Does Aluminium Attract Magnet? Try These Safe Home Tests

Does Aluminium Attract Magnet?

When you grab a fridge magnet and press it to a soda can or a roll of kitchen foil, you might wonder: does aluminium attract magnet, or is this just a myth? Let’s clear it up right away—aluminum does not attract a magnet in the way iron or steel does. If you try the classic fridge magnet test, you’ll notice that a magnet slides right off aluminum. But is that the end of the story? Not quite! Aluminum’s unique properties mean there’s more to discover—especially when you bring motion into the mix.

Is aluminum magnetic or not?

Aluminum is not magnetic in the way most people expect. Technically, it is considered paramagnetic, which means it has a very weak and temporary response to magnetic fields. This effect is so slight that, for everyday purposes, aluminum is treated as non-magnetic. In contrast, metals like iron and nickel are ferromagnetic—they strongly attract magnets and can even become magnets themselves.

- Ferromagnetism: Strong, permanent attraction (iron, steel, nickel)

- Paramagnetism: Very weak, temporary attraction (aluminum, titanium)

- Diamagnetism: Weak repulsion (copper, bismuth, lead)

- Induction effects (eddy currents): Forces due to moving magnets near conductors (aluminum, copper)

Will a magnet stick to aluminum in real life?

Try it yourself: place a magnet on an aluminum can, window frame, or aluminum foil. You’ll find that the magnet does not stick—no matter how strong the magnet is. This is why people often say, “aluminum magnetic” is a trick question. So, do magnets stick to aluminium? Under normal conditions, the answer is no. The same goes for the question, “can magnets stick to aluminum?” The everyday answer is still no. However, if you move a strong magnet quickly past a piece of aluminum, you might feel a gentle push or resistance. This isn’t true magnetism, but a different effect called eddy currents—more on that later.

Why the confusion about aluminum and magnets?

The confusion comes from mixing up different types of magnetic effects. Aluminum’s high electrical conductivity means it interacts with magnets in moving situations. For example, in recycling plants, spinning magnets can “push” aluminum cans away from other materials. But this is not because the aluminum is magnetic in the traditional sense. Instead, it’s due to induced currents created by the moving magnetic field.

- Intrinsic magnetism: Built into the material’s atomic structure (ferromagnetism, paramagnetism, diamagnetism)

- Induction effects: Caused by motion and conductivity (eddy currents)

Magnets stick strongly to ferromagnetic materials like iron and steel. Aluminum is not one of them—any force you feel between a magnet and aluminum is usually due to induced currents when the magnet or the metal is moving.

In summary, if you’re wondering, “will a magnet stick to aluminum” or “does a magnet stick to aluminum,” the answer for normal, everyday situations is no. But aluminum’s unique electrical properties open up fascinating possibilities for recycling, engineering, and science—topics we’ll explore further in the next sections. Understanding these basics helps you make sense of hands-on tests and real-world applications, and sets the stage for deeper dives into what makes each metal unique.

Why Aluminum Behaves Differently

Ferromagnetism versus paramagnetism in plain terms

Ever wondered why some metals snap to a magnet while others do nothing at all? The answer comes down to three basic magnetic classes: ferromagnetism, paramagnetism, and diamagnetism. These classes describe how different materials react to a magnetic field, and understanding them helps you see why aluminum stands out.

Ferromagnetic materials—like iron, nickel, and cobalt—have many unpaired electrons whose spins align strongly in the same direction. This alignment creates powerful, permanent magnetic domains. That’s why a fridge magnet or a steel nail jumps to a magnet and stays stuck. These are the classic “magnetic metals.”

Paramagnetic materials—such as aluminum and titanium—have a few unpaired electrons. When exposed to a magnetic field, these electrons weakly align with it, but the effect is so faint and temporary that the material shows almost no attraction. As soon as the field is gone, so is any trace of magnetism. That’s why is aluminum magnetic? Technically, yes—but only very weakly, so you’ll never notice it in daily life.

Diamagnetic materials—like copper, gold, and bismuth—have all their electrons paired. When placed in a magnetic field, they create a tiny opposing field, resulting in weak repulsion rather than attraction.

| Material | Magnetic Class | Qualitative Strength |

|---|---|---|

| Iron | Ferromagnetic | Strong attraction |

| Nickel | Ferromagnetic | Strong attraction |

| Cobalt | Ferromagnetic | Strong attraction |

| Steel (most types) | Ferromagnetic | Strong attraction |

| Aluminum | Paramagnetic | Very weak, temporary attraction |

| Titanium | Paramagnetic | Very weak, temporary attraction |

| Copper | Diamagnetic | Very weak repulsion |

| Gold | Diamagnetic | Very weak repulsion |

Why aluminum is classified as paramagnetic

So, is aluminum a magnetic material? Not in the sense most people expect. Aluminum’s electrons are arranged so that only a minimal number are unpaired. These unpaired electrons weakly align with an external magnetic field, but the effect is so subtle it’s essentially invisible in everyday tests. That’s why aluminum is called a paramagnetic metal—not ferromagnetic, and certainly not a strong magnet.

When you ask, “is aluminium a magnetic material,” it’s important to remember this distinction. Aluminum’s temporary and faint response to magnets is a result of its atomic structure, not its ability to conduct electricity or resist rust. So, does aluminium attract magnet? Only in a way that’s so weak, you’ll never see it in a typical kitchen or workshop.

What metals are actually magnetic?

For practical purposes, only ferromagnetic metals are truly magnetic. They show strong, lasting attraction to magnets, and many can become magnets themselves. Here’s a quick way to check what metals are not magnetic and which metals are not magnetic in your daily life:

- Try a fridge magnet on coins, cans, and jewelry—iron-based items will stick, aluminum and copper will not.

- Notice how most stainless steel kitchenware does not stick to a magnet, unless it contains enough iron in the right structure.

- In MRI environments, only non-magnetic metals like aluminum or titanium are allowed for safety—ferromagnetic metals are strictly avoided.

If you want to dig deeper, university physics departments and materials science textbooks are excellent resources for authoritative explanations of these properties.

Understanding which metals are not magnetic—and why—is key when choosing materials for electronics, medical devices, or any project where magnetic interaction matters. Next, we’ll see how these classes influence what you feel when magnets move near aluminum, and why that’s not the same as being magnetic.

Why Moving Magnets Feel Different Near Aluminum

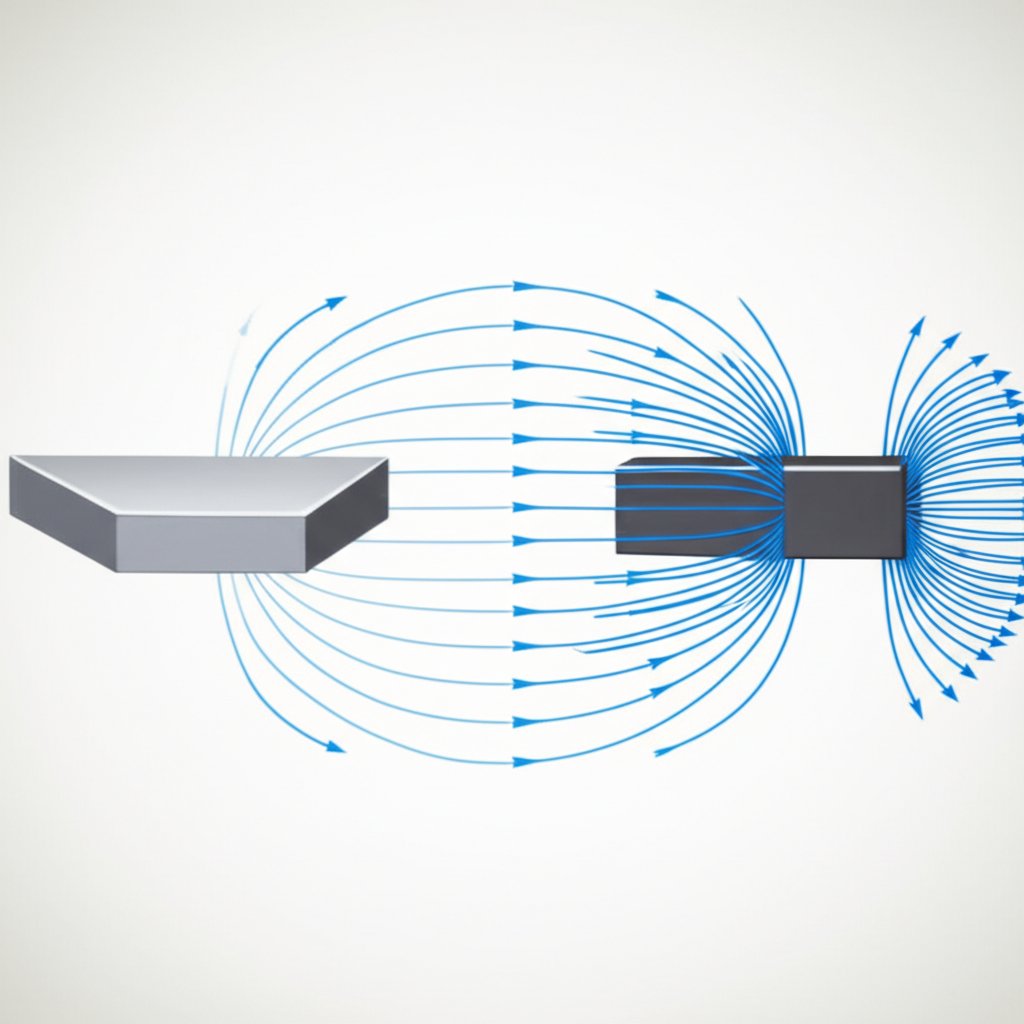

What you feel when a magnet moves near aluminum

Ever tried sliding a strong magnet down an aluminum ramp or dropping it through an aluminum tube? You’ll notice something surprising: the magnet slows down, almost as if the aluminum is pushing back. But wait—does a magnet stick to aluminium? No, it doesn’t. So why does it feel like there’s an invisible force at work?

This puzzling effect comes from eddy currents, a phenomenon that happens only when there’s motion between aluminum and magnets. Unlike the direct pull you get from magnets that stick to aluminum (which doesn’t actually happen with pure aluminum), this is all about movement and electricity.

Eddy-current braking in everyday demos

Let’s break it down. When a magnet moves near or inside a piece of conductive metal like aluminum, its magnetic field changes rapidly in that area. This changing field makes electrons inside the aluminum swirl in circles—these are called eddy currents. According to Lenz’s law, the magnetic fields created by these currents always push back against the motion that caused them. That’s why a falling magnet in an aluminum tube drifts down slowly, as if cushioned by an invisible hand. This isn’t because aluminum is magnetic in the traditional sense, but because it’s an excellent conductor. This effect is the foundation for many science demonstrations and even real-world technologies like magnetic braking systems in roller coasters and trains (see Exploratorium).

| Type of Effect | How It Works | When You Notice It |

|---|---|---|

| Intrinsic Magnetism | Depends on the material’s atomic structure—works with static magnets (ferromagnetic, paramagnetic, diamagnetic) | Magnet sticks or repels even when not moving (e.g., iron, steel) |

| Induction (Eddy Currents) | Requires a moving magnet or changing field and a conductive material—generates opposing forces (Lenz’s law) | Felt only when magnet or metal is moving (e.g., drag in aluminum, copper) |

Aluminum nonstick versus magnetic drag

So, will magnets stick to aluminum? Not in the way they stick to a fridge door. But if you move a magnet quickly across an aluminum sheet, you’ll feel resistance—almost like magnetic drag. This is why some people mistakenly think aluminum is magnetic. In reality, this drag is a result of induced currents, not true magnetism. To visualize the difference, imagine:

- Trying to stick a magnet to an aluminum can: it slides off (no stickiness).

- Dropping a magnet through a plastic tube: it falls fast (no resistance).

- Dropping a magnet through an aluminum tube: it falls slowly (strong resistance from eddy currents).

| Effect | Requires Motion? | Depends on Conductivity? | Material Example |

|---|---|---|---|

| Intrinsic Magnetism | No | No | Iron, Nickel, Cobalt |

| Eddy-Current Induction | Yes | Yes | Aluminum, Copper |

- Faster magnet motion creates stronger eddy currents and more drag.

- Stronger magnets enhance the effect.

- Thicker or wider aluminum increases the induced currents.

- Closed-loop paths (like tubes or rings) amplify the braking force.

So if you’re searching for a magnet for aluminum or want to know if magnets for aluminum exist, remember: the interaction is all about movement, not static sticking. This distinction clears up confusion about aluminum and magnets, and helps you understand why does magnet stick to aluminum is not the right question—focus on what happens when things move instead.

Next, we’ll dig into the numbers and science behind these effects, so you can read datasheets and specs with confidence and see why aluminum’s magnetic drag is both a challenge and a tool in engineering.

Understanding Susceptibility and Permeability

Magnetic susceptibility made readable

Sounds complex? Let’s break it down. Imagine you’re reading a datasheet or a materials handbook and see the term magnetic susceptibility. What does it really mean? Simply put, magnetic susceptibility measures how much a material becomes magnetized when placed in a magnetic field. If you picture a magnet near aluminum, this value tells you how much the aluminum "responds"—even if it’s barely noticeable.

For paramagnetic materials like aluminum, the susceptibility is small and positive. This means aluminum will align ever so slightly with an external field, but the effect is so weak you’ll need sensitive lab equipment to detect it. In practical terms, this is why aluminum doesn’t show any obvious attraction to magnets, even though it technically has a nonzero response (see University of Texas Physics).

Relative permeability in context

Next, you might encounter relative permeability—another key term in technical specs. This value compares the material’s internal magnetic field to that of empty space (also called the permeability of free space). Here’s the practical part: for most paramagnetic and diamagnetic materials, including aluminum, the relative permeability is very close to one. This means that the material barely alters the magnetic field passing through it.

So, what about the magnetic permeability of aluminum or permeability of aluminium? Both terms refer to the same property: how easily a magnetic field can pass through aluminum compared to free space. The aluminum magnetic permeability is only slightly greater than that of free space. That’s why, in most practical tests, aluminum behaves as if it’s nearly nonmagnetic. This subtle difference is why aluminum is chosen for applications where minimal magnetic interference is important.

Numbers near one for relative permeability indicate near-nonmagnetic behavior in practical tests. For aluminum, this means you won’t notice any magnetic effects without specialized equipment.

Where to find trusted numbers

If you’re searching for exact values for aluminum permeability, start with authoritative sources. These resources compile tested and peer-reviewed numbers you can trust:

- Materials science handbooks (such as ASM Handbooks)

- University physics department websites and lecture notes

- Recognized standards organizations (like ASTM or ISO)

- Peer-reviewed scientific articles on material properties

For example, the University of Texas Physics resource explains that the magnetic permeability of aluminum is so close to that of free space that, for most engineering purposes, it can be treated as nearly identical. This is also reflected in many engineering tables and reference charts. If you see a value for aluminium permeability that’s much higher or lower than one, double-check the measurement conditions—frequency, field strength, and temperature can all influence the reported number (see Wikipedia).

Keep in mind: at higher frequencies or very strong fields, permeability can become more complex and may be reported as a range or even a complex number (with real and imaginary parts). For most home and classroom magnet tests, though, these details won’t make a difference.

Understanding aluminum magnetic permeability and susceptibility helps you interpret technical specs, choose the right materials for projects, and avoid confusion when reading about “magnetic” metals. Next, we’ll show you how to put this knowledge into action with safe, hands-on experiments you can try at home or in the classroom.

Hands-on Experiments You Can Repeat

Curious to see for yourself if aluminum attracts a magnet? You don’t need a lab—just a few everyday items and a bit of curiosity. These safe, simple experiments will answer questions like "is aluminum foil magnetic" and "will a magnet stick to aluminium," while helping you spot what sticks to aluminum like a magnet and what doesn’t. Let’s get started!

Simple Magnet Stick Test

- Materials: Small neodymium magnet (or any strong fridge magnet), aluminum can or bar, aluminum foil, steel paperclip, copper coin or strip

- Safety Notes: Keep magnets away from electronics, credit cards, and pacemakers. Handle strong magnets carefully to avoid pinching fingers.

- Touch your magnet to the aluminum can or a sheet of aluminum foil. Does it stick?

- Now, try the same with the steel paperclip. What happens?

- Repeat with the copper coin or strip.

You’ll notice that the magnet sticks firmly to steel but slides off aluminum and copper. So, do magnets stick on aluminum? No, and the same is true for copper—"do magnets stick to copper" is answered with a clear no. This quick test shows that aluminum is not magnetic in the way that steel is.

Aluminum Foil and Moving Magnet Demo

- Materials: Roll of aluminum foil (the longer and thicker, the better), strong magnet, stopwatch or phone timer

- Roll a sheet of aluminum foil into a tube just wider than your magnet, or use the core of a store-bought roll.

- Hold the roll vertically and drop the magnet through the center.

- Observe how slowly the magnet falls compared to dropping it through a cardboard tube of similar size.

What’s happening? Even though aluminum isn’t magnetic, a moving magnet induces eddy currents in the foil, which create an opposing magnetic field and slow the magnet dramatically (see The Surfing Scientist). The longer or thicker the foil, or the stronger the magnet, the greater the effect. This demo is a classic answer to "is aluminium foil magnetic"—it’s not, but it sure interacts with moving magnets in a surprising way!

Control Comparisons with Steel and Copper

- Materials: Steel baking sheet, plastic sheet (for control), copper strip or coin

- Place a steel baking sheet at a slight angle. Slide the magnet down—notice how it sticks and may not slide easily.

- Now, try the same with an aluminum baking sheet. The magnet slides smoothly, but if you give it a push, you’ll feel it slow down more than on plastic.

- Try dropping the magnet down a copper tube or strip if available. The effect is similar to aluminum, but often even more pronounced due to copper’s higher conductivity.

These comparisons help you see not only what sticks to aluminum like a magnet (hint: nothing), but also how movement creates a unique interaction. The copper test reinforces that, like aluminum, copper is not magnetic—"do magnets stick to copper" is a no—but both metals show strong eddy current effects with moving magnets.

Observation Log Template

| Material | Test Type | Sticks Y/N | Motion Slows Y/N | Notes |

|---|---|---|---|---|

| Aluminum Can | Stick Test | No | No | Magnet slides off |

| Steel Paperclip | Stick Test | Yes | – | Strong attraction |

| Aluminum Foil (Tube) | Drop Test | No | Yes | Magnet falls slowly |

| Copper Coin | Stick Test | No | No | No attraction |

| Steel Baking Sheet | Slide Test | Yes | – | Magnet may not slide |

| Aluminum Baking Sheet | Slide Test | No | Yes | Magnet slows as it slides |

Tips for better results:

- Repeat each test three times for consistency.

- Check for coatings or hidden screws that might give false positives (sometimes a magnet will stick to a disguised steel fastener, not the aluminum itself).

- Try different magnet strengths and foil thicknesses to see how the effects change.

By following these steps, you’ll have hands-on proof that, while a magnet stick to aluminum is a myth for static contact, moving magnets reveal a fascinating side of this everyday metal. Next, we’ll explore why some aluminum objects seem magnetic and how to identify the real source of the effect.

Why Some Aluminum Assemblies Seem Magnetic

Alloying and Trace Ferrous Contamination

Ever placed a magnet on an aluminum tool or frame and felt a slight tug, or even saw it stick? You might wonder, “why is aluminum not magnetic in theory, but acts differently in real life?” Here’s the key: pure aluminum and most standard aluminum alloys are not magnetic—they’re paramagnetic, so the attraction is too weak to notice. However, the story changes when other metals get involved. Many everyday aluminum parts are actually alloys, and sometimes small amounts of iron or other ferromagnetic metals are present as contaminants or deliberate additives. Even a tiny amount of iron can make a spot on an aluminum part respond to a magnet, especially when you use a strong neodymium magnet. This is why isn’t aluminum magnetic in its pure form, but certain alloys or contaminated batches can fool your magnet test.

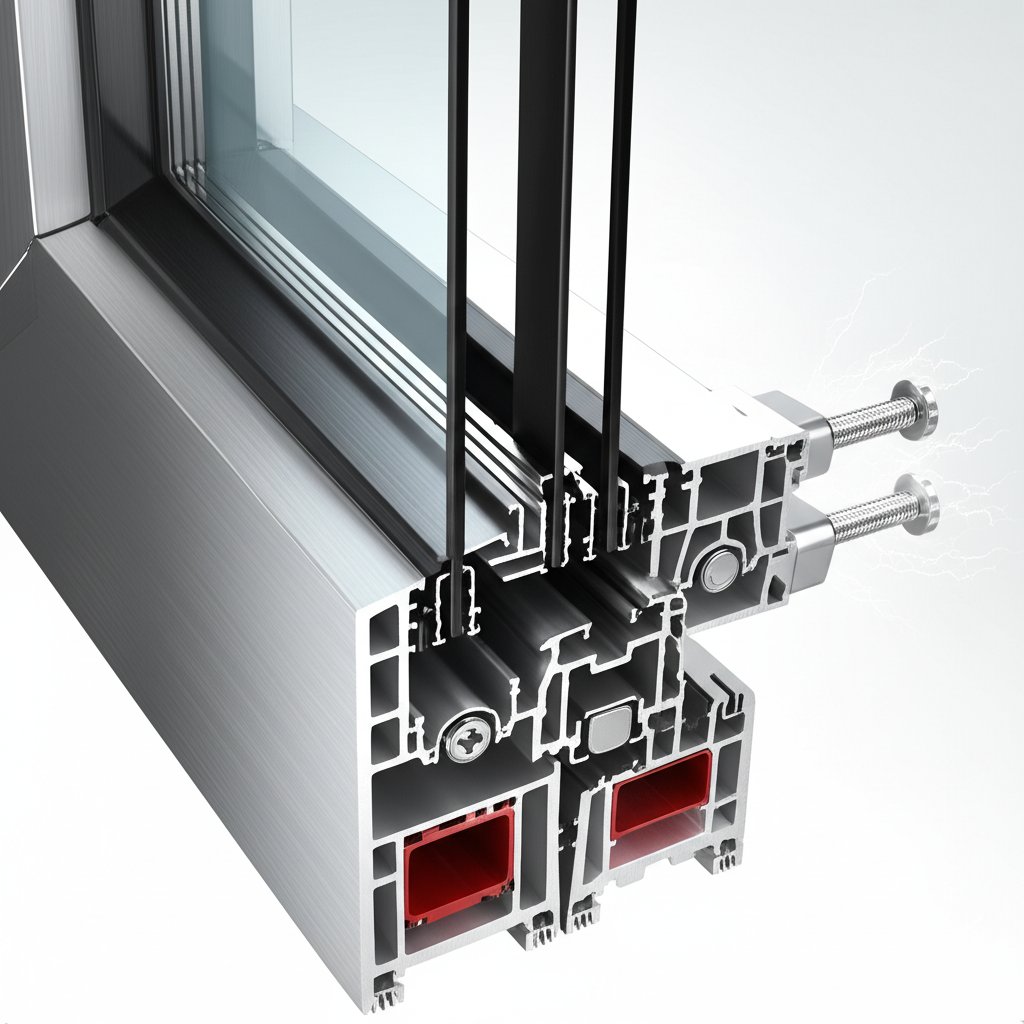

Coatings, Fasteners, and Inserts That Fool the Magnet Test

Imagine running a magnet over an aluminum window frame and feeling it stick in one spot. Does aluminum stick to a magnet after all? Not quite. Many aluminum products are assembled with steel screws, magnetic stainless steel fasteners, or have hidden steel inserts for strength. These embedded parts are often hidden by paint, plastic caps, or anodized coatings, making it easy to mistake them for part of the aluminum itself. In some cases, even a thin layer of steel dust from manufacturing can create a weak magnetic response. So, if you find that a magnet sticks to what you think is aluminum, check for hidden hardware—especially at joints, hinges, or mounting points. And remember, does stainless steel magnet stick? Only certain grades do, so it’s always worth checking with a known magnet and comparing to pure steel or aluminum samples.

- Test with a magnet after disassembling the part, if possible.

- Use a plastic scraper to gently check beneath coatings or paint for hidden metal.

- Compare bare aluminum stock to finished assemblies—true aluminum is not magnetic, but fasteners or inserts might be.

- Document your findings with photos and keep a simple log if you’re sorting or troubleshooting.

| Part/Area | Magnet Response | Suspected Cause | Notes |

|---|---|---|---|

| Aluminum Bar (bare) | No | Pure aluminum | Non-magnetic as expected |

| Window Frame (corner) | Yes | Steel fastener inside | Check for screws beneath cap |

| Machined Plate (surface) | Weak | Iron dust contamination | Clean and retest |

| Extrusion (joint) | Yes | Magnetic stainless insert | Inspect with magnet after disassembly |

Anodizing and Surface Treatments Explained

What about anodized aluminum magnetic effects? Anodizing is a process that thickens the natural oxide layer on aluminum for corrosion resistance and color. It does not alter the underlying magnetic properties—aluminum remains nonmagnetic after anodizing. If a magnet seems to stick to anodized aluminum, it’s almost always due to hidden hardware or contamination, not the anodized layer itself. This is a common source of confusion, but the science is clear: aluminum is not magnetic, regardless of the surface treatment.

So, does aluminum stick to magnets? Not unless something else is present. Reports of magnetic aluminum typically result from misidentified materials, hidden steel, or composite assemblies. For critical projects, always check for material certifications or markings—these provide assurance that your aluminum is pure and will behave as expected in magnetic environments.

In summary, why is aluminium not magnetic and why isn’t aluminum magnetic in your tests? It’s a property of the metal’s atomic structure, not just the surface. If you detect magnetism, look for fasteners, inserts, or contamination. This detective work helps you avoid surprises in electronics, recycling, or engineering projects. Next, let’s see how to measure and interpret these effects with the right tools for the job.

Testing Tools and How to Read Their Outputs

When a Magnet Test Is Enough

When you’re sorting metals at home, in a workshop, or even in a recycling center, the classic magnet test is your go-to tool. Place a magnet on your sample—if it sticks, you’re likely dealing with a ferromagnetic metal like iron or most types of steel. If it slides off, as with aluminum, you know you’re looking at a non-ferromagnetic metal. For most everyday questions—like, "do magnets work on aluminum?" or "is aluminum ferromagnetic?"—this simple test tells you what you need to know. Aluminum magnetism is so weak that it won’t affect your results in practical situations.

- Sorting scrap or recycling: Use the magnet test for quick separation—aluminum and copper won’t stick, while steel will.

- Material checks in construction: Identify support beams or fasteners that must be nonmagnetic.

- Home experiments: Confirm that kitchen foil or soda cans are not magnetic; use as a teaching moment about why is steel a magnetic material, but aluminum is not.

But what if you need to go beyond “stick or not stick”? That’s where more advanced tools come in.

Using Gaussmeters and Flux Probes

Imagine you’re an engineer, researcher, or technician who needs to measure very weak magnetic responses—maybe to check if can aluminum be magnetized in a specialized setting, or to quantify the tiny effects in sensitive electronics. Here, a gaussmeter or flux probe is essential. These instruments measure the strength of a magnetic field in units like gauss or tesla, letting you detect even the faint paramagnetic signal from aluminum.

- Purpose: Quantify weak magnetism, check for residual fields, or validate nonmagnetic status in critical parts.

- Required precision: Gaussmeters and magnetometers offer precise readings, but require careful calibration—always follow the manufacturer’s setup and zeroing procedures.

- Environment: Avoid stray fields from nearby electronics or steel tools that could skew measurements.

- Documentation level: Log instrument settings, sample orientation, and environmental conditions for reliable results.

| Instrument | Setting | Material | Reading/Units | Interpretation |

|---|---|---|---|---|

| Gaussmeter | DC, 1x sensitivity | Aluminum Bar | ~0 Gauss | No residual magnetism |

| Gaussmeter | DC, 10x sensitivity | Steel Screw | High Gauss | Strong ferromagnetic response |

| Flux Probe | AC, calibrated | Aluminum Sheet | Minimal | Paramagnetic, not magnetized |

Tip: Keep your test geometry consistent—same distance, angle, and orientation each time. Repeat trials to confirm your results and avoid stray influences from nearby metal objects.

These advanced tools are especially helpful when you need to prove that can aluminum be magnetized (the answer is no, under normal conditions), or to compare readings against known standards like steel. Remember, is steel a magnetic material? Absolutely—it provides a clear, strong signal, making it a perfect control sample.

Metal Detectors and Eddy-Current Instruments

Let’s say you’re searching for hidden objects in walls, checking for cracks in metal parts, or verifying alloy differences. Metal detectors and eddy-current meters are your best bet—but their readings mean something different. These devices respond to electrical conductivity and the presence of metal, not to ferromagnetism. That means they’ll easily detect aluminum, copper, or even nonmagnetic stainless steel, even though these materials don’t "stick" to magnets.

- Purpose: Find hidden metal, inspect welds, or sort alloys in manufacturing.

- Required precision: High for defect detection; lower for simple presence/absence checks.

- Environment: Avoid interference from rebar, wiring, or nearby ferromagnetic clutter.

- Documentation level: Record instrument settings, sample size, and any calibration steps for traceability.

| Instrument | Setting | Material | Reading/Units | Interpretation |

|---|---|---|---|---|

| Metal Detector | Standard Sensitivity | Aluminum Pipe | Detected | High conductivity, not magnetic |

| Eddy-Current Meter | Crack Detection | Aluminum Plate | Signal Change | Possible defect or alloy change |

These readings help you answer questions about aluminum magnetism in a different way—by confirming presence or quality, not magnetic order. When you need to distinguish between a steel and an aluminum object, remember that is steel a magnetic material? Yes, so it will respond to both magnet tests and magnetic field meters, while aluminum will only show up on detectors that measure conductivity.

-

Decision Flow for Choosing a Test:

- What’s your purpose—sorting, defect detection, or scientific measurement?

- How precise do you need to be—quick check or quantitative analysis?

- What’s your environment—lab, field, or factory floor?

- How will you document—simple notes or full calibration logs?

Many so-called ‘magnetic’ alarms near aluminum actually result from nearby ferromagnetic parts. Always isolate your sample and retest if you get unexpected results.

By understanding which tools to use—and what their readings really mean—you’ll be able to confidently answer questions like “do magnets work on aluminum,” “is aluminum paramagnetic,” and “can aluminum be magnetized” in any setting. Next, we’ll wrap up with practical takeaways and trusted sourcing tips for projects where nonmagnetic metals matter most.

Actionable Takeaways and Trusted Sourcing

Practical implications for recyclers, engineers, and makers

When you’re working with metals, knowing exactly what metals are attracted to a magnet can save time, money, and even prevent costly mistakes. For recyclers, the fact that aluminum is not magnetic is a huge advantage—magnets quickly sort out steel from nonmagnetic materials, streamlining the recycling process. Engineers and designers, meanwhile, often need to select metals that are not magnetic to avoid interference with sensitive electronics, sensors, or magnetic resonance (MR) environments. Makers and DIY enthusiasts pick aluminum when they want lightweight, corrosion-resistant structures that won’t stick to magnets—perfect for creative builds, robotics, or custom furniture.

- Recyclers: Rely on aluminum’s nonmagnetic nature for efficient sorting and contamination-free recycling.

- Engineers: Specify aluminum for housings, brackets, or enclosures where low magnetic interference is critical, especially in EVs and electronics.

- Makers: Choose aluminum when you need a metal that will not attract magnets, ensuring smooth operation in moving parts or magnetic-free zones.

Use aluminum when you need structural strength with minimal magnetic interaction. Always verify assemblies for hidden ferrous parts or fasteners to guarantee true nonmagnetic performance.

Design notes for sensors, MR environments, and EV assemblies

In advanced applications—think medical imaging rooms, electric vehicles, or high-precision robotics—the question isn’t just does aluminum attract magnets, but which metal is non magnetic and stable enough for demanding environments. Aluminum’s paramagnetic nature means it won’t disrupt magnetic fields, making it a top choice for:

- Sensor housings and brackets in automotive and industrial electronics

- Battery enclosures and chassis components in EVs, where stray magnetism can cause malfunction

- Fixtures and furniture for MR rooms, where what will magnets stick to is a critical safety concern

It’s also important to note that, while aluminum itself is nonmagnetic, fasteners or inserts made from steel or certain stainless steels may still be magnetic. Always check these components when nonmagnetic performance is required.

Recommended sourcing for aluminum extrusion components

Choosing the right supplier is key to ensuring your aluminum parts remain nonmagnetic and meet strict dimensional and quality standards. For automotive, electronics, or industrial projects where does aluminum attract magnets is not just a curiosity but a design requirement, start your sourcing with proven, quality-focused partners:

- Aluminum extrusion parts — Shaoyi Metal Parts Supplier: A leading integrated precision auto metal parts solutions provider in China, trusted by global brands for their IATF 16949 certified, fully traceable, and expertly engineered aluminum extrusions.

- Look for suppliers who provide full material traceability, alloy certification, and can support custom shapes or surface treatments to fit your exact needs.

Quality-controlled extrusions help maintain the expected nonmagnetic behavior and dimensional stability, reducing false positives in magnet tests and ensuring predictable eddy-current effects when used in braking or sensing subsystems.

In summary, whether you’re sorting scrap, designing for the next generation of EVs, or building something unique in your workshop, understanding which metal has the strongest magnetic attraction (iron, cobalt, nickel), and which metals are not magnetic (aluminum, copper, gold, silver) empowers you to make smarter, safer choices. For any project where what sticks to aluminum is a concern, rest assured: pure aluminum is your go-to nonmagnetic solution.

Frequently Asked Questions about Aluminum and Magnetism

1. Is aluminum magnetic or does it attract magnets?

Aluminum is considered paramagnetic, meaning it only shows a very weak and temporary response to magnetic fields. In everyday situations, magnets will not stick to aluminum, so it is treated as non-magnetic. Any resistance you feel when moving a magnet near aluminum is due to eddy currents, not true magnetism.

2. Why do magnets not stick to aluminum objects?

Magnets do not stick to aluminum because it lacks the internal structure needed for strong magnetic attraction (ferromagnetism). Aluminum's weak paramagnetic response is undetectable without sensitive equipment, so magnets simply slide off aluminum surfaces in real life.

3. Can a magnet ever pick up or attract aluminum?

A magnet cannot pick up or attract aluminum under normal conditions. However, if a magnet moves quickly near aluminum, eddy currents are generated, causing a temporary opposing force. This effect is not true magnetic attraction but a result of aluminum's high electrical conductivity.

4. Why do some aluminum items seem magnetic or make a magnet stick?

If a magnet appears to stick to an aluminum item, it's usually due to hidden steel fasteners, inserts, or contamination with ferrous metals. Pure aluminum and standard aluminum alloys remain non-magnetic, but assemblies may include magnetic parts that lead to confusion.

5. How can I test if something is aluminum or steel using a magnet?

A simple stick test works: touch a magnet to the object. If it sticks, the item is likely steel or contains ferromagnetic components. If it slides off, it's likely aluminum or another non-magnetic metal. For critical applications, verify with certified suppliers like Shaoyi, who provide non-magnetic aluminum extrusion parts for automotive and engineering needs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —