Mastering Interlocking Aluminum Extrusion Profile Design

Mastering Interlocking Aluminum Extrusion Profile Design

TL;DR

Effective design of interlocking aluminum extrusion profiles hinges on selecting the right joint geometry and maintaining precise dimensional tolerances. By creating integrated features like snap-fits, dovetails, and nesting joints, designers can build strong, stable assemblies without relying on traditional fasteners. Success requires a deep understanding of material properties, wall thickness consistency, and how the profile's shape impacts manufacturability and assembly efficiency.

Fundamental Principles of Interlocking Extrusion Design

Designing interlocking aluminum extrusions is a strategic approach to creating elegant, strong, and efficient connections between components. Unlike simple butt joints that require external fasteners or welding, interlocking profiles feature integrated mating geometries that allow them to connect directly. This method simplifies assembly, reduces the bill of materials, and often enhances the structural integrity of the final product. The core principle is to use the extrusion process itself to create complex cross-sections that serve both a structural and a connectional purpose.

The versatility of the aluminum extrusion process enables the creation of numerous joint types, each suited for different applications and performance requirements. These joints are broadly categorized by their assembly method and whether they create a permanent or separable connection. Understanding these fundamental types is the first step toward leveraging their full potential in a design.

Common Joint Geometries and Their Mechanics

Several primary types of interlocking joints are commonly used in product design, each with distinct mechanical properties. A few of the most important include:

- Snap-Fit Joints: Also known as snap-lock joints, these are designed for rapid, often permanent assembly. They rely on the elastic properties of aluminum, where a flexible feature (like a barb or clip) deflects during insertion and returns to its original shape to lock the two profiles together. This method is excellent for reducing assembly time and eliminating the need for extra hardware.

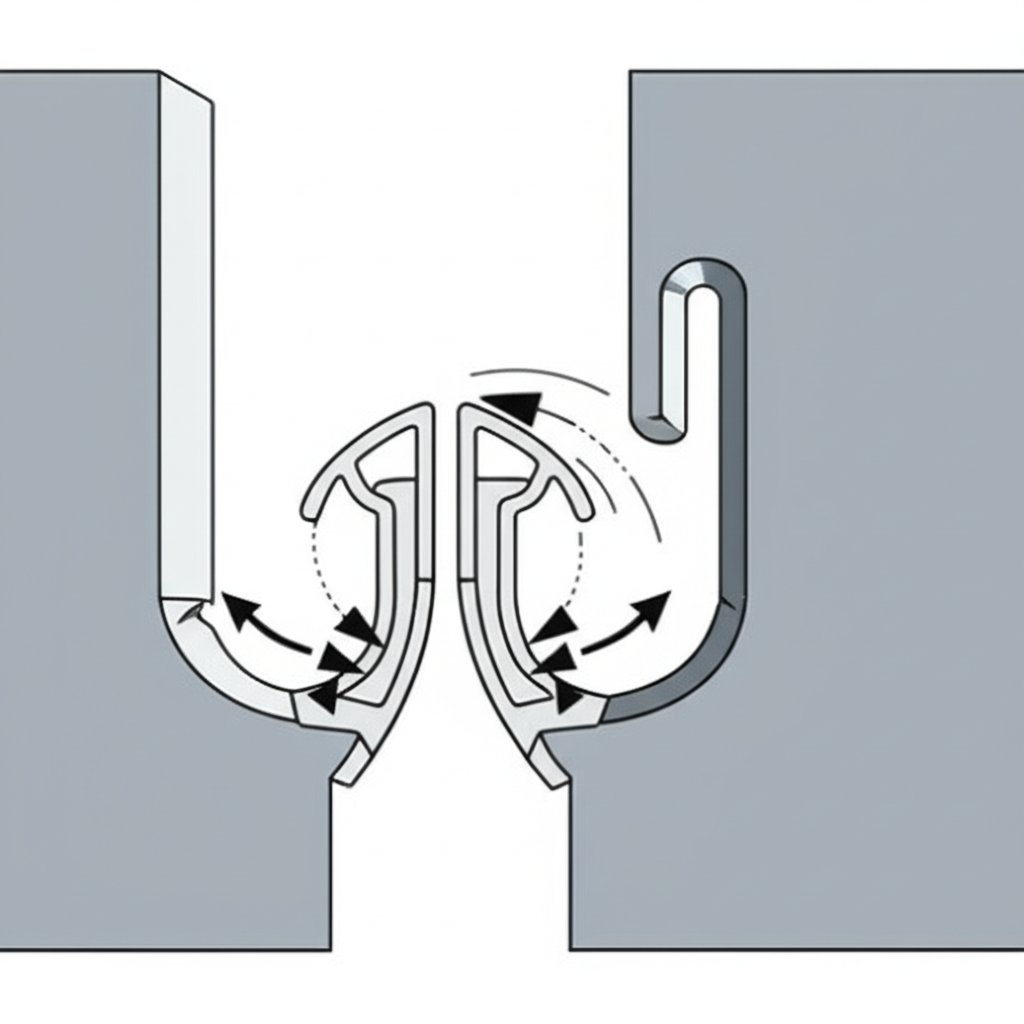

- Interlocking Joints: This category often refers to joints that assemble via a rotational motion, such as a modified tongue-and-groove where curved elements prevent disassembly through a straight-line pull. The connection is secured once assembled and can only be taken apart by a counter-rotating motion, making it highly resistant to separation under normal loads.

- Nesting Joints: These joints use mating surfaces like a classic tongue-and-groove or half-lap to achieve precise alignment. While they align parts perfectly, they don't typically lock them together on their own and may require adhesives or secondary fasteners to create a permanent or semi-permanent assembly. Their primary function is alignment and load distribution.

- Slip-Fit Joints: Sometimes called sleeve joints, these profiles are designed to slide together along their length. This creates a strong, continuous connection ideal for linear applications but can be challenging to assemble in confined spaces.

Key Design Considerations for Optimal Performance

Creating a successful interlocking aluminum profile requires more than just choosing a joint type; it demands careful consideration of several critical engineering parameters. These factors directly influence the part's strength, manufacturability, cost, and overall performance in its intended application. Overlooking these details can lead to parts that are difficult to produce, fail to meet performance specifications, or are unnecessarily expensive. As detailed in best practices from industry experts, focusing on these elements early in the design phase prevents costly rework.

A well-designed extrusion balances the ideal geometry with the practical limitations of the extrusion process. Factors such as the aluminum alloy's properties, the consistency of wall thickness, and the precision of dimensional tolerances are paramount. Each decision represents a trade-off between performance, cost, and ease of manufacturing, and a holistic approach is necessary to achieve an optimized design.

Tolerances, Wall Thickness, and Material Selection

Precision is critical, especially for features like snap-fits where the exact dimensions determine the locking force and durability. Engineers must identify which dimensions are critical for function and apply tighter tolerances only where necessary to control costs. Communicating these needs clearly to the extrusion manufacturer ensures the final product performs as intended.

Wall thickness is another crucial factor. Large variations in wall thickness within a single profile can cause inconsistent cooling rates during manufacturing, leading to warping or dimensional inaccuracies. A best practice is to maintain uniform wall thickness whenever possible. If variations are unavoidable, designing smooth transitions between different thicknesses helps ensure consistent material flow through the extrusion die.

The choice of aluminum alloy also has a significant impact. Different alloys offer unique combinations of strength, corrosion resistance, surface finish, and extrudability. For example:

- 6063 Alloy: Often chosen for its excellent surface finish and extrudability, making it ideal for architectural and decorative applications.

- 6061 Alloy: Provides superior strength and good corrosion resistance, suitable for structural components.

- 7075 Alloy: Offers very high strength, making it a common choice for demanding aerospace and defense applications.

A Practical Guide to Designing Common Interlocking Joints

Translating theoretical principles into functional geometry is where design becomes a practical exercise. Designing a robust interlocking feature requires a step-by-step approach that considers the forces at play, the assembly process, and the material's behavior. Two of the most common and effective interlocking features are the snap-fit joint and the dovetail (a type of slip-fit or interlocking joint). Mastering their design provides a solid foundation for creating a wide range of custom profiles.

For any interlocking design, the process begins with defining the functional requirements. Will the joint be permanent or separable? What loads must it withstand? How will the user assemble it? The answers to these questions will guide the geometric decisions, such as the angle of a locking barb or the depth of a receiving channel. It is essential to visualize the entire lifecycle of the joint, from extrusion to final assembly and use.

Designing a Snap-Fit Joint

Snap-fit joints are valued for their assembly speed and fastener-free design. Creating an effective one involves carefully balancing flexibility and strength.

- Define the Locking Mechanism: The most common design is a cantilever hook or barb that deflects upon entry into a receiving groove and snaps back to create an undercut, preventing separation. The lead-in angle of the barb should be gradual (e.g., 30-45 degrees) to ease assembly, while the locking face should be sharper (e.g., 90 degrees) for a secure hold in permanent applications.

- Calculate Deflection and Stress: The cantilevered feature must be flexible enough to deflect without exceeding the aluminum alloy's elastic limit, which would cause permanent deformation. This requires careful calculation based on the material's modulus of elasticity and yield strength. The thickness and length of the flexible arm are the primary variables to adjust.

- Ensure Proper Tolerances: The success of a snap-fit relies on precise dimensions. The interference between the barb and the receiving feature must be tightly controlled. Too much interference will create excessive assembly force or cause breakage, while too little will result in a loose, insecure connection.

Designing a Dovetail Joint

Dovetail joints, a form of slip-fit joint, provide excellent resistance to tensile forces and ensure precise alignment. The design process focuses on creating self-aligning and mechanically locking geometry.

- Establish the Geometry: A classic dovetail features a trapezoidal tongue that slides into a matching groove. For a rotational interlock, the mating surfaces are curved. The angle of the dovetail determines its holding strength; steeper angles provide a stronger mechanical lock but may require more precision during manufacturing.

- Consider Assembly Method: A straight dovetail requires linear sliding for assembly. This is simple but requires clearance at one end of the extrusion. A rotational interlock is assembled by angling one part relative to the other and rotating it into place, which is useful for enclosed assemblies where linear sliding is impossible.

- Manage Friction and Clearance: The fit between the male and female components must be precise. A small clearance is needed to allow for smooth assembly and to accommodate manufacturing tolerances and surface finishes (like anodizing, which adds thickness). The design should aim for a snug fit that minimizes play without making assembly overly difficult.

Optimizing for Manufacturability, Cost, and Assembly

An interlocking profile design is only successful if it can be manufactured efficiently, assembled easily, and produced within budget. Design choices have significant downstream consequences, impacting everything from the cost of the extrusion die to the labor required for final assembly. A strategic designer thinks beyond the part itself and considers the entire production ecosystem. By simplifying profiles and designing for the process, engineers can dramatically reduce costs and lead times.

One of the most powerful advantages of designing interlocking features is the potential to eliminate secondary operations and components. A clever snap-fit or nesting joint can replace screws, brackets, and adhesives, which not only saves on material costs but also drastically cuts down on assembly time and labor. This holistic approach, which balances technical performance with commercial viability, is the hallmark of expert-level extrusion design.

Furthermore, early collaboration with an extrusion manufacturer is crucial for validating a design's manufacturability. An experienced partner can provide invaluable feedback on die complexity, potential extrusion challenges, and cost-saving opportunities. For projects in demanding sectors, such as automotive, where precision and quality are non-negotiable, this partnership becomes even more critical. For automotive projects demanding precision-engineered components, consider custom aluminum extrusions from a trusted partner. Shaoyi Metal Technology offers a comprehensive one-stop service, from rapid prototyping to full-scale production under a strict IATF 16949 certified quality system, helping to streamline manufacturing and ensure components meet exact specifications.

Your Path to Advanced Extrusion Design

Mastering the design of interlocking aluminum extrusions unlocks new levels of performance, efficiency, and design elegance. By moving beyond simple profiles and embracing integrated joining features, you can reduce complexity, lower assembly costs, and create stronger, more streamlined products. The key takeaways are to ground your design in fundamental principles, pay meticulous attention to critical parameters like tolerances and wall thickness, and always consider the downstream impacts on manufacturing and assembly. By applying these strategies, you can transform a simple piece of aluminum into a sophisticated, high-performance component.

Frequently Asked Questions

1. What is an aluminum extrusion snap-fit joint?

An aluminum extrusion snap-fit, or snap-lock, is an integrated joining feature where one profile has a flexible barb or clip that deflects when pushed into a receiving channel on another profile. Once inserted, the feature “snaps” back into place, creating a mechanical lock that prevents the two parts from separating without the need for additional fasteners. This method is prized for its rapid assembly and clean aesthetics.

2. How do you connect aluminum profiles without fasteners?

You can connect aluminum profiles without traditional fasteners by designing them with integrated interlocking geometries. Common methods include snap-fit joints, which lock together automatically; slip-fit joints like dovetails, which slide together to form a strong mechanical bond; and rotational interlocking joints, which are assembled by rotating one part into another. These methods rely on the profile's shape for connection, reducing assembly time and component count.

3. What are blind joints in aluminum extrusions?

Blind joints refer to connections where the fastening mechanism is hidden from view after assembly, creating a clean, seamless appearance. Interlocking profiles are an excellent way to create blind joints. For example, a snap-fit connection is inherently blind because the locking feature is contained within the profiles. Another method involves using internal connectors or cleats that slide into hidden channels to join two extrusions end-to-end or at corners, keeping all hardware out of sight.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —