost.

The most common methods include:

- Stamping: This process involves shaping sheets of metal using a die. Stamped steel control arms are cost-effective to produce in high volumes, which is why they are common in many passenger vehicles. While traditionally associated with higher weight, modern advancements in high-strength steel alloys have allowed for the production of lighter and more robust stamped components than ever before.

- Casting: In this method, molten metal (like aluminum or iron) is poured into a mold. Casting allows for more complex shapes, which can be optimized for strength while minimizing material usage and weight. Cast aluminum arms are a popular lightweight option.

- Forging: Forging involves shaping metal using localized compressive forces. This process aligns the internal grain structure of the metal, resulting in parts with superior strength and fatigue resistance compared to stamped or cast alternatives. Forged aluminum arms are often found in high-performance vehicles where strength and low weight are paramount.

Interestingly, while stamped steel is often seen as the heavier option, it remains a key part of modern lightweighting strategies. Automakers are under constant pressure to meet stricter emissions regulations, and advanced stamping techniques using high-strength, low-alloy (HSLA) steels enable them to create components that are both strong and surprisingly light, all while controlling costs. For automotive manufacturers, achieving this balance of precision, quality, and cost-effectiveness is crucial. Companies specializing in this area, like Shaoyi (Ningbo) Metal Technology Co., Ltd., provide the advanced metal stamping solutions necessary to produce these complex, high-performance components, from initial prototypes to full-scale mass production.

Ultimately, a part's performance is a combination of its material and how it was formed. A forged aluminum arm will have different properties than a cast aluminum one, just as a modern stamped high-strength steel arm can outperform an older, simpler design. When selecting replacement parts, it's beneficial to consider both factors to ensure you get the performance characteristics you're looking for.

Frequently Asked Questions

1. What is the best material for control arms?

There is no single "best" material, as the ideal choice depends on your priorities. If you are looking for maximum performance, improved handling, and better fuel efficiency, lightweight cast aluminum is often a preferred option, as highlighted in guides from retailers like Perform-Ex Auto. However, if your primary concerns are durability, initial cost, and strength for heavy-duty applications, stamped or cast steel remains an excellent and reliable choice.

2. What is the difference between stamped and forged control arms?

The main difference lies in the manufacturing process and resulting strength. Stamped control arms are made by pressing a sheet of steel into a desired shape, which is a cost-effective method for mass production. Forged control arms are created by heating metal and compressing it into a die. This forging process aligns the metal's internal grain flow with the part's shape, resulting in a component that is significantly stronger and more resistant to fatigue than a stamped or even a cast part.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —