How Forged Control Arms Are Made: A Technical Look

How Forged Control Arms Are Made: A Technical Look

TL;DR

Forged control arms are manufactured by heating a solid billet of metal, typically an aluminum alloy or steel, to a malleable temperature. This heated metal is then shaped into its final form by pressing it between custom dies under extreme pressure. This process is superior to casting or stamping because it realigns the metal's internal grain structure, resulting in a component with significantly greater strength, durability, and resistance to fatigue.

What Is a Forged Control Arm?

A forged control arm is a critical suspension component that connects a vehicle's chassis to the wheel assembly, allowing the wheels to move vertically while maintaining stability and steering control. As described by experts at SH Auto Parts, the term "forged" refers specifically to its manufacturing method: forcing a heated metal billet between powerful dies under high pressure to form its shape. This method is fundamentally different from casting (pouring molten metal into a mold) or stamping (shaping and welding sheet metal).

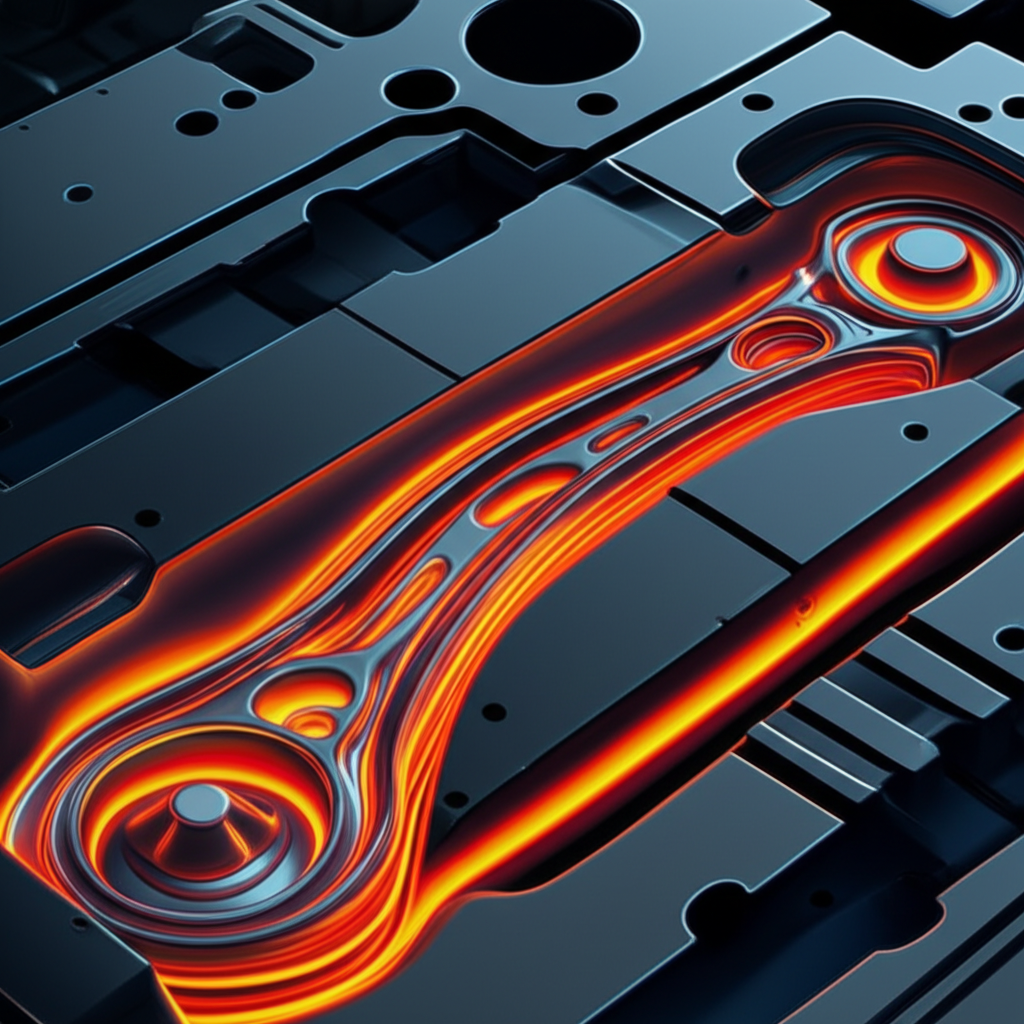

The primary reason for using the forging process for a high-stress part like a control arm lies in its metallurgical benefits. The immense pressure of forging realigns and refines the metal's internal grain structure, forcing it to follow the contours of the component. This continuous grain flow eliminates internal voids and weak points, leading to exceptional tensile strength and fatigue resistance. For drivers, this means a more reliable suspension that maintains proper wheel alignment under dynamic conditions, from sharp turns to rough road surfaces, ultimately enhancing both safety and vehicle handling.

The Step-by-Step Forging Process Explained

The creation of a forged control arm is a precise, multi-stage process that transforms a simple metal billet into a high-strength automotive component. Each step is critical to ensuring the final product meets exacting standards for durability and performance.

- Material Selection and Billet Preparation: The process begins with selecting the appropriate raw material, typically a high-grade aluminum alloy (like 6061-T6) or an alloy steel (like 4140). The choice depends on the desired balance of weight, strength, and cost. The material is cut into short, solid bars called billets, which are the starting blocks for each control arm.

- Heating the Billet: The billets are transported to a furnace and heated to a specific temperature range—hot enough to become plastic and malleable, but well below their melting point. For aluminum, this is typically around 400-500°C. This precise heating is crucial for allowing the metal to be shaped without cracking.

- Closed-Die Forging: The heated billet is placed onto the bottom half of a custom-made, hardened steel die. A powerful press or hammer then forces the top half of the die down onto the billet with immense pressure. This action squeezes the hot metal, forcing it to flow and fill every cavity of the die, creating the complex shape of the control arm. This is the key step where the metal's grain structure is refined and aligned.

- Trimming (Deflashing): As the metal is compressed, a small amount of excess material known as "flash" squeezes out from the edges of the dies. After the forging is complete, the part is moved to a trimming press where this flash is sheared off, leaving the clean shape of the control arm.

- Heat Treatment: To achieve maximum strength and hardness, the forged part undergoes heat treatment. This often involves solution heat treating, quenching (rapid cooling), and artificial aging (reheating to a lower temperature for a set period). This process locks the metallurgical structure into its strongest possible state.

- Finishing and Inspection: In the final stages, the control arm may undergo shot peening to improve fatigue resistance and is then machined to create precise surfaces for bushings and ball joints. Every part is subjected to rigorous quality control, which can include non-destructive testing to ensure there are no internal flaws before it is approved for assembly.

Common Materials: Aluminum vs. Steel Forging

The choice between aluminum and steel is one of the most significant decisions in designing a forged control arm, as each material offers a distinct set of advantages. The selection directly impacts the vehicle's performance, handling characteristics, and overall cost. For those seeking specialized manufacturing, companies like Shaoyi Metal Technology offer custom hot forging services for the automotive industry, working with both types of materials to meet specific engineering requirements.

Aluminum alloys are prized for their high strength-to-weight ratio. A forged aluminum control arm is significantly lighter than its steel counterpart, which reduces the vehicle's "unsprung mass"—the weight not supported by the suspension. This reduction allows the suspension to react more quickly to road imperfections, improving ride quality and handling. Furthermore, aluminum is naturally corrosion-resistant, giving it a longer lifespan in harsh environments with salt and moisture. These benefits make it the preferred choice for performance cars and electric vehicles where efficiency and agility are paramount.

Steel, on the other hand, is known for its sheer strength, durability, and lower material cost. Forged steel control arms can withstand extreme stress and repeated impacts, making them ideal for heavy-duty trucks, off-road vehicles, and commercial applications. While heavier than aluminum, steel's high fatigue strength ensures reliability under constant, heavy loads. The trade-off is its susceptibility to rust, which requires protective coatings to prevent corrosion over time.

| Feature | Aluminum Forging | Steel Forging |

|---|---|---|

| Weight | Lightweight | Heavy |

| Strength-to-Weight Ratio | High | Moderate |

| Corrosion Resistance | Excellent | Poor (requires coating) |

| Cost | Higher | Lower |

| Common Application | Performance cars, EVs | Trucks, heavy-duty vehicles |

Forged vs. Other Manufacturing Methods: Casting and Stamping

While forging is a superior method for high-stress applications, control arms can also be made by casting or stamping. Understanding the differences reveals why forging is often the preferred choice for safety-critical suspension components. Each method produces a part with distinct structural characteristics and performance limitations.

Casting involves pouring molten metal into a mold and letting it cool. This process is excellent for creating complex shapes, but the resulting product has a random, non-directional grain structure. This can lead to internal porosity and brittleness, making cast parts less resistant to shock and fatigue compared to forged parts. While suitable for less critical components, casting is generally not preferred for high-stress control arms where the strength and durability of forging are required.

Stamping is a common method for mass-produced vehicles, where steel sheets are pressed into shape and then welded together to form a hollow control arm. As detailed in patent documents, this technique is cost-effective but has inherent weaknesses. The welds can become stress points prone to failure, and the hollow structure is less rigid than a solid forged part. Stamped arms may flex under heavy cornering, negatively affecting handling and alignment.

Ultimately, forging stands apart because it shapes solid metal, refining its internal structure to create a component that is both stronger and more durable. The continuous, aligned grain flow achieved through forging provides unparalleled resistance to the bending forces and cyclic loads that a control arm endures, ensuring long-term reliability and optimal vehicle performance.

Frequently Asked Questions

1. How are control arms manufactured?

Control arms are typically manufactured using one of three main methods: forging, casting, or stamping. Forging involves shaping a heated solid metal billet under extreme pressure. Casting consists of pouring molten metal into a mold. Stamping involves pressing sheet metal into shape and welding the pieces together to create a hollow arm. Forging is generally considered the strongest method.

2. What is a forged control arm?

A forged control arm is a suspension component made by heating metal and pressing it into shape with dies. This process aligns the metal's internal grain structure, making the part exceptionally strong and resistant to fatigue and impact. It is used in applications where durability and precise handling are critical.

3. How is forged aluminum made?

Forged aluminum is made by heating an aluminum alloy billet to a specific temperature where it becomes malleable. It is then placed in a die and shaped under immense pressure from a press or hammer. This process refines the grain structure, producing a lightweight part with a very high strength-to-weight ratio.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —