Custom Forged Wheel Offsets Explained: Stop Guessing Your Fitment

What Wheel Offset Really Means for Your Vehicle

Ever wondered what does offset mean on wheels when shopping for your next set? You're not alone. Understanding wheel offset is the foundation of achieving perfect fitment, and getting it wrong can lead to rubbing, handling issues, or an appearance that misses the mark entirely.

Wheel offset is the distance in millimeters between the wheel's mounting surface and its true centerline. This single measurement determines how far inward or outward your wheel sits within the wheel well.

When you're investing in custom forged wheels, knowing what is the offset of a wheel becomes even more critical. Unlike mass-produced alternatives with limited sizing options, precision-manufactured forged wheels can be built to exact offset specifications, giving you complete control over your vehicle's stance and performance.

The Mounting Surface and Centerline Relationship

Imagine splitting your wheel perfectly in half from front to back. That imaginary line running through the center is your wheel's centerline. Now, picture where your wheel bolts to your hub—that's the mounting surface. The wheel offset meaning becomes clear when you measure the distance between these two points.

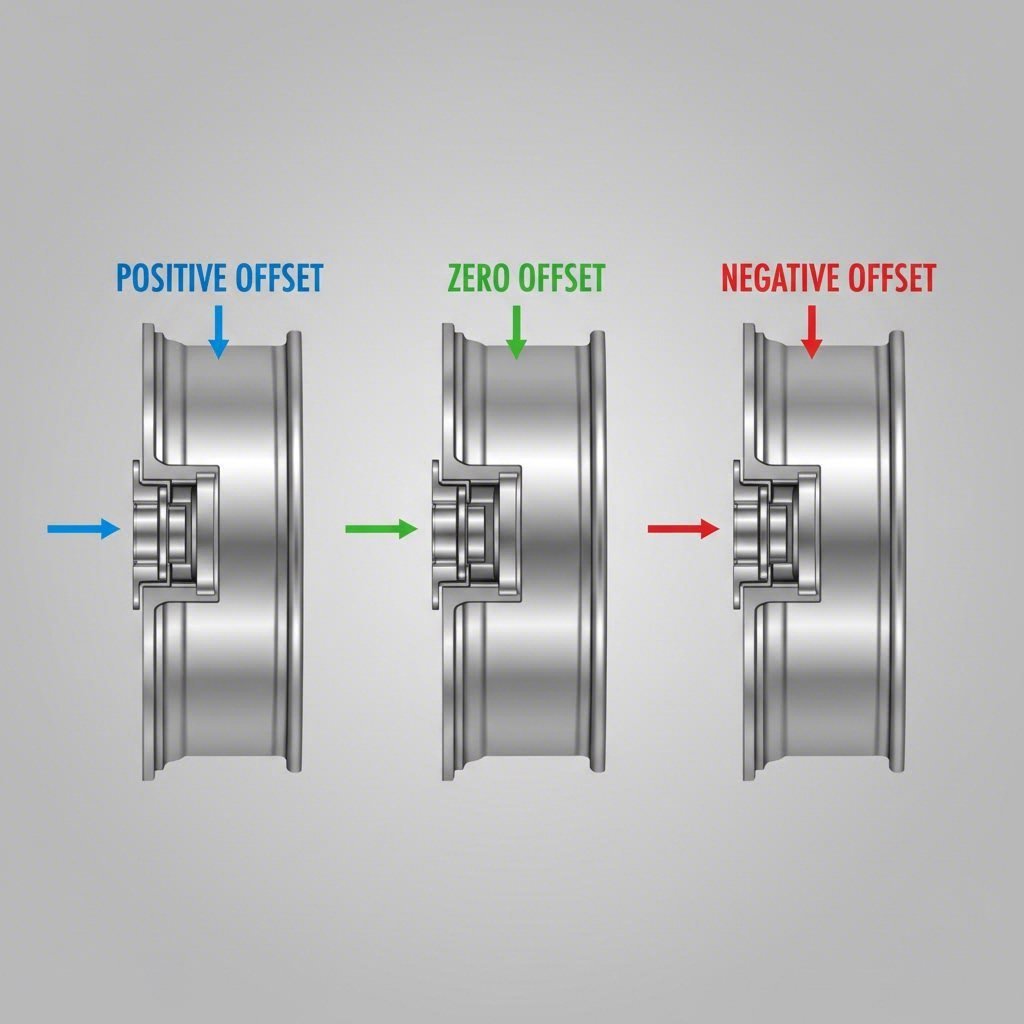

This relationship creates three distinct offset types:

- Positive offset: The mounting surface sits toward the front face of the wheel, pushing the wheel inboard

- Negative offset: The mounting surface sits toward the back of the wheel, pushing the wheel outboard

- Zero offset: The mounting surface aligns perfectly with the centerline

Each configuration dramatically changes how your wheel positions itself within the fender, affecting everything from aesthetics to suspension geometry.

Why Millimeters Matter in Wheel Fitment

You might think a few millimeters couldn't make much difference, but when it comes to wheel offset explained properly, those small increments are everything. A change of just 5mm can mean the difference between a flush fitment and tire rubbing against your fender or suspension components.

According to Forgelite Wheels, both wheel width and offset must be considered together to determine if wheels are suitable for your car. This precision matters because offset affects vehicle handling, brake clearance, suspension component clearance, and fender clearance simultaneously.

For enthusiasts investing in custom forged wheels, this precision manufacturing capability is a game-changer. Rather than settling for whatever offset is available off the shelf, you can specify exact millimeter requirements that deliver the perfect stance while maintaining proper clearances and handling characteristics.

Positive vs Negative Offset and Zero Offset Differences

Now that you understand what offset measures, let's explore how positive vs negative offset configurations actually affect your vehicle's stance and performance. Each offset type positions your wheel differently within the wheel well, creating distinct visual effects and handling characteristics. Choosing the right one depends entirely on your goals—whether that's maintaining factory handling, achieving an aggressive stance, or building a dedicated off-road rig.

| Type | Mounting Position | Visual Effect | Common Applications | Typical Vehicles |

|---|---|---|---|---|

| Positive Offset | Mounting surface closer to the outer lip (front face) of the wheel | Wheel tucked inward toward suspension; sleek, streamlined appearance | Factory fitments, improved aerodynamics, maintaining OEM handling | Sedans, sports cars, front-wheel-drive vehicles, modern CUVs |

| Zero Offset | Mounting surface aligned exactly with the wheel's centerline | Flush fitment with fender; balanced, robust stance | Off-road builds, aftermarket truck setups, balanced stance projects | Trucks, SUVs, some performance builds |

| Negative Offset | Mounting surface closer to the inner lip (back) of the wheel | Wheel pokes outward beyond fender; aggressive, wide stance | Lifted trucks, off-road vehicles, show cars, stanced builds | Lifted trucks, Jeeps, dedicated off-road rigs, deep-dish wheel enthusiasts |

Positive Offset and Inward Wheel Positioning

So what is positive offset exactly? When a wheel's mounting surface sits closer to its outer lip—the side facing you when you look at the wheel head-on—the wheel has a positive offset. This configuration pulls the wheel inward toward the vehicle's suspension and frame, keeping more of the wheel tucked inside the wheel well.

According to Fifteen52, positive offset wheels are commonly found on sedans, sports cars, and most modern vehicles because they maintain factory-installed handling characteristics while providing a sleek appearance. There's also a practical benefit: tucking the wheels inward can improve fuel economy by reducing aerodynamic drag.

You'll notice most stock wheels come with positive offset for good reason. Manufacturers engineer their suspension geometry around specific offset values to optimize:

- Steering response and feel

- Brake system clearance

- Suspension component clearance during turns

- Proper tire wear patterns

When comparing positive offset vs negative offset wheels, keep in mind that positive values typically range from +20mm to +50mm or higher on modern passenger vehicles. The higher the positive number, the further inward your wheel sits.

When Negative Offset Creates Aggressive Stance

Negative offset wheels flip the equation entirely. Here, the mounting surface sits closer to the inner lip of the wheel, pushing the entire assembly outward from the vehicle. This creates that head-turning "poke" where your wheels extend beyond the fender line.

Negative offset rims are popular in specific automotive cultures for good reason. As Dan The Tire Man explains, negative offset creates a wider stance commonly seen on lifted trucks, off-road vehicles, and performance builds seeking that aggressive appearance.

However, going too aggressive with vs offset wheels configurations comes with trade-offs. More negative offset means:

- Increased steering effort due to altered scrub radius

- Higher stress on wheel bearings and suspension components

- Potential for road spray and debris damage to body panels

- Possible legal issues if tires extend too far beyond fenders

When offset vs offset comparisons matter most is during lifted truck builds. If you've installed a leveling kit or suspension lift, the additional clearance often allows—or even requires—moving to a more negative offset to achieve proper fitment and stance.

Zero offset represents the middle ground. The mounting surface aligns perfectly with the wheel's centerline, creating a balanced appearance that's neither tucked nor poked. This configuration is common on trucks and SUVs seeking a tough, robust stance without the complications of extreme negative offset.

Understanding these three offset types gives you the foundation for making informed decisions about your custom forged wheel specifications. The next step is understanding how offset relates to another critical measurement—backspacing—and why confusing the two can lead to costly fitment mistakes.

Offset vs Backspacing and How They Connect

Here's where things get confusing for many enthusiasts. You've got offset figured out, but then someone mentions wheel backspacing, and suddenly the conversation takes a different turn. What is backspacing on wheels, and how does it relate to offset? These two measurements describe similar concepts but from different reference points—and understanding both is essential for precise fitment.

Think of it this way: offset tells you where your mounting surface sits relative to the wheel's centerline, while rim backspacing measures from the mounting surface to the wheel's inner lip. Both measurements help determine how your wheel positions itself, but they answer slightly different questions.

- Offset: Measures from the mounting surface to the wheel's centerline; expressed as a positive, negative, or zero millimeter value

- Backspacing: Measures from the mounting surface to the inner edge (back lip) of the wheel; typically expressed in inches

- Key difference: Offset is relative to the centerline, while backspacing is relative to the inner lip

- Width dependency: Backspacing changes with wheel width even if offset stays the same; offset remains constant regardless of width changes alone

- Common usage: European and import manufacturers favor offset (ET notation), while American wheel builders often reference backspacing

Converting Between Offset and Backspacing Measurements

Need to work with an offset to backspace calculator concept manually? The math is straightforward once you understand the relationship. Since backspacing measures from the mounting surface to the inner lip, and offset measures from the mounting surface to the centerline, you simply need to know your wheel width to convert between them.

Here's the conversion logic: backspacing equals half the total wheel width (usually about 1 inch wider than the stated width) plus the offset. If you're working in mixed units—which is common since offset uses millimeters and backspacing typically uses inches—you'll need to convert accordingly. One inch equals 25.4 millimeters.

For example, imagine you have a 10-inch wide wheel. The total width including flanges is likely about 11 inches. Half of that is 5.5 inches (140mm). Add the +25mm offset, and you get 165mm of backspacing—or roughly 6.5 inches. Knowing how to work out wheel offset from backspacing works the same way in reverse: subtract half the wheel width from the backspacing measurement.

How Wheel Width Changes the Equation

Here's the critical insight many enthusiasts miss: wheel offset vs backspacing behaves differently when you change wheel width. If you increase your wheel width while keeping the same offset, your backspacing actually increases. The wheel grows outward from the centerline on both sides, pushing the inner lip further inward.

This matters tremendously when you're figuring out how to work out rim offset for a wider wheel upgrade. A wheel that's 2 inches wider with the same offset will have 1 additional inch of backspacing—meaning it extends 1 inch further inward toward your suspension components. That single inch can be the difference between perfect clearance and constant rubbing on control arms or struts.

When shopping for custom forged wheels, you'll often encounter situations where knowing how to find out offset of rims requires understanding both measurements. Some wheel manufacturers list only backspacing, while others provide offset in the ET format. Being comfortable converting between these values ensures you're comparing apples to apples and selecting the exact specifications your build requires.

With offset and backspacing now demystified, the next logical step is learning how to actually measure these values on your existing wheels—whether you're reading factory stamps or breaking out the measuring tools yourself.

How to Measure and Determine Your Wheel Offset

Ready to get your hands dirty? Whether you're verifying specs on wheels you already own or figuring out what offset you need for an upgrade, knowing how to measure wheel offset yourself puts you in control. The good news is you don't need expensive equipment—just some basic tools and a methodical approach.

There are three reliable ways to determine wheel offset: reading the manufacturer's stamped markings, measuring manually with simple tools, or using digital measurement devices for precision work. Let's walk through each method so you can confidently figure out wheel offset on any wheel you encounter.

Reading Factory Offset Stamps on Your Wheels

The fastest way to find wheel offset is checking for factory markings already stamped into the metal. Most manufacturers stamp critical specifications directly onto the wheel, saving you the trouble of measuring. But where exactly should you look?

According to AutoZone, offset markings are typically stamped on the back of the wheel or inside the barrel. You'll usually find them near the hub bore or along the inner spoke area. The marking you're searching for uses "ET" notation—a German abbreviation for "Einpresstiefe," meaning insertion depth.

Here's how to interpret what you find:

- ET45: Positive 45mm offset—mounting surface is 45mm toward the outer face

- ET0: Zero offset—mounting surface aligns with centerline

- ET-15: Negative 15mm offset—mounting surface is 15mm toward the inner lip

Beyond the ET marking, you'll often find additional specifications stamped nearby, including wheel diameter, width, and sometimes the manufacturer's part number. If you're trying to find out offset of rims from an aftermarket brand, check the inner barrel area or the back of the center cap mounting area—different manufacturers place their stamps in varying locations.

Can't locate any markings? Older wheels, refinished wheels, or some budget options may lack clear stamps. That's when manual measurement becomes essential.

DIY Measurement Techniques for Accurate Results

When stamps aren't available—or you want to verify manufacturer claims—measuring offset yourself is straightforward with the right approach. You'll need a tape measure or ruler, a straight edge long enough to span the wheel's diameter, and optionally a caliper for precision work.

Follow this step-by-step process to determine wheel offset accurately:

- Remove the wheel from the vehicle: Safely jack up your vehicle and remove the wheel completely. While it's possible to measure with the wheel mounted, working with it removed gives you full access and improves accuracy.

- Measure the total wheel width: Lay the wheel face-down on a flat surface. Place your straight edge across the rim's outer edges and measure the total width using your tape measure. Measure from the inside of one lip to the inside of the opposite lip—not the outer edges. This gives you the true mounting width.

- Calculate the centerline: Divide your wheel width measurement by two. For an 8-inch wide wheel, your centerline sits at 4 inches. This is your reference point for offset calculation.

- Measure the backspacing: With the wheel still face-down, lay your straight edge across the back of the wheel so it rests on both inner lips. Measure the distance from the straight edge down to the mounting surface—the flat area where your wheel contacts the hub.

- Calculate the offset: Subtract your centerline measurement from the backspacing measurement. If backspacing exceeds the centerline distance, you have positive offset. If it's less, the offset is negative.

Here's a practical example from AutoZone's measurement guide: With an 8-inch wide wheel and 5 inches of backspacing, your centerline is 4 inches. Subtracting 4 from 5 gives you +1 inch of offset. Since wheel offset is expressed in millimeters, multiply by 25.4 to convert—giving you approximately +25mm offset.

For those wondering how to work out wheel offset with maximum precision, digital calipers eliminate the guesswork in step four. They're especially helpful when measuring backspacing on wheels with complex spoke designs where laying a straight edge can be tricky.

Common Measurement Mistakes to Avoid

Even experienced enthusiasts make errors when learning how do you measure the offset of a rim. Here are the pitfalls that lead to fitment disasters:

- Measuring to the outer lip edge: Always measure to the inside of the lip where the tire bead seats, not the outer decorative edge. Including the lip overhang throws off your width measurement.

- Ignoring tire interference: If measuring with a tire mounted, the tire bead can prevent accurate straight-edge placement. Remove the tire when possible.

- Confusing backspacing with offset: These are related but different measurements. Double-check which value you're calculating before ordering wheels based on your results.

- Rounding too aggressively: A 5mm error might seem minor, but it can mean the difference between clean fitment and fender contact. Measure twice and be precise with your conversions.

Understanding how to find wheel offset through both reading stamps and manual measurement gives you flexibility when evaluating wheels from any source. With these techniques mastered, you're equipped to verify specifications before committing to a purchase—protecting your investment in custom forged wheels that demand precise fitment.

How Offset Affects Handling and Suspension Performance

So you've nailed down offset measurements and understand the difference between positive and negative configurations. But here's what most guides skip over entirely: how does wheel offset work when your vehicle is actually in motion? The truth is, offset doesn't just change how your wheels look—it fundamentally alters how your car drives, steers, and wears its components over time.

When you modify wheel offset, you're essentially repositioning the entire contact patch of your tire relative to your suspension's pivot points. This single change ripples through your entire chassis, affecting everything from steering feedback to brake performance. Understanding how does offset work on wheels from a dynamics perspective is what separates informed enthusiasts from those chasing fitment disasters.

Scrub Radius Changes and Steering Response

Ever wondered why some wheel setups make steering feel heavy or unpredictable? The answer often lies in scrub radius—and offset is the primary factor controlling it.

Scrub radius is the distance between where your tire contacts the ground and where your steering axis intersects that same ground plane. When these two points align closely, steering feels light and predictable. Push them apart, and things get interesting—sometimes in ways you don't want.

According to Lifted Trucks, every inch you push a wheel outward changes the leverage applied to your suspension. A more negative offset increases the scrub radius, which creates a longer lever arm acting on your steering components.

Here's how rim offset explained through scrub radius affects your driving experience:

- Increased negative offset: Widens scrub radius, creating heavier steering effort and potentially causing the wheel to "kick back" over bumps or during hard braking

- Excessive positive offset: Can create negative scrub radius, leading to steering instability under braking as the wheels want to toe outward

- Factory-matched offset: Maintains the engineered scrub radius for predictable, balanced steering feel in all conditions

For daily drivers, staying within 5mm of factory offset—a guideline Curva Concepts calls "The 5mm Rule"—preserves your vehicle's intended steering characteristics. Exceed that range, and you'll need to evaluate whether the handling trade-offs match your goals.

Suspension Geometry Impacts from Offset Modifications

Beyond steering feel, how does offset wheels work affects the entire suspension system's geometry and longevity. Your suspension was engineered around specific load paths and leverage ratios. Change the offset, and you're rewriting those engineering calculations.

When you push wheels outward with more negative offset, you're essentially extending the lever arm that acts on critical suspension components. According to industry experts, this increased leverage accelerates wear on:

- Ball joints and wheel bearings: More negative offset acts like a longer pry bar, increasing load with every bump and turn

- Tie rods: Excess leverage creates steering strain, especially during off-road impacts or aggressive cornering

- Control arms: Excessive outward wheel spacing increases angular force, amplifying fatigue over time

- Hub assemblies: The farther out your wheel sits, the greater the stress on hub components, leading to premature failure

What happens when the rim offset is too much in either direction? The consequences extend beyond component wear. Extreme offset changes alter camber and toe angles under load, forcing your alignment to compensate in ways that accelerate tire wear. You might notice uneven tread patterns, particularly on inner or outer shoulders, even with a fresh alignment.

Braking Performance Considerations

Here's something rarely discussed: offset modifications can compromise your braking system's effectiveness. When you alter scrub radius significantly, the forces generated during hard braking create uneven loads across your contact patch. This can manifest as:

- Steering pull during braking, especially on uneven surfaces

- Increased stopping distances due to inconsistent tire loading

- Premature brake pad wear from altered caliper alignment

- Heat buildup issues if reduced clearances restrict airflow to rotors

According to Curva Concepts, insufficient brake caliper clearance from improper offset selection creates heat buildup and potential brake failure, while suspension interference causes premature component wear and handling degradation.

Recognizing Symptoms of Improper Offset

How do you know if your current offset is causing problems? Your vehicle will tell you—if you know what to look for. Watch for these warning signs that indicate your offset selection needs reconsideration:

- Steering wheel vibration: Often indicates altered load distribution causing uneven tire wear or bearing stress

- Pulling to one side: Asymmetric scrub radius changes or uneven suspension loading

- Increased steering effort: Common with excessive negative offset increasing scrub radius

- Clunking over bumps: Stressed ball joints or tie rod ends reaching their limits

- Rapid inner or outer tire wear: Geometry changes forcing camber compensation

- Wheel bearing noise: Premature bearing wear from increased lateral loads

- Brake pedal pulsation: Rotor warping from heat buildup or caliper misalignment

These symptoms don't always appear immediately. Sometimes they develop gradually over thousands of miles as components wear under increased stress. That's why understanding how does rim offset work before making changes saves you from expensive repairs down the road.

Why This Matters for Custom Forged Wheel Investments

When you're investing in premium custom forged wheels, getting offset right isn't just about fitment—it's about protecting your investment. A $4,000 set of precision-manufactured wheels paired with incorrect offset creates a cascade of problems: accelerated bearing wear, compromised handling, premature tire replacement, and potential suspension damage.

The precision manufacturing that makes forged wheels exceptional also means you can specify exact offset values that maintain your vehicle's engineered dynamics. Unlike grabbing whatever offset is available from a warehouse, custom forged wheel orders let you dial in the perfect balance between aggressive stance and preserved handling characteristics.

Think of proper offset selection as insurance for your entire drivetrain. The few millimeters you sacrifice in visual aggression often translate to thousands of miles of additional component life and a driving experience that remains predictable and enjoyable. With offset fundamentals and performance implications now clear, the next step is knowing how to diagnose and solve specific fitment problems when they arise.

Troubleshooting Common Offset Fitment Problems

You've done the research, measured twice, and installed your new wheels—but something isn't right. Maybe you're hearing that dreaded scraping sound during turns, or your wheels are poking out so far they're catching everyone's attention for the wrong reasons. Offset on wheels creates some of the most frustrating fitment issues enthusiasts face, but the good news? Most problems have straightforward solutions once you diagnose the root cause.

According to Apex Wheels, tire rubbing is more than just an annoying noise—it's a sign that something in your setup isn't dialed-in properly. Rubbing can lead to premature tire wear, damaged fenders, and in extreme cases, can become a safety hazard. Let's break down the most common offset-related fitment problems and how to fix them.

Diagnosing Fender and Suspension Rubbing Issues

When your tires start making contact where they shouldn't, the cause typically falls into one of several categories. Understanding where the rubbing occurs tells you exactly what's wrong with your offset for wheels selection.

As industry experts explain, incorrect wheel offset determines where the wheel sits relative to the hub. If a wheel's offset is too low (more "poke"), your tires might rub against the fenders. If the offset is too high, you risk the wheel coming into contact with suspension components or inner fender liners.

Here's how to identify what's causing your rubbing:

- Outer fender contact: Your offset is too negative, pushing the wheel outward. Common during full steering lock or when suspension compresses over bumps

- Inner fender liner contact: Offset may be correct, but tire width exceeds available clearance. Look for scuff marks on plastic liner components

- Suspension component contact: Your offset is too positive, tucking the wheel too far inward. Check control arms, struts, and brake calipers for tire marks

- Compression rubbing only: Suspension travel exceeds available clearance—may require ride height adjustment rather than offset change

According to Apex Wheels, worn suspension components like old shocks, tired bushings, or sagging springs can throw your suspension geometry out of spec, lowering your effective ride height and reducing fender clearance. A worn suspension compresses more easily, making rubbing more likely over dips, driveways, or during spirited driving.

Correcting Excessive Poke or Tuck Problems

Sometimes the issue isn't rubbing—it's appearance or legality. Excessive poke creates practical problems beyond aesthetics, while overly tucked wheels can look unfinished or cause clearance issues with suspension components.

According to Three Piece US, if the wheel and tire poke out more than an inch or so past the fender, you probably made a mistake somewhere. Excessive poke isn't just an aesthetic concern—it slings road debris onto your paint, may violate local vehicle codes, and increases stress on wheel bearings.

For trucks specifically, offset on truck wheels requires careful consideration. As enthusiast resources note, the wider you go with offset truck wheels, the more lift you're going to want—things should remain proportional. You don't want 5 inches of poke on a leveling kit alone.

| Symptom | Likely Offset Cause | Recommended Solution |

|---|---|---|

| Tire rubs outer fender during turns | Offset too negative (excessive poke) | Switch to higher positive offset wheels or roll fenders professionally |

| Tire contacts inner fender liner | Tire too wide for offset combination | Reduce tire width or adjust offset to push wheel outward slightly |

| Rubbing on control arms or struts | Offset too positive (wheel tucked too far inboard) | Use wheel spacers cautiously or switch to lower offset wheels |

| Rubbing only over bumps or dips | Insufficient suspension clearance under compression | Raise ride height, install stiffer springs, or reduce tire diameter |

| Excessive wheel poke beyond fender | Offset far too negative for application | Switch to higher offset wheels or add fender flares for coverage |

| Wheels appear sunken or tucked | Offset too positive for desired stance | Add quality wheel spacers or select wheels with more negative offset |

| Brake caliper clearance issues | Wheel spoke design conflicts with offset | Verify caliper clearance before purchase; consider different wheel design |

Staggered Fitment and Different Front/Rear Offsets

Here's something that trips up many enthusiasts: your front and rear wheels often require different offsets for wheels to achieve proper fitment. This is especially true for performance vehicles and trucks where staggered setups are common.

According to Three Piece US, staggered fitment means having different wheel and/or tire sizes in the front and rear of the car. Typically, this uses a wider wheel and tire setup on the rear axle compared to the front. For RWD applications, a wider rear tire translates to more grip during acceleration.

Why do offsets in wheels need to differ front to rear? Several factors come into play:

- Different fender clearances: Rear wheel wells often provide more room than fronts, allowing for more aggressive offset

- Steering clearance: Front wheels must clear suspension components throughout their full steering range—rear wheels don't turn

- Body line differences: Many vehicles have wider rear quarters than front fenders, requiring different offsets for consistent flush appearance

- Weight distribution: Rear-biased weight in some sports cars demands wider rear tires, which affects optimal offset selection

For example, a typical staggered setup might run a front wheel at +30mm offset and a rear at +45mm offset, even though the rear is wider. The higher positive offset on the wider rear wheel keeps it from poking excessively while still achieving that muscular, planted stance.

Fender Clearance and Tire/Wheel Width Combinations

Offset doesn't exist in isolation—it works together with wheel width and tire size to determine final fitment. When calculating whether a setup will work, you need to consider all three factors simultaneously.

Think about it this way: a 9-inch wide wheel with +35mm offset positions the outer lip differently than a 10-inch wide wheel with the same +35mm offset. The wider wheel extends further outward from that mounting point, potentially creating fender contact even though the offset remained unchanged.

According to Apex Wheels, running meatier tires for increased grip or aesthetics is common, but if your tire diameter or width exceeds your car's available clearance—particularly at full steering lock or when your suspension compresses—you're almost guaranteed to have them rub.

When evaluating offsets for wheels combined with tire sizing, follow these guidelines:

- Measure actual clearance: With current setup at full compression and full steering lock, identify minimum distances to fender and suspension

- Account for tire growth: Tires expand at highway speeds; leave 5-10mm additional clearance beyond static measurements

- Consider load conditions: A car full of passengers compresses suspension further than an empty vehicle

- Check multiple points: Clearance at the top of the fender doesn't guarantee clearance at the liner or suspension components

According to fitment experts, flush fitment—where wheels align vertically with the fender—uses square-fitting tires, not stretched or balloon spec. A good rule of thumb: wheel width multiplied by 25 gives you ideal tire width. For example, a 9.5-inch wheel should run approximately a 235-width tire.

When offset in wheels creates borderline fitment, you have several correction options: professional fender rolling to gain outer clearance, trimming inner fender liners for inboard clearance, or fine-tuning ride height if you're running adjustable suspension. As industry sources note, if you're running adjustable coilovers, a slight lift or dialing some preload into the mix can make a big difference—raising ride height just 5-10mm often solves rubbing without compromising handling or aesthetics.

With troubleshooting fundamentals covered, the next step is understanding how offset requirements vary across different vehicle platforms—because what works perfectly on a European sports car may be completely wrong for a truck or JDM build.

Vehicle-Specific Offset Ranges and Selection Guide

Here's the reality most wheel offset chart resources miss: the "perfect" offset for a BMW M3 would be a disaster on a lifted Silverado, and vice versa. Different vehicle architectures demand fundamentally different offset approaches based on their suspension geometry, intended use, and body design. Understanding what is offset on wheels for your specific platform eliminates guesswork and ensures your custom forged wheels deliver exactly the stance and performance you're after.

Why does this matter so much? Factory engineers spend years developing suspension geometry around specific offset values. When you understand those baseline parameters, you can make informed decisions about how far to push beyond stock—whether you're chasing track performance, show car aesthetics, or daily driver practicality.

| Vehicle Category | Typical Offset Range | Common Wheel Widths | Key Considerations | Example Platforms |

|---|---|---|---|---|

| European Sports Cars | +35mm to +55mm | 8.5" to 11" | Tight fender tolerances; brake clearance critical; staggered setups common | BMW M Series, Porsche 911, Audi RS Models |

| JDM Platforms | +30mm to +45mm | 8" to 10" | Aggressive camber popular; fender rolling often required; lower offsets for drift builds | Nissan 370Z/GTR, Toyota Supra, Subaru WRX/STI |

| American Muscle | +20mm to +45mm | 9" to 11" | Wide rear quarters allow aggressive fitment; staggered for drag/street; M14 bolt patterns common | Ford Mustang, Chevy Camaro, Dodge Challenger |

| European Luxury Sedans | +35mm to +50mm | 8" to 10" | Conservative factory offsets; air suspension adds complexity; hubcentric fit essential | Mercedes E/S Class, BMW 5/7 Series, Audi A6/A8 |

| Trucks and SUVs | +12mm to -25mm | 9" to 12" | Lift height determines ideal offset; negative offsets common; bearing stress considerations | Ford F-150, Chevy Silverado, Jeep Wrangler, Toyota 4Runner |

Sports Car and Performance Vehicle Offset Ranges

When you're working with European sports cars and performance platforms, precision matters more than anywhere else. These vehicles feature carefully engineered suspension geometry where even small offset changes create noticeable handling differences. According to Three Piece US, for most cars, a 9-10 inch wide wheel is the sweet spot, allowing for 255 to 275 wide tires—dimensions that align perfectly with European performance platforms.

What makes these vehicles unique? Several factors influence their offset requirements:

- Tight fender tolerances: German and Italian sports cars feature precisely sculpted fenders with minimal clearance margins, demanding accurate offset specifications

- Large brake packages: Factory performance brakes often require higher positive offsets to clear calipers, especially on front axles

- Staggered configurations: Rear-wheel-drive layouts commonly run wider rear wheels, requiring different offsets front to rear for consistent flush appearance

- Track-oriented suspension: Stiffer springs and limited suspension travel reduce compression clearance concerns but increase importance of static fitment accuracy

JDM platforms offer slightly more flexibility. As wheel offsets explained for these vehicles, the Japanese tuning culture embraces aggressive negative camber setups that allow for lower offset wheels without immediate fender contact. However, this approach requires supporting modifications—fender rolling, pulling, or aftermarket wide-body kits—to execute properly.

American muscle cars present interesting opportunities. Their wide rear quarters and relatively simple suspension designs accommodate broader offset ranges than European counterparts. A Mustang or Camaro can often run wheels 15-20mm more aggressive than stock without major modifications, giving you that filled-out muscular stance enthusiasts love.

Truck and SUV Offset Considerations

If there's one segment where offset wheels explained content is widely available, it's trucks and SUVs. But here's what most guides miss: your ideal offset depends entirely on your lift configuration and intended use.

According to Ozzy Tyres, trucks generally take lower offset wheels, typically in the +12 to -12 range. This contrasts sharply with cars, which commonly accept +30 to +50 offsets. The difference stems from fundamentally different suspension architectures and body designs.

Stock height trucks typically work best with offsets closer to factory specifications, usually in the +12 to +25mm range. Once you add a leveling kit or 2-3 inch lift, you gain clearance that allows—and often looks better with—zero or slightly negative offsets. Full suspension lifts of 4 inches or more open the door to aggressive negative offsets in the -10 to -25mm range, creating that commanding "poke" stance popular in the truck community.

But remember the bearing stress discussion from earlier? According to industry research, every inch of additional poke increases leverage on your wheel bearings and suspension components. For trucks used for towing, hauling, or off-road work, staying closer to factory offset protects these components under heavy load conditions.

Matching Offset to Your Driving Goals

Beyond vehicle type, your intended use should drive offset selection. Here's a decision framework based on specific goals:

Track and Performance Use: Prioritize staying within 5mm of factory offset to maintain engineered suspension geometry. According to performance wheel specialists, larger diameter wheels need more aluminum, meaning they're heavier. If you're going for all-out performance, opt for the smallest wheels that will fit over your brakes while keeping offset close to stock.

Show Car and Stance: Aesthetic goals often justify pushing offset limits. The rim offset chart ranges above represent conservative starting points—show builds frequently exceed these with supporting modifications like air suspension, adjustable camber arms, and fender work. Just understand you're trading some handling precision for visual impact.

Daily Driver Comfort: Stick to the middle of your platform's offset range. This approach delivers improved aesthetics over bone-stock fitment while preserving ride quality, steering feel, and component longevity. You'll avoid the compromises that come with extreme offset choices.

Off-Road and Overlanding: For trucks and SUVs tackling trails, moderate negative offset (-5 to -15mm) widens your track for stability without creating excessive stress on drivetrain components. Avoid extreme poke that catches on obstacles or slings debris into your paint.

The offset chart wheels data above gives you starting parameters, but real-world fitment depends on your specific vehicle, modifications, and goals. What works on your buddy's otherwise identical car may not work on yours due to production tolerances, previous modifications, or different tire choices. Always verify clearances with your specific configuration before committing to custom forged wheel specifications.

With platform-specific offset knowledge now in your toolkit, understanding why custom forged wheels offer superior offset flexibility becomes the logical next step—and why that precision manufacturing matters for getting your exact specifications right.

Custom Forged Wheels and Precision Offset Manufacturing

You've learned what rim offset is and how to select the right range for your vehicle platform. But here's a question worth asking: why does the manufacturing method of your wheels matter when specifying offset? The answer lies in what separates custom forged wheels from mass-produced cast or flow-formed alternatives—and it comes down to one word: precision.

When you order off-the-shelf wheels, you're limited to whatever offsets the manufacturer decided to produce. Maybe they offer +35mm and +45mm options for your fitment. But what if your ideal setup requires +40mm? With cast production, you're out of luck. Custom forged wheel manufacturing changes that equation entirely, allowing you to specify exact millimeter requirements that deliver the precise stance and clearance your build demands.

Manufacturing Precision in Custom Forged Wheels

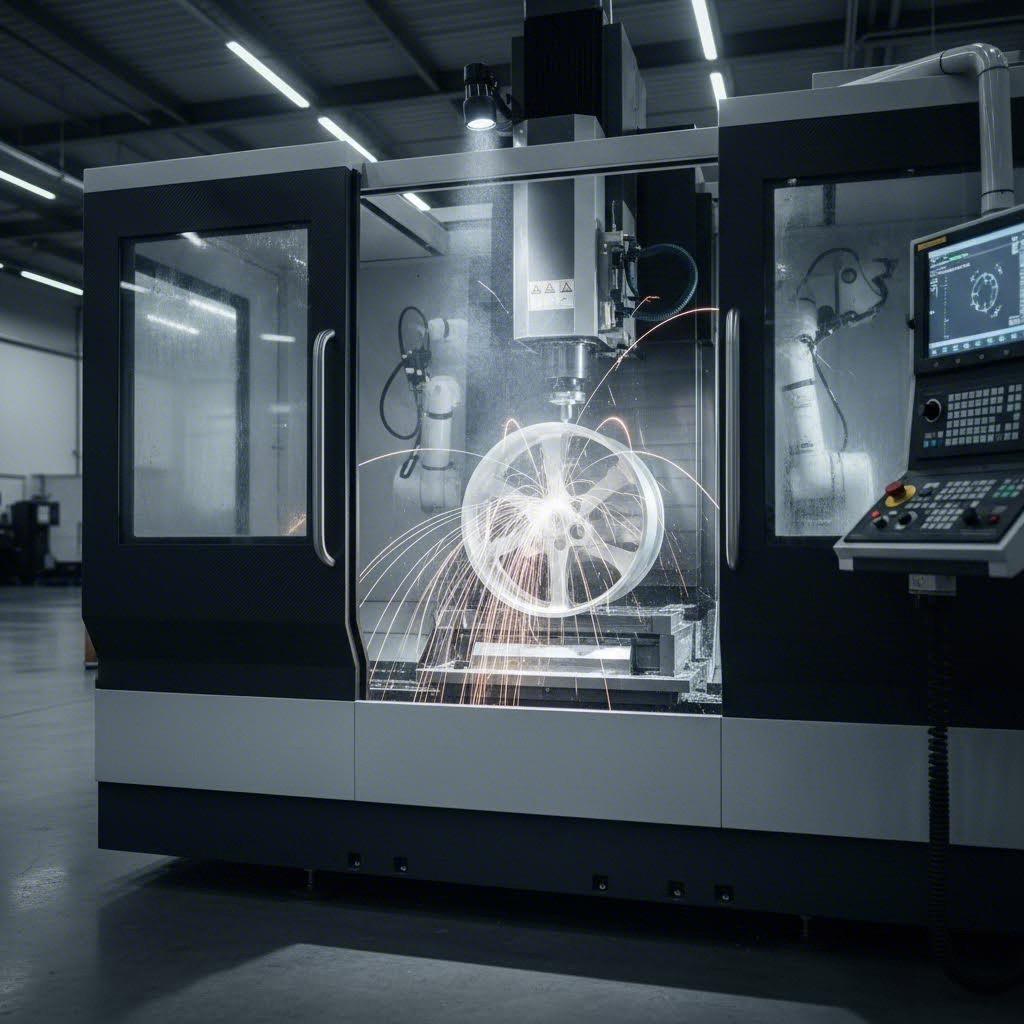

So what makes forged wheels capable of such precise custom wheel offset specifications? It starts with how the wheel is actually created. According to MP Wheels, forged wheels undergo a three-stage journey—massive press forging, precision-controlled heat treatment, and CNC finishing—ensuring each wheel is lightweight, strong, consistent, and refined down to the last spoke.

Unlike casting, where molten metal pours into a mold with inherent tolerances and potential inconsistencies, forging applies immense pressure to reshape solid metal billets. This process eliminates the voids and weak spots that often appear in cast wheels, creating a denser, more refined grain structure throughout the material.

Here's where offset precision enters the picture. As industry sources explain, CNC machines sculpt the forged blank into the final wheel design, cutting intricate spoke patterns, offsets, and rim widths to exact specifications. This computer-controlled machining means your custom wheel offsets can be programmed to precise millimeter values—not rounded to the nearest convenient production increment.

When you explain offset wheels to someone unfamiliar with custom manufacturing, this distinction matters. Cast wheels come in fixed offset options because retooling molds is expensive. Forged wheels are machined individually, making any offset within the design parameters equally achievable.

Why Forged Wheels Offer Superior Offset Flexibility

Imagine you've measured your vehicle meticulously, calculated ideal clearances, and determined that +38mm offset delivers the perfect flush fitment. With mass-produced wheels, you'd likely compromise—either tucking slightly with +40mm or risking clearance issues at +35mm. Custom forged manufacturing eliminates that compromise.

According to forged wheel specialists, customization options for size, offset, and finish allow drivers to order custom forged wheels built specifically for their car and driving goals. This isn't marketing fluff—it's the fundamental advantage of precision manufacturing applied to wheel production.

What is rim offset flexibility worth in practical terms? Consider these advantages that custom forged wheels deliver over cast alternatives:

- Exact millimeter offset specifications: Order +37mm instead of settling for +35mm or +40mm—precision that eliminates fitment compromises

- Optimized suspension geometry: Maintain factory-engineered scrub radius and handling characteristics by matching offset to exact requirements

- Perfect staggered fitments: Specify different front and rear offsets independently, achieving ideal stance at both axles simultaneously

- Maximized tire clearance: Dial in the most aggressive offset your setup allows without guessing between available production options

- Superior material strength: Forging eliminates porosity and inconsistencies, meaning the wheel maintains structural integrity even with aggressive offset designs

- Reduced weight at equivalent strength: Denser grain structure allows thinner material sections without sacrificing durability, contributing to lower unsprung mass

The precision hot forging process used by manufacturers with IATF 16949 certification—the automotive industry's quality management standard—ensures these specifications are met consistently. Companies like Shaoyi Metal Technology demonstrate how precision-engineered automotive components, from suspension arms to drive shafts, benefit from the same rigorous forging and quality control processes that make custom wheel manufacturing possible.

This ecosystem of precision automotive manufacturing matters because your wheels don't exist in isolation. They interface with hubs, bearings, brake components, and suspension systems—all requiring exact dimensional tolerances. When your custom wheels offset specifications match the precision of other forged components in your drivetrain, the entire system works harmoniously.

For enthusiasts investing in premium custom forged wheels, this manufacturing precision protects your investment in two ways. First, you get exactly the fitment you specify rather than a compromise. Second, the superior material properties of forged construction mean your wheels maintain that precise geometry over years of use—no warping, no dimensional changes from stress cycling, no degradation of the offset you so carefully selected.

With manufacturing precision explained, the final piece of the puzzle is synthesizing everything you've learned into an actionable decision framework—a step-by-step process for selecting the perfect offset for your specific build.

Making the Right Offset Decision for Your Build

You've absorbed everything from basic definitions to vehicle-specific recommendations. Now it's time to put that knowledge to work. What does wheel offset mean for your specific project? It means the difference between a build that looks right, drives right, and protects your investment—versus one that creates problems you'll be chasing for years.

Understanding wheel offset isn't just academic. When you're investing thousands in custom forged wheels, getting this single measurement wrong cascades into rubbing issues, accelerated component wear, compromised handling, and ultimately, disappointment. The good news? Following a systematic approach eliminates the guesswork entirely.

Your Five-Step Offset Selection Process

Whether you're building a track-focused sports car or a head-turning show truck, this framework guides you from initial goals to final verification. Work through each step methodically, and you'll arrive at offset specifications that deliver exactly what you're after.

- Define your primary goal: Be honest about what matters most. Are you chasing maximum track performance where factory-like handling is non-negotiable? Building a show car where aggressive stance trumps practicality? Or creating a daily driver that improves on stock appearance without sacrificing comfort? Your answer shapes every decision that follows. According to Custom Offsets, whether you're looking for an easy bolt-on fit or a more aggressive look, knowing your goal upfront determines the right path forward.

- Establish your baseline measurements: Before exploring new wheels, document what you're starting with. Measure your current wheel offset using the stamped ET markings or manual measurement techniques covered earlier. Record available clearances at full suspension compression and full steering lock. Note your suspension configuration—stock, leveled, lifted, or lowered. This baseline tells you exactly how much room you have to work with.

- Research your platform's offset range: Consult the vehicle-specific recommendations from the previous section. Cross-reference with fitment galleries showing real-world examples on your exact vehicle. According to industry resources, galleries with over 100,000 truck builds provide proven fitment data you can trust. Identify the offset range that matches your goals and vehicle configuration.

- Calculate your target specifications: Based on your goal, baseline, and platform research, determine your target offset. For performance builds, stay within 5mm of factory. For aggressive stance, push toward the limits your research indicates. For daily drivers, aim for the middle of your platform's recommended range. Don't forget to account for wheel width changes—remember, wider wheels with the same offset push further outward.

- Verify before committing: Before finalizing your custom forged wheel order, validate your specifications. Use test-fit wheels if available, or work with manufacturers who provide fitment verification. Confirm brake caliper clearance, suspension component clearance, and fender clearance at full compression and steering lock. This final check prevents costly mistakes.

Matching Offset Choice to Your Driving Goals

What does offset mean for wheels in practical terms? It means your choice should align with how you actually use your vehicle. Here's how to match offset selection to specific driving scenarios:

For track and canyon driving: Prioritize handling preservation. Staying within 5mm of factory offset maintains your vehicle's engineered suspension geometry, keeping steering feel predictable and component stress within design limits. The minor aesthetic compromise is worth the confidence you'll have pushing hard through corners.

For show car and stance builds: Aggressive offset becomes the centerpiece of your vision. Work with precision manufacturers who can deliver exact millimeter specifications—+38mm instead of settling for +35mm or +40mm. According to automotive specialists, consulting with professionals or referring to your vehicle's specifications ensures the correct wheel size and offset for your specific make and model. Custom forged manufacturing makes exact specifications achievable rather than aspirational.

For daily driver upgrades: Balance aesthetics with practicality. Moderate offset changes—10-15mm more aggressive than stock—deliver noticeable visual improvement without the compromises of extreme fitments. You'll still enjoy comfortable steering, normal tire wear, and component longevity.

For off-road and work truck applications: Factor in real-world demands. Moderate negative offset widens your track for stability, but excessive poke increases bearing stress under heavy loads. If you're towing, hauling, or tackling trails regularly, err toward conservative offset choices that protect your drivetrain.

Protecting Your Premium Wheel Investment

When you understand what is offset on a wheel and select it properly, you're protecting more than just fitment—you're protecting a significant financial investment. Custom forged wheels represent premium engineering and materials. Pairing them with incorrect offset specifications undermines everything that makes them valuable.

Consider what proper offset selection actually delivers:

- Preserved handling characteristics: Your vehicle continues to steer, brake, and corner as engineered

- Extended component life: Wheel bearings, ball joints, and suspension components operate within design limits

- Optimal tire wear: Correct offset maintains proper alignment geometry, maximizing tire life

- Aesthetic satisfaction: The stance you envisioned becomes the stance you achieve

- Long-term reliability: No premature failures, no unexpected repair bills, no regrets

According to wheel fitment experts, knowing the maximum backspace your vehicle can handle and the backspace the wheel you're considering has is how you know if it will fit without rubbing on anything. This precision prevents the costly trial-and-error that plagues enthusiasts who skip the homework.

Your Next Steps

You now have everything needed to specify offset wheels with confidence. Here's how to move forward:

Start by documenting your current setup. Measure existing wheel offset and clearances using the techniques outlined earlier. Take photos at full steering lock and under compression—these become your reference points for evaluating new specifications.

Research real-world examples on your exact platform. Fitment galleries and enthusiast forums provide invaluable data from owners who've already done the trial-and-error work. Learn from their experiences rather than repeating their mistakes.

When you're ready to order, work with manufacturers capable of delivering exact specifications. Precision matters—a manufacturer with IATF 16949 certification and rigorous quality control, like Shaoyi Metal Technology, ensures your custom offset specifications translate into wheels that meet exact tolerances. Their precision hot forging solutions and in-house engineering deliver robust components from rapid prototyping to high-volume production, streamlining procurement with globally compliant manufacturing.

Understanding offset transforms wheel shopping from guesswork into precision engineering. You're no longer hoping a wheel fits—you're specifying exactly what your build requires. That confidence, backed by the knowledge you've gained, ensures your custom forged wheel investment delivers exactly the stance, performance, and satisfaction you're after.

Frequently Asked Questions About Custom Forged Wheel Offsets

1. What does +35 offset mean?

A +35 offset means the wheel's mounting surface sits 35 millimeters toward the front face (street side) of the wheel from its centerline. This positive offset pulls the wheel inward toward the suspension, creating a tucked appearance common on sedans, sports cars, and front-wheel-drive vehicles. The higher the positive number, the further inboard your wheel positions itself within the fender.

2. How does wheel offset affect vehicle handling and safety?

Wheel offset directly impacts scrub radius, which affects steering response, brake performance, and suspension stress. Incorrect offset can cause heavy steering feel, steering wheel kickback over bumps, premature bearing wear, and uneven tire wear patterns. Staying within 5mm of factory offset preserves engineered handling characteristics, while extreme offset changes increase leverage on ball joints, tie rods, and hub assemblies.

3. What is the difference between wheel offset and backspacing?

Offset measures from the mounting surface to the wheel's centerline in millimeters, while backspacing measures from the mounting surface to the inner lip in inches. Backspacing changes with wheel width even when offset stays constant. To convert, add half the wheel width to the offset value. Both measurements help determine fitment, but offset remains constant regardless of width changes alone.

4. Why choose custom forged wheels for precise offset specifications?

Custom forged wheels can be manufactured to exact millimeter offset specifications through CNC machining, unlike cast wheels with limited production options. Precision hot forging with IATF 16949 certification ensures consistent quality. This allows you to order +38mm instead of settling for +35mm or +40mm, achieving perfect fitment while maintaining structural integrity through denser grain structure.

5. How do I know if my wheel offset is causing fitment problems?

Common signs include tire rubbing on fenders during turns, contact with suspension components, steering wheel vibration, pulling to one side, increased steering effort, and rapid inner or outer tire wear. Excessive poke beyond fenders or tucked appearance may indicate improper offset. Check for scuff marks on fender liners, control arms, and brake calipers to diagnose the specific issue.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —