Custom Aluminum Profiles For Automotive Chassis Systems, Validated

Why Custom Aluminum Profiles Are Reshaping Automotive Chassis Design in 2025

When you picture the future of automotive engineering, do you imagine lighter vehicles, smarter structures, and seamless integration of new technologies? That vision is rapidly taking shape—thanks to custom aluminum profiles for automotive chassis systems. But what exactly are these profiles, and why are they so essential now?

What custom aluminum profiles bring to chassis performance

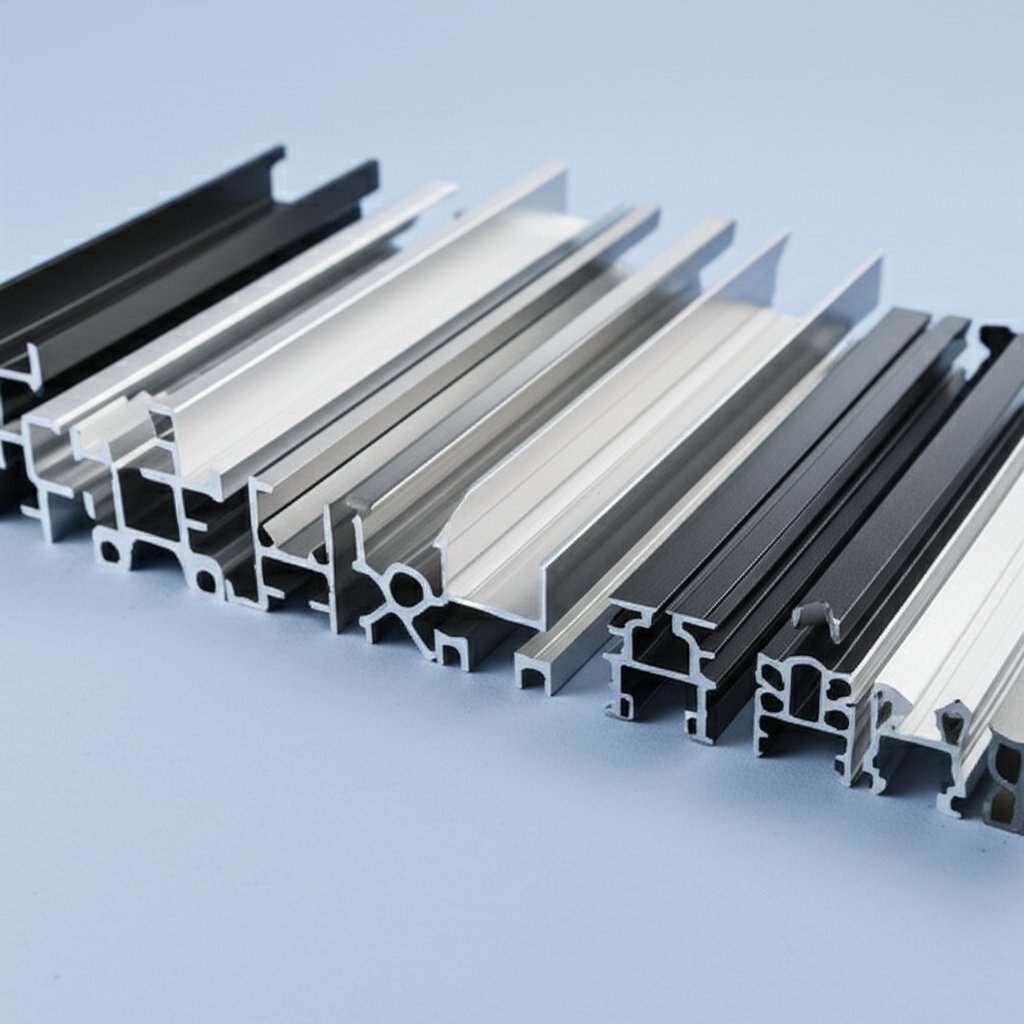

Custom aluminum extrusions, also known as aluminum extrusion profiles, are engineered cross-sections designed to perform specific functions within a vehicle’s chassis. Unlike off-the-shelf shapes, these bespoke profiles are tailored for maximum efficiency, enabling precision fitment and integration of multiple features—think mounting points, channels, or reinforcement ribs—all in one continuous piece. This design freedom allows automakers to:

- Reduce vehicle weight without sacrificing strength

- Integrate multiple functions into a single component

- Improve manufacturability and assembly efficiency

- Enhance crash energy management and occupant safety

- Achieve stable tolerances and repeatable quality

- Boost corrosion resistance for long-term durability

It’s no surprise that structural aluminum extrusions are now the backbone of many modern chassis architectures, especially in electric vehicles (EVs) where every kilogram counts.

Key chassis members suited to extrusion

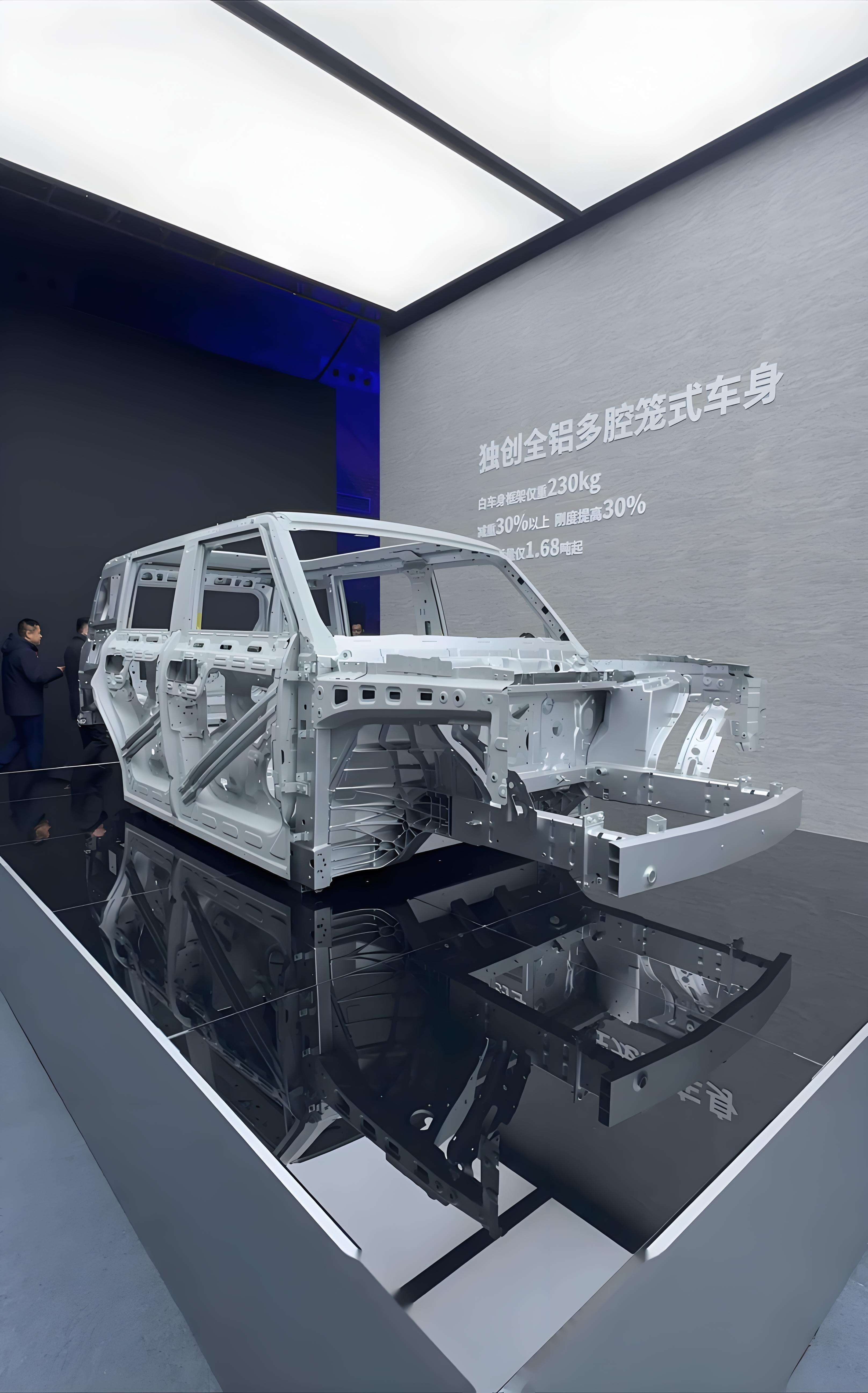

Imagine the core skeleton of a car—rails, subframes, cross-members, crash boxes, and battery enclosures. These are all prime candidates for custom aluminum extrusions. Why? Because closed-section profiles, multi-void designs, and integrated join flanges can be engineered for optimal load paths and stiffness, while keeping mass to a minimum. For example, aluminum tube profiles are frequently used for cross members and crash beams, offering high strength-to-weight ratios and excellent energy absorption during collisions.

Here’s a quick reference to how different chassis members benefit from extrusion:

| Chassis Member | Extrusion Attribute |

|---|---|

| Main rails | Closed sections, multi-voids |

| Subframes | Integrated join flanges, complex shapes |

| Cross-members | Aluminum tube profiles, tailored wall thickness |

| Crash boxes | Energy-absorbing multi-voids |

| Battery enclosures | High surface area, integrated cooling channels |

These engineered solutions are at the heart of high-performance aluminum extrusions industrial applications, where precision and reliability are non-negotiable.

Lightweighting without compromising stiffness

Sounds complex? Actually, the science behind custom aluminum extrusions is straightforward: by optimizing the profile’s geometry, you can maximize stiffness and crashworthiness while minimizing material usage. For EVs, this means more range and better battery packaging. For all vehicles, it means improved handling, safety, and fuel efficiency. The ability to fine-tune wall thicknesses and incorporate multi-chamber designs gives engineers a powerful toolkit that steel stampings or castings simply can’t match.

- Section efficiency through closed or multi-void designs

- Consistent, stable tolerances for reliable assembly

- Repeatable crash energy management for safety validation

- Integrated features that reduce downstream processing

Custom aluminum extrusion profiles deliver unmatched strength-to-weight for closed-section chassis members, making them a preferred choice for design-for-manufacturability and automated assembly.

Looking ahead to 2025, chassis design priorities are clear: EV platform packaging, multi-material joining, enhanced corrosion durability, and resilient global sourcing. Specialized partners who understand aluminum extrusion profiles can help you meet these challenges. For those seeking a trusted, end-to-end solution, Shaoyi Metal Parts Supplier offers proven expertise in automotive aluminum extrusion parts—covering the full spectrum from design-for-extrusion to finishing. Their capabilities in custom aluminum profiles for automotive chassis systems make them a practical resource for teams needing production-ready solutions now.

In summary, custom aluminum profiles are the enablers of modern, efficient, and resilient automotive chassis systems. They empower automakers to innovate faster, integrate smarter, and deliver vehicles that meet the demands of the next generation of mobility.

Alloy and Temper Selection for Chassis Extrusions

When you’re tasked with specifying materials for aluminium extrusion profiles in automotive chassis systems, the options can feel overwhelming. Should you choose a well-proven 6xxx alloy, or do the demands of your design justify stepping up to a 7xxx series? And how do you balance strength, formability, corrosion resistance, and joining requirements—all while keeping costs and manufacturability in check?

Choosing between 6xxx and 7xxx for chassis loads

Imagine you’re developing a new cross-member or a battery enclosure using extruded aluminum profile. The 6xxx series (like 6061 and 6063) is the workhorse for automotive chassis applications. Why? These alloys strike a practical balance of strength, extrudability, and corrosion resistance, making them ideal for complex aluminum extruded profiles that need to be both lightweight and durable (see reference). They also respond well to heat treatment, allowing for further tuning of mechanical properties.

However, if your design calls for maximum strength—say, for a highly loaded suspension mount or a crash-critical member—7xxx series alloys come into play. These alloys offer higher strength and stiffness, but with tradeoffs: more challenging extrusion, increased sensitivity to corrosion, and tougher joining, especially by welding. For most chassis members, the 6xxx family is sufficient, but 7xxx alloys may be justified in specific, validated use cases.

| Comparison Area | 6xxx Series | 7xxx Series | Welded Steel/Composites |

|---|---|---|---|

| Strength | Good (tunable via temper) | Higher (critical applications) | Steel: highest; Composites: variable |

| Formability | Excellent for complex extruded profiles | Lower; more difficult to extrude | Steel: moderate; Composites: process-dependent |

| Corrosion Resistance | High, especially with coatings | Lower; needs careful management | Steel: needs protection; Composites: inherent |

| Weldability/Joining | Good with proper temper | Challenging; may require special techniques | Steel: excellent; Composites: varies |

| Cost/Lead-Time | Efficient for most alu extrusion profile needs | Higher; longer lead times | Steel: moderate; Composites: high |

Temper implications for forming and joining

The temper of an aluminium extrusion profile defines its final mechanical properties and processing history. For example, T4 and T6 are common tempers: T4 offers good formability and moderate strength, while T6 maximizes strength for structural applications. But here’s the catch: if your joining strategy involves welding, some tempers may lose strength in the heat-affected zone, requiring post-weld heat treatment or the use of alternative bonding methods. Always pair your extruded profiles with a compatible joining and finishing plan to avoid costly rework down the line.

Crashworthiness and energy absorption considerations

Crash management is a central concern for any chassis design. Aluminum extruded profiles can be engineered for controlled deformation, but the choice of alloy and temper will influence how energy is absorbed and dissipated during impact. 6xxx series alloys, with their balance of ductility and strength, are often preferred for crash boxes and crumple zones. For ultra-high-performance needs, 7xxx alloys may be considered, but only with rigorous validation and attention to corrosion and fatigue management.

| Chassis Material | Crash Energy Absorption | Fatigue Response | Coatability |

|---|---|---|---|

| 6xxx Extruded Aluminum Profile | Predictable, tunable via design | Good, with proper design | Excellent with anodizing/painting |

| 7xxx Extruded Profiles | High, but needs careful validation | Lower; sensitive to joining | Requires more protection |

| Steel/Composites | Steel: high; Composites: engineered | Steel: superior; Composites: variable | Steel: paint; Composites: inherent color/finish |

Start with 6xxx series for most chassis members—only escalate to 7xxx or alternative materials when specific load cases and test evidence demand it. Early integration of material and joining strategies is essential for reliable, cost-effective results.

- Check environment: Will corrosion be a long-term concern?

- Crash management: Does your design require energy absorption or controlled deformation?

- Service fatigue: Are there cyclic loads that could drive fatigue failures?

- Joining strategy: Is your chosen alloy/temper compatible with welding or adhesives?

- Surface finish: Will the application demand a specific appearance or coating?

By taking a strategic approach to alloy and temper selection, you’ll build a foundation for safe, efficient, and manufacturable chassis systems. Up next, we’ll cover how to translate your material choices into robust, extrusion-friendly designs for every critical chassis member.

Design-for-Extrusion Rules

When you transform a chassis concept into reality, how do you ensure your aluminum extrude design is both robust and cost-effective? The answer lies in mastering a few key principles of design-for-extrusion (DFE). Let’s break down the essentials so your custom profile extrusions not only meet structural goals, but also minimize headaches on the shop floor.

Cross-section fundamentals for stiffness and buckling

Imagine you’re designing a main rail or crash member. Closed or multi-void sections are your best friends for maximizing bending and torsional stiffness without adding unnecessary weight. Why? Closed shapes like box rails or multi-chamber profiles resist deformation far better than open channels. This is why aluminum profile extrusion is favored for critical chassis members—these shapes deliver excellent load-carrying capacity and energy absorption in a compact form. For areas subject to crash loads or high bending moments, integrating internal webs or ribs can further boost rigidity without a major increase in mass.

Wall thickness, radii, and uniformity guidelines

Sounds simple, but achieving a high-quality aluminium extruded profile starts with uniform wall thickness. Uneven walls cause uneven cooling, leading to warping, dimensional drift, and higher scrap rates. Gradual transitions between thick and thin areas, rather than abrupt steps, help maintain structural integrity and manufacturability. Generous internal radii—think smooth, rounded corners instead of sharp angles—improve metal flow during extrusion, extend die life, and reduce the risk of cracks or die wear. For example, a box rail with rounded inside corners will be more stable and easier to produce than one with sharp 90-degree edges.

- Favor closed or multi-void sections for bending/torsion efficiency

- Target uniform wall thickness to reduce distortion and improve quality

- Maintain generous internal radii for better metal flow and die durability

- Place stiffeners or ribs where shear flows are highest

- Co-design flanges or grooves for adhesives, friction stir welding (FSW), or mechanical fasteners

Integrating joining and assembly features into the profile

Why add machining steps later when you can build features right into your extrusion profiles? By incorporating flanges, grooves, or slots for joining (whether for adhesives, FSW, or mechanical fasteners), you streamline assembly and reduce downstream costs. For instance, a battery enclosure might include integrated panel grooves, while a cross-member could have pre-formed flanges for direct mounting. Smart integration also improves repeatability and helps with automated assembly—key for modern automotive production lines (see reference).

| Chassis Topology | Typical Design Intent | Extrusion Attribute |

|---|---|---|

| Box rail | Bending stiffness | Closed section, uniform walls |

| Omega section | Crush stability | Multi-void, internal ribs |

| Multi-void crash member | Energy absorption | Multiple chambers, controlled deformation |

| Hat channel | Fastener access | Open shape, integrated flanges |

- DFE Checklist for Engineers:

- Define primary load cases and stiffness axes

- Map crash crush zones and energy absorption paths

- Validate minimum features against die capabilities

- Reserve machining allowances near hole clusters or complex join areas

- Confirm coating clearances for post-extrusion finishing

Small changes to wall uniformity and corner radii in your aluminum profile extrusion can yield big gains in die life, dimensional stability, and reduced scrap—making your chassis solution more reliable and cost-effective.

Designing with these principles ensures your aluminium profile not only performs under real-world loads, but also moves smoothly from concept to production. Next, we’ll explore how joining and assembly methods further shape the geometry and performance of your custom profile extrusions.

Joining Methods That Shape Chassis Profile Geometry

When you finalize your chassis design, how do you ensure that each extruded member comes together to form a safe, robust structure? The answer lies in your joining strategy. The method you choose—be it welding, adhesives, or mechanical fastening—not only defines the assembly sequence but also influences the geometry of your custom aluminum profiles. Let’s break down the main joining options and how each shapes the final result.

Welding and Friction Stir Welding for Structural Joints

Welding is a go-to for permanent, high-strength connections in structural aluminium extrusions. Traditional arc welding, using techniques such as MIG or TIG (with aluminium tig filler rods), delivers excellent continuity across joints, making it ideal for main rails or crash-critical members. However, you’ll notice that welding introduces heat-affected zones, which can lower fatigue life and cause distortion. Friction stir welding (FSW), on the other hand, is a solid-state process that produces low-defect joints with minimal heat input—great for precision extrusions and applications where dimensional stability is paramount. The trade-off? FSW requires good access for tooling and can be limited by profile complexity or wall thickness variations, often necessitating careful planning of aluminum extrusion machining steps in advance.

Pros and Cons: Welding & FSW

-

Welding:

+ High joint strength and continuity

− Heat input reduces local fatigue resistance and may distort thin walls -

Friction Stir Welding:

+ Excellent dimensional control, low porosity

− Tooling access and profile geometry can limit applicability

Adhesive Bonding with Mechanical Backup

Imagine joining two extruded aluminum shapes where access for welding is limited, or where you want to distribute loads evenly across a wide area. Structural adhesives—often paired with mechanical backup like rivets—offer a solution. Adhesive bonding excels at sealing joints and distributing stress, especially when you integrate aluminium extrusion trim features such as grooves or flanges directly into the profile. This method requires meticulous surface preparation and curing time, but it avoids introducing heat and preserves the finish of your aluminium extrusion accessories. Mechanical backup ensures redundancy, maintaining joint integrity if the adhesive is compromised.

Pros and Cons: Adhesive Bonding

-

Adhesives:

+ Even load distribution, excellent sealing

− Requires surface prep, environmental controls, and curing time -

Adhesive + Mechanical:

+ Redundant, robust joints

− Added assembly complexity, potential for local stress risers

Rivets, Clinching, and Mixed-Material Strategies

For serviceable or modular assemblies, mechanical fastening methods like rivets, bolts, and clinching are widely used. These techniques are especially valuable for joining extruded aluminum shapes to other materials—think steel brackets or composite panels. While fasteners simplify disassembly and enable field repairs, they introduce localized stress concentrations that can initiate fatigue cracks if not managed with proper aluminium extrusion accessories like gussets or stiffener plates. Careful attention to hole placement, edge distances, and local reinforcement is essential for maintaining long-term durability.

Pros and Cons: Mechanical Fastening

-

Rivets/Bolts:

+ Fast, reversible assembly

− Local stress raisers, potential for loosening under vibration -

Clinching:

+ No heat, fast cycle time

− Limited to compatible materials and thicknesses

| Design Constraint | Welding/FSW | Adhesive Bonding | Mechanical Fastening |

|---|---|---|---|

| Access for Tooling | Requires direct access, joint fit-up | Moderate; surface prep needed | Good; some blind fasteners available |

| Flange Width | Wide enough for weld bead or FSW tool | Allows adhesive spread, backup fasteners | Supports fastener heads or clinch features |

| Hole-to-Edge Distance | Not applicable | Not applicable | Must be sufficient to avoid splits/cracks |

| Local Thickness Build-up | Minimize to reduce distortion | May require thickening for fastener backup | Reinforcement plates or bosses may be needed |

| Sealant Beads | Not typical | Essential for environmental sealing | Optional for corrosion protection |

| Coating Compatibility | Post-weld treatments often required | Must ensure adhesive compatibility | Fastener materials must be corrosion-matched |

Fatigue cracks often nucleate at geometric discontinuities near joints—smooth transitions, generous runouts, and thoughtful placement of features can dramatically improve durability.

- Joint Selection Flow for Chassis Engineers:

- Define primary load case and required durability (static, fatigue, crash)

- Evaluate assembly sequence and access for tools or curing

- Assess serviceability—will the joint need to be disassembled?

- Match joining method to material pairing and coating plan

- Incorporate aluminum extrusion machining allowances for holes, slots, or integrated features

- Specify aluminium extrusion trim or accessories for joint reinforcement as needed

- Validate with physical or virtual fatigue and corrosion testing

By carefully considering these joining strategies, you’ll not only optimize the geometry and assembly of your custom extruded aluminum shapes, but also set the stage for long-term structural performance. Next, we’ll explore how to validate your chassis solution—from global stiffness to crash performance—ensuring every joint and profile meets the demands of modern automotive engineering.

Structural Validation

When you engineer custom aluminum profiles for automotive chassis systems, how do you ensure your design stands up to real-world demands—before it ever hits the road? Structural validation is the answer, and it’s a process that brings together simulation, physical testing, and smart design choices. Let’s break down what matters most and how you can build confidence in your structural extruded aluminum solutions.

Designing for Stiffness and Buckling

Imagine your vehicle’s chassis under hard cornering or a heavy load. Global stiffness—how much the frame flexes overall—directly affects handling and safety. Local strength, especially at joints, keeps critical connections from deforming or failing. For extruded structural aluminum parts, you’ll want to check these attributes early in the design cycle using CAD-based section property calculations and linear finite element analysis (FEA). These tools help you spot potential weak points in your extruded aluminium rails and guide you in refining cross-sections for optimal performance.

Don’t forget buckling: thin-walled profiles are efficient but can be prone to local or global instability under compression. Using FEA, you can predict where buckling might occur and reinforce those areas—often with minimal weight penalty. This is where the flexibility of profile precision extrusions shines, allowing you to tailor geometry for strength without excess material.

Fatigue-Life Considerations and Surface Finish Effects

Ever wondered why some chassis parts last for years while others develop cracks? The answer often lies in fatigue. Every bump, vibration, and load cycle adds up, so it’s crucial to assess fatigue durability—especially at welds, joints, and notches. Start by identifying high-stress regions through detailed FEA. Then, validate your assumptions with coupon tests on the chosen alloy and weld configurations.

Surface finish matters too. A smooth, defect-free finish in fatigue-critical zones can dramatically extend service life. For example, a precision extrusion with minimal surface roughness will resist crack initiation far better than a rough or poorly finished profile. Consider post-weld treatments and avoid sharp transitions to further reduce stress concentrations.

Crashworthiness Principles for Extruded Members

Crash energy absorption is a defining requirement for modern chassis systems. Here, extruded structural aluminum can be engineered to fold and deform in a controlled way, protecting occupants by absorbing impact forces. Validating crashworthiness starts with nonlinear FEA to simulate folding, buckling, and progressive collapse. But simulation alone isn’t enough—physical subcomponent crush tests and full assembly trials are critical for confirming real-world performance.

- Validation Ladder for Chassis Extrusions:

- CAD section property checks (stiffness, mass, inertia)

- Linear FEA for global stiffness and joint strength

- Nonlinear/detailed FEA for crash and fatigue hot spots

- Material and weld coupon tests for baseline properties

- Subcomponent crush rigs for local energy absorption

- Full assembly trials for integrated system validation

Correlating simulation with physical testing early in the process is key—don’t rely on models alone. Real-world data closes the loop, ensuring your precision extrusion designs meet both safety and durability targets.

| Test Type | Primary Purpose | Relevant Standards Family |

|---|---|---|

| Section Property Analysis | Stiffness, mass distribution | ISO (dimensional/quality) |

| FEA (Linear/Nonlinear) | Stiffness, strength, crash simulation | SAE (fatigue, structural) |

| Coupon Mechanical Tests | Material/weld properties | ASTM (mechanical, corrosion) |

| Subcomponent Crush Tests | Energy absorption, deformation | SAE (crash, fatigue) |

| Full Assembly Trials | System-level validation | ISO (quality, validation) |

- Improve surface finish in fatigue-critical regions to delay crack initiation

- Apply post-weld heat treatments where feasible to restore strength

- Use generous radii at corners and transitions to reduce stress concentration

- Implement anti-corrosion strategies at galvanic interfaces and exposed edges

By following this structured validation approach, you’ll ensure your custom aluminum chassis profiles deliver the required stiffness, strength, and crashworthiness—while also standing up to years of service. Up next, we’ll look at how manufacturability and cost factors shape your final design decisions, bridging the gap from engineering to production.

Manufacturing and Cost Considerations That Matter for Chassis Profiles

When you’re engineering custom aluminum profiles for automotive chassis systems, how do you balance performance ambitions with real-world manufacturing and cost constraints? Sounds like a tall order, but with the right strategies, you’ll find that manufacturability and cost efficiency can go hand-in-hand—especially when you understand the levers available at each stage of the process.

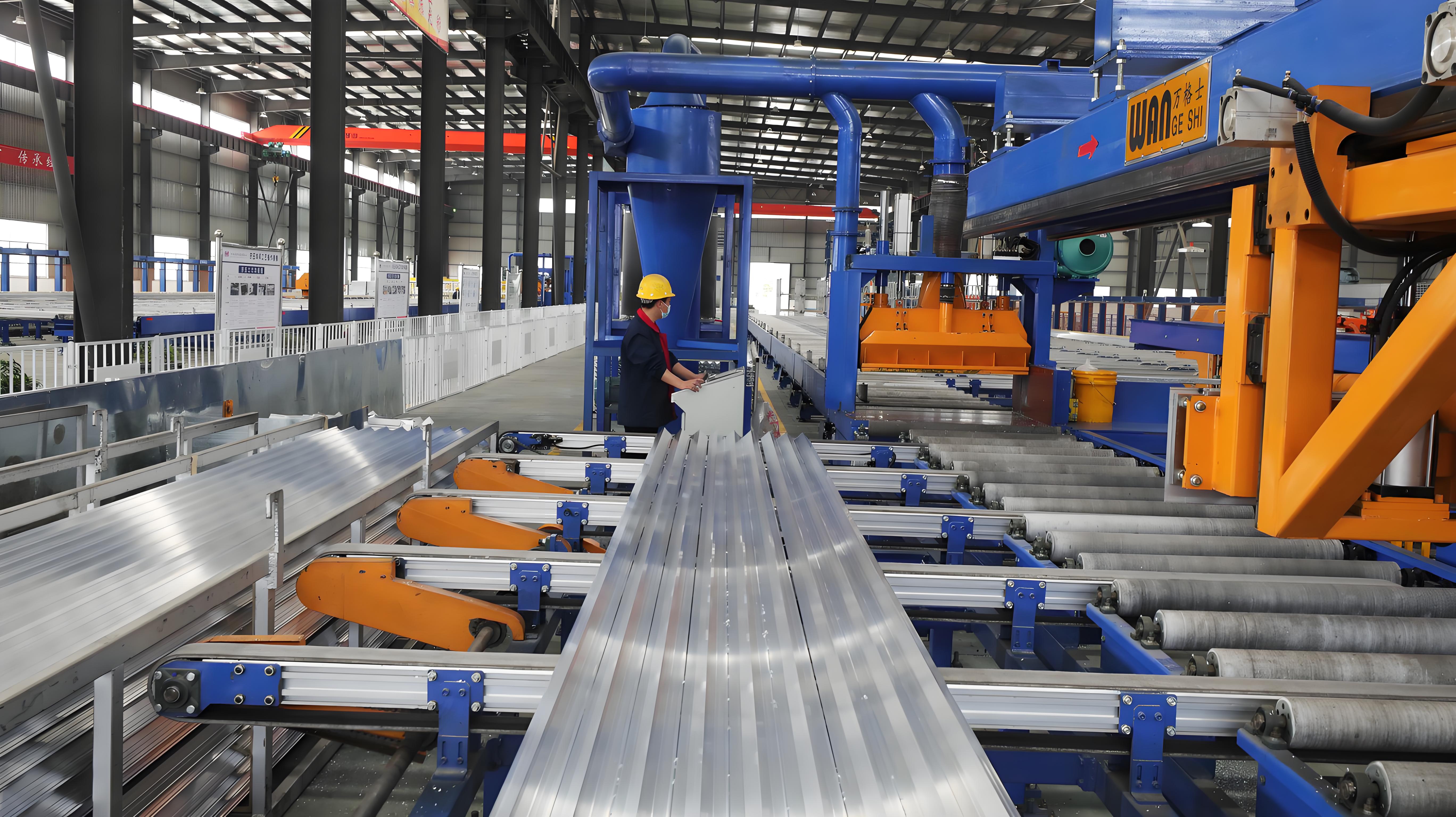

Die Complexity and Its Impact on Lead Time

Ever wondered why some projects move fast while others get stuck waiting for parts? The answer often starts with the aluminum extrusion die. Simple, symmetrical profiles use standard aluminum extrusions and can leverage existing dies, getting you to production quickly and affordably. But as soon as your design calls for deep hollows, multi-voids, or intricate details, custom aluminium extrusion dies are required. These dies take more time to engineer and manufacture—typically several weeks—since precision machining and hardened steel are essential for complex shapes. The more complex the die, the higher the upfront cost and the longer the lead time. That’s why early design simplification and close supplier collaboration can dramatically reduce both schedule and tooling investment.

Secondary Operations That Drive Cost

Once your extrusion leaves the press, it often needs further processing to meet final chassis requirements. Each added step—CNC machining, piercing, friction stir welding (FSW), adhesive bonding, heat treatment, or surface finishing—introduces cost, extends cycle time, and can affect dimensional accuracy. For example, custom cut aluminum extrusion profiles tailored for battery enclosures may require precision machining and anodizing, while rails or cross-members might need welding or e-coat for corrosion protection.

To help you visualize where costs and risks accumulate, here’s a quick reference table:

| Operation | Cycle Time Impact | Fixturing/Setup | Rework Risk | Dimensional Stack-Up |

|---|---|---|---|---|

| Sawing/Cutting | Low | Simple | Low | Minimal |

| CNC Machining | Moderate | Custom | Medium | Local |

| Piercing/Drilling | Low-Moderate | Moderate | Medium | Local |

| FSW/Welding | Moderate-High | Specialized | Medium-High | Joint-specific |

| Adhesive Application | Moderate | Controlled | Low-Medium | Minimal |

| Heat Treatment | High | Batch | Medium | Global |

| Straightening | Low | Simple | Low | Global |

| Anodizing/Painting | Moderate | Batch | Medium | Surface |

| E-coat | Moderate | Batch | Low-Medium | Surface |

Post-Processing Choices and Takt Alignment

Imagine you’re scaling up to high-volume production. Every extra step—be it a custom finish, extra machining pass, or specialized packaging—affects takt time and throughput. Stock aluminum extrusion profiles might be ready to use with minimal work, but custom profiles often need tailored post-processing. The key is to consolidate as many features as possible into the initial extrusion, reducing reliance on slow or costly secondary operations. This approach not only streamlines assembly but also ensures better alignment with the overall production cycle and supply chain.

- Consolidate features into the extrusion to minimize downstream machining

- Design datum surfaces for fast, repeatable location and clamping

- Standardize hole families and slot sizes where possible

- Minimize asymmetry to reduce twist, warpage, and die wear

Early supplier involvement can eliminate expensive downstream corrections—by tuning wall uniformity, optimizing die flow, and aligning your design with the capabilities of your aluminum extrusion supply chain.

- Procurement Checklist for Chassis Extrusions:

- Confirm aluminium extrusion die build timelines and clarify ownership terms

- Validate secondary operation capacity and lead times for your chosen aluminum extrusion company

- Agree on inspection and quality plans for each critical stage

- Align packaging and shipping requirements to protect surface finish and dimensional integrity

By understanding these manufacturing and cost factors, you empower both engineering and procurement to collaborate effectively—ensuring your next chassis project is delivered on time, on budget, and to the highest standard. In the next section, we’ll show you how to anchor your specifications and validation plans to industry standards, setting the stage for robust, repeatable production.

Standards and References

When you’re specifying custom aluminum profiles for automotive chassis systems, how do you ensure every detail—from alloy selection to final inspection—meets industry expectations? The answer is found in aligning with authoritative standards. Imagine you’re an aluminium profile manufacturer or an engineering team: referencing the right standards not only streamlines communication but also builds trust with suppliers, auditors, and customers.

Material and Temper References

Start by anchoring your choices to globally recognized material and temper standards. The Aluminum Association is the primary source for alloy designation and temper systems, managing a comprehensive registry that covers everything from 1xxx to 7xxx series alloys. Their standards are adopted internationally and updated regularly to reflect new developments in aluminum profile manufacturing (see reference). This ensures that when you specify a particular alloy-temper combination, every aluminium extrusion manufacturer or aluminium profile supplier will understand exactly what’s required—reducing ambiguity and risk.

- Aluminum Association: Alloy & temper designations, general extrusion guidance

- ASTM: Mechanical properties, material tests, coatings, corrosion methods

- SAE: Automotive fatigue, structural, and joining practices

- ISO: Measurement, quality systems, test methodologies

Dimensional and Tolerance Frameworks

Sounds complex? Actually, referencing standard frameworks for dimensions and tolerances makes life much easier. The Aluminum Association and ANSI provide detailed guidelines for standard aluminium extrusions, covering everything from wall thickness to straightness and twist. For custom chassis profiles, these references help you define what’s acceptable for fit, function, and downstream processing. ISO standards further support this by outlining measurement and inspection protocols—so your drawings are universally understood, whether you’re working locally or globally.

Testing and Quality Systems References

When it’s time to validate your parts, ASTM and SAE standards come into play. ASTM covers mechanical testing, corrosion resistance, and surface quality, while SAE provides best practices for fatigue, joining, and crashworthiness—critical for automotive applications. ISO standards round out the picture by defining quality management systems and test methodologies that ensure every batch of extrusions meets your requirements. This layered approach is why most aluminium extrusion manufacturers and suppliers base their quality systems on a blend of these standards, always referencing the latest revisions to keep pace with industry progress.

| Project Phase | Standards Category | Key Reference Bodies |

|---|---|---|

| Design | Alloy/temper, dimensions | Aluminum Association, ANSI, ISO |

| Material Qualification | Mechanical/corrosion tests | ASTM, ISO |

| Process Control | Manufacturing tolerances, quality systems | Aluminum Association, ISO |

| Validation Testing | Fatigue, crash, joining | SAE, ASTM |

| Production Quality | Inspection, documentation | ISO, Aluminum Association |

Before releasing your drawings, always align notes and callouts with your chosen standards set—and avoid mixing conflicting tolerance schemes. Referencing the latest standards for standard aluminium extrusions in 2025 is your best insurance for robust, repeatable results.

By mapping your project to these standards, you’ll notice smoother supplier collaboration and fewer surprises during validation and production. Next, we’ll dive into failure modes and quality control, equipping you with the inspection tactics that prevent costly issues before they reach the assembly line.

Failure Modes and Quality Control You Can Act On for Chassis Extrusions

When you’re responsible for the reliability of automotive chassis systems, how do you ensure that every aluminum profile performs flawlessly—mile after mile? It starts with understanding where things go wrong and how to catch issues before they escalate. Let’s break down the most common failure origins, the inspection tactics that make a difference, and the role of quality control in mixed-material environments.

Common Failure Origins in Chassis Extrusions

Imagine you’re examining a batch of precision aluminum extrusion profiles destined for a new vehicle platform. Where should you look for trouble? Here are the typical culprits:

- Fatigue crack initiation at notches, holes, or sharp transitions—especially in small aluminum extrusions with complex geometry

- Weld or friction stir welding (FSW) defects—porosity, incomplete fusion, or heat-affected zones with reduced strength

- Surface damage—scratches, dents, or roughness that act as stress risers and accelerate crack growth

- Galvanic corrosion—especially where alum extrusions contact steel fasteners or brackets

- Dimensional drift—profiles that don’t meet tolerance, leading to assembly misfits or unintended stresses

Understanding how are aluminum extrusions made is the first step to identifying these risks. The process—from billet inspection to die design, extrusion, and finishing—shapes the profile’s integrity and its susceptibility to these failure modes.

Inspection Tactics That Catch Defects Early

Sounds daunting? Actually, effective inspection is all about layering the right checks at every stage. Here’s how leading manufacturers do it:

- Raw material checks: Verify alloy composition and purity before extrusion begins

- Process monitoring: Use automated systems to control temperature, pressure, and extrusion speed, reducing the risk of internal defects and warping

- In-line quality checks: Employ sensors and cameras to spot surface flaws and dimensional deviations as profiles exit the press

- Post-extrusion inspection: Measure dimensions, assess surface quality, and test mechanical properties to ensure aluminum extrusions shapes meet design intent

- Traceability and documentation: Maintain detailed records to track every profile from raw billet to final assembly

For critical joints or crash-sensitive areas, non-destructive testing—like ultrasonic or dye penetrant inspection—helps catch subsurface flaws that could otherwise escape notice.

Corrosion and Mixed-Material Interfaces

When alum extrusions are joined to steel or other metals, galvanic corrosion can threaten long-term durability. Preventive measures include:

- Applying sealants or isolation layers between dissimilar metals

- Specifying compatible coatings or anodizing to protect exposed surfaces

- Controlling assembly environments to minimize contamination

These steps are especially important for small aluminum extrusions with high surface-area-to-volume ratios, where even minor corrosion can quickly undermine structural integrity.

| Failure Mode | Mitigation Strategy |

|---|---|

| Fatigue cracks at notches/holes | Smoother transitions, generous radii, avoid sharp corners |

| Weld/FSW defects | Post-weld finishing, controlled process parameters, NDT inspection |

| Surface damage | Protective handling, surface finishing, in-line inspection |

| Galvanic corrosion | Sealants, isolation materials, compatible coatings |

| Dimensional drift | Tighter fixturing, statistical process control (SPC), regular calibration of measurement tools |

Surface finish and edge quality in high-cycle regions often determine the real-world life of aluminum profiles—more so than nominal section strength or alloy choice.

- Quality Control Plan for Chassis Extrusions:

- Verify incoming alloy and temper with chemical analysis and certification

- Perform in-process dimensional checks at key stages

- Apply non-destructive evaluation (NDT) for joints and welds

- Set surface finish acceptance criteria for all visually critical areas

- Audit corrosion protection measures, especially at mixed-material joints

By integrating these tactics and understanding how are aluminum extrusions made, you’ll catch problems early, reduce scrap, and deliver chassis systems that stand the test of time. Next, we’ll show you how to translate these quality insights into a robust sourcing and supplier collaboration plan for your next project.

Sourcing Roadmap and Trusted Partners for Execution in Chassis Extrusions

When you’re ready to turn your chassis design into reality, how do you ensure you’re partnering with the right supplier? With so many custom aluminum extrusion manufacturers and global sourcing options, it’s easy to feel overwhelmed. Let’s break down a clear, practical path to sourcing—so your next project delivers on performance, cost, and quality.

What to Ask Potential Partners Before RFQ

Imagine you’re preparing to request quotes for a new chassis system. What separates a routine supplier from a true engineering partner? Start by asking questions that reveal real capability, not just catalog offerings. For example:

- Do you have proven experience with aluminium extrusion automotive applications—especially chassis systems?

- Which alloys and tempers can you support, and do you offer in-house die engineering?

- Can you provide both wholesale aluminum extrusions and highly customized solutions?

- What downstream processes are available—machining, joining, coating, and assembly?

- How do you handle quality control and traceability for safety-critical parts?

- Are you familiar with PPAP, IATF 16949, or other automotive quality systems?

- What is your geographic footprint—do you serve my region or offer support like aluminum extrusion california or multiple bonnell aluminum locations?

Asking these questions upfront helps you filter out suppliers who aren’t equipped for the demands of custom aluminum extrusions suppliers in the automotive sector.

Design-to-Manufacture Collaboration Best Practices

Sourcing isn’t just about price—it’s about partnership. The best custom aluminum extrusion suppliers work with you from design through production, helping you avoid costly pitfalls. Here’s a proven collaboration flow:

- Shortlist suppliers with demonstrated chassis experience and a track record in aluminium extrusion automotive.

- Share load cases, joining strategies, and key requirements early—this ensures your partner understands real-world performance targets.

- Co-develop DFE (Design-for-Extrusion) drawings and review manufacturability before releasing for tooling.

- Align on inspection and validation plans—including dimensional checks, mechanical tests, and corrosion audits.

- Set up a pilot run to correlate simulation and test data, refining both product and process before scaling up.

Throughout this process, look for suppliers who bring proactive engineering support and transparency. For teams seeking a one-stop, globally proven solution, Shaoyi Metal Parts Supplier stands out. They offer end-to-end support on custom aluminum profiles for automotive chassis systems—from DFM analysis and die design to precision machining and finishing—all managed under rigorous automotive quality protocols. This approach is especially valuable when you need to streamline supply chains and accelerate development cycles.

Action Plan for Your Next Chassis Extrusion

Ready to move from concept to production? Here’s a concise checklist to guide your sourcing decision:

| Selection Criteria | Why It Matters |

|---|---|

| Alloy & Temper Breadth | Supports both standard and high-performance needs |

| Die Engineering Depth | Enables complex, reliable custom shapes |

| Downstream Capability | Machining, joining, coating, assembly in-house |

| Quality System Maturity | PPAP/IATF 16949 for traceable, repeatable results |

| Logistics Coverage | Regional support or global reach—think bonnell aluminum locations or aluminum extrusion california |

- Request technical case studies or references from similar chassis projects

- Clarify DFM and design review processes

- Ask about lead times for both prototypes and production orders

- Confirm after-sales support and responsiveness

The most successful chassis programs treat suppliers as engineering partners—not just vendors. Early collaboration balances performance, cost, and lead time, and lessons from pilot runs should be formalized into your 2025 production standards.

By following this roadmap, you’ll notice fewer surprises and more predictable results—whether you’re sourcing from custom aluminum extrusion manufacturer in your region or evaluating global wholesale aluminum extrusions networks. The right partner will help you translate your intent into a robust, validated chassis solution that stands up to the demands of modern automotive engineering.

Frequently Asked Questions

1. What are custom aluminum profiles used for in automotive chassis systems?

Custom aluminum profiles are engineered extrusions designed for key chassis components like rails, subframes, cross-members, and battery enclosures. Their tailored shapes enable lightweight structures, integrated features, and improved manufacturability, supporting modern vehicle demands such as electric vehicle packaging and crash performance.

2. How do custom aluminum extrusions improve vehicle safety and performance?

Custom extrusions allow precise control over cross-section geometry, enabling closed or multi-void designs that maximize strength-to-weight ratio and energy absorption. These profiles can be engineered for predictable crash management, higher stiffness, and reliable assembly, directly contributing to occupant safety and vehicle handling.

3. What should I consider when selecting an alloy or temper for chassis extrusions?

Consider the balance between strength, corrosion resistance, formability, and joining compatibility. 6xxx series alloys are common for their extrudability and corrosion performance, while 7xxx series offer higher strength for demanding applications but require extra care in joining and protection. Early alignment with joining and finishing plans is crucial.

4. How can I ensure quality and durability in custom aluminum chassis profiles?

Implement a comprehensive quality control plan that includes alloy verification, in-process dimensional checks, non-destructive testing of joints, and surface finish inspections. Address potential failure modes such as fatigue, weld defects, and corrosion through design best practices and by working with experienced suppliers who follow automotive standards.

5. Why choose Shaoyi for automotive aluminum extrusions?

Shaoyi offers a one-stop solution with integrated manufacturing, precision CNC machining, and extensive finishing options. Their IATF 16949 certification, digital MES system, and proven track record with leading automotive brands ensure reliable quality, fast development, and simplified supply chain management for custom chassis components.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —