Custom Forged Wheel Barrel Types: Match Your Build To The Right Lip

Understanding Custom Forged Wheel Barrels and Their Critical Role

Ever wondered what actually holds your tire in place and gives your wheels that aggressive, eye-catching depth? That's the barrel - and choosing the right one can make or break your entire build.

The Anatomy of a Forged Wheel Barrel

So, what is a forged wheel barrel exactly? Simply put, the barrel is the outermost cylindrical section of a wheel where the tire is mounted, as defined by Powerhouse Wheels. It encompasses the entire area from the outer lip to the inner flange, housing the tire bead and determining your wheel's overall depth profile.

When you're looking at a forged rim, you'll notice the barrel includes several critical elements: the flanges (those flared outer portions keeping your tire secure), the bead seat where the tire edge connects, and the drop center - that ring-like area closest to the centerline with the smallest inside diameter. Understanding these components is essential when selecting custom forged wheel barrel types for your specific application.

Unlike cast alternatives, a forged wheel starts as high-quality aluminum alloy that's been pressure-formed for superior strength. This forged wheels definition matters because the manufacturing process directly impacts how barrels can be customized and configured for your build.

Why Barrel Selection Defines Your Build

Imagine ordering a set of premium Brixton Forged wheels only to discover they don't clear your brake calipers or rub against your fenders. That's precisely why barrel type selection isn't just important - it's critical.

The barrel you choose influences virtually every aspect of wheel fitment and appearance:

- Tire Fitment: Barrel width and profile determine which tire sizes mount properly and how the sidewall sits relative to the lip

- Fender Clearance: Barrel depth combined with offset dictates how far the wheel extends toward or away from your vehicle's body

- Brake Compatibility: The inner barrel profile must provide adequate clearance for calipers, especially with big brake kit installations

- Visual Stance: Whether you want a subtle OEM-plus look or an aggressive deep-dish appearance, barrel type is the primary determining factor

While manufacturers like BBS pioneered mold-forged technology back in 1983, barrel customization options have evolved dramatically since then. Yet here's the problem - despite this evolution, detailed educational resources explaining what are forged wheels and their barrel configurations remain surprisingly scarce. Most manufacturer product pages assume you already understand the terminology, leaving enthusiasts to piece together information from scattered forum posts.

That's exactly the gap this guide fills. Whether you're considering Brixton Forged options or exploring other premium manufacturers, understanding barrel types empowers you to communicate precisely with wheel builders and achieve the exact fitment your project demands. In the sections ahead, you'll learn how different lip styles, construction methods, and specifications work together - giving you the knowledge to match your build to the perfect barrel configuration.

The Four Primary Barrel Lip Types Explained

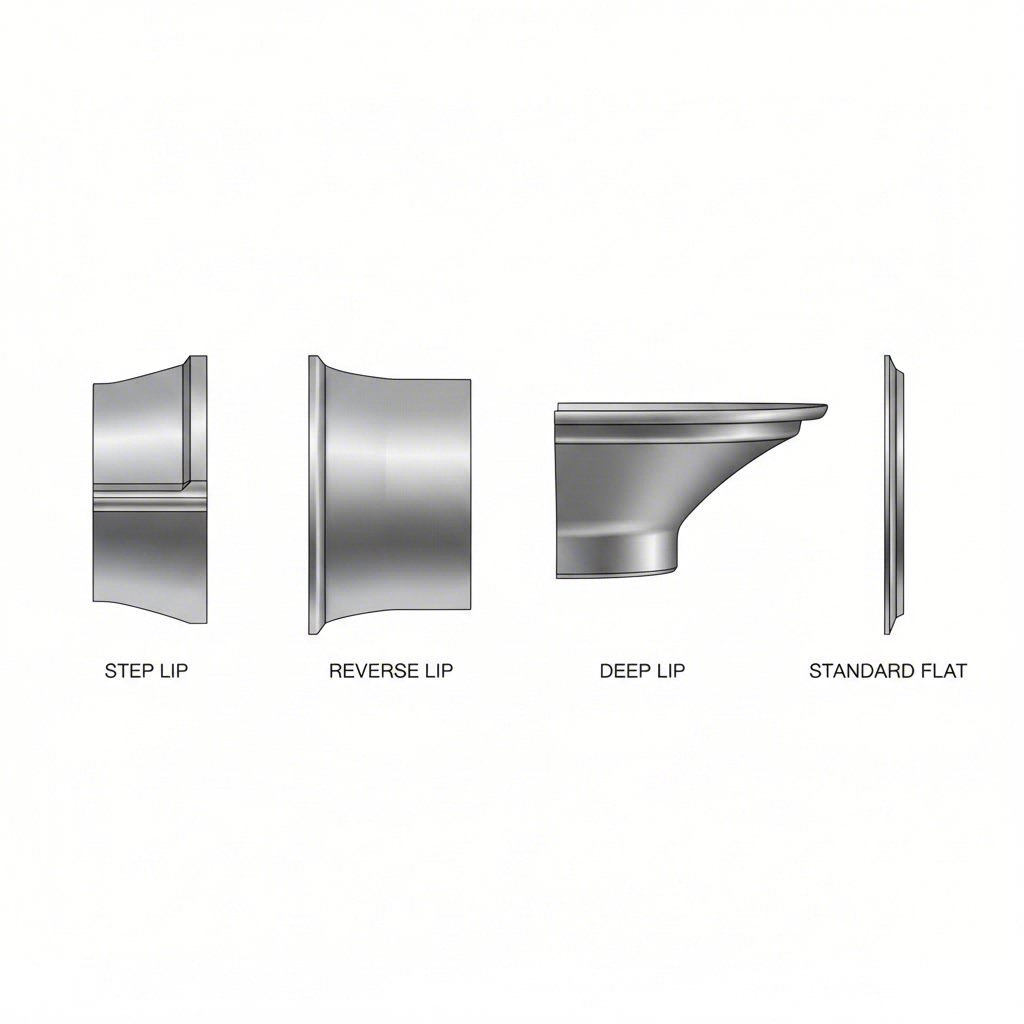

Now that you understand why barrel selection matters, let's dive into the specific lip configurations available. Whether you're building a show-stopping stance car or a track-ready machine, the lip style you choose fundamentally shapes both aesthetics and fitment. Here's where things get interesting - each of the four primary barrel lip types creates a distinctly different relationship between your wheel's offset and backspacing.

Step Lip vs Reverse Lip Configurations

When examining 3 piece wheels or 2 piece wheels closely, you'll notice the lip profile varies dramatically between designs. Understanding these differences helps you communicate exactly what you want when ordering custom barrels.

Step Lip Barrels feature a noticeable drop or ledge from the face mounting surface to the outer edge. According to Juju Wheels, this creates a classic, motorsport-inspired look while offering a functional advantage - the ability to increase overall wheel diameter through step-up conversions. For example, you can convert a 17-inch wheel to 18-inch or even 19-inch using double step configurations. The stepped design often provides additional structural strength, and many enthusiasts appreciate how it creates the illusion of deeper lip depth while maintaining rigidity.

Reverse Lip Barrels (also called flat lip barrels) present a smooth, continuous surface with no drop step. The mounting surface and outer edge sit on the same plane, creating a clean, modern aesthetic that makes the wheel face appear larger and flatter. These are popular choices for contemporary show builds and three piece wheels designed for sleek visual profiles. One key consideration: reverse lips require flat inner barrels to ensure proper flush fitment - mixing step lips with flat barrels creates stress points, air leaks, and unsafe assembly.

Matching your lip style with the correct barrel type isn't optional - it's critical for structural integrity and aesthetic quality.

Deep Lip Barrels for Maximum Visual Impact

Want that head-turning presence when your car rolls by? Deep lip barrels maximize the visible lip depth for an aggressive stance that commands attention. These configurations push the wheel face further inward, creating substantial exposed barrel surface between the center and outer edge.

Deep lip designs are particularly popular on 18 inch deep dish rims and larger applications where visual drama is the priority. They work exceptionally well with multi spoke wheels, where the contrast between intricate center designs and expansive lip surface creates stunning visual depth. However, this aggressive approach requires careful attention to fender clearance and suspension geometry - the extended lip pushes your effective wheel width outward significantly.

Standard Barrels take the opposite approach with flat, conservative profiles designed for practical fitment. These configurations work well for daily drivers prioritizing function over show-car aesthetics. The minimal lip exposure means less concern about curb damage and easier tire mounting, though you sacrifice the visual drama that draws many enthusiasts to custom forged wheels in the first place.

Complete Barrel Type Comparison

When specifying custom barrels for your 19 inch rims or any other size, this breakdown helps you match characteristics to your goals:

| Lip Style | Visual Characteristics | Best Applications | Fitment Considerations | Typical Use Cases |

|---|---|---|---|---|

| Step Lip | Visible ledge/drop from face to edge; motorsport-inspired; creates deeper appearance | Diameter step-up conversions; classic builds; strength-focused applications | Requires step inner barrels; mounting plane lowered relative to edge | Vintage restorations; track wheels; heritage styling |

| Reverse/Flat Lip | Smooth continuous surface; modern aesthetic; larger face appearance | Show builds; contemporary styling; sleek profile goals | Must pair with flat barrels only; same-plane mounting surface | Luxury vehicles; modern sports cars; clean aesthetics |

| Deep Lip | Maximum exposed barrel depth; aggressive stance; dramatic visual presence | Stance builds; show cars; maximum visual impact | Requires generous fender clearance; affects suspension geometry | VIP builds; drift cars; show-focused applications |

| Standard/Flat Profile | Minimal lip exposure; conservative appearance; practical profile | Daily drivers; OEM-plus builds; functionality priority | Most forgiving fitment; easier tire mounting; less curb concern | Street cars; commuter vehicles; subtle upgrades |

How Lip Type Affects Offset and Backspacing

Here's where barrel selection gets technical - and where many builders make costly mistakes. Each lip type creates a different relationship between offset (the distance from the wheel's centerline to the mounting surface) and backspacing (the distance from the mounting surface to the inner edge of the wheel).

With step lip configurations, the lowered mounting plane effectively shifts how offset translates to actual wheel positioning. A wheel with identical offset specifications will sit differently depending on whether it uses step or flat lip barrels. Deep lip barrels push the visual mass of the wheel outward while the mounting point remains constant, creating aggressive presence without necessarily requiring extreme offset numbers.

When shopping for black wheel rims or any finish option, remember that the lip style determines how that finish displays. Deep lips showcase more barrel surface area in your chosen color or texture, while standard profiles minimize exposed barrel area. This interplay between structural configuration and aesthetic presentation is precisely why understanding custom forged wheel barrel types matters before you commit to a purchase.

With lip styles now clear, the next critical consideration is how these barrels are actually manufactured - and why construction method dramatically impacts both performance and longevity.

Barrel Construction Methods and Material Science

You've selected your ideal lip style - but here's the thing: two barrels with identical profiles can perform completely differently based on how they're made. The manufacturing method behind your barrel determines everything from weight savings to crash behavior. Let's break down the three primary construction approaches used in multi-piece wheel building.

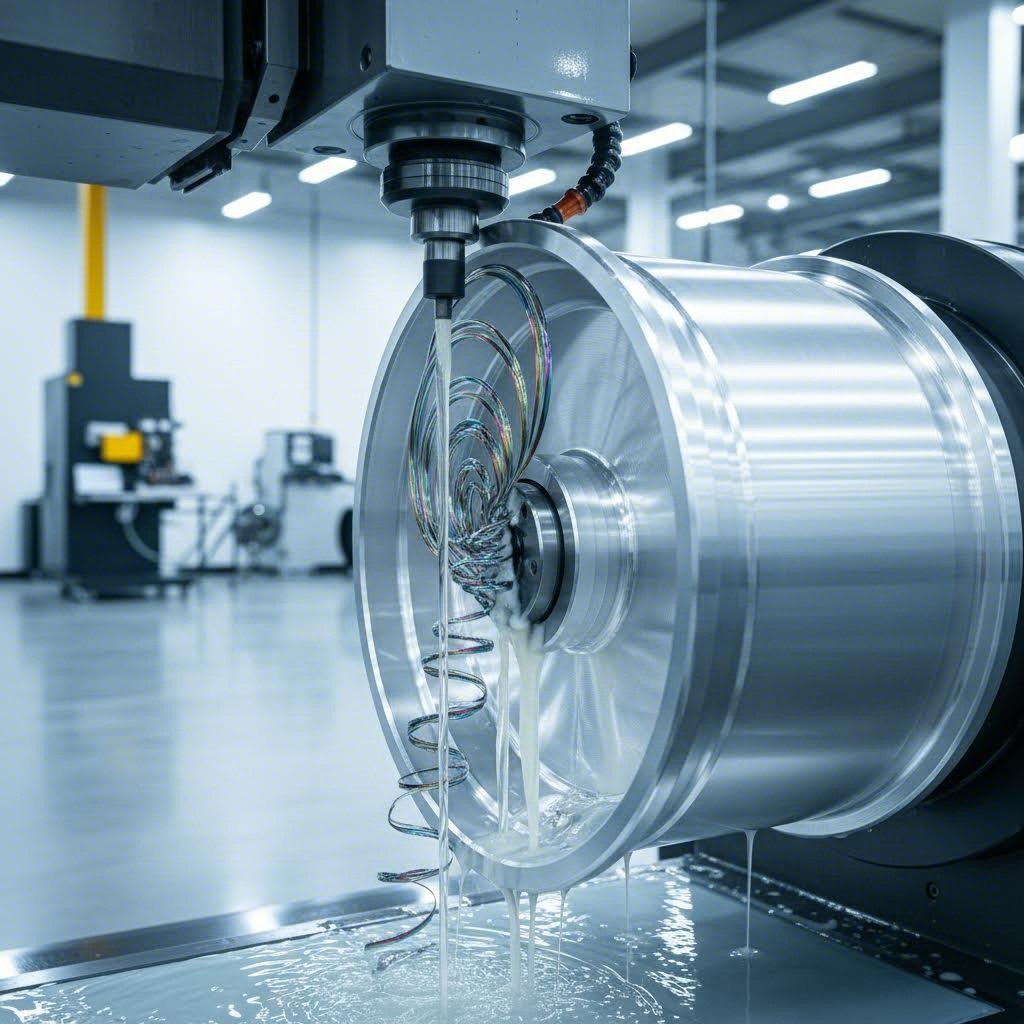

Spun vs Cast vs Fully Forged Barrel Construction

When exploring how are forged wheels made, you'll quickly discover that barrel construction varies significantly across the industry. Each method offers distinct advantages depending on your priorities.

Spun Barrels (Flow-Formed/Rotary Forged)

Spun barrels represent a hybrid approach that's gained tremendous popularity. According to JC Forged Wheels, the process starts with a cast wheel barrel featuring a shortened, thickened profile. A rotary machine then spins, heats, and uses rollers to press the thickened section into its final width and shape. This combination of heat, pressure, and spinning aligns the grain structure and molecular properties of the aluminum alloy, creating significantly greater strength in the barrel section.

You might encounter various names for this technology - rotary forged wheels, flow formed, spun forged, or hybrid forged. They all describe essentially the same process. The result? A barrel with forged-like strength characteristics at a fraction of fully forged pricing.

Cast Barrels

Cast barrels use the most straightforward manufacturing approach: molten aluminum poured into a mold, then cooled and solidified into the desired shape. As OX Wheels explains, this method allows for intricate designs at lower cost. However, the cooling process can create inconsistencies in material density, potentially resulting in microscopic air bubbles within the metal. To compensate for these material irregularities, manufacturers often add redundant material to increase strength - making cast barrels heavier than alternatives.

Fully Forged Barrels

At the pinnacle of barrel construction sit fully forged options. The aluminum wheel forging process begins with a solid billet of aluminum, heated and subjected to immense pressure - typically 8,000 to 10,000 tons - pressing it into a dense, uniform block called a "forging." This intense pressure eliminates any porosity and aligns the grain structure, creating exceptionally strong material that allows manufacturers to use significantly less aluminum while maintaining superior strength.

Forged monoblock wheels and fully forged multi-piece components represent the ultimate expression of this technology. The resulting barrels are typically 25-30% lighter than cast equivalents in the same size, according to industry testing.

How Manufacturing Method Affects Barrel Performance

Sounds complex? Here's the practical breakdown of what each construction method means for your build:

Spun/Flow-Formed Barrel Pros and Cons

- Pros: Lighter than cast (approaching forged weight savings); stronger barrel section due to grain alignment; more affordable than fully forged; good balance of performance and value

- Cons: Face/spoke section remains cast (potential weakness point under extreme impact); limited to specific barrel designs; not as light or strong as true forged construction

Cast Barrel Pros and Cons

- Pros: Most affordable option; allows intricate designs; widely available; suitable for daily driving applications

- Cons: Heaviest construction method; potential material inconsistencies; more susceptible to cracking under severe impact; requires additional material for adequate strength

Fully Forged Barrel Pros and Cons

- Pros: Lightest weight possible; superior strength-to-weight ratio; bends rather than shatters under extreme impact (safer failure mode); maximum customization potential; excellent resale value

- Cons: Highest cost; longer lead times for custom specifications; limited manufacturer availability

The Role of 6061-T6 Aluminum Alloy

Regardless of construction method, 6061-T6 aluminum alloy serves as the industry standard for premium barrel manufacturing. This aerospace-grade material offers an ideal combination of properties for wheel applications:

- Strength-to-Weight Ratio: Provides excellent structural integrity without unnecessary mass - critical for reducing unsprung weight

- Corrosion Resistance: Naturally resists oxidation and environmental degradation, maintaining appearance and integrity over years of use

- Machinability: Responds well to CNC machining processes, enabling precise barrel profiles and custom specifications

While magnesium wheels and magnesium alloy wheels offer even lighter weight, they require specialized care and aren't suitable for all applications. Magnesium rims remain primarily in motorsport contexts where ultimate weight savings justify their higher cost and maintenance requirements. For most custom forged wheel barrel applications, 6061-T6 aluminum delivers the optimal balance.

Weight, Durability, and Cost Trade-offs

When you're specifying barrels for your build, the construction method creates clear trade-offs:

Weight Impact: Fully forged barrels deliver the most significant weight reduction - crucial for performance-focused builds where unsprung mass directly affects handling, acceleration, and braking response. Flow-formed barrels offer meaningful improvement over cast options, making them excellent value propositions for street performance applications.

Durability Considerations: Under heavy impact, cast barrels tend to crack or break due to voids in the aluminum structure. Forged aluminum behaves differently - it bends out of shape rather than shattering catastrophically, providing safer failure characteristics that give drivers time to stop safely.

Cost Reality: Expect fully forged barrels to command premium pricing due to material costs, specialized equipment, and labor-intensive manufacturing. Rotary forged options typically cost about a quarter of fully forged pricing while delivering much of the performance benefit. Cast barrels remain the budget-friendly choice when cost takes priority over weight optimization.

Understanding these construction fundamentals prepares you for the next consideration: how barrel types integrate with different wheel construction categories - monoblock, 2-piece, and 3-piece designs each offer distinct barrel customization possibilities.

How Barrel Types Integrate with Wheel Construction

Now that you understand barrel construction methods, here's the next piece of the puzzle: how does your chosen barrel type actually connect to the wheel itself? The answer depends entirely on whether you're looking at monoblock, 2-piece, or 3-piece construction. Each approach offers dramatically different levels of barrel customization - and understanding these differences helps you determine which construction style matches your goals.

Monoblock Barrel Integration

With 1 piece forged wheels, there's no separate barrel to select - and that's precisely the point. The entire wheel, including what would be the barrel section, is machined from a single forged billet of aluminum. According to K7 Forged, this single-piece construction eliminates potential failure points like bolts or welds, making forged monoblocks the gold standard for strength-to-weight ratio.

What does this mean for barrel customization? Simply put - you're working with what the manufacturer offers. The barrel profile, depth, and lip style are all determined during the design phase and machined as an integrated part of the wheel. You can't swap a deeper lip or change width specifications after production.

However, this limitation comes with significant advantages. Monoblock construction delivers:

- Lower maintenance requirements: No seals to check or hardware to re-torque

- Lighter overall weight: No additional bolts, seals, or connection hardware adding mass

- Consistent strength: No joints or connection points that could potentially fail under stress

For daily drivers and track applications where reliability trumps customization, monoblock designs make compelling sense. Some enthusiasts initially explore forgeline flow formed wheels or similar hybrid options when they want monoblock simplicity with improved performance characteristics over standard cast alternatives.

Multi-Piece Barrel Customization Options

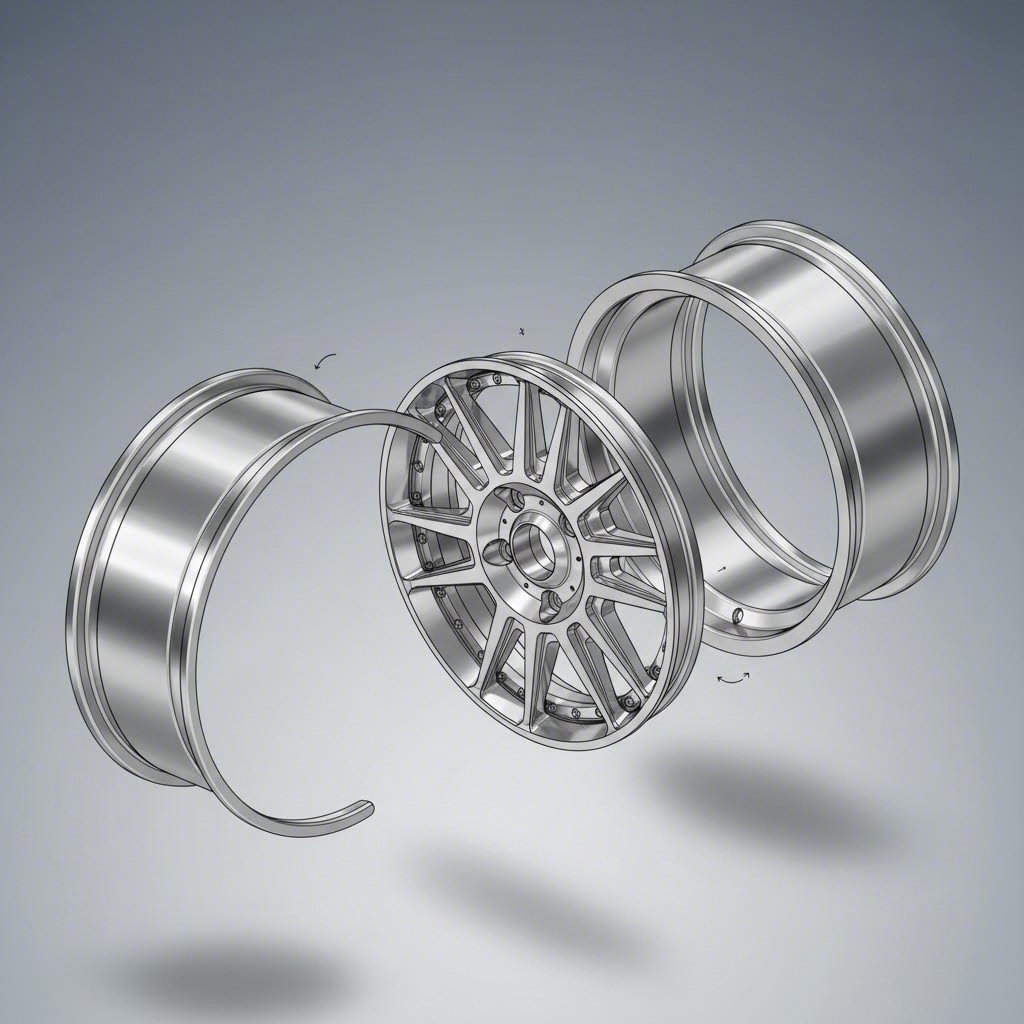

When you step into 2 piece forged wheels and 3 piece forged wheels territory, barrel customization possibilities expand dramatically. This is where your understanding of lip styles and construction methods from previous sections truly pays off.

2-Piece Construction

Two-piece wheels combine a forged center (the face with spokes) with a spun or forged barrel section. These components are typically welded together, creating a permanent assembly that's lighter than 3-piece options while still offering some customization flexibility. You'll choose your barrel width and lip style during the ordering process, and manufacturers can often adjust specifications within certain ranges to achieve your desired fitment.

The trade-off? Once assembled, 2-piece wheels function essentially like monoblocks in terms of repairability. If you damage the barrel, you're typically looking at replacing the entire wheel rather than just the affected component.

3-Piece Construction

Here's where things get exciting for enthusiasts who want ultimate control. As Work Wheels UK explains, a 3 piece forged wheel consists of three separate components: an outer lip, inner barrel, and center face that bolt together and seal. This modular approach means you can tailor width, offset, and style independently to match your specific car, brakes, and tires.

The real magic of 3 pieces wheels? Adaptability. If you curb a lip, you swap just that part instead of replacing the entire wheel. Want to run wider tires next season? Order new barrels with increased width. Upgrading to a different vehicle? The centers might transfer with new barrel specifications.

Three-piece construction transforms wheels from a fixed purchase into an evolving platform that adapts as your build changes.

This explains why you'll see 3-piece forged wheels dominating at enthusiast shows and events - the ability to spec exact lip depths, choose step-lip or reverse-lip configurations, and select exposed hardware finishes creates endless personalization possibilities.

Barrel Customization Comparison by Construction Type

When deciding between construction types, this breakdown clarifies what's possible with each approach:

| Construction Type | Barrel Customization Level | Width Adjustment Range | Rebuild Capability |

|---|---|---|---|

| Monoblock (1-Piece) | Fixed at manufacturing; no post-production changes possible | None - must order new wheel for different width | Not rebuildable; damage typically requires full replacement |

| 2-Piece | Moderate; barrel selected during order but permanently attached | Manufacturer-dependent; typically within 0.5" increments during ordering | Limited; welded construction prevents component swapping |

| 3-Piece | Maximum; independent selection of inner barrel, outer lip, and center | Extensive; mix different inner/outer barrels to achieve virtually any width | Fully rebuildable; individual components replaceable; can re-spec for different vehicles |

Making the Construction Choice

Your ideal construction type depends on how you prioritize different factors. Performance builds focused on lap times often gravitate toward monoblock designs - the weight savings and maintenance simplicity align with track goals. Meanwhile, show builds and stance projects typically favor 3-piece construction where custom lip depths and rebuild capability justify the premium investment.

For classic builds like model a wheels restorations or vintage applications, 3-piece construction offers another advantage: the ability to achieve period-correct aesthetics with modern engineering. You can spec barrels that create authentic visual profiles while benefiting from contemporary materials and manufacturing quality.

Understanding how barrel types integrate with wheel construction is essential - but none of it matters if your measurements are wrong. Next, you'll learn exactly how to measure and specify custom barrel dimensions to ensure perfect fitment on your specific vehicle.

Measuring and Specifying Custom Barrel Dimensions

You've chosen your lip style, understood construction methods, and selected your wheel configuration - but here's where builds succeed or fail. Incorrect measurements lead to wheels that rub fenders, interfere with brake calipers, or won't seat tires properly. Getting your barrel specifications right requires precision, patience, and understanding the relationships between different dimensions.

Measuring Barrel Depth and Backspacing

When specifying custom barrel dimensions, the relationship between barrel depth and backspacing often confuses first-time buyers. Here's the simple explanation: deeper barrels push your wheel's mounting surface further outward from the wheel's centerline.

According to Holley's wheel measurement guide, backspacing is measured from the mounting surface to the back outermost edge of the wheel in inches. This measurement directly determines how far inside your fender well the wheel sits. A wheel with 4 inches of backspacing positions the mounting pad 4 inches from the inner lip edge.

Offset works differently - it's measured from the mounting surface to the centerline of the wheel barrel in millimeters. Most modern vehicles use positive offset, which pushes the hub mating surface outward from center. Vintage builds often use negative offset for that classic deep-dish appearance.

Why does this matter for barrel selection? When you choose a deeper lip barrel, you're effectively changing where the mounting surface sits relative to the wheel's outer edge. Two wheels with identical offset specifications can have completely different visual presence and fitment characteristics based on barrel depth alone.

Deeper barrels create more exposed lip but push the mounting surface outward - always verify fender clearance before committing to aggressive barrel depths.

Width Specifications for Proper Tire Fitment

Here's something many enthusiasts don't realize: wheel width isn't measured edge-to-edge. As the Holley guide clarifies, width is measured from bead point to bead point on the barrel. A wheel labeled as 10 inches wide might actually measure 11.5 to 12 inches from outer edge to outer edge - and that extra width could be enough to cause rubbing issues.

For proper tire fitment, you need to measure from the mounting pad to the outer lip edge, then repeat for the inner edge. These measurements determine:

- Tire stretch capability: Narrower barrels relative to tire width create stretched sidewall looks

- Bead seating: Correct width ensures tire beads seat properly against barrel flanges

- Load distribution: Properly matched barrel width distributes tire forces evenly across the bead seat

When working with 14 inch rims 4 lug applications or similar compact setups, width precision becomes even more critical. Smaller diameter wheels have less circumference to absorb measurement errors, meaning a half-inch miscalculation creates proportionally larger fitment problems than the same error on larger wheels.

Step-by-Step Barrel Measurement Process

Ready to measure your vehicle for custom barrel specifications? Follow this process to gather the data manufacturers need:

- Document your bolt pattern: Measure center-to-center between two opposing wheel studs. For 14 inch rims 4x100 applications, you'll measure 100mm between opposing studs. Five-lug patterns require measuring from one stud's center to the outer edge of the opposite stud, then multiplying by 1.4 for accuracy.

- Measure current backspacing: Place a straight edge across your current wheel's face, then measure from the straight edge down to the mounting surface. Record this in inches.

- Check fender-to-hub clearance: With suspension at ride height, measure from your hub face to the inner fender lip. This determines maximum backspacing before contact occurs.

- Verify brake caliper clearance: Measure from your brake caliper's outermost point to where the wheel barrel's inner surface will sit. Add at least 3mm clearance margin for safety.

- Measure suspension component clearance: Check distance to control arms, sway bars, and tie rod ends at full steering lock. As the Holley reference notes, front tire clearance at full lock is commonly overlooked - and discovering rubbing after purchase ruins your day.

- Document total package height: Calculate your proposed wheel diameter plus tire sidewall height to ensure adequate clearance from fender lips and wheel well liners throughout suspension travel.

US Standard vs European Standard Specifications

When ordering custom barrels, you'll encounter two measurement systems that don't always translate cleanly. US manufacturers typically specify dimensions in inches, while European builders use millimeters. For 14 inches rims and most applications, conversion is straightforward - but hardware compatibility creates hidden complications.

Three-piece wheel assembly hardware varies by manufacturer origin:

- M6 hardware (6mm): Common on Japanese and some European three-piece wheels; requires specific torque specifications

- M7 hardware (7mm): Less common; found on certain specialty manufacturers

- M8 hardware (8mm): Standard on many American and European premium wheels; provides maximum clamping force

This matters because replacement hardware and rebuild kits aren't universally interchangeable. Ordering M7 bolts for M8 barrels creates dangerous assembly failures. Always verify hardware sizing when sourcing barrels from different manufacturers than your wheel centers.

Consequences of Incorrect Measurements

What happens when measurements go wrong? The problems range from annoying to dangerous:

Fender Rubbing: Insufficient backspacing or excessive barrel width pushes the tire into fender contact during suspension compression or steering input. You'll hear it immediately - that grinding sound means paint damage and potential tire wear.

Brake Caliper Interference: Barrels specified too deep on the inner edge contact brake calipers. This prevents proper wheel mounting or, worse, creates metal-on-metal contact while driving. For big brake kit installations, inner barrel clearance verification is absolutely critical.

Improper Tire Seating: Barrel width mismatched to tire size prevents proper bead seating. Underwidth barrels stretch tires beyond safe limits; overwidth barrels allow beads to move during cornering, potentially causing sudden deflation.

When understanding what does forged wheels mean for your build, remember that premium construction doesn't compensate for measurement errors. The question of what is better alloy or forged wheels becomes irrelevant if fitment prevents proper installation. Similarly, debates about forged wheels vs alloy wheels miss the point when incorrect barrel specs create unsafe conditions.

The difference between forged wheels and alloy wheels in terms of measurement requirements is minimal - both demand precision. What distinguishes quality forged barrel suppliers is their ability to work within exact specifications you provide, which is why accurate measurements matter so much.

With proper measurements in hand, you're ready to consider real-world applications - how different barrel configurations serve show builds versus performance applications, and which specifications match your specific driving style.

Practical Applications and Real-World Barrel Selection

You've got your measurements locked in and understand the technical specifications - but here's the real question: which barrel type actually suits your build? The answer depends entirely on how you'll use your vehicle. A show-stopping stance car demands completely different barrel considerations than a weekend track warrior or a daily commuter. Let's explore how real-world applications shape your barrel selection.

Barrel Selection for Show vs Performance Builds

When you're building for maximum visual impact, deep lip barrels become your best friend. According to Mario's Wheel Repair, deep-dish wheels instantly make a car look more planted and performance-focused. That pronounced outer lip and aggressive stance have become staples in enthusiast builds for good reason - they command attention like few other modifications can.

However, show builds and track builds often require opposite approaches to barrel selection:

Show/Stance Builds: These applications prioritize visual drama over weight optimization. Deep lip barrels maximize exposed surface area, creating that head-turning presence when your car rolls by. Wider tire fitment becomes possible with proper barrel width, and the classic motorsport heritage of designs like BBS RS or Work Meister S1 wheels delivers undeniable aesthetic appeal.

But there's a trade-off. As the reference material notes, the extended outer lip is more vulnerable to curb rash and road debris. Show builds typically see limited driving, making this acceptable - but daily-driven stance cars require more careful consideration.

Track/Performance Builds: Here, the priorities flip completely. Forged truck wheels and performance applications demand lightweight fully forged barrels that reduce unsprung mass. According to GVICHN's buyer guide, forged wheels significantly reduce unsprung mass, which directly improves vehicle handling and performance. This weight reduction translates to better acceleration, improved braking performance, and more responsive handling characteristics.

For serious track applications, two-piece designs typically offer a slight weight advantage due to fewer components and joining points. Standard or conservative barrel profiles also provide better brake clearance for the larger rotors and calipers common in competition settings.

Matching Barrel Type to Your Driving Style

Imagine pulling into a car show with wheels that look incredible but barely clear your brake calipers. Or picture attacking a track day with heavy multi-piece wheels that add unsprung weight where you need it least. Matching barrel type to your actual driving style prevents these scenarios.

Barrel Recommendations by Application Type

- Stance/Show Builds: Deep lip barrels with step or reverse lip configurations; 3-piece construction for maximum customization; aggressive widths paired with stretched tires; prioritize visual impact over weight savings

- Track/Competition: Standard profile barrels with fully forged construction; monoblock or 2-piece designs for minimal weight; adequate clearance for big brake kits; focus on strength-to-weight ratio

- Daily Drivers: Conservative barrel depths balancing aesthetics with durability; flow-formed construction for value and performance; avoid extreme lip exposure that invites curb damage; consider forged rims for trucks if driving a pickup or SUV

- VIP/Luxury Builds: Moderate lip depth with premium finishes; reverse lip configurations for clean modern aesthetics; air suspension compatibility for adjustable ride height; 3-piece construction for rebuild capability

- Off Road Wheel Applications: Standard or flat profile barrels with maximum strength; fully forged construction to handle impact; focus on durability over visual depth; force offroad wheels or similar designs prioritize function

Brake Clearance and Suspension Considerations

Here's where barrel selection gets critically practical. Your dream deep-dish setup means nothing if it interferes with your braking system or suspension components.

Big Brake Kit Compatibility: Deep lip barrels push the wheel face inward, which sounds great for aesthetics - but that inner barrel surface moves closer to your brake calipers. Many deep-dish wheels may not accommodate larger brake kits without spacers, as the reference material warns. Before committing to aggressive barrel depths, verify clearance with your specific caliper dimensions.

For forged wheels truck applications or any vehicle with upgraded brakes, standard profile barrels often provide the safest clearance margins. The reduced visual drama is worthwhile when it prevents metal-on-metal contact with your calipers.

Lowered Vehicle Clearance: Stance builds running coilovers or lowering springs face additional challenges. At compressed ride height, the relationship between your suspension components and inner barrel changes dramatically. Control arms, sway bar end links, and tie rod ends all require clearance verification - especially at full steering lock.

Three-piece construction offers an advantage here. If you discover clearance issues after installation, you can potentially swap to different barrel specifications rather than replacing entire wheels. This adaptability explains why serious stance builders often invest in 3-piece forged wheel setups despite higher costs.

Tire Stretch and Air Suspension Compatibility

Want that aggressive stretched tire look on your off road rim or street build? Barrel width selection directly enables or limits your tire stretch options.

Wider barrels relative to tire size create the stretched sidewall appearance popular in stance culture. However, this setup requires careful attention to bead seating and air pressure - stretched tires under aggressive driving can unseat from the barrel. For show-only applications, aggressive stretch works beautifully. For vehicles seeing spirited driving, moderate stretch on appropriately sized barrels balances aesthetics with safety.

Air Suspension Compatibility: Builds running air suspension gain unique barrel selection flexibility. When you can raise ride height at the touch of a button, aggressive barrel depths become more practical - you simply air up before encountering obstacles that would scrape a static setup.

However, air suspension also requires considering barrel clearance at both minimum and maximum ride heights. Your wheels might clear everything at show height but contact components when aired out for driving. Test clearances at multiple suspension positions before finalizing barrel specifications.

The best barrel selection balances your visual goals with practical realities - stunning wheels that can't clear your brakes serve no purpose beyond frustration.

Whether you're building forged wheels truck applications for work duty, selecting an off road rim setup for weekend adventures, or creating a show car with force offroad wheels aesthetics, barrel type fundamentally shapes what's possible. The key is honest assessment of how you'll actually use your vehicle - then selecting barrels that serve that purpose without compromise.

With application considerations clear, the next factor to evaluate is the financial side - understanding whether premium barrel options justify their cost through longevity, rebuildability, and long-term value.

Evaluating Barrel Options and Value Considerations

You've identified your ideal barrel configuration and understand the technical requirements - but here's the question that stops many enthusiasts mid-build: is the premium price tag actually worth it? When a set of forged 3-piece wheels can exceed $10,000 compared to $2,000 for cast alternatives, according to Performance Plus Tire, the cost difference demands serious consideration. Let's break down whether premium barrel options justify their investment through real-world value.

Investment Value of Premium Barrel Construction

Think of premium wheel barrels less like a purchase and more like an investment - one that potentially pays dividends over years of ownership. The value proposition extends far beyond initial aesthetics.

According to industry data, forged wheels typically last seven to ten years with proper maintenance - considerably longer than cast counterparts. Their superior resistance to moisture damage, corrosion, and oxidation means your investment holds up over time. This longevity directly impacts total cost of ownership when you calculate price-per-year rather than upfront expense alone.

For those seeking cheap forged wheels or affordable forged wheels, flow-formed construction offers a compelling middle ground. These hybrid designs cost roughly a quarter of fully forged pricing while delivering meaningful weight savings and improved durability over cast options. It's often the best affordable rims for a sedan buyer looking to balance performance with budget reality.

However, the true value proposition of premium wheel construction emerges in specific scenarios:

- Material Grade: Aerospace-grade 6061-T6 aluminum costs more but resists corrosion and maintains structural integrity under stress - cheaper alloys simply can't match this performance

- Construction Method: Fully forged barrels command premium pricing due to the intense pressure forging process, specialized equipment, and lower production volumes - but deliver 25-30% weight reduction over cast equivalents

- Finish Options: Custom powder coating, polished lips, brushed faces, and multi-tone finishes add cost but dramatically impact visual presence and durability

- Customization Level: Made-to-order specifications with exact offset, width, and lip depth configurations require individual engineering - mass-produced wheels simply can't offer this precision

Long-Term Cost Considerations

Here's where 3-piece construction reveals its hidden value advantage: rebuildability. Unlike monoblock designs where damage typically means full replacement, three-piece wheels allow component-level repairs that preserve your investment.

Curbed a lip on your expedition wheels during parallel parking? Replace just that outer barrel section rather than the entire wheel. Want to run wider tires on your expedition rims next season? Order new barrels with increased width while keeping your existing centers. This modularity transforms wheels from a fixed purchase into an adaptable platform.

The math becomes compelling over time. As Performance Plus Tire notes, racing teams save considerably over a season by replacing just damaged components rather than entire wheel sets. The same principle applies to street builds - one curbed lip replacement costs far less than one new premium wheel.

Consider these long-term value factors:

- Damage Repair: 3-piece designs allow individual component replacement; monoblock damage often requires complete wheel replacement

- Width Adaptability: Changing barrel specifications accommodates different tire sizes, suspension setups, or body modifications without starting over

- Vehicle Transferability: Quality centers can potentially transfer to your next vehicle with new barrel specifications - extending your initial investment across multiple builds

- Resale Value: Premium forged wheels from recognized manufacturers maintain value far better than budget alternatives; buyers specifically seek quality construction

The premium wheel investment also provides future flexibility. As your build evolves - whether adding a big brake kit, changing suspension geometry, or modifying fenders - replaceable barrels adapt without requiring entirely new wheels. This forward-compatibility often justifies higher initial investment for enthusiasts who know their builds will continue developing.

Premium barrels aren't just about today's setup - they're about maintaining options for tomorrow's modifications.

That said, honest assessment matters. If you're building a daily driver with no plans for aggressive modifications, the rebuildability advantage offers less practical value. Similarly, expedition wheels or similar applications seeing rough duty might benefit more from affordable forged wheels that you can replace without financial heartbreak if damaged.

The decision ultimately balances your build's specific requirements against realistic budget constraints. Premium barrel construction delivers genuine value for show builds, evolving projects, and long-term ownership scenarios - but only when you'll actually utilize those advantages. Understanding exactly what you're paying for helps ensure your investment delivers returns that match your expectations.

With value considerations clear, the next critical step is understanding how to source quality forged barrel components from certified manufacturers who can deliver the precision your build demands.

Sourcing Quality Forged Barrel Components

You've determined your ideal barrel specifications, understood the value proposition, and you're ready to move forward - but here's where many builds hit an unexpected roadblock. Not all manufacturers deliver equal quality, and the difference between a certified precision forging specialist and a corner-cutting supplier can mean the difference between wheels that perform flawlessly and components that fail catastrophically. Let's explore what separates quality forged barrel sourcing from risky alternatives.

Working with Certified Forging Specialists

When you're specifying custom wheel machining requirements, manufacturer certifications aren't just marketing buzzwords - they're your insurance policy against receiving substandard components. According to Flexi Forge Wheel, choosing a certified manufacturer isn't just a preference - it's a necessity in an industry where quality, safety, and durability are paramount.

Why does this matter so much for barrel components? Wheels are safety-critical parts. A barrel that fails under load doesn't just ruin your day - it creates potentially dangerous conditions at highway speeds. Proper certifications verify that manufacturers maintain consistent quality control processes throughout production.

The key certifications to look for when sourcing custom cnc wheels and barrel components include:

- ISO 9001: This global quality management standard confirms a company follows strict quality control processes at every production stage - from design through final inspection

- IATF 16949: Specifically designed for automotive industry suppliers, this certification covers the entire production process and focuses on continuous improvement and defect prevention

- JWL/JWL-T: Japanese standards for alloy wheels that confirm products meet safety and quality requirements for both passenger and truck applications

- VIA Certification: Independent third-party testing through Japan's Vehicle Inspection Association, providing additional verification beyond manufacturer claims

- TÜV Certification: Particularly important for European markets, indicating products passed rigorous quality and safety testing

For enthusiasts exploring parallel forged wheels or similar premium options, verifying these certifications protects your investment. As Rusch Wheels explains, quality materials are the basis for quality results - their forgings come from IATF 16949 and ISO 9001 certified factories using full automation processes with ultrasonic material detection.

Quality Standards in Barrel Manufacturing

What actually happens inside a certified forging facility that makes such a difference? The answer lies in precision hot forging solutions and rigorous quality control protocols that amateur operations simply cannot replicate.

Premium barrel manufacturing begins with material verification. Quality facilities use ultrasonic detection equipment to identify any internal flaws in aluminum billets before forging begins. According to the Rusch Wheels manufacturing documentation, their forgings are created using extreme pressure of 12,000 tons followed by T6 heat treatment - creating high-integrity, multi-directional grain structures that deliver maximum strength.

The cnc custom wheels production process at certified facilities typically includes:

- Material Inspection: Incoming aluminum alloy undergoes chemical composition verification and ultrasonic testing for internal defects

- Precision Forging: Billets are heated and pressed under immense pressure, with temperature and force parameters monitored continuously

- Heat Treatment: T6 heat treatment processes are precisely controlled to achieve optimal material properties

- CNC Machining: Computer-controlled lathes and milling machines achieve tolerances measured in thousandths of an inch

- Dimensional Verification: Every critical dimension is checked against engineering specifications before proceeding

- Surface Preparation: Hand filing, buffing, and polishing prepare surfaces for coating

- Finishing: Multiple coating and baking cycles ensure durable, consistent finishes

- Final Inspection: Runout measurement, visual inspection, and documentation before shipping

This level of process control explains why forged customs from certified manufacturers command premium pricing - and why that premium often represents genuine value rather than marketing markup.

Selecting a Manufacturing Partner

Whether you're building rock forged wheels for off-road applications or show-quality street pieces, your manufacturing partner selection directly impacts results. Here's what separates quality suppliers from the rest:

In-House Engineering Capability: Quality manufacturers maintain engineering teams who can review your specifications, identify potential issues, and optimize designs for manufacturability. This expertise prevents costly mistakes before production begins.

Rapid Prototyping: The ability to produce prototype components quickly - sometimes in as little as 10 days - allows verification before committing to full production runs. For custom barrel specifications, this capability proves invaluable.

Testing Infrastructure: Beyond certifications, look for manufacturers who perform rigorous product testing. As the Flexi Forge reference notes, reputable manufacturers conduct impact testing, cornering fatigue testing, radial fatigue testing, and rotary bending tests to guarantee structural integrity.

Companies like Shaoyi (Ningbo) Metal Technology exemplify the certified precision forging capability that serious wheel builders should seek. Their IATF 16949 certification, in-house engineering, and rapid prototyping capabilities demonstrate the standards that apply to quality barrel component manufacturing. Located near Ningbo Port, such manufacturers offer globally compliant production with efficient logistics - factors that matter when sourcing forged customs for your project.

Certifications verify capability, but testing proves performance - seek manufacturers who do both.

The investment in properly sourced barrel components pays dividends throughout your wheel's lifetime. Quality forged barrels from certified manufacturers resist the porosity issues, inconsistent material properties, and premature failures that plague budget alternatives. When your wheels are the only thing between your vehicle and the road, that quality difference matters immensely.

With sourcing fundamentals clear, you're ready to synthesize everything into a clear decision framework - a checklist approach that ensures your custom barrel selection succeeds from specification through installation.

Making Your Custom Barrel Decision with Confidence

You've absorbed the technical knowledge, understood construction differences, and explored real-world applications - now it's time to put everything together into actionable decisions. Whether you're specifying barrels for a show-stopping stance build or a weekend track weapon, this final framework ensures you don't overlook critical factors that separate successful wheel projects from expensive mistakes.

Your Custom Barrel Selection Checklist

Before placing that order for true forged rims, walk through this systematic process. Each step builds on the previous, creating a comprehensive specification that manufacturers can execute precisely:

- Determine Your Primary Use Case: Be brutally honest here. Will this vehicle see track days, daily commuting, weekend shows, or serious off-road duty? Your answer shapes every subsequent decision. Track builds demand lightweight fully forged barrels; show builds prioritize deep lip aesthetics; daily drivers need durability that survives parking lots. Don't spec show-car depths for a vehicle that regularly encounters curbs.

- Measure All Vehicle Clearances: Grab your measuring tools and document every critical dimension - fender-to-hub distance, brake caliper protrusion, suspension component clearance at full steering lock, and available space at both ride height and full compression. These measurements become your non-negotiable constraints. Reference your data against proposed barrel depths before committing.

- Select Your Lip Style: With clearances verified, choose between step lip, reverse lip, deep lip, or standard configurations. Consider how each style affects the visual presence you're targeting. Remember that stark forged wheels and similar premium options offer various lip configurations - select the profile that achieves your aesthetic goals within your measured clearance envelope.

- Choose Your Construction Method: Match construction to your priorities. Fully forged barrels deliver maximum weight savings for performance applications. Flow-formed options balance cost and capability for street builds. Cast barrels serve budget-conscious projects where weight optimization isn't critical. For enthusiasts who appreciate classic designs like the fikse fm10, understand that construction quality matters as much as styling heritage.

- Verify Manufacturer Certifications: This step protects your investment and your safety. Confirm your chosen supplier holds IATF 16949, ISO 9001, JWL, or equivalent certifications. Request documentation - legitimate manufacturers readily provide proof. Quality certifications indicate consistent processes that deliver reliable forging rims you can trust at speed.

Moving Forward with Confidence

With your checklist complete, you're positioned to specify custom barrel requirements that manufacturers can execute accurately. But here's the final consideration: are forged wheels aluminium exclusively? Yes - quality forged wheel barrels use aerospace-grade aluminum alloys, typically 6061-T6, for their optimal strength-to-weight properties. While you might encounter questions about what is forged carbon fiber in other applications, aluminum remains the material of choice for wheel barrel construction.

Your specification package should include:

- Intended application and driving conditions

- Complete vehicle clearance measurements

- Desired lip style and barrel depth

- Width and offset requirements

- Construction method preference

- Finish specifications

When evaluating potential suppliers, prioritize those demonstrating in-house engineering capability and rapid prototyping options. Manufacturers like Shaoyi (Ningbo) Metal Technology exemplify the standards to seek - IATF 16949 certification, rigorous quality control, and the ability to produce prototypes in as little as 10 days. Their globally compliant manufacturing and proximity to major shipping ports streamline procurement for custom forged components.

The knowledge you've gained through this guide transforms you from a passive buyer into an informed specifier. You understand why barrel type matters, how construction methods affect performance, and what measurements ensure proper fitment. You recognize the value proposition of premium components and know which certifications verify manufacturer capability.

Custom forged wheel barrel selection isn't about finding the cheapest option or the most aggressive look - it's about matching precisely the right specifications to your specific build requirements.

Armed with proper specifications and quality-certified suppliers, your custom barrel project moves from concept to reality with confidence. The wheels you install will deliver the fitment, performance, and aesthetics you envisioned - because you took the time to understand exactly what you needed before placing that order.

Frequently Asked Questions About Custom Forged Wheel Barrel Types

1. What are the different types of wheel forging?

The three primary wheel forging types are fully forged, flow-formed (rotary forged), and cast construction. Fully forged wheels are pressed from solid aluminum billets under 8,000-10,000 tons of pressure, creating the lightest and strongest option. Flow-formed wheels combine casting for the face with spinning and pressing for the barrel, offering a middle ground between cost and performance. Cast wheels use molten aluminum poured into molds - most affordable but heaviest. Each method produces different barrel characteristics affecting weight, durability, and customization potential.

2. Which BBS wheels are forged?

BBS offers several forged wheel lines including the FI-R with its signature milled spokes and the Le Mans featuring a classic motorsport mesh design. Both are crafted from premium forged aluminum for maximum strength and minimal weight. BBS pioneered mold-forged technology in 1983, and their forged lineup continues to set industry standards. When selecting BBS forged wheels, you can choose between monoblock, 2-piece, and 3-piece construction - each offering different barrel customization options for fitment and aesthetic preferences.

3. What are specialty forged wheels made of?

Premium specialty forged wheels are typically manufactured from 6061-T6 aerospace-grade aluminum alloy. This material offers an ideal combination of strength-to-weight ratio, corrosion resistance, and machinability for wheel applications. The T6 heat treatment process optimizes the aluminum's mechanical properties. While magnesium alloys appear in some motorsport applications for even lighter weight, 6061-T6 aluminum remains the standard for street and performance forged wheels due to its balance of performance, durability, and maintenance requirements.

4. What is the difference between step lip and reverse lip barrel configurations?

Step lip barrels feature a visible ledge or drop between the face mounting surface and outer edge, creating a motorsport-inspired appearance and enabling diameter step-up conversions. Reverse lip (flat lip) barrels present a smooth, continuous surface with no drop, producing a modern aesthetic where the wheel face appears larger. The critical difference lies in compatibility - step lips require step inner barrels, while reverse lips must pair with flat barrels only. Mixing configurations creates stress points, air leaks, and unsafe wheel assembly.

5. Are 3-piece forged wheels worth the higher cost?

Three-piece forged wheels justify their premium through rebuildability, adaptability, and long-term value. Unlike monoblock designs where damage requires full replacement, 3-piece construction allows individual component replacement - a curbed lip costs far less to replace than an entire wheel. You can also change barrel specifications to accommodate different tire sizes or suspension modifications without purchasing new wheels entirely. Quality 3-piece forged wheels from certified manufacturers typically last 7-10 years and maintain strong resale value, making them cost-effective for evolving builds and serious enthusiasts.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —