An Essential Guide to Die Set Components and Functions

TL;DR

A die set is a precision manufacturing tool that cuts and forms sheet metal into a specific shape. Its essential components function together to ensure accuracy and repeatability. The core parts include the foundational die plates (or shoes) that hold everything, guide pins and bushings for precise alignment, and the working elements like punches and die blocks that perform the actual cutting and forming operations. Additional components like springs and pads control material flow and provide necessary force.

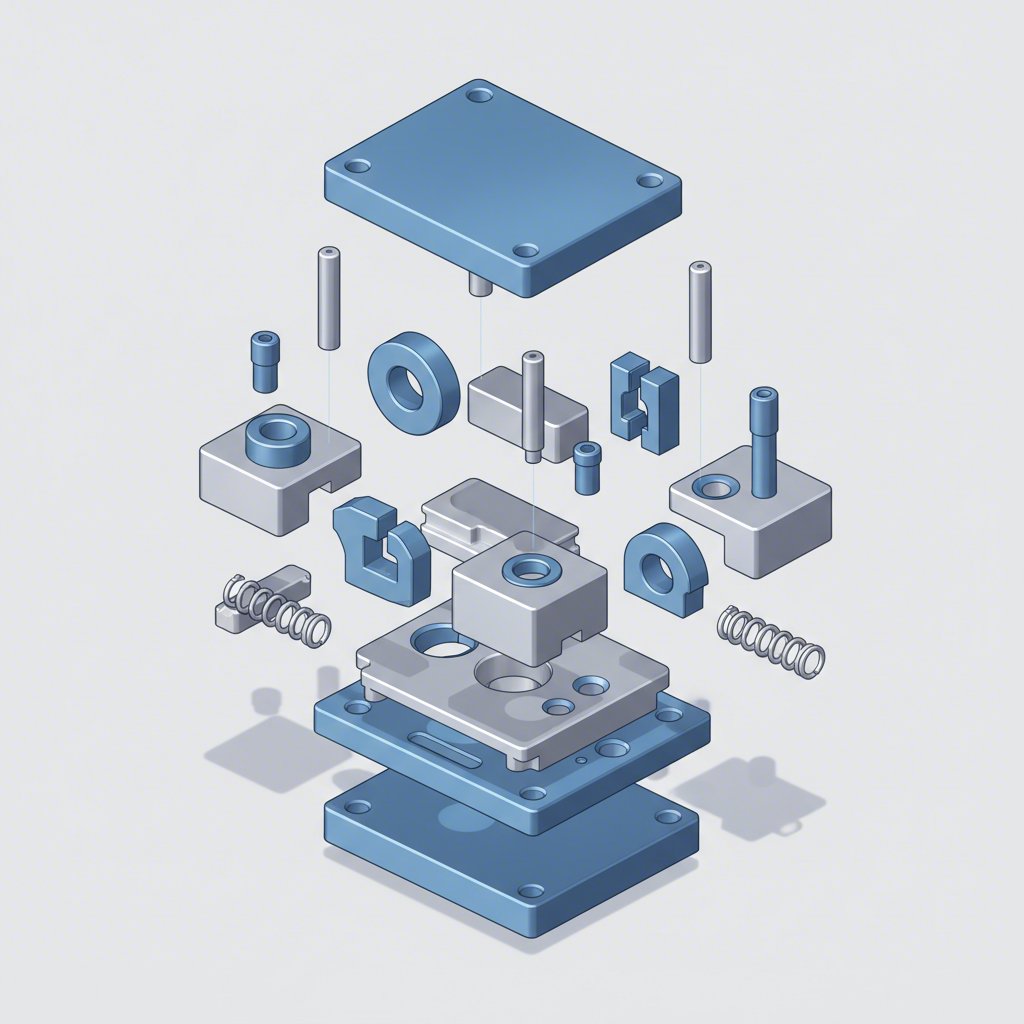

The Foundation: Core Anatomy of the Die Set

At the heart of any stamping operation lies the die set, which serves as the robust foundation for all other working components. The primary elements of this base are the die plates, also known as die shoes. A complete die set consists of an upper shoe (which holds the punch assembly) and a lower shoe (which holds the die block), brought into perfect alignment by guide components. These plates are meticulously machined from high-quality steel or aluminum to be perfectly flat and parallel, a critical requirement for producing consistent, high-quality parts. The choice of material depends on the application; while steel is common for its durability, aluminum is often preferred for its lighter weight, faster machining, and excellent shock absorption, making it ideal for high-impact blanking dies.

The design and thickness of the die shoes are directly related to the amount of force the die must withstand. For instance, a coining die, which compresses metal under immense pressure, requires significantly thicker and more robust shoes than a simple die used for light bending operations. This foundational strength prevents deflection and ensures that the force from the press is transmitted efficiently to the workpiece. The lower die shoe is typically machined with strategically placed holes. These openings allow slugs and scrap material generated during piercing or blanking to fall through and be cleared from the press, preventing die damage and operational stoppages.

Furthermore, the die set is the interface between the tool and the press machine. The upper and lower shoes have mounting features, such as shanks or bolt holes, that secure the entire die assembly into the press ram and bolster plate. This secure mounting is essential for safety and operational precision. For complex applications, especially in industries like automotive manufacturing, the design of the die set is paramount. Companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. specialize in creating custom stamping dies where the foundational components are engineered to meet the extreme demands of producing intricate automotive parts with high precision and longevity.

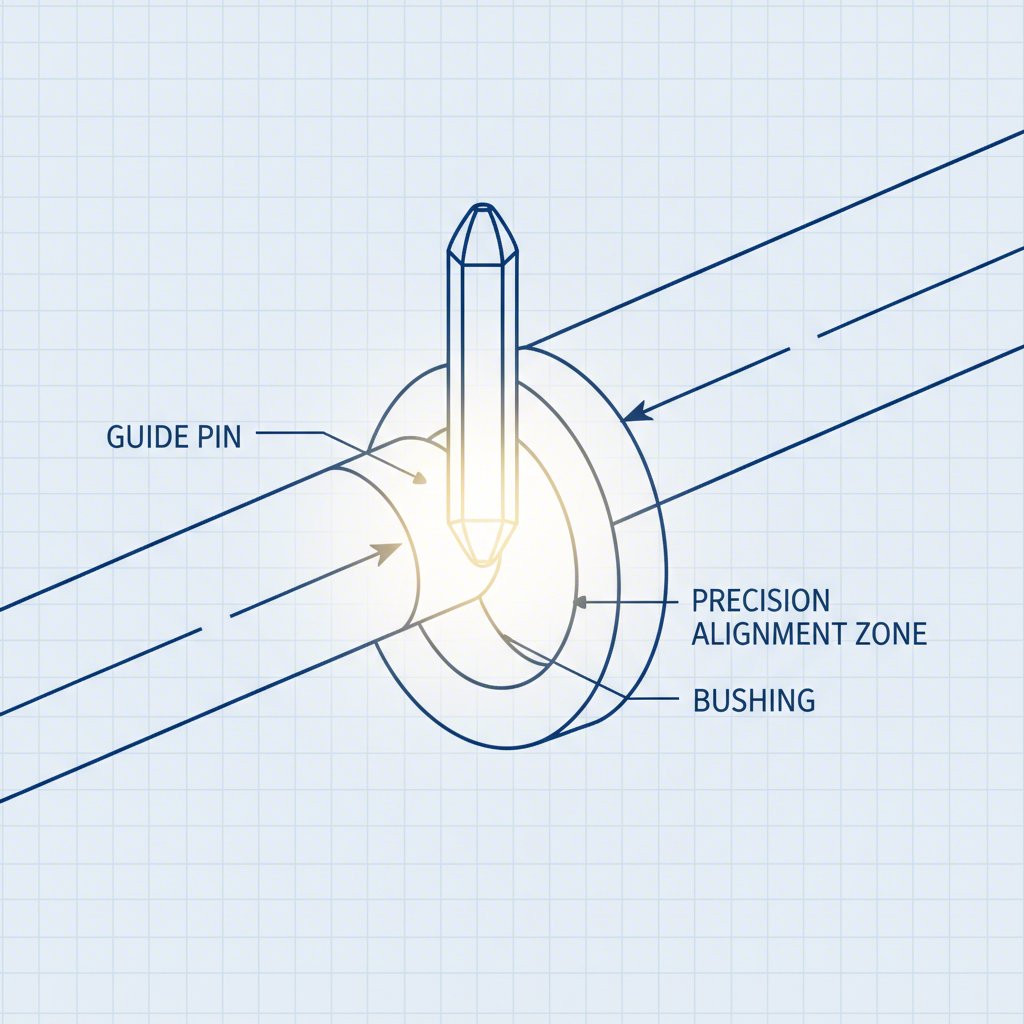

Precision in Motion: Guide Pins, Bushings, and Heel Blocks

While die shoes provide the foundation, the remarkable precision of a stamping die is achieved through its guidance system. The primary components responsible for this are guide pins (also called pillars or guide posts) and guide bushings. These elements work in tandem to ensure the upper and lower halves of the die align perfectly with every stroke of the press, often maintaining tolerances as tight as 0.0001 inches. This exact alignment is crucial for maintaining the correct clearance between cutting punches and die blocks, which directly impacts part quality, tool wear, and die life.

There are two principal types of guide pin systems, each suited for different operational demands. The traditional choice is friction pins, which are hardened, precision-ground steel pins that slide within aluminum-bronze bushings. These bushings are often embedded with graphite plugs for self-lubrication to minimize friction and wear. The alternative is a ball bearing-style system, where the pins ride on a series of ball bearings held in a cage. This design dramatically reduces friction, allowing for higher press speeds without generating excessive heat, and makes it easier for technicians to separate the die halves for maintenance.

| Feature | Friction Pins | Ball Bearing Pins |

|---|---|---|

| Friction Level | Higher | Very Low |

| Operating Speed | Lower to Medium | High |

| Precision | Good to High | Very High |

| Cost | Lower | Higher |

In operations where significant side thrust is generated—for example, in forming or cam-driven dies—guide pins alone may not be sufficient to prevent deflection. In these cases, heel blocks are added. These are robust, precision-machined steel blocks attached to both die shoes that engage with each other to absorb lateral forces. They typically use wear plates made of dissimilar metals, such as steel against aluminum-bronze, to prevent galling and ensure smooth operation. It is a critical principle in die design that guide components are meant to align a properly functioning die, not to compensate for a poorly maintained or misaligned press ram.

The Working End: Punches, Die Blocks, and Retainers

The components that perform the actual work of cutting and forming the sheet metal are the punch and the die block. The punch is the male component, typically mounted to the upper die shoe, which pushes into the material. The die block, or die cavity, is the female component, mounted on the lower shoe, that defines the final shape of the part. The precise relationship and clearance between the punch and die block determine the quality of the cut or form.

Punches and die blocks are used for a variety of operations, and their terminology reflects their function. For example, a 'blanking' operation is when the piece punched out of the sheet is the desired part, known as the blank. Conversely, a 'piercing' operation is when the punch creates a hole in the part, and the punched-out material, called a slug, is discarded as scrap. These working components are responsible for numerous processes, including:

- Blanking: Cutting the outer profile of a part from the sheet stock.

- Piercing: Creating internal holes or features in the part.

- Coining: Applying high pressure to stamp a detailed impression into the metal.

- Drawing: Stretching and forming sheet metal into deep, cup-like shapes.

- Bending: Forming the material along a straight axis.

To facilitate maintenance and quick changeovers, punches are often held in place by retainers. One of the most common types is the ball-lock retainer. This device uses a spring-loaded ball bearing that snaps into a teardrop-shaped groove on the shank of the punch. This system allows a die maintenance technician to quickly remove a worn or broken punch and install a new one without disassembling the entire die, significantly reducing downtime. This modularity is a key feature of modern, efficient die design.

Material Control and Force Application: Pads and Springs

Effectively managing the sheet metal during a high-speed stamping operation is just as critical as the cutting and forming itself. This is the role of various pads and springs within the die set. A pad is a pressure-loaded plate that holds, controls, or strips the metal. For instance, a stripper pad is a spring-loaded plate that surrounds the cutting punches. After a punch pierces the material, the metal's elasticity causes it to grip the punch; the stripper pad holds the material down, allowing the punch to withdraw cleanly.

In forming operations, other types of pads are used. Pressure pads are essential in wipe bending, where they hold the material firmly against the lower die section to ensure a crisp, accurate bend. In deep drawing operations, draw pads (also called binders) apply controlled pressure to the perimeter of the blank. This pressure is critical for regulating the flow of material into the die cavity. Too little pressure allows the material to wrinkle, while too much pressure restricts flow and can cause the part to split or fracture. These pads are typically secured with components like spools or shoulder bolts, which allow them to move up and down while applying consistent force.

The force for these pads is supplied by springs. The choice of spring depends on the force, travel, and life-cycle requirements of the application. The three main types are:

- Coil Springs: Made of spring steel, these are common, cost-effective, and suitable for applications requiring moderate force.

- Urethane Springs: These provide good stripping pressure and are often used in prototype or short-run tooling due to their lower cost.

- Nitrogen Gas Springs: These are cylinders charged with nitrogen gas that can deliver extremely high and consistent force throughout the press stroke. They have a very long life expectancy and are preferred for demanding applications like deep drawing.

Frequently Asked Questions

1. What is a die component?

A die component is any individual part that makes up a complete stamping die assembly. These components work together to cut or form sheet metal. Key examples include die plates (the foundation), guide pins and bushings (for alignment), punches and die blocks (the cutting/forming elements), springs (for force), and stripper pads (for material control). Each component has a specific function crucial to the die's overall performance and precision.

2. What are the components of die casting?

While it sounds similar, die casting is a different manufacturing process from die stamping. Die casting involves forcing molten metal under high pressure into a mold cavity, called a die or mold. The main components include the two halves of the die (the cover die and the ejector die), an ejector pin system to push the solidified part out, and runners or gates that channel the molten metal into the cavity. The materials used are typically non-ferrous alloys like aluminum, zinc, and magnesium.

3. What are die cut components?

Die cut components are parts produced through a process called die cutting, which is often used for softer materials like paper, plastic, fabric, or foam, in addition to thin metals. The 'die' in this context can be a sharp, custom-shaped blade (a steel-rule die) pressed into the material to cut out a specific shape, much like a cookie cutter. The resulting products are used in everything from packaging and gaskets to electronic insulators and medical devices.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —