Essential Automotive Die Manufacturing Techniques

TL;DR

Automotive die manufacturing is a precision engineering process for creating specialized tools, or dies, used to cut, stamp, and form sheet metal into vehicle components. This process is the backbone of modern vehicle production, ensuring every part is made with consistency and accuracy. It relies on advanced automotive die manufacturing techniques such as CNC machining, Electrical Discharge Machining (EDM), and high-speed cutting, utilizing durable materials like tool steel and carbide to produce millions of identical parts.

Understanding the Fundamentals of Automotive Die Manufacturing

At its core, die manufacturing is the intricate process of designing and creating specialized tools called dies. In the automotive industry, these tools are indispensable, serving as the molds and cutters that shape raw metal into the vast array of components that make up a modern vehicle. From the sleek lines of a car's body panels to the complex geometry of engine brackets, dies are the hidden backbone that ensures every part is produced to exact specifications. This precision is critical not just for aesthetics but for the safety, performance, and reliability of the vehicle.

The primary function of a die is to cut or form material, often sheet metal, with extreme repeatability. This is achieved through immense pressure, where a press forces the metal into or through the die. According to manufacturing experts at Alicona, precision dies are engineered to achieve micrometer-level tolerances, distinguishing them from standard tools. This capability allows for the mass production of complex parts with a level of consistency that manual processes could never replicate, making it a cornerstone of efficient, large-scale manufacturing.

The advantages of using high-quality dies in automotive production are significant. They enable manufacturers to produce parts that are not only identical but also meet stringent quality standards. This consistency is vital for seamless assembly and the overall structural integrity of the vehicle. As noted in a guide by Fremont Cutting Dies, the key benefits include:

- Consistency & Accuracy: Every product is identical, meeting strict quality and safety standards.

- Scalability: Dies allow production to scale quickly and cost-effectively to meet consumer demand.

- Cost-Effectiveness: While the initial investment is significant, the long-term savings from efficient mass production are substantial.

- Enhanced Product Quality: High-quality dies result in high-quality components, reducing errors and boosting customer satisfaction.

Ultimately, the die manufacturing process is what allows for the safe, reliable, and aesthetically pleasing vehicles we see on the road today. It bridges the gap between raw material and a finished, functional automotive component, enabling the production of everything from transmission gaskets and battery insulators to the car's exterior shell.

Core Types of Dies Used in Automotive Production

Automotive dies can be broadly categorized based on their primary function, with the two main classifications being cutting dies and forming dies. Cutting dies are designed to shear or remove material, performing operations like blanking (cutting the outer shape of a part) and punching (creating holes). Forming dies, on the other hand, reshape the material without removing it, through processes like bending, drawing, and flanging. Within these broad categories, several specific types of dies are crucial for automotive production, each with a unique mechanism and application.

Simple dies perform a single operation with each stroke of the press, making them suitable for basic parts. In contrast, more complex dies are designed for efficiency in high-volume production. Compound dies perform multiple cutting operations, such as punching and blanking, in a single station and with a single press stroke. This design ensures high accuracy for flat parts because all operations occur simultaneously, eliminating potential errors from moving the part between stations. However, they are generally less suited for parts requiring complex forming.

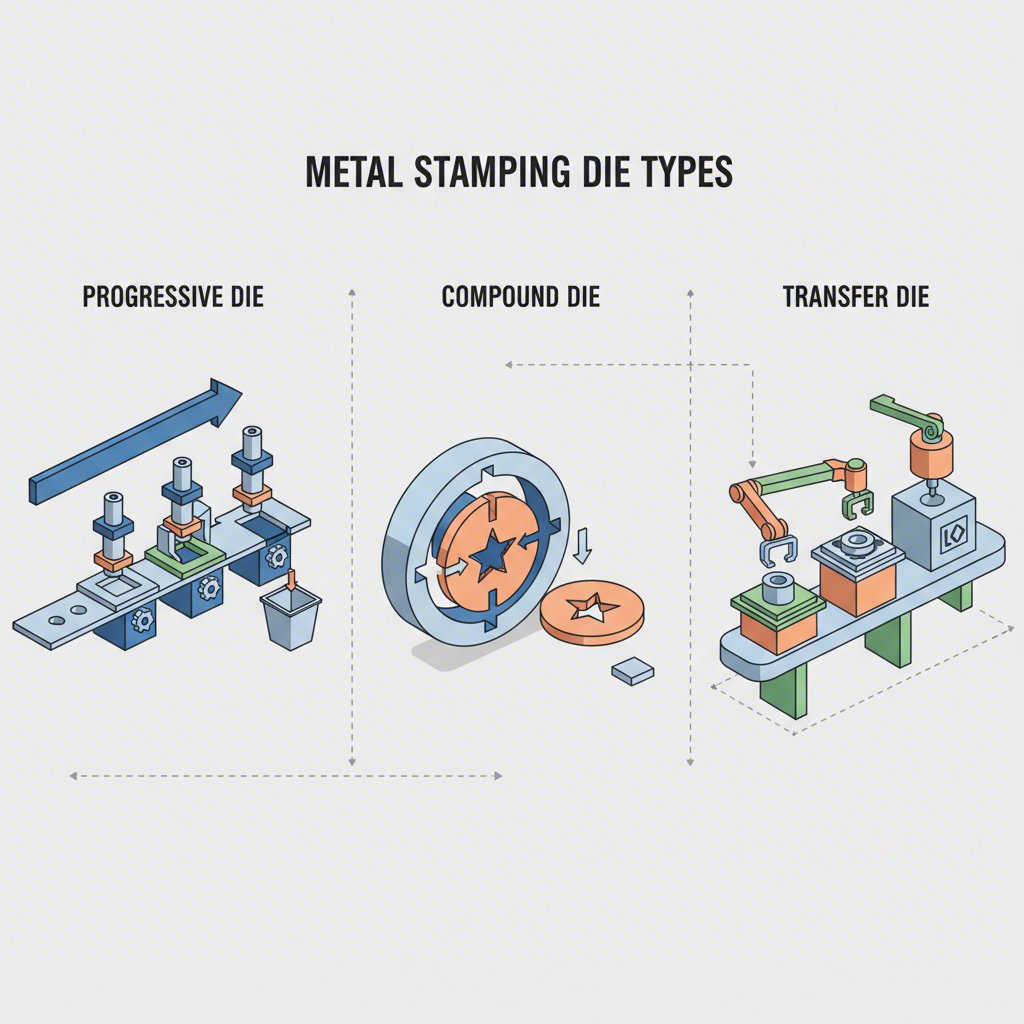

Progressive dies are a mainstay of modern automotive manufacturing. As detailed by Evans Tool & Die, a continuous strip of metal is fed through the die, and a series of sequential operations (punching, bending, forming) are performed at different stations with each press stroke. This method is highly efficient for producing complex components in large volumes, such as electronic connectors or small brackets. Transfer dies operate on a similar principle of sequential operations but handle individual, pre-cut blanks that are mechanically transferred from one station to the next. This makes them ideal for larger and more intricate parts, like deep-drawn body panels, where a continuous strip feed is not practical.

To clarify their differences, consider the following comparison:

| Die Type | Mechanism | Ideal Use Case | Key Advantage |

|---|---|---|---|

| Compound Die | Multiple cutting operations in a single station/stroke. | Simple, flat parts like washers and gaskets. | High accuracy and cost-effective for simple geometries. |

| Progressive Die | Sequential operations on a continuous metal strip. | High-volume, complex parts like connectors and brackets. | High speed and efficiency for mass production. |

| Transfer Die | Sequential operations on individual blanks transferred mechanically. | Large, complex parts like body panels and structural frames. | Flexibility for deep-drawn and irregularly shaped components. |

The choice between these die types depends entirely on the part's geometry, the required production volume, and cost considerations. Each type plays a specific role in efficiently manufacturing the thousands of unique components that constitute a complete vehicle.

The Step-by-Step Die Manufacturing Process

Creating a high-performance automotive die is a rigorous, multi-stage process that combines sophisticated software with precision engineering. Each step is critical to ensuring the final tool can reliably produce millions of identical parts with minimal deviation. The end-to-end journey from concept to a production-ready die can be broken down into five key stages.

- Design & Engineering: The process begins in the digital realm. Using advanced Computer-Aided Design (CAD) software, engineers create a detailed 3D model of the die. As explained by Actco Tool & Manufacturing, this digital blueprint allows for simulations and analysis to optimize performance and identify potential issues before any metal is cut. This stage is crucial for defining the die's dimensions, features, and operational flow to ensure it meets the part's specifications perfectly.

- Material Selection: The choice of material is fundamental to a die's durability and performance. The most common materials are high-strength tool steels (like D2 for wear resistance or H13 for heat resistance) and cemented carbide for extreme-wear applications. The selection depends on factors such as the material being stamped, the expected production volume, and the complexity of the operation. The right material ensures the die can withstand the immense stresses of repeated use.

- Precision Machining & Finishing: This is where the digital design becomes a physical tool. A combination of advanced manufacturing techniques is used to shape the selected material. CNC (Computer Numerical Control) milling and turning create the basic geometry, while precision grinding achieves flat surfaces and tight tolerances. For intricate details or hardened materials, Electrical Discharge Machining (EDM) is often employed to erode the metal with electrical sparks, achieving a level of detail that traditional machining cannot.

- Heat Treatment & Coating: After machining, the die components undergo heat treatment. This process involves carefully controlled heating and cooling cycles to harden the steel, significantly increasing its strength and resistance to wear and deformation. Following heat treatment, a specialized coating—such as Titanium Nitride (TiN) or Diamond-Like Carbon (DLC)—may be applied. These ultra-thin, hard coatings reduce friction and further extend the die's operational life.

- Assembly, Testing & Verification: In the final stage, all the individual components of the die set—including punches, die blocks, and guide pins—are meticulously assembled. The completed die is then installed in a press for testing. During these trial runs, the first parts are produced and carefully inspected to verify that they meet all dimensional and quality requirements. Any necessary adjustments are made to fine-tune the die's performance before it is approved for full-scale production. This rigorous process requires significant expertise, which is why leading manufacturers often partner with specialized firms. For instance, companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. leverage IATF 16949 certification and advanced CAE simulations to deliver high-quality automotive stamping dies for OEMs and Tier 1 suppliers.

This meticulous, step-by-step approach is essential for creating dies that deliver the precision, longevity, and reliability required by the demanding automotive industry.

Key Techniques and Technologies in Modern Die Manufacturing

Modern automotive die manufacturing relies on a suite of sophisticated techniques that enable the creation of highly precise, durable, and complex tools. These technologies have moved far beyond traditional machining, allowing for the shaping of hardened materials to microscopic tolerances. Understanding these core techniques is key to appreciating the engineering behind high-quality automotive components.

High-Speed Cutting (HSC)

High-Speed Cutting, or HSC, is a milling process that operates at significantly higher rotational speeds and feed rates than conventional machining. This technique reduces cutting forces, minimizes heat transfer into the workpiece, and produces a superior surface finish. For die manufacturing, HSC is invaluable for roughing and finishing hardened tool steels, often reducing the need for subsequent polishing. Its speed and precision can dramatically shorten lead times in die production.

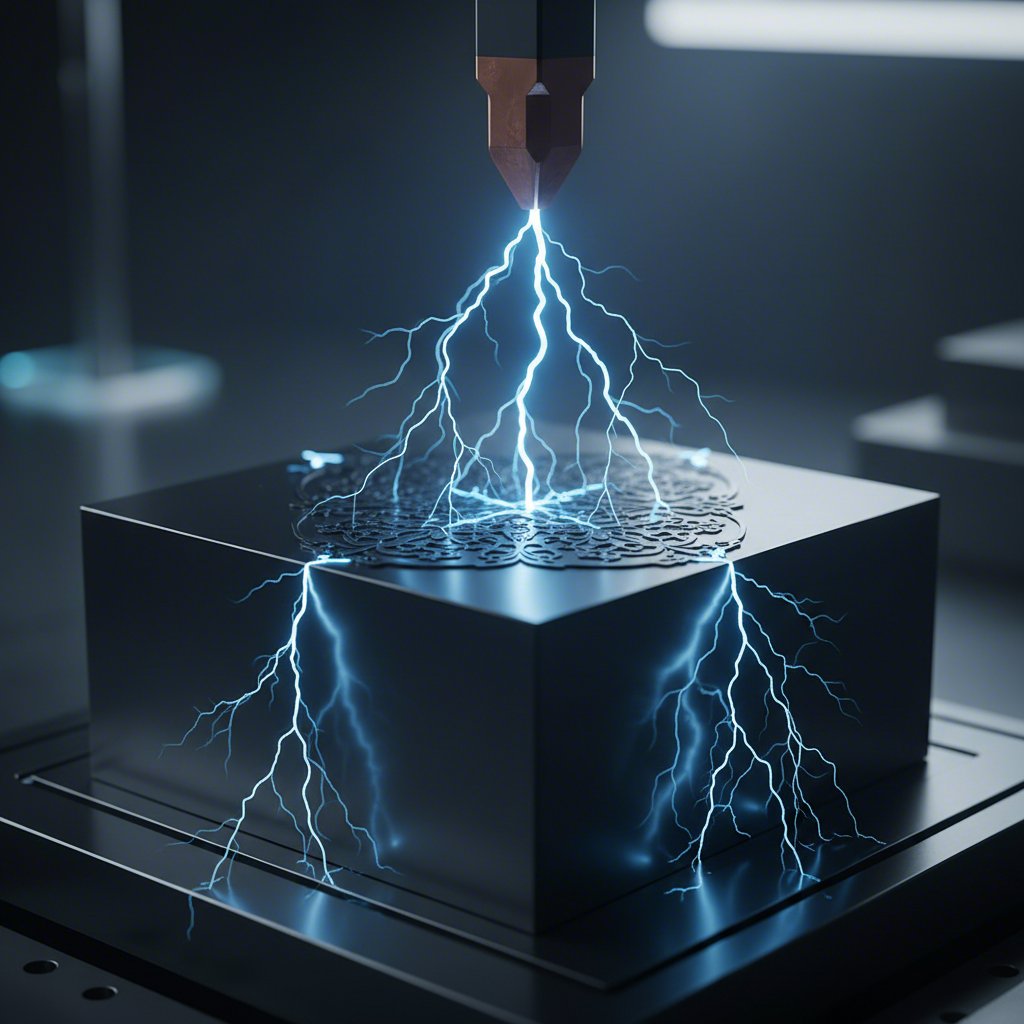

Electrical Discharge Machining (EDM)

EDM is a non-contact machining process that uses controlled electrical sparks to erode material. It is essential for creating complex shapes, sharp internal corners, and fine details in hardened steels and carbides that are difficult or impossible to machine with traditional cutters. There are two main types:

- Sinker EDM: An electrode, shaped like the desired cavity, is submerged in a dielectric fluid and advanced toward the workpiece. Sparks jump the gap, eroding the workpiece to create a negative impression of the electrode.

- Wire EDM: A thin, electrically charged wire moves along a programmed path to cut intricate contours and profiles through the material. It is used for making punches, die openings, and other precise through-features.

Precision Grinding

Grinding uses an abrasive wheel to achieve exceptionally flat surfaces and precise dimensional accuracy. In die manufacturing, it is a critical finishing step used to meet the tightest tolerance requirements for mating surfaces, cutting edges, and guide components. The final surface finish achieved through grinding is crucial for die performance and the quality of the stamped parts.

Stamping and Deep Drawing

While stamping is the process the die performs, the techniques to create dies for these operations are highly specialized. Deep drawing is a specific metal forming process where a flat sheet metal blank is drawn into a hollow body while minimizing reduction in sheet thickness. Creating a die for deep drawing requires careful engineering to control material flow and prevent defects like wrinkling or tearing. The design must account for factors like punch radius, die clearance, and blank holder pressure to successfully form complex parts like oil pans or body panels.

The benefits of these modern techniques over more traditional methods are clear:

| Technique | Primary Benefit | Application in Die Making |

|---|---|---|

| High-Speed Cutting (HSC) | Speed and excellent surface finish. | Machining hardened tool steel cavities and cores. |

| EDM (Sinker & Wire) | Ability to machine hard materials and create complex geometries. | Creating fine details, sharp corners, and intricate punch/die openings. |

| Precision Grinding | Ultra-high dimensional accuracy and surface flatness. | Finishing critical surfaces and cutting edges to micrometer tolerances. |

These advanced automotive die manufacturing techniques work in concert to produce tools that are not only accurate but also robust enough to withstand the rigors of mass production, ensuring the quality and consistency of automotive parts.

Essential Materials and Coatings for High-Performance Dies

The performance and lifespan of an automotive die are fundamentally determined by the materials from which it is made. The intense pressures, repetitive impacts, and abrasive forces of stamping and forming operations demand materials with exceptional hardness, toughness, and wear resistance. The selection process is a careful balance of performance requirements, longevity, and cost.

The backbone of die manufacturing is Tool Steels. These are specific alloys of iron and carbon, with additional elements that provide properties tailored for tooling. Different grades are used for different applications. For example, D2 tool steel is a high-carbon, high-chromium steel known for its excellent abrasion resistance, making it a common choice for cutting and forming dies. H13 tool steel offers superior toughness and resistance to heat checking, making it ideal for hot-forming applications. These steels provide a robust and reliable foundation for most automotive dies.

For applications requiring even greater durability and wear resistance, manufacturers turn to Cemented Carbide. Typically composed of tungsten carbide particles bonded with cobalt, carbide is significantly harder than tool steel and can maintain a sharp cutting edge for much longer. This makes it ideal for high-volume production runs where minimizing downtime for die maintenance is critical. However, carbide is also more brittle and expensive than tool steel, so it is often used for specific inserts or high-wear components within a larger steel die set.

To further enhance performance, Surface Coatings are applied to the working surfaces of the die. These are micro-thin layers of ceramic or metallic compounds deposited through processes like Physical Vapor Deposition (PVD). Common coatings include:

- Titanium Nitride (TiN): A general-purpose coating that increases hardness and reduces friction.

- Chromium Nitride (CrN): Offers excellent resistance to adhesion, making it suitable for forming applications where material sticking is a concern.

- Diamond-Like Carbon (DLC): Provides an extremely hard, low-friction surface, ideal for demanding applications.

These coatings act as a protective barrier, reducing wear and extending the die's life far beyond that of an uncoated tool. The choice between these materials involves a trade-off between cost and performance. While a carbide die with a DLC coating represents a significant upfront investment, its extended life and reduced maintenance can lead to a lower total cost of ownership in a high-volume manufacturing environment.

Frequently Asked Questions

1. How are dies manufactured?

The manufacturing of a die is a multi-step process that starts with a digital design using CAD software. Based on this design, a suitable material like tool steel is selected and then precisely shaped using techniques such as CNC milling, grinding, and Electrical Discharge Machining (EDM). The components then undergo heat treatment to increase hardness, followed by assembly and rigorous testing to ensure they meet exact specifications before being used in production.

2. What are the methods of die operation?

A die operates by performing several key functions: locating the workpiece, clamping it securely, working on the material, and then releasing it. The 'working' function is where value is added and includes operations like cutting, piercing, bending, forming, drawing, and stamping. The specific method depends on the die's design, such as a progressive die that performs sequential operations or a compound die that performs multiple cuts in a single stroke.

3. What are the two types of die?

Dies can be classified in several ways, but a primary distinction is made based on their function: cutting dies and forming dies. Cutting dies are used to shear, blank, or punch material, effectively removing it to create a desired shape or hole. Forming dies, on the other hand, reshape the material without cutting it away. They do this through processes like bending, drawing, and flanging to transform a flat sheet of metal into a three-dimensional part.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —