Custom Forged Wheel Lip Designs: From Spec Sheet To Street Presence

Understanding Custom Forged Wheel Lip Designs

Ever noticed how certain wheels catch your eye from across a parking lot? That striking visual depth, the dramatic shadow lines, the sense of dimension that makes a vehicle look planted and purposeful? You're noticing the wheel lip at work.

The wheel lip refers to the outer edge or rim of a wheel that creates visual depth and dimension. According to MotorTrend's wheel anatomy guide, this outer rim is critical because it, along with air pressure and the wheel's safety bead, holds the tire on the wheel. But beyond its functional role, the lip is where aesthetics truly come alive.

The wheel lip is the outer edge of the wheel on either the front face (curb side) or the back face (differential side). It defines the wheel's visual profile and directly impacts both tire fitment and overall vehicle stance.

When we talk about custom forged wheel lip designs, we're discussing precision-engineered outer edges machined from solid aluminum billets to exact specifications. These aren't generic, off-the-shelf components. They're tailored to your vehicle's unique requirements and your personal aesthetic vision.

What Makes a Wheel Lip Custom

Customization goes far beyond choosing a color. True custom lip designs involve selecting specific widths, profiles, and finishes that complement your vehicle's body lines. You'll decide on lip depth, which affects how much the wheel "steps out" from the face. You might choose engraved details, specialized finishes, or unique contours that set your wheels apart from factory options.

Wheels with lip customization options give enthusiasts control over their vehicle's visual stance without compromising structural integrity. Whether you prefer aggressive forged star rims with deep-dish profiles or subtle, flush-mounted designs, the lip becomes your canvas for personal expression.

Forged vs Cast Lip Construction Basics

Understanding construction methods is essential before investing in custom wheels. The differences between forged and cast lips directly impact strength, weight, and longevity.

Forged wheels begin as solid cylindrical billets cut from continuously cast aluminum logs. As Aura Forged explains, these billets undergo 8,000 to 12,000 tons of hydraulic pressure, which compresses and aligns the aluminum's grain structure. This process eliminates the porosity and inconsistencies common in cast alternatives, creating wheels that are approximately 25-30% lighter while offering superior strength.

Cast wheels, by contrast, are formed by pouring liquid aluminum into molds. While more affordable, this method creates random grain boundaries as the metal cools. According to AST Forged Wheels, these inconsistencies can lead to cracking under pressure, requiring manufacturers to use more material and resulting in heavier wheels with lower load-bearing capacity.

For custom lip designs specifically, forged construction offers a significant advantage: precision. CNC machining can achieve tolerances as tight as ±0.008 inches on forged blanks, allowing for intricate lip profiles and detailed engraving that simply isn't possible with cast alternatives. When your wheel spins at highway speeds, roughly 750-850 rotations per minute, this precision translates directly into smoother, vibration-free performance.

Types of Lip Designs and Their Visual Impact

So you understand what a wheel lip is and why forged construction matters. But here's where things get interesting: not all lips are created equal. The profile you choose dramatically affects how your wheels look, how they complement your vehicle's lines, and even how they perform. Let's break down the four main lip design types you'll encounter when shopping for rims with lips.

Step Lip and Reverse Lip Explained

Imagine looking at a wheel from the side. A step lip features a noticeable drop or ledge from the face mounting surface to the outer edge. According to Juju Wheels, this creates a classic, motorsport-inspired look that gives the illusion of a deeper lip while maintaining structural strength.

Step lips come in several variations:

- Single Step: One raised edge on the outer lip, providing a clean yet distinctive profile. This design adds subtle visual depth and enhances wheel rigidity.

- Double Step: Two distinct raised edges creating a more intricate, multi-level appearance. As noted by SRR Hardware, this style makes wheels look more dynamic and sophisticated.

- Triple Step: Three layered steps offering maximum visual complexity. This attention-grabbing design is popular among enthusiasts seeking bold statements.

- Negative Step: A recessed or set-back lip creating a concave, dished appearance where the outer lip sits inside the wheel barrel.

The reverse lip (often called a negative step) deserves special attention. This design creates a concave profile that curves inward toward the wheel center. SRR Hardware explains that negative step lips provide a unique sense of depth, making wheels appear larger and more aggressive. They're particularly popular in the aftermarket wheel industry for vehicles where owners want maximum visual impact.

Flat Lip vs Rolled Lip Characteristics

On the opposite end of the spectrum, you'll find flat and rolled lip designs. Each serves different aesthetic goals and practical considerations.

A flat lip (also called a reverse lip in some contexts) features no drop step whatsoever. The surface flows smoothly and evenly outward from the wheel face. Here's what makes flat lips distinctive:

- Visual Profile: Clean, modern aesthetic with a sleek, uninterrupted surface.

- Face Appearance: Makes the wheel face appear larger and flatter.

- Practical Benefit: Easier to clean and maintain due to the absence of stepped edges.

- Common Use: Popular on modern aftermarket wheels and show builds where minimalist design is preferred.

The rolled lip introduces a different engineering approach. According to Condor Speed Shop, rolled lip wheels feature a contoured outer edge that curves outward, creating enhanced hoop strength. This design is often described as having "triple" lip strength due to the structural benefits of the rolled contour.

- Structural Advantage: The rolled profile combined with spun aluminum construction offers superior strength compared to flat alternatives.

- Visual Effect: Gives the appearance of a larger wheel diameter.

- Weight Consideration: Adds a small amount of additional weight compared to flat designs.

- Technology: Considered "newer" technology in wheel manufacturing.

Which style suits your build? Consider your priorities. Step lips deliver that aggressive, motorsport heritage look and can even enable diameter conversions on modular wheels. Flat lips offer understated elegance that works beautifully on luxury vehicles and modern builds. Rolled lips provide the structural confidence you'll appreciate on performance applications. And engraved rims with custom lip detailing add another layer of personalization we'll explore next.

Understanding these distinctions helps you communicate precisely what you want when specifying your custom forged wheel lip designs. But how do these lip choices interact with different wheel construction types? That's where things get even more interesting.

How Wheel Construction Affects Lip Customization

You've selected your ideal lip profile. Maybe you're drawn to that aggressive step lip aesthetic or prefer the clean lines of a flat design. But here's the critical question many enthusiasts overlook: how does your wheel's construction type determine what lip options are actually available to you?

The answer lies in understanding three distinct construction methods: monoblock (1-piece), 2-piece, and 3-piece wheels. Each approach offers fundamentally different levels of lip customization, and knowing these differences before you order can save you from disappointment or, worse, fitment failures.

Monoblock vs Modular Lip Options

Think of monoblock forged wheels as sculptures carved from a single block of stone. According to Apex Wheels, these 1-piece wheels combine the face disc, center section, and barrel in a single forging, meaning the lip is machined directly from that same solid aluminum billet. This creates exceptional structural integrity, but your lip specifications are locked in during manufacturing.

What does this mean for you? With monoblock construction:

- Lip dimensions are fixed: The width, profile, and depth are determined during the forging and CNC machining process.

- No post-purchase modifications: You can't swap out the lip section for a different size or finish later.

- Maximum strength: The continuous grain structure from forging extends through the entire wheel, including the lip, offering unmatched durability.

- Weight advantage: No bolts, assembly flanges, or overlapping sections means less material and lighter overall weight.

Modular wheels flip this equation entirely. As Vivid Racing explains, 2-piece and 3-piece constructions separate the wheel into distinct components that are either welded or bolted together. This modular approach transforms your lip options from fixed to flexible.

With 3-piece wheels, the barrel itself splits into inner and outer sections joined with a center piece. This means manufacturers can create a far greater range of widths and offsets for a single wheel design. Want a deeper lip? Order a wider outer barrel section. Prefer a more subtle look? Swap to a narrower outer lip component. According to Apex Wheels, this customization makes 3-piece wheels ideal for cars with unique fitment requirements.

Two-piece wheels offer a middle ground. They attach a cast or forged center section to a single barrel, providing more offset and width options than monoblock designs while maintaining simpler construction than 3-piece alternatives. Wheel engraving and finish customization become particularly accessible on modular designs since individual components can be treated separately before assembly.

How Barrel Depth Affects Your Lip Choices

Barrel depth is the unsung hero of lip customization. Imagine the barrel as a cylinder extending from the wheel face inward toward your vehicle's hub. The deeper this barrel, the more dramatic your lip options become.

On modular wheels, barrel depth directly determines how wide your outer lip section can be. A deeper barrel creates more visual "dish" or concavity, allowing for those eye-catching deep-lip profiles that make custom forged wheel lip designs so desirable. However, this relationship introduces practical constraints:

- Brake clearance: Deeper barrels push the wheel face outward, potentially reducing space for brake calipers.

- Suspension geometry: Aggressive lip depths may require suspension modifications to prevent rubbing.

- Tire stretch: Wider lips often pair with stretched tire setups, affecting sidewall protection and ride quality.

For monoblock designs, barrel depth is predetermined by the wheel's specifications. You'll select from available offsets and widths rather than customizing individual components. This limits flexibility but simplifies decision-making and eliminates concerns about component compatibility.

Three-piece wheels offer maximum barrel depth flexibility. Since inner and outer sections are separate, you can specify exactly how much visual depth you want on each side of the wheel. Engraving wheels with custom text or logos becomes straightforward when you can work with individual lip sections during finishing.

| Construction Type | Lip Customization Flexibility | Weight | Strength | Typical Applications |

|---|---|---|---|---|

| Monoblock (1-Piece) | Fixed during manufacturing; no post-purchase changes | Lightest option; no assembly hardware | Highest; continuous grain structure throughout | Track performance, daily drivers, weight-conscious builds |

| 2-Piece | Moderate; various offset/width combinations available | Heavier than monoblock due to welding or assembly flanges | Good; depends on welding quality | Street performance, show builds, moderate customization needs |

| 3-Piece | Maximum; interchangeable inner/outer barrels with varied widths and finishes | Heaviest; bolts and reinforced assembly flanges add weight | Varies; barrel sections typically spun from aluminum discs limiting reinforcement options | Show cars, unique fitments, motorsports requiring trackside repairs, engraved wheels projects |

Here's something worth noting: 3-piece wheels come with maintenance considerations that monoblock designs simply don't have. According to Apex Wheels, modular constructions are inherently prone to air leaks since their barrel sections rely on sealants or gaskets. Those assembly bolts? They'll need frequent tightening and inspection on road cars. For enthusiasts who prioritize the set-and-forget reliability of their wheels, monoblock might be the smarter choice despite reduced lip customization options.

Understanding these construction differences empowers you to make informed decisions. If maximum lip customization and the ability to refresh your look over time matters most, modular construction delivers. If strength, minimal maintenance, and weight savings are your priorities, monoblock forged wheels offer advantages that outweigh their customization limitations. Either way, knowing what's possible with each construction type ensures your custom lip design vision translates perfectly from spec sheet to street presence.

With construction methods clarified, you're ready to explore one of the most personal customization options available: lip engraving and personalization techniques that transform your wheels into truly one-of-a-kind pieces.

Lip Engraving and Personalization Options

So you've chosen your construction type and selected the perfect lip profile. Now comes the question that separates standard custom wheels from truly personalized forged wheel lips: how do you make them unmistakably yours?

Engraving rims transforms your wheels from manufactured components into personal statements. Whether you want your brand logo, a meaningful phrase, geometric patterns, or signature designs, modern engraving techniques make it possible without compromising the structural integrity that makes forged wheels superior in the first place.

Laser Engraving vs CNC Machining Methods

Two primary technologies dominate custom wheel lip engraving: laser engraving and CNC machining. Each offers distinct advantages depending on your design goals and the level of detail you're seeking.

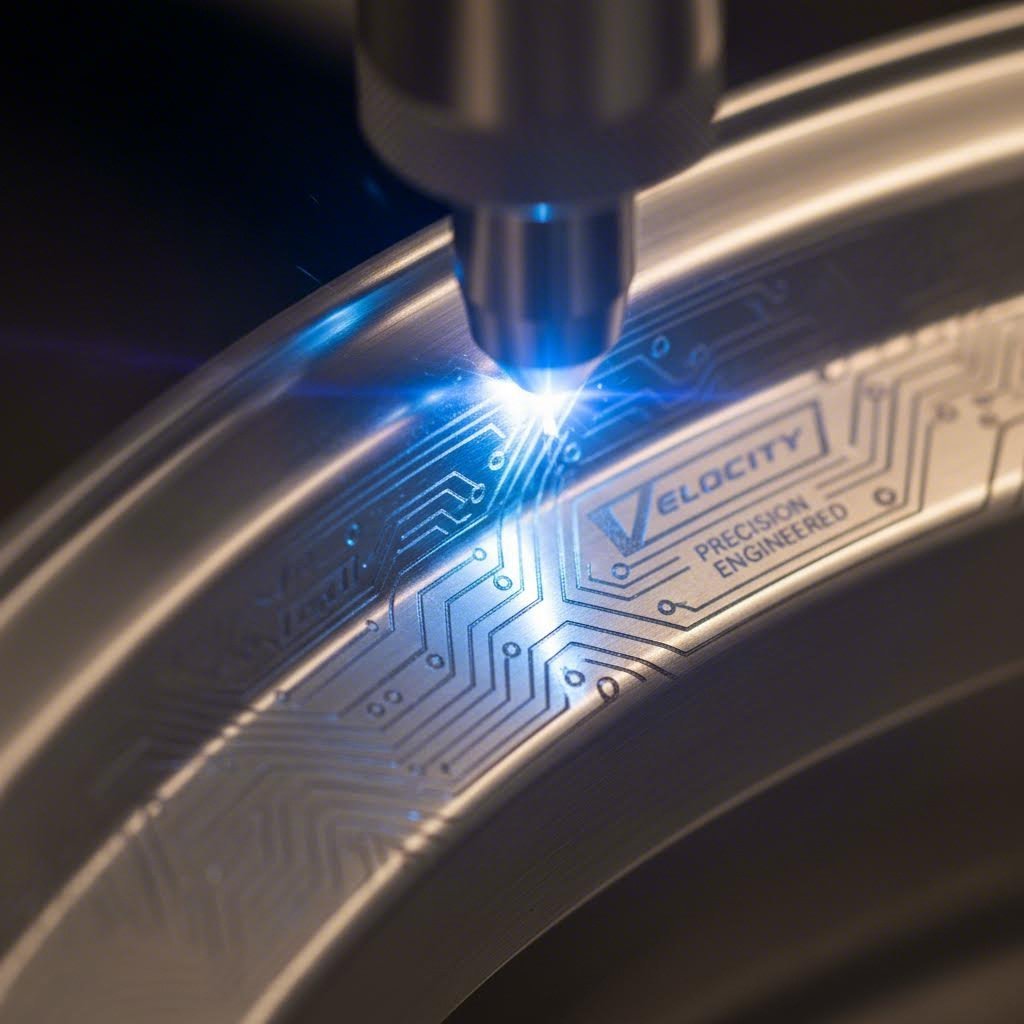

Laser engraving uses a focused beam of light to vaporize material from the wheel's surface. According to EIE Carbon, the laser beam heats and vaporizes material in the exact shape of your logo design, with intensity and focus carefully controlled to create fine details and sharp edges. The result? Precise, permanent markings that won't fade, peel, or wear off over time.

Here's what makes laser engraving particularly appealing for personalized forged wheel lips:

- Precision: Capable of reproducing intricate designs, fine text, and complex patterns with exceptional accuracy.

- Permanence: The engraving becomes part of the wheel surface itself, not a surface treatment that can degrade.

- Finish compatibility: Works beautifully on paintless, matte, satin, and painted surfaces alike.

- Minimal depth: Typically removes less than 0.5 mm of material, preserving structural integrity.

CNC machining for logo engraving operates differently. As noted by WheelsHome, this process uses very small engraving tools to mark the center cap or lip through a light milling procedure. The CNC approach can achieve slightly deeper cuts than laser methods, creating designs with more tactile presence.

The key distinction? Laser engraving excels at fine detail and photographic-quality reproduction. CNC machining offers more dimensional depth and can work with harder surface treatments. For most custom wheel lip engraving applications, laser technology provides the precision enthusiasts expect from premium wheels.

Popular Lip Engraving Styles and Patterns

What exactly can you engrave on your wheel lips? The options extend far beyond simple brand names. Modern engraving technology opens up a world of personalization possibilities:

- Brand logos: Your company identity, car club emblem, or favorite manufacturer's mark permanently displayed on every wheel.

- Custom text: Names, build names, memorable dates, or meaningful phrases that tell your vehicle's story.

- Geometric patterns: Repeating designs, hash marks, or technical-looking patterns that add visual texture to the lip surface.

- Signature designs: Your actual signature reproduced on the wheels, similar to an American Force wheels sticker aesthetic but permanently integrated into the metal.

- Serial numbers and specifications: Technical details, part numbers, or production information for authentication and documentation.

Wondering about placement? Engraved graphics can be positioned on various parts of the wheel lip, including the outer face, inner edge, or even the barrel section on modular designs. The location you choose affects visibility and aesthetic impact, so consider how your wheels will typically be viewed.

Does Engraving Affect Wheel Strength?

This concern stops many enthusiasts from pursuing custom lip engraving, but the reality is reassuring. When performed properly by experienced technicians, engraving removes minimal material and has negligible impact on structural integrity.

EIE Carbon emphasizes that laser experts carefully adjust engraving parameters including power, speed, and frequency to achieve desired depth and quality without damaging the base material. The calibration process ensures machines are dialed in precisely for the specific alloy and finish being engraved.

Quality inspection follows every engraving process. Reputable manufacturers verify that logos have been engraved accurately and to specifications, addressing any imperfections before wheels leave the facility. This attention to detail means you can enjoy personalized forged wheel lips with complete confidence in their performance.

Finish Options for Engraved Areas

Engraving doesn't limit your finish choices. In fact, it can enhance them. Consider these approaches:

- Contrasting fills: Engraved areas can be painted a different color to make designs pop against the surrounding lip finish.

- Natural aluminum: Leave engraved sections raw to create subtle texture differences against polished or painted surfaces.

- Clear coat protection: Apply protective coatings over engraved areas to preserve detail while adding gloss or matte effects.

- Two-tone treatments: Combine engraving with machined or brushed finishes for dimensional visual interest.

To customize your own graphics, you'll need to provide your design in a digital format compatible with engraving equipment. Common formats include vector files such as .ai, .eps, or .svg, or high-resolution bitmap images like .png or .jpeg. Your manufacturer's design team will confirm the rationality and feasibility of your concept, ensuring the final result matches your vision.

With engraving options understood, you're ready to tackle the practical considerations that determine whether your custom lip design actually fits your vehicle. Let's explore the fitment factors that turn dream wheels into reality.

Fitment Factors for Custom Lip Designs

You've selected the perfect lip profile, chosen your construction type, and maybe even planned custom engraving. But here's where dream wheels meet reality: will they actually fit your vehicle? This question trips up countless enthusiasts who focus exclusively on aesthetics while overlooking the engineering that makes those aesthetics possible.

Custom forged wheel lip designs demand more than visual compatibility. They require precise measurements, careful calculations, and sometimes vehicle modifications to achieve that aggressive stance without rubbing, scraping, or damaging critical components. Let's walk through the practical fitment considerations that separate successful builds from expensive headaches.

Lip Width and Tire Fitment Considerations

Imagine you've ordered stunning deep-lip wheels only to discover your tires won't seat properly or your fenders shred rubber every time you hit a bump. Sounds frustrating, right? Understanding how lip width affects tire fitment prevents this scenario entirely.

The relationship works like this: wider outer lips push the tire's sidewall outward from the wheel face. According to Holley Performance, this outward positioning directly affects how close the tire comes to your vehicle's fender, inner liner, and suspension components. A wheel with one inch of additional lip width effectively pushes the tire one inch closer to potential contact points.

Several factors determine whether your desired lip width will work:

- Current wheel width and offset: Your baseline. Measure your existing setup before considering changes.

- Tire section width: Wider tires on the same wheel create more sidewall bulge, reducing fender clearance.

- Tire stretch: Running narrower tires on wider wheels reduces sidewall bulge but affects ride quality and protection.

- Fender gap at rest: How much space exists between your tire and fender when the vehicle sits at normal ride height.

- Suspension travel: Your fender gap shrinks dramatically when the suspension compresses over bumps or during cornering.

Holley's experts recommend a practical approach: remove a wheel, set the car at normal ride height on jack stands, then measure from the hub mating surface to the furthest point inside the fender edge. This measurement represents your maximum positive offset, telling you exactly how far outward the wheel can extend without fender contact.

For the outside clearance, things get simpler. Measure from your fender's inner edge to the hub mounting surface. This gives you the starting point for calculating how much additional lip width you can accommodate. If your current wheels have 30mm of clearance, you could theoretically add 25-27mm of lip width while maintaining a safe margin.

Brake Clearance and Suspension Factors

Here's where aggressive custom lip designs introduce their biggest challenge. Deep lips look incredible, but they can collide with brake calipers, creating dangerous interference that prevents proper wheel mounting or causes damage during driving.

According to WheelsGang's technical guide, brake caliper clearance depends on a measurement called X-factor: the vertical distance from the wheel's mounting pad to the point where the back of the spoke would contact a brake caliper. This measurement, combined with your wheel's disk type, determines whether you can run those deep lips you're eyeing.

The physics are straightforward:

- Low disk wheels: Spokes sit closest to the hub, maximizing lip depth but minimizing brake caliper clearance.

- Medium disk wheels: A compromise profile offering moderate lip depth with extra millimeters for larger calipers.

- High disk wheels: Spokes sit farthest from the hub, clearing big brakes but limiting lip depth potential.

WheelsGang recommends maintaining at least 3mm of cold clearance between your brake caliper and wheel spokes. Anything under 2mm risks contact during hard braking or pad knock-back. Their measurement process involves placing a ruler across the brake rotor's face and using a caliper to measure how far the brake body protrudes beyond the rotor's hat.

But spoke clearance isn't the only concern. Even if spokes clear, the wheel barrel can still contact calipers. WheelsGang notes that step-lip barrels lose roughly 13mm of internal clearance compared to same-diameter reverse-lip designs. Double-step lips? Expect to lose about 25mm of inner radius. This matters tremendously if you're downsizing wheel diameter or running aggressive lip styles.

The Offset-Lip-Position Relationship

Offset, lip width, and wheel positioning form an interconnected triangle that determines your vehicle's final stance. Understanding this relationship prevents ordering wheels that look perfect on paper but fail in practice.

As Holley explains, offset measures the distance between the wheel's mounting surface and its centerline. Positive offset means the mounting surface sits toward the outside of the wheel, creating flush fitment common on modern factory vehicles. Negative offset positions the mounting surface inward, pushing more of the barrel and lip outward for that classic deep-dish aesthetic.

When you increase lip width on a wheel, the overall width grows. If the mounting surface stays in the same position, that additional width extends outward toward your fenders. This is why aggressive lip designs often require negative offset adjustments to maintain proper clearance. The trade-off? More negative offset means the wheel protrudes further from the hub, potentially stressing suspension components and affecting handling characteristics.

Front wheels introduce additional complexity because they turn. Holley's experts point out that you can't simply measure inward clearance and call it done. You need to check clearance at full steering lock in both directions, identifying the suspension components most likely to contact the inner wheel edge. Many enthusiasts discover their limiting factor isn't the fender but rather control arms, tie rods, or brake lines.

Key Measurements Before Ordering

Ready to order your custom lip design? Gather these measurements first to ensure your specifications translate perfectly to your vehicle:

- Current wheel specifications: Diameter, width, offset, and bolt pattern of your existing wheels as your baseline reference.

- Brake caliper dimensions: Measure caliper protrusion beyond the rotor hat and overall caliper width.

- Rotor diameter: Confirm your rotors' outer diameter to verify minimum wheel size requirements.

- Fender gap at ride height: Measure the space between your current tires and fenders with the vehicle sitting normally.

- Suspension travel: Check how much the suspension compresses during normal driving, especially if lowered.

- Inner clearance points: Identify what components limit inward wheel positioning, such as control arms, brake lines, or struts.

- Desired stance: Decide whether you want flush, slightly poked, or aggressively stanced wheel positioning.

- Steering clearance: For front wheels, check clearance at full lock in both directions.

If measurements reveal tight tolerances, you have options. Adding negative camber, if your suspension allows adjustment, can create additional fender clearance. Rolling or pulling fenders represents another solution for outside edge interference. For brake clearance issues, switching to a higher disk profile or adding hub-centric spacers of 3-5mm can solve the problem without compromising your lip design goals.

Online tools like those at Throtl's wheel fitment guide can help visualize how different specifications affect fitment. By inputting your OEM wheel specs alongside your desired custom specifications, you can identify potential clearance issues before committing to an order.

With fitment factors understood, the next step is matching your lip design choices to how you'll actually use your vehicle. Show cars, track machines, and daily drivers each demand different approaches to custom lip selection.

Choosing Lip Designs by Vehicle Application

Here's a question that separates informed enthusiasts from impulse buyers: are you selecting custom forged wheel lip designs based on how your vehicle actually gets used, or just chasing what looks good in photos?

Visual appeal matters, absolutely. But the lip style that wins trophies at car shows might be completely wrong for your weekend track sessions. And that aggressive deep-dish look you're eyeing? It could become a daily driver nightmare if you haven't considered practical factors. Let's match lip design choices to real-world vehicle applications so your wheels perform as beautifully as they look.

Matching Lip Style to Your Driving Purpose

Think about how you actually spend time behind the wheel. Your primary use case should drive every lip design decision, from profile depth to finish selection.

Show cars represent the extreme end of visual customization. When your vehicle's purpose centers on static display and photography, deep step lips deliver that dramatic shadow-line effect judges and spectators notice. According to ThreePiece.us, stance fitment with fender-to-lip positioning prioritizes aesthetics at +30 while accepting -50 in performance terms. For show builds, that trade-off makes perfect sense.

Show car wheel lip styles typically feature:

- Maximum lip depth: Deep step or double-step profiles creating pronounced visual dimension.

- Aggressive offsets: Negative offset positioning that pushes lips outward for dramatic stance.

- Mirror finishes: Polished or chrome treatments that catch light and draw attention.

- Custom engraving: Personalized details that distinguish your build at close inspection.

Track vehicles flip priorities entirely. Every gram matters when you're chasing lap times, and that stunning deep-lip design adds unsprung weight exactly where it hurts performance most. Track wheel lip designs favor flat or minimal-step profiles that reduce rotational mass without sacrificing structural integrity.

As Wheels Doctor explains, performance driving demands lightweight options like carbon fiber or forged monoblock wheels for enhanced speed and handling. Translated to lip design, this means:

- Flat lip profiles: Minimal material extending beyond the wheel face.

- Monoblock construction: Single-piece forging eliminates assembly hardware weight.

- Functional finishes: Matte or satin treatments that hide track debris better than chrome.

- Conservative widths: Just enough lip to mount performance tires properly.

Street performance builds occupy the middle ground. You want presence at meetups but also need confidence pushing through canyon roads or spirited highway pulls. According to ThreePiece.us, flush fitment represents this ideal balance: wheels vertically aligned with fenders, minimal gap, yet fully functional suspension that handles bumps without bottoming out.

Street builds benefit from:

- Single-step lips: Enough visual depth for presence without excessive weight penalty.

- Moderate offsets: Positioning that looks aggressive but maintains proper suspension geometry.

- Durable finishes: Treatments that handle occasional brake dust and road grime.

- Square tire fitment: Standard tire sizing that protects lips from curb damage.

Daily driver forged wheels demand the most practical approach. Your wheels will encounter parking lots, speed bumps, potholes, and weather extremes. According to Wheels Doctor, daily commuting calls for solid durability and affordability, with alloy wheels offering performance benefits while remaining practical for urban environments.

Daily driver considerations include:

- Rolled or minimal-step lips: Contours that resist curb damage better than sharp step edges.

- Protective finishes: Powder coating or ceramic coatings that shrug off brake dust and road salt.

- Conservative widths: Lip dimensions that maintain adequate fender clearance for varied road conditions.

- Easy maintenance: Finishes and profiles that clean quickly without special care.

Finish Options for Different Applications

Your lip profile tells half the story. The finish you choose determines how that profile interacts with light, how it ages over time, and how much maintenance your wheels demand.

Polished lip finish options deliver maximum visual impact. Mirror-like reflections create depth and dimension that photographs beautifully and stops onlookers at shows. However, polished aluminum requires regular attention. Brake dust, road film, and environmental contaminants dull that shine quickly without consistent cleaning and occasional re-polishing.

Brushed finishes offer a sophisticated alternative. The directional grain pattern catches light differently than polished surfaces, creating subtle visual movement. Brushed lips hide minor scratches and swirl marks better than mirror finishes, making them practical for street and daily applications where perfect maintenance isn't realistic.

Painted finishes provide the most protection and color customization. Modern automotive paints with clear coat protection resist fading, chipping, and corrosion far better than exposed metal finishes. Color-matched lips integrate seamlessly with vehicle paint, while contrasting colors create intentional visual statements.

Chrome plating remains the classic choice for ultimate shine. True chrome involves multiple plating layers over the aluminum substrate, creating exceptional corrosion resistance and that iconic mirror finish. The trade-off? Chrome requires careful maintenance, shows water spots easily, and repair or refinishing proves more complex than other finish types.

| Application Type | Recommended Lip Styles | Ideal Finishes | Key Considerations |

|---|---|---|---|

| Show | Deep step, double step, negative step for maximum visual depth | Polished, chrome, or high-gloss painted with custom engraving | Prioritize visual impact over practicality; expect regular maintenance; consider air suspension for adjustable stance |

| Track | Flat lip, minimal step, rolled profiles for weight reduction | Matte, satin, or durable painted finishes that hide track debris | Minimize unsprung weight; choose monoblock construction; prioritize brake clearance for upgraded calipers |

| Street | Single step, moderate depth creating presence without excess weight | Brushed, satin, or painted finishes balancing looks and durability | Balance aesthetics with functionality; maintain proper suspension travel; consider protective clear coats |

| Daily | Rolled lip, minimal step, or flat profiles for damage resistance | Powder coated, ceramic coated, or durable painted for low maintenance | Prioritize curb resistance; choose finishes that handle brake dust; maintain adequate fender clearance for varied conditions |

Notice how each application demands different trade-offs? Show builds sacrifice practicality for presence. Track setups surrender visual drama for performance gains. Street and daily applications find their sweet spots somewhere in between, balancing what looks good with what works reliably.

The smartest approach? Be honest about how you'll actually use your vehicle. That Instagram-worthy deep-lip setup looks incredible, but if you're parking in tight city spots five days a week, those polished edges will accumulate battle scars faster than you'd like. Conversely, ultra-conservative daily driver specs on a dedicated weekend show car waste the opportunity for visual impact that really matters in that application.

With your application-matched lip style and finish selected, the next critical step is understanding how to communicate these specifications to manufacturers and navigate the custom ordering process successfully.

The Custom Ordering Process Explained

You've done your homework. You understand lip profiles, construction types, engraving options, fitment requirements, and application-matched styling. Now comes the moment of truth: translating all those decisions into an actual order that delivers wheels matching your vision.

Here's the challenge many enthusiasts face. Manufacturers offer impressive customization menus, but the custom wheel ordering process itself often lacks clear guidance. What specifications do you actually need to provide? How do you communicate complex preferences without confusion? What quality certifications separate professional operations from questionable suppliers? Let's demystify the entire journey from initial inquiry to wheels in hand.

Communicating Your Custom Lip Specifications

Think of your specification sheet as the blueprint for your wheels. The more precise and complete your information, the better your results. Vague requests lead to assumptions, and assumptions lead to disappointment when boxes arrive with wheels that don't match your expectations.

Start by gathering every measurement and preference before contacting manufacturers. This custom lip specifications guide will ensure nothing falls through the cracks:

- Wheel diameter and width: Exact dimensions in inches, such as 19x9.5 or 20x10, determining the overall wheel size.

- Bolt pattern (PCD): Your vehicle's lug configuration, like 5x114.3 or 5x120, ensuring proper hub mounting.

- Center bore: The hub bore diameter in millimeters that matches your vehicle's hub, typically ranging from 57.1mm to 72.6mm depending on make and model.

- Offset specification: Your desired ET value in millimeters, such as ET35 or ET45, positioning the wheel relative to the hub face.

- Lip profile type: Step lip, flat lip, rolled lip, or reverse lip, specifying single, double, or triple step variations if applicable.

- Lip width: The outer lip dimension, typically ranging from 2 to 4 inches depending on barrel depth and desired visual impact.

- Construction type: Monoblock, 2-piece, or 3-piece, determining your customization flexibility and assembly method.

- Finish specifications: Polished, brushed, painted, powder coated, or chrome, including any two-tone or contrasting lip treatments.

- Engraving details: Custom text, logos, or patterns with digital files in vector format (.ai, .eps, .svg) or high-resolution images.

- Load rating requirements: Minimum load capacity needed for your vehicle, typically 690kg to 1250kg per wheel.

When submitting your specifications, include photographs of your vehicle showing current wheel positioning and fender gaps. Side-profile shots and close-ups of your brake setup help manufacturers verify clearance requirements. If you've measured your brake caliper protrusion, include those numbers with your submission.

Request confirmation of your specifications in writing before production begins. Reputable manufacturers will provide a detailed order summary listing every parameter, giving you the opportunity to catch errors before aluminum meets tooling. This verification step prevents costly mistakes and extended forged wheel lead times from remake orders.

What to Expect from the Manufacturing Process

Understanding the production timeline helps set realistic expectations. Custom forged wheel lip designs aren't pulled from warehouse shelves. They're manufactured specifically for your order through a multi-stage process that demands precision at every step.

The journey typically unfolds like this:

Design confirmation (1-3 days): Your specifications get reviewed by engineering teams who verify feasibility. Complex lip profiles, unusual offsets, or tight brake clearances may require additional consultation. Expect questions during this phase if your specifications push design boundaries.

Prototype development (7-14 days for complex designs): Some manufacturers offer rapid prototyping capabilities, producing sample components that verify your specifications before full production. Precision hot forging specialists like Shaoyi (Ningbo) Metal Technology demonstrate this capability with prototyping available in as little as 10 days, allowing buyers to physically verify critical dimensions before committing to complete sets.

Forging and heat treatment (5-10 days): Aluminum billets undergo intense pressure forging at approximately 8,000 tons of force according to WheelsHome's manufacturing data. Following initial shaping, T6 heat treatment heats wheels to 985°F, then water quenches them before aging at 355°F. This process achieves hardness ratings around 95 Brinell with tensile strength reaching 45,000 psi.

CNC machining (3-7 days): Multi-axis CNC machines operating at up to 20,000 RPM cut your specified spoke patterns, lip profiles, and mounting surfaces. This stage determines the precision of your custom lip design, with tolerances as tight as 0.1mm for detailed features.

Finishing (5-14 days): Your chosen finish gets applied, whether anodizing, powder coating, diamond-cutting, or PVD treatment. Complex multi-stage finishes like polished lips with painted centers require additional time. Engraving occurs during this phase if specified.

Quality inspection and shipping (2-5 days): Final wheels undergo testing protocols before packaging and shipment. Location matters here. Established forging specialists near major shipping hubs like Ningbo Port can significantly reduce delivery times to international destinations.

Total forged wheel lead times typically range from 4-8 weeks for standard custom specifications. Complex designs with unusual dimensions, exotic finishes, or prototype verification requirements may extend timelines to 10-12 weeks. Rush orders are sometimes available at premium pricing, but quality-focused manufacturers won't sacrifice proper heat treatment or finishing steps regardless of schedule pressure.

Quality Certifications and What They Mean

Not all manufacturers operate at the same quality standards. Wheel manufacturer certifications provide objective verification of production capabilities and quality control systems. Understanding these certifications helps you identify partners who deliver consistent results.

IATF 16949 certification represents the gold standard for automotive component manufacturing. This internationally recognized quality management system standard specifically addresses automotive production requirements, including defect prevention, variation reduction, and waste elimination throughout the supply chain. Manufacturers holding this certification, such as Shaoyi Metal Technology, demonstrate rigorous process controls that translate directly to wheel component quality.

Beyond certifications, evaluate these quality indicators:

- In-house engineering: Manufacturers with dedicated engineering teams can optimize your specifications rather than simply executing drawings.

- Testing protocols: Ask about fatigue testing cycles, impact testing procedures, and x-ray inspection capabilities. Quality operations test wheels to 1,000,000+ cycles according to industry standards.

- Material traceability: Reputable manufacturers document aluminum alloy sources and heat treatment records for every production lot.

- Proven component experience: Forging specialists producing other precision automotive components like suspension arms and drive shafts bring the same manufacturing discipline to wheel production.

- Transparent communication: Manufacturers willing to share production photos, testing documentation, and facility information demonstrate confidence in their operations.

Price shopping without considering certifications and capabilities invites problems. The cheapest quote often correlates with corners cut in material quality, heat treatment, or finishing durability. When your wheels rotate at 750-850 RPM at highway speeds, that initial savings disappears fast if quality issues emerge.

Preparing for Your Order

Before reaching out to manufacturers, complete this preparation checklist:

- Document your vehicle: Year, make, model, and any suspension or brake modifications affecting fitment.

- Gather measurements: Current wheel specs, brake caliper dimensions, fender clearances, and desired stance positioning.

- Define your priorities: Visual impact, performance, durability, or budget, understanding which factors matter most.

- Prepare design files: If engraving is desired, have vector or high-resolution logo files ready for submission.

- Set realistic timelines: Plan for 6-10 weeks from order to delivery, longer for complex specifications.

- Budget appropriately: Custom forged wheels command premium pricing, so understand the investment before requesting quotes.

With specifications prepared and quality standards understood, you're ready to engage manufacturers confidently. The next consideration? Understanding how different options affect pricing and evaluating the long-term value of your custom forged wheel investment.

Cost Factors and Value Considerations

So you've navigated specifications, verified fitment, and identified quality manufacturers. Now comes the question everyone asks but few answer directly: what will custom forged wheel lip designs actually cost, and is the investment worth it?

Pricing in this space varies dramatically. According to JL Wheels, forged wheels range from $300 per wheel for value-oriented options to over $2,500 per wheel for premium brands with complex designs. That's a massive spread, and understanding what drives these differences helps you make informed decisions rather than overpaying or sacrificing quality for false savings.

What Drives Custom Lip Pricing

Think of custom forged wheel pricing as a building block system. Each specification choice adds or subtracts from your final cost, and lip designs contribute significantly to the equation.

Here's what affects your bottom line:

- Material grade: Not all 6061-T6 aluminum forgings are equal. According to Forgelite Wheels, proprietary forgings from reputable manufacturers cost twice as much as average Chinese market pricing. Higher-grade materials with precise alloy blending and controlled heat treatment deliver superior strength and consistency.

- Lip width: Wider outer lips require more material and longer machining time. A 4-inch lip demands significantly more aluminum than a 2-inch profile, directly increasing per-wheel costs.

- Finish complexity: JL Wheels notes that standard silver machined finishes represent baseline pricing, while premium options add $100 to $400+ per wheel. Custom paint matching your vehicle's body color, polished or chrome treatments, powder coating, and brushed finishes all command premiums.

- Engraving detail: Simple text engraving costs less than intricate geometric patterns or multi-location logo placement. Laser engraving setup time and complexity directly influence pricing.

- Construction type: Monoblock wheels typically cost less than modular alternatives due to simpler manufacturing. Three-piece wheels require additional machining, assembly labor, and hardware, adding to per-set pricing.

- Design complexity: According to JL Wheels, simple 5-spoke designs are easier and cheaper to machine than intricate multi-spoke or mesh patterns with deep concavity. More complex designs require more machining time, increasing labor costs.

- Size specifications: Larger diameters (20", 21", 22") require more material than smaller options (17", 18"). Wider wheels also use more aluminum, and unusual bolt patterns or custom offsets may add to costs.

Manufacturing location also plays a significant role. Forgelite explains that US-made forged wheels command premiums up to $20,000 per set, while Chinese-manufactured alternatives typically sell at 40-70% less. The difference stems primarily from labor costs: skilled operators and machine shops charge $100-$200 per hour in the US versus $15-$20 per hour in China. Creating a set of forged wheels can take anywhere from half a day to several days, making labor a substantial cost component.

Custom Forged vs OEM and Replica Value

Here's where the real value conversation gets interesting. Comparing custom forged wheel pricing against OEM replacements or replica alternatives reveals why enthusiasts choose forged despite higher initial costs.

Durability advantages: The forging process creates wheels that are much stronger than cast alternatives. JL Wheels emphasizes that forged wheels are less likely to crack or fail under impact, providing safety benefits that justify premium pricing. When you factor in potential repair or replacement costs from damaged cast wheels, the forged vs cast wheel cost comparison shifts significantly.

Weight savings: Forged construction achieves significant weight reduction that improves acceleration, braking, and handling. This unsprung weight reduction delivers measurable performance benefits that OEM cast wheels simply cannot match. Better heat dissipation for brakes represents another functional advantage.

Resale value: Quality forged wheels from reputable manufacturers maintain value far better than replica alternatives. Buyers recognize the difference, and premium wheels can actually enhance your vehicle's resale price rather than representing lost expense.

Customization value: Many companies build wheels to your exact specifications, offering personalization impossible with OEM or off-the-shelf options. This wheel lip upgrade value extends beyond aesthetics to precise fitment optimization for your specific vehicle and preferences.

Modular Construction Cost Savings

If budget constraints make full custom forged sets challenging, modular construction offers an interesting alternative approach.

Three-piece wheels allow interchangeable barrel sections, meaning you can potentially upgrade lip styles or widths without replacing entire wheel sets. Damaged a lip section? Replace just that component rather than the entire wheel. Want deeper lips next season? Order new outer barrels rather than complete wheels.

This modular wheel cost savings approach works particularly well for enthusiasts who expect their preferences to evolve or who participate in different vehicle uses requiring varied setups. The initial investment in quality centers pays dividends through component flexibility over time.

However, approach budget options cautiously. Forgelite warns that things are usually cheap for a reason, and some corners have to be cut to bring down costs. Low-cost manufacturers may use inferior forgings, skip proper quality control, or apply finishes that degrade quickly. Liquid paint finishes common on budget wheels offer durability roughly 20 times lower than proper powder coating. Out-of-tolerance wheel runout from inadequate quality control creates dangerous vibrations that cannot be corrected after purchase.

Hidden Costs to Budget

Your wheel investment extends beyond the wheels themselves. JL Wheels recommends budgeting for:

- New tires: Different wheel sizes typically require new rubber.

- TPMS sensors: New sensors or rebuilding existing ones for proper tire pressure monitoring.

- Mounting and balancing: Professional installation can add $100+ for a complete set.

- Lug nuts or bolts: Extended, style-specific, or security lug hardware may be required.

Factor these additions into your total project budget to avoid surprises after your custom lip designs arrive.

With cost factors understood and value propositions clear, you're equipped to make investment decisions aligned with both your aesthetic goals and practical budget. The final step? Synthesizing everything into a decision framework that guides you confidently from specification to purchase.

Making Your Custom Lip Design Decision

You've absorbed a lot of information. Lip profiles, construction methods, engraving techniques, fitment calculations, application matching, ordering protocols, and cost considerations. Now it's time to pull everything together into a practical framework that transforms knowledge into action.

The difference between enthusiasts who end up with stunning custom forged wheel lip designs and those who struggle with disappointing results? A systematic approach. Following a structured decision process ensures nothing gets overlooked and your final specifications align perfectly with your goals.

Your Custom Lip Design Decision Checklist

Before contacting any manufacturer, work through this custom wheel buying guide sequentially. Each step builds on the previous one, creating specifications that translate seamlessly from your vision to finished wheels.

- Define your primary application. Be honest about how you'll actually use your vehicle. Show car? Track machine? Street performer? Daily driver? Your answer determines which lip styles, finishes, and construction types make sense. Trying to optimize for everything means optimizing for nothing.

- Select your construction type. Choose monoblock for maximum strength and minimal maintenance. Select 2-piece for moderate customization flexibility. Go 3-piece when you need maximum lip width options or plan to swap components over time. Your construction choice locks in your customization boundaries.

- Choose your lip profile. Match profile to application. Step lips for show presence, flat lips for track weight savings, rolled lips for daily durability. Consider single, double, or triple step variations if pursuing aggressive styling.

- Gather all fitment measurements. Document current wheel specs, brake caliper dimensions, fender clearances at ride height, suspension travel, and inner clearance points. Check front wheels at full steering lock. Missing measurements create ordering mistakes.

- Calculate your safe lip width range. Using your fender gap and offset measurements, determine how much additional lip width you can accommodate. Build in 3-5mm safety margin for suspension compression and road variations.

- Specify your finish requirements. Match finish durability to your usage intensity. Polished for shows, brushed or painted for street, powder coated for daily abuse. Consider maintenance requirements before committing to high-gloss treatments.

- Plan any engraving details. If personalizing your lips, prepare digital files in vector format. Decide on placement, sizing, and whether engraved areas will be filled or left natural.

- Establish your realistic budget. Include wheels, tires, sensors, mounting, and hardware in your total. Quality forged wheels command $1,200-$8,000+ per set depending on specifications. Budget accordingly rather than compromising critical quality factors.

- Research manufacturer certifications. Verify IATF 16949 or equivalent quality management certification. Confirm in-house engineering capabilities and testing protocols. Review production experience with precision automotive components.

- Request written specification confirmation. Before production begins, obtain detailed documentation of every parameter. Verify dimensions, finishes, and engraving details match your requirements exactly.

Working through this forged wheel decision checklist systematically prevents the frustrating scenarios that plague unprepared buyers: wheels that don't clear brakes, lips that rub fenders, finishes that don't match expectations, or quality issues that emerge after installation.

Finding the Right Manufacturing Partner

Your specifications are only as good as the manufacturer executing them. Choosing wheel manufacturer partners demands the same rigor you applied to defining your lip designs.

Quality forging operations share common characteristics that distinguish them from questionable suppliers. Look for these indicators when evaluating potential partners:

Certification credentials matter. IATF 16949 certification demonstrates that a manufacturer operates under internationally recognized automotive quality management standards. This certification requires rigorous process controls, defect prevention systems, and continuous improvement protocols. According to NNX Forged, manufacturers with this certification ensure every wheel meets strict dynamic balance, runout, bending fatigue, radial fatigue, and impact testing requirements.

In-house engineering capabilities. Manufacturers with dedicated engineering teams don't just execute your drawings. They optimize specifications, identify potential issues before production, and suggest improvements based on manufacturing expertise. This collaborative approach produces better results than simple order fulfillment.

Proven automotive component experience. Forging specialists who produce other precision automotive components like suspension arms and drive shafts bring the same manufacturing discipline to wheel production. This cross-component experience demonstrates mastery of forging processes, heat treatment protocols, and tight-tolerance machining that directly benefits wheel quality.

Rapid prototyping capabilities. The ability to produce prototype components quickly allows you to verify critical dimensions before committing to full production. Precision hot forging specialists like Shaoyi (Ningbo) Metal Technology offer prototyping in as little as 10 days, enabling physical verification of specifications that catches potential issues early.

Mass production capacity. Whether you need a single set or volume orders, capable manufacturers maintain consistent quality across production scales. In-house engineering combined with robust quality systems ensures the wheels in your fifth set match the precision of your first.

Strategic location advantages. Manufacturers located near major shipping hubs like Ningbo Port can significantly reduce delivery times to international destinations. This logistical advantage translates to faster project completion and reduced shipping complications.

Transparent communication. Reputable manufacturers willingly share production photos, testing documentation, and facility information. This transparency demonstrates confidence in their operations and provides assurance that your investment is protected.

According to TreadWorks, finding the perfect wheels is like choosing the right pair of shoes for a special occasion. They need to look good and fit good. This analogy extends to choosing your manufacturing partner: the relationship needs to work as well as the final product.

Custom Lip Design Tips for Success

A few final considerations that separate successful custom wheel projects from frustrating experiences:

Start conservative, then refine. If you're unsure about aggressive lip widths or deep-dish profiles, begin with moderate specifications. You can always order more aggressive barrels for modular wheels later, but you can't unbend rubbed fenders or unscrape damaged lips.

Document everything. Photograph your vehicle from multiple angles before ordering. Save all communications with manufacturers. Keep specification sheets accessible. This documentation proves invaluable if questions arise during production or after delivery.

Plan for timeline realities. Custom forged wheels require 4-8 weeks minimum, often longer for complex specifications. Build this timeline into your project planning rather than expecting rush miracles that compromise quality.

Invest in proper installation. Your precision-forged wheels deserve professional mounting and balancing. Torque lug nuts to manufacturer specifications and re-torque after 50-100 miles of driving as recommended by Performance Plus Tire.

Maintain your investment. Different finishes require different care. Establish cleaning routines appropriate to your lip finish type and usage intensity. Regular maintenance preserves both appearance and resale value.

Custom forged wheel lip designs represent more than aesthetic upgrades. They're expressions of personal vision executed through precision engineering. By approaching the decision systematically, verifying fitment thoroughly, and partnering with certified manufacturers who understand automotive quality requirements, you transform those spec sheet specifications into street presence that turns heads and delivers satisfaction every time you walk toward your vehicle.

Your wheels are waiting. Now you know exactly how to specify them.

Frequently Asked Questions About Custom Forged Wheel Lip Designs

1. How much does it cost to have custom forged wheels made?

Custom forged wheel pricing ranges from $300 to over $2,500 per wheel depending on specifications. Key cost factors include material grade, lip width, finish complexity, engraving detail, and construction type. A complete set typically costs $1,200 to $8,000+. Budget options may use inferior forgings or skip quality control, so verify IATF 16949 certification when evaluating manufacturers. Additional costs include new tires, TPMS sensors, mounting, balancing, and lug hardware.

2. Are forged wheels the strongest option available?

Forged wheels offer superior strength compared to cast alternatives due to their compressed and aligned grain structure. The forging process uses 8,000 to 12,000 tons of hydraulic pressure, eliminating porosity and inconsistencies found in cast wheels. This makes forged wheels approximately 25-30% lighter while providing higher load-bearing capacity. However, because manufacturers use less material to achieve equivalent strength, impact resistance depends on proper engineering and quality manufacturing standards.

3. What is the difference between step lip and flat lip wheel designs?

Step lip wheels feature a noticeable drop or ledge from the face to the outer edge, creating shadow lines and a motorsport-inspired look. Options include single, double, and triple step variations for varying visual depth. Flat lip wheels have no drop step, featuring a smooth, uninterrupted surface that makes the wheel face appear larger. Flat lips are easier to clean and suit modern, minimalist aesthetics, while step lips deliver more aggressive styling for show builds.

4. How long does it take to get custom forged wheels manufactured?

Standard custom forged wheel orders typically require 4-8 weeks from specification confirmation to delivery. This timeline includes design confirmation (1-3 days), forging and heat treatment (5-10 days), CNC machining (3-7 days), finishing (5-14 days), and quality inspection with shipping (2-5 days). Complex designs with unusual dimensions, exotic finishes, or prototype verification may extend timelines to 10-12 weeks. Manufacturers near major shipping hubs like Ningbo Port can reduce international delivery times.

5. Does engraving affect the structural integrity of forged wheel lips?

When performed correctly by experienced technicians, engraving has minimal impact on wheel strength. Laser engraving typically removes less than 0.5mm of material, preserving structural integrity. Quality manufacturers carefully adjust engraving parameters including power, speed, and frequency to achieve desired depth without damaging the base material. Each wheel undergoes quality inspection after engraving to verify accuracy and specifications before shipping.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —