Factors Affecting Stamping Die Cost: 5 Key Drivers Analysis

TL;DR

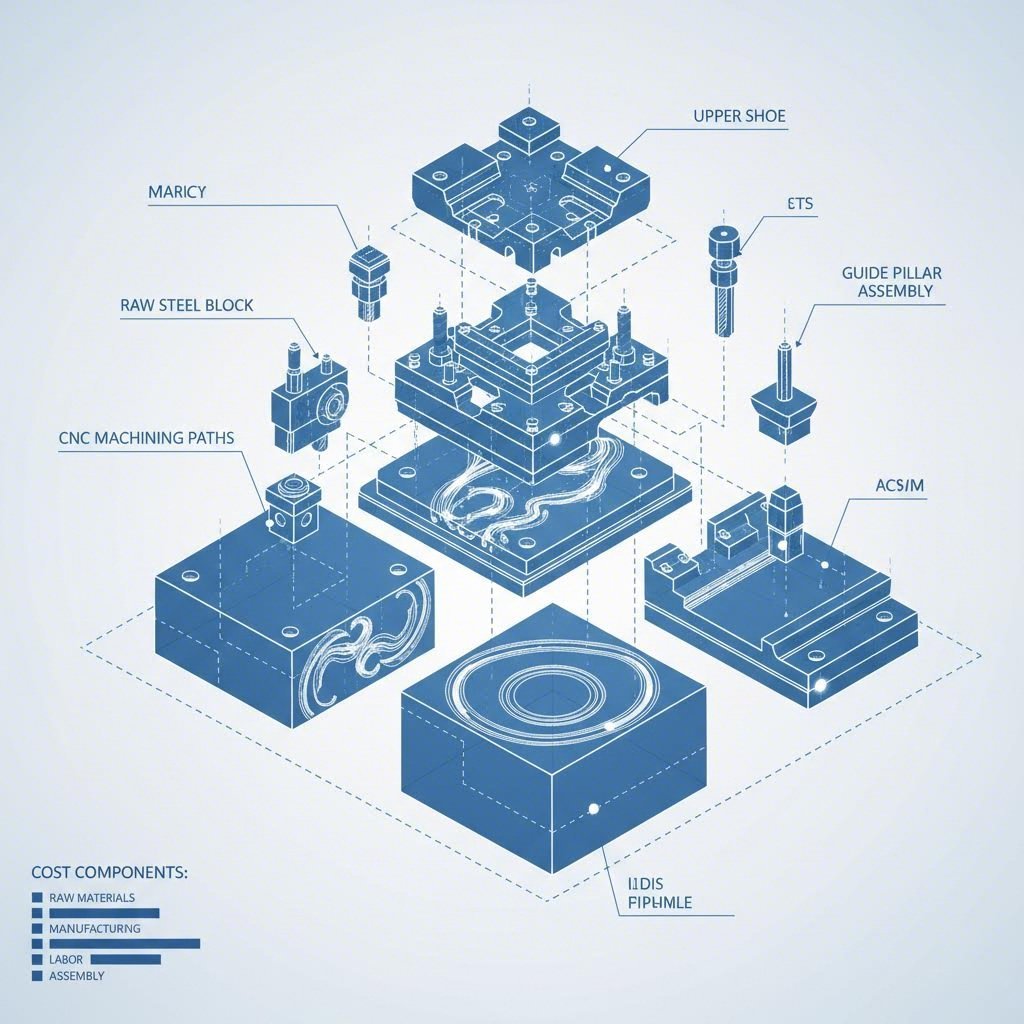

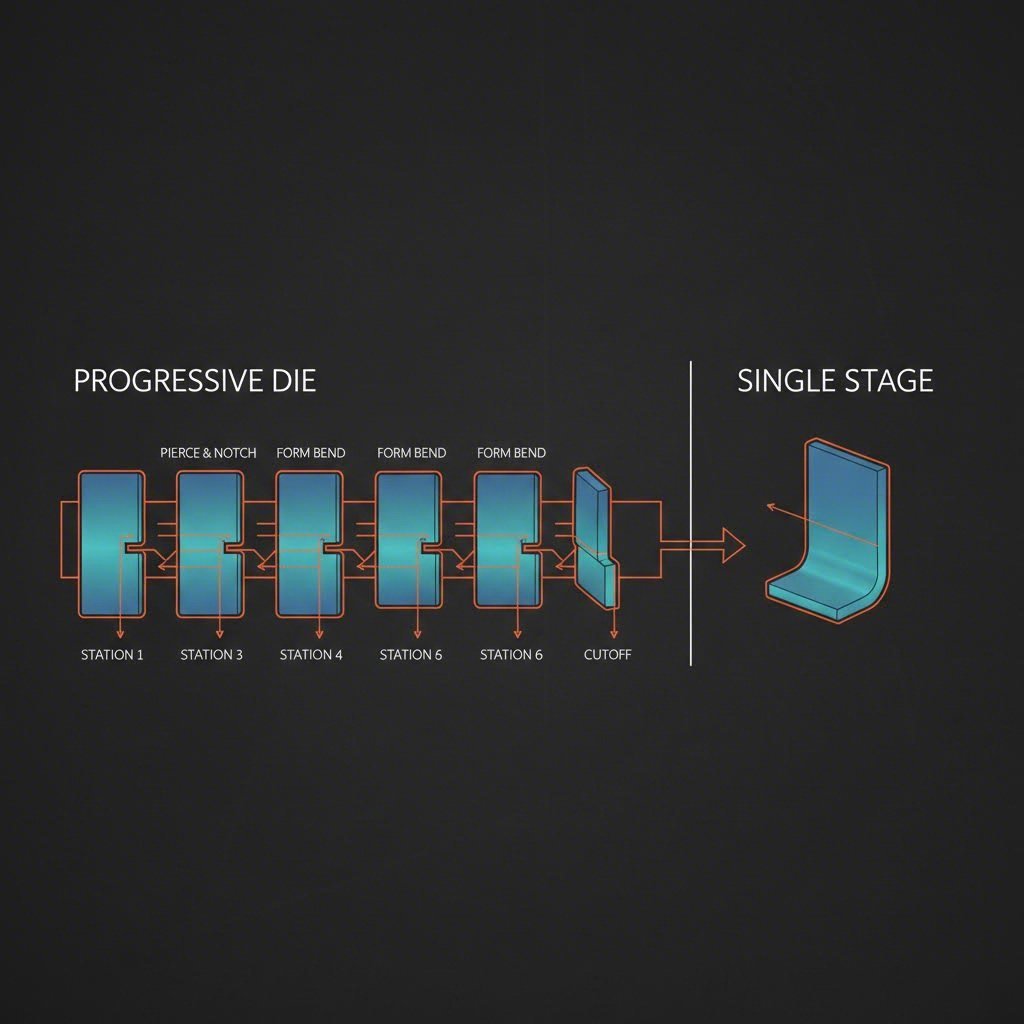

Stamping die cost is primarily driven by four core factors: part complexity (tolerances and geometry), die type (progressive vs. single-stage), material selection, and production volume. A useful rule of thumb from industry data suggests that each additional station in a progressive die increases the total cost by roughly 8–12% due to added design and machining time. While "Class A" tooling requires a higher initial investment (often exceeding $50,000) for hardened tool steels and ease of maintenance, it drastically reduces the per-unit price for high-volume runs. Conversely, soft tooling works best for prototypes but lacks long-term durability.

Part Complexity & Geometry: The Primary Cost Driver

The physical design of the part is the single most significant variable in determining the price of a stamping die. Complexity is not just about the number of features; it is about the mechanics required to form them. A simple flat washer requires a basic blanking operation, whereas a deep-drawn automotive body panel involves complex contours that may require multiple redraws, cams, and slides to achieve the final shape.

Tight tolerances are a major cost multiplier. As tolerances shrink below ±0.001 inches, the die manufacturer must employ precision EDM (Electrical Discharge Machining) and jig grinding rather than standard CNC milling. This precision labor is significantly more expensive. Furthermore, complex geometry dictates the number of stations required in the die. According to cost estimation data from Shaoyi, adding a single station to a progressive die design typically inflates the tool price by 8% to 12%. Engineers can reduce these costs by applying Design for Manufacturability (DFM) principles, such as relaxing non-critical tolerances and simplifying bend radii to reduce the total station count.

Die Type & Production Volume: Matching Tool Class to Needs

Your Estimated Annual Usage (EAU) should dictate the class of tooling you commission. The industry categorizes dies into classes based on durability and volume capability:

- Class A Tooling: Designed for high-volume production (often exceeding 1 million strikes). These dies use premium hardened tool steels and are engineered for easy maintenance. While the upfront cost is high, they offer the lowest piece-part price and minimal downtime.

- Class C Tooling: Often referred to as "soft tooling," these are built for low-volume runs or prototypes (under 10,000 parts). They use cheaper materials and simplified designs, reducing initial investment but increasing maintenance needs and per-part labor costs.

The choice between progressive dies and single-stage (line) dies also impacts the budget. Progressive dies, which perform multiple operations with each press stroke, carry a higher price tag due to their complexity and size. However, for volumes above 25,000 parts per year, the efficiency of a progressive die usually offsets the initial NRE (Non-Recurring Engineering) cost by significantly lowering the labor cost per part.

Material Selection: Workpiece vs. Tool Steel

Material costs impact the quote from two angles: the material you are stamping and the material the die is made from. High-strength materials like titanium, Inconel, or Advanced High-Strength Steel (AHSS) are abrasive and tough to form. Stamping these materials requires the die to be constructed from premium-grade carbide or specially coated tool steels to prevent rapid wear. Carbide tooling can cost three times as much as standard D2 tool steel due to the need for diamond finishing and wire burning.

Conversely, stamping softer metals like aluminum or brass allows for the use of standard A2 or D2 tool steel, which is easier and cheaper to machine. Procurement teams must understand this trade-off: requesting a quote for a stainless steel part will invariably result in a higher tooling cost than the same part design in mild steel, simply because of the die wear factor.

Secondary Cost Factors: Labor, Location, and Niche

Beyond the physical tool, vendor-specific variables play a massive role in the final quote. Labor rates vary drastically by region; a die shop in a high-cost-of-living area like California will charge significantly more for design and machining hours than a shop in Wisconsin or overseas. Additionally, the "niche" of the die shop matters. A manufacturer specializing in massive Class A automotive panels will have high overhead and hourly rates that make them uncompetitive for small, simple brackets.

It is also critical to consider the Total Cost of Ownership (TCO) rather than just the sticker price. Low-cost imported dies may seem attractive initially but often suffer from "hidden costs" like inferior steel quality, communication barriers, and expensive shipping delays. Shaoyi Metal Technology bridges this gap by offering a turnkey solution that combines cost-effective manufacturing with IATF 16949-certified precision. Whether you need rapid prototyping (delivering 50 parts in as little as five days) or high-volume automotive production, their integrated approach ensures that the tooling investment aligns perfectly with your quality standards and volume requirements, mitigating the risks often associated with global sourcing.

Cost Estimation Methods: How Suppliers Calculate Quotes

Understanding how suppliers generate their numbers can help you negotiate better. There are two primary methods used in the industry:

| Method | Description | Pros & Cons |

|---|---|---|

| Similarity-Based | Estimates cost based on historical data of similar past projects. |

Pros: Fast and requires less detail. Cons: High margin of error; often misses unique complexity factors. |

| Analytical (Software) | Calculates cost by breaking down every machining hour, material pound, and heat treat cycle. |

Pros: Highly accurate and transparent. Cons: Time-consuming; requires detailed CAD models. |

For the most accurate pricing, procurement managers should request an analytical breakdown. This transparency allows you to see exactly how design changes—like loosening a tolerance or changing a material—would impact the final die cost.

Strategic Sourcing Implications

The cost of a stamping die is not a fixed commodity price but a reflection of risk, durability, and capacity. The most effective way to control these costs is not to demand a lower margin from the supplier, but to collaborate on Design for Manufacturability (DFM). By engaging with your die partner early in the design phase, you can identify the "cost drivers" in your geometry—such as tight radii or unnecessary tolerances—and eliminate them before steel is ever cut. Ultimately, the goal is to balance the upfront NRE expense with the long-term reliability required to keep your production line running without interruption.

Frequently Asked Questions

1. How much does a metal stamping die cost?

Costs vary wildly based on complexity. A simple single-stage die for a small bracket might cost between $3,000 and $5,000. However, a complex progressive die for an automotive component typically ranges from $15,000 to over $50,000. Large Class A transfer dies for body panels can easily exceed $150,000.

2. What are the defects in the stamping process that increase cost?

Common defects include splitting, wrinkling, and excessive burrs. These issues often stem from poor die design or incorrect material selection. Fixing these defects requires expensive die rework, trial-and-error adjustments (debugging), and production downtime. Investing in simulation software during the design phase can prevent these costly errors.

3. What are the 7 steps in the stamping method?

While processes vary, the standard sequence often includes: 1) Blanking (cutting the rough shape), 2) Piercing (adding holes), 3) Drawing (forming depth), 4) Bending (creating angles), 5) Air Bending (forming without bottoming out), 6) Bottoming/Coining (stamping for precision), and 7) Trimming (removing excess material). Each step adds a "station" to the die, incrementally increasing the tooling cost.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —