Why Cast Iron Vs Steel Die Sets Matters for Your Business

The Die Set Material Decision That Impacts Every Stamped Part

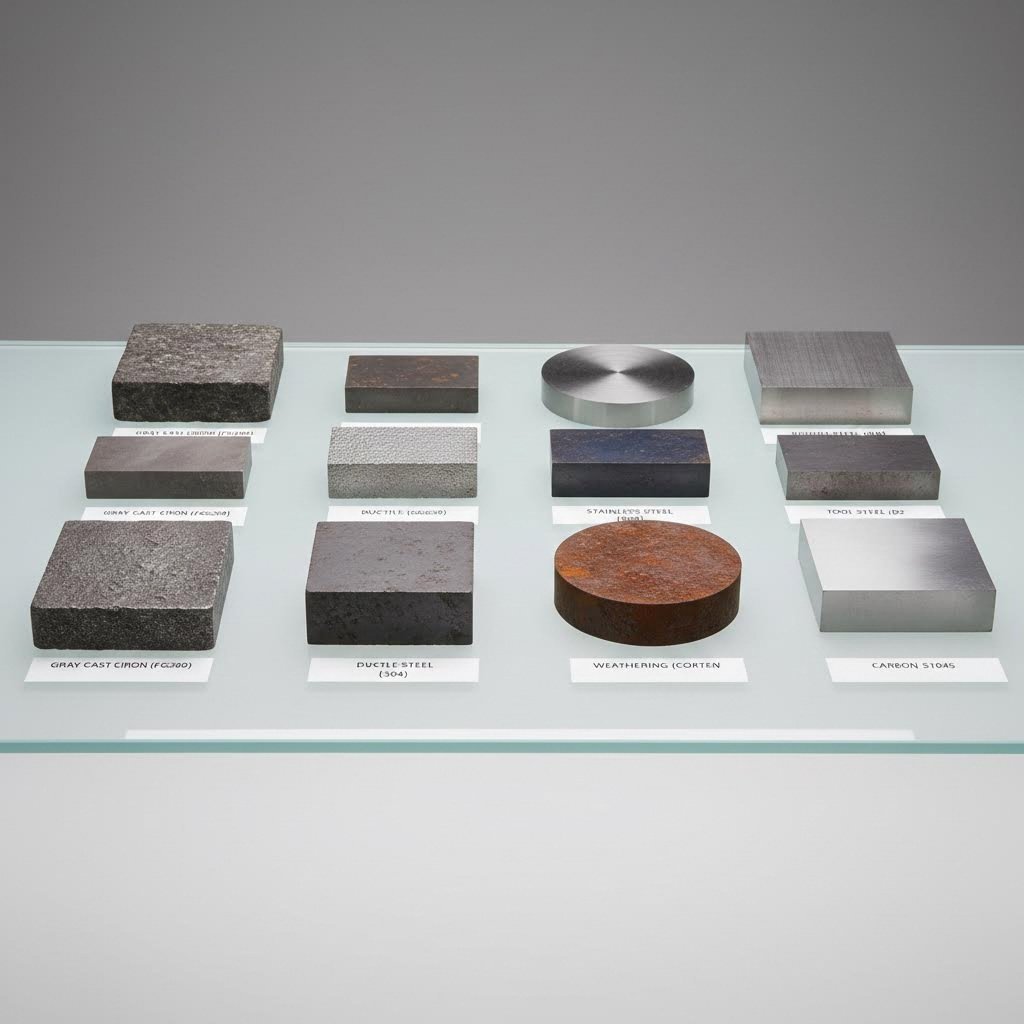

Imagine running your stamping press at full capacity when suddenly, dimensional inconsistencies start appearing on your parts. You inspect the tooling and discover premature wear on your die set—a problem that traces back to a single decision made months ago: choosing the wrong material. This scenario plays out in manufacturing facilities more often than most engineers care to admit.

When it comes to cast iron vs steel die sets, the stakes couldn't be higher. Your material selection directly influences part quality, tool longevity, and ultimately, your bottom line. Yet surprisingly, finding reliable guidance on this critical comparison remains frustratingly difficult.

Why Material Choice Makes or Breaks Your Stamping Operation

The difference between cast iron and steel in die set applications extends far beyond basic material properties. Each option brings distinct characteristics to your stamping operation—from vibration absorption to wear patterns under repeated cycling. Understanding how to tell cast iron from steel isn't just about metallurgical knowledge; it's about predicting how your tooling will perform across thousands or even millions of production cycles.

Cast steel vs cast iron represents a fundamental trade-off between rigidity and dampening, between initial cost and long-term value. Making the wrong choice can result in:

- Premature die wear requiring costly replacements

- Dimensional drift that pushes parts out of tolerance

- Excessive vibration that accelerates machine wear

- Unplanned production downtime during critical runs

The Hidden Costs of Choosing the Wrong Die Set Material

Beyond the obvious replacement expenses, poor material selection creates ripple effects throughout your operation. Quality rejections increase. Maintenance intervals shorten. Press operators notice subtle changes in how the tooling behaves. Learning how to tell cast iron from cast steel helps you avoid these compounding problems before they start.

This guide delivers what's missing from existing resources: a definitive ranking of die set materials based on real-world performance factors. We'll evaluate each option against five critical criteria—durability, precision retention, vibration dampening, cost-effectiveness, and maintenance requirements. Whether you're running high-volume blanking operations or precision automotive stamping, you'll find actionable guidance for your specific application.

How We Evaluated and Ranked Each Die Set Option

Selecting between cast iron vs steel die sets requires more than gut instinct or habit. You need a structured approach that accounts for how each material actually performs under real production conditions. That's exactly why we developed a systematic evaluation framework—one that weighs the factors experienced machinists and engineers consistently identify as critical.

Five Performance Factors That Determine Die Set Rankings

When you're running a stamping operation, certain material properties matter more than others. Through analysis of production data and input from practical machinists, we identified five key performance factors that separate exceptional die sets from problematic ones:

- Vibration dampening capability: How effectively the material absorbs press vibrations and shock loads during stamping cycles

- Dimensional stability under load: The material's ability to maintain precise alignment when subjected to repeated forming forces

- Wear resistance over production cycles: How well guide pins, bushings, and mounting surfaces hold up across thousands of hits

- Machinability for precision fitting: The ease of achieving tight tolerances during die set manufacturing and maintenance

- Total cost of ownership: Initial investment plus ongoing maintenance, replacement frequency, and downtime costs

Experienced machinists consistently point to vibration dampening as a key differentiator when comparing materials. The tensile strength of cast iron tells only part of the story—it's the graphite structure within cast iron that absorbs energy and prevents vibration from transferring through the die set into your parts and press.

How We Weighted Each Evaluation Criterion

Not every factor carries equal importance across all applications. A high-volume blanking operation prioritizes different properties than a precision forming shop. Here's how we weighted each criterion based on general stamping requirements:

| Evaluation Criterion | Weight | Why It Matters for Stamping |

|---|---|---|

| Vibration Dampening | 25% | Reduces part defects, extends press life, and improves surface finish quality |

| Dimensional Stability | 25% | Maintains die alignment and ensures consistent part dimensions across production runs |

| Wear Resistance | 20% | Determines maintenance intervals and overall die set lifespan |

| Machinability | 15% | Affects initial manufacturing precision and repair ease during maintenance |

| Total Cost of Ownership | 15% | Balances upfront investment against long-term operational expenses |

Understanding the cast iron yield strength and iron hardness values helps predict wear patterns, but ultimate strength of cast iron—often expressed as UTS of cast iron—indicates how the material handles peak forming loads. These metal type strengths directly influence which applications suit each material best.

Production volume thresholds play a crucial role in material recommendations. For runs exceeding 500,000 parts annually, the superior dampening of gray cast iron often justifies its higher initial cost. Lower volumes may favor steel options that offer acceptable performance at reduced upfront investment. The cast iron tensile strength limitations matter less when vibration control drives your quality outcomes.

With this evaluation framework established, let's examine how each die set material ranks across these critical performance factors—starting with precision steel solutions designed for the most demanding applications.

Precision Steel Die Sets with CAE Simulation Support

When automotive OEMs demand consistent quality across millions of stamped components, precision steel die sets emerge as the clear frontrunner. These aren't your standard fabricated steel assemblies—they're engineered solutions backed by advanced computer-aided engineering that predicts and prevents defects before the first production hit.

In the ongoing debate of cast iron vs steel die sets, precision steel claims the top ranking for applications where dimensional accuracy and certification requirements leave zero room for compromise. Let's explore why this material leads our rankings for demanding stamping operations.

Why Precision Steel Leads for Automotive Stamping

Automotive stamping operates in a world of microns and milliseconds. Your stamping die set must deliver identical parts whether you're on hit number 100 or hit number 1,000,000. Precision steel die sets excel here because the material offers exceptional dimensional stability under the sustained loading cycles that automotive production demands.

Consider what happens during a typical progressive die operation. Each station performs a specific forming, piercing, or blanking function—and alignment between stations must remain perfect throughout the production run. Steel's consistent elastic behavior means your die set returns to its exact starting position after every cycle, maintaining the precise relationships between die components that complex automotive parts require.

IATF 16949 certification has become the entry ticket for automotive tooling suppliers. This quality management standard ensures that every aspect of die set design, manufacturing, and validation follows documented procedures traceable to specific performance requirements. When you're producing cast steel parts or any precision-stamped component for major automakers, working with certified suppliers eliminates the quality uncertainty that can derail production launches.

The CAE Simulation Advantage in Modern Die Sets

Here's where modern precision steel die sets truly separate themselves from conventional tooling. Computer-aided engineering simulation allows engineers to virtually test die designs before committing to physical production. They can predict material flow, identify potential thinning or splitting zones, and optimize forming sequences—all before machining a single piece of tool steel.

Think about the traditional approach: build the die, run trial parts, identify problems, modify the tooling, repeat. Each iteration costs time and money. CAE simulation compresses this cycle dramatically by resolving issues in the digital environment where changes cost nothing but engineering hours.

Advanced simulation also enables optimization that simply wasn't possible with trial-and-error methods. Engineers can test dozens of blank holder pressure profiles or draw bead configurations in hours rather than weeks. The result? Dies that work right the first time, with first-pass approval rates that seemed impossible a generation ago.

Manufacturers like Shaoyi exemplify this modern approach to precision steel die sets. Their engineering team combines IATF 16949-certified processes with advanced CAE simulation to achieve a 93% first-pass approval rate—a remarkable figure that translates directly into shorter development cycles and faster production ramps. With rapid prototyping capabilities delivering initial tooling in as little as 5 days, they demonstrate how precision steel solutions can accelerate rather than delay your production timeline.

The precision required for these dies often demands sophisticated equipment. A milling machine with CNC control enables the tight tolerances that steel die components require, while comprehensive tooling like a quality drill set ensures proper hole placement for guide pins and fasteners.

Key Advantages of Precision Steel Die Sets

When evaluating precision steel against other die set materials, several distinct benefits emerge:

- Dimensional accuracy: Steel's predictable behavior under load ensures consistent part dimensions across extended production runs

- Engineering support: Precision steel suppliers typically offer design assistance, simulation services, and troubleshooting expertise

- Quality certification: IATF 16949 and other automotive certifications provide documented quality assurance that OEMs require

- Fast turnaround: Advanced manufacturing methods enable rapid prototyping and shortened development timelines

- Modification flexibility: Steel die sets can be welded, re-machined, and adjusted more readily than cast alternatives

Ideal Applications for Precision Steel Die Sets

Not every stamping operation needs precision steel—but certain applications absolutely demand it. Consider precision steel die sets when your operation involves:

- Progressive dies: Multi-station tooling where alignment between stations directly impacts part quality

- Complex forming operations: Deep draws, compound curves, or sequential forming that requires precise material control

- Tight-tolerance automotive components: Parts with dimensional requirements measured in hundredths of a millimeter

- High-strength steel stamping: Advanced materials that impose significant loads on die components

- Safety-critical parts: Components where quality failures create liability or recall risks

The casted steel components in precision die sets undergo rigorous inspection and heat treatment to ensure consistent performance. Unlike steel building kits that prioritize economy over precision, automotive-grade die sets represent the pinnacle of steel tooling technology.

While precision steel die sets command premium pricing, the total cost picture often favors them for demanding applications. Fewer tryout iterations, higher first-pass rates, and reduced scrap during production ramp-up offset the initial investment. When your application demands certified quality and engineering support, precision steel delivers unmatched value.

But what about high-volume blanking operations where vibration dampening matters more than dimensional precision? That's where gray cast iron enters the picture—and earns its own top ranking for a different set of requirements.

Gray Cast Iron Die Sets for High-Volume Blanking

When your stamping press hammers away at thousands of blanking cycles per hour, something interesting happens. The die set becomes more than just a tool holder—it becomes a vibration management system. This is precisely where gray cast iron die sets claim their rightful place at the top of the rankings for high-volume operations.

In the cast iron vs steel die sets comparison, gray iron earns its premier position through metallurgical properties that steel simply cannot replicate. Let's examine why experienced stamping engineers consistently choose gray cast iron for their most demanding blanking applications.

Gray Iron's Unmatched Vibration Dampening for Heavy Stamping

What makes gray iron so exceptional at absorbing the brutal shock loads of high-speed blanking? The answer lies within its unique microstructure. By cast iron definition, gray iron contains graphite in flake form distributed throughout the metal matrix. These graphite flakes act like millions of tiny shock absorbers, dissipating vibrational energy that would otherwise transfer through your die set into the press and—ultimately—into your parts.

Consider what happens during a blanking operation. The punch contacts the material, shear forces build rapidly, and then—snap—the blank separates. That sudden release creates a shock wave that travels through the entire tooling system. In a steel die set, this energy bounces around with minimal absorption. In gray iron casting, those graphite flakes convert mechanical energy into heat, dramatically reducing transmitted vibration.

The properties of cast iron material extend beyond dampening. Gray iron's graphite structure provides natural lubricity that reduces galling between sliding components. Guide pins moving through bushings experience less friction and wear. This self-lubricating characteristic means your die set requires less maintenance and delivers more consistent performance across extended production runs.

Machinability represents another significant advantage. The same graphite that provides dampening also makes gray iron exceptionally easy to machine. Cutting tools glide through the material, producing excellent surface finishes without the work hardening that complicates steel machining. When you need precise fitting of die components—and you always do—gray iron cooperates rather than fights back.

When Production Volume Justifies Gray Cast Iron Investment

Gray cast iron die sets cost more upfront than basic steel alternatives. So when does the investment make sense? The answer depends on your production volumes and quality requirements.

Operations exceeding 500,000 cycles annually typically see the vibration dampening benefits compound into substantial savings. Reduced press wear, fewer part quality issues, and extended die life offset the higher initial cost. For blanking operations running into the millions of cycles, gray iron becomes not just preferable but essential for sustainable production.

The cast iron material properties that make gray iron excel also dictate its ideal configurations. Four-post die sets for blanking leverage gray iron's mass and stability, providing the rigid foundation that heavy blanking operations demand. Large progressive die shoes benefit from gray iron's thermal stability—the material maintains dimensional consistency even as production heat builds during extended runs.

Pros of Gray Cast Iron Die Sets

- Superior vibration dampening: Graphite flake structure absorbs shock loads that would transmit through steel

- Thermal stability: Maintains dimensional accuracy as operating temperatures fluctuate during production

- Cost-effective for large die shoes: Material and machining costs scale favorably for bigger components

- Self-lubricating properties: Reduces galling and extends guide component life

- Excellent machinability: Allows precise fitting and straightforward maintenance modifications

Cons of Gray Cast Iron Die Sets

- Brittleness under shock loads: Is cast iron brittle? Yes—gray iron lacks the ductility to absorb sudden impact without risk of fracture

- Heavier weight: Die sets require more robust handling equipment and impose greater loads on press bolsters

- Limited tensile strength: Cannot handle the same peak loads as steel without risking failure

- Fracture risk: Cast iron may crack or shatter when it is subjected to sudden, severe impact loading

The brittleness factor deserves careful consideration. Gray iron excels at absorbing repetitive vibration, but it cannot flex under sudden overload the way steel can. If your operation risks die crashes or accidental overloading, this characteristic demands attention in your material selection process.

Ideal Applications for Gray Cast Iron Die Sets

Gray iron's unique properties of cast iron material align perfectly with specific stamping scenarios:

- Four-post die sets for blanking: Maximum stability and vibration control for high-speed blanking operations

- Large progressive die shoes: Thermal and dimensional stability across extended production cycles

- High-volume production: Operations exceeding 500,000 annual cycles where dampening benefits accumulate

- Precision blanking: Applications where vibration-induced quality variations create scrap or rework

- Heavy-gauge material stamping: Operations generating significant shock loads during material separation

When your blanking operation demands the ultimate in vibration control and you're running volumes that justify premium tooling, gray cast iron delivers performance that steel alternatives simply cannot match. The material has earned its reputation among stamping professionals for good reason.

But what if you need more toughness than gray iron provides while still wanting better dampening than steel? That's where ductile iron enters the conversation—offering a compelling middle ground for applications that don't fit neatly into either category.

Ductile Iron Die Sets for Balanced Performance

What happens when you need more toughness than gray iron offers but still value the vibration dampening that steel lacks? You turn to ductile iron—also known as SG iron or nodular iron. This material occupies a strategic middle ground in the cast iron vs steel die sets debate, combining characteristics from both material families in ways that solve specific manufacturing challenges.

Understanding the difference between sg iron and cast iron (specifically gray iron) starts with examining what happens at the microscopic level. While gray iron features graphite in flake form, ductile iron contains graphite shaped into tiny spheroids or nodules. This seemingly small structural change creates dramatically different mechanical behavior—and opens up applications where neither gray iron nor steel quite fits the bill.

Ductile Iron Bridges the Gap Between Strength and Dampening

Think about the challenge many stamping operations face. Gray iron excels at absorbing vibration but can fracture under sudden impact. Steel handles shock loads well but transmits every vibration directly through the die set. What if your application involves moderate forming forces with occasional shock loading? Neither extreme works perfectly.

Ductile iron's nodular graphite structure provides the answer. Those spheroidal graphite particles still absorb vibrational energy—just not quite as effectively as gray iron's flakes. However, the rounded shape eliminates the stress concentration points that make gray iron brittle. The result? A material that bends rather than breaks when overloaded, while still offering meaningful dampening benefits.

The difference between cast iron and cast steel becomes most apparent when you examine how each responds to impact. Steel deforms plastically under excessive load. Gray cast iron fractures with little warning. Ductile iron behaves more like steel in this regard—it can absorb unexpected impacts without catastrophic failure while retaining much of the cast iron family's signature vibration absorption.

When comparing cast iron cast steel properties in die set applications, ductile iron consistently delivers tensile strength values two to three times higher than gray iron. Yield strength follows a similar pattern. This strength advantage means ductile iron die sets can handle forming operations that would stress gray iron beyond its limits.

When SG Iron Outperforms Both Gray Iron and Steel

The sg iron vs cast iron comparison reveals specific scenarios where ductile iron emerges as the clear winner. Consider forming operations—draws, bends, and shapes that impose sustained loading rather than the sudden shock of blanking. These applications generate less vibration than blanking but still benefit from some dampening. They also require die sets that can handle the sustained stress of metal flowing under pressure.

Two-post die sets for forming operations represent an ideal application for ductile iron. The material's combination of strength and dampening suits the loading profile perfectly. You get enough vibration absorption to protect part quality and press components, plus the toughness to handle forming forces without risking fracture.

Medium-volume production runs often favor cast iron steel hybrids like ductile iron. At volumes between 100,000 and 500,000 annual cycles, you need performance beyond what mild steel delivers but may not require gray iron's ultimate dampening capability. Ductile iron hits this sweet spot economically and mechanically.

Pros of Ductile Iron Die Sets

- Higher tensile and yield strength: Approximately two to three times stronger than gray iron, enabling use in more demanding applications

- Good machinability: While slightly more challenging than gray iron, still machines well compared to steel alternatives

- Better shock resistance: Nodular graphite structure allows plastic deformation rather than brittle fracture under impact

- Moderate vibration dampening: Retains meaningful absorption characteristics despite the structural changes

- Improved fatigue life: Handles cyclic loading better than gray iron over extended production runs

Cons of Ductile Iron Die Sets

- More expensive than gray iron: Higher material and processing costs increase initial investment

- Less dampening than gray iron: Nodular structure sacrifices some vibration absorption for strength gains

- Requires more precise heat treatment: Achieving optimal properties demands careful metallurgical control during production

- Limited availability: Fewer foundries specialize in precision ductile iron castings compared to gray iron

Ideal Applications for Ductile Iron Die Sets

When does ductile iron make the most sense for your operation? Consider this material when your stamping application involves:

- Two-post die sets for forming: Applications where forming forces require strength beyond gray iron's capability

- Medium-volume production: Runs between 100,000 and 500,000 cycles annually that benefit from balanced properties

- Moderate shock loading: Operations with occasional impact events that would risk gray iron fracture

- Drawing operations: Deep draws and complex forms where sustained loading dominates over sudden shock

- Progressive dies with forming stations: Tooling combining blanking and forming where different stations face different loading conditions

The difference between cast iron and cast steel becomes less about choosing one or the other and more about recognizing that ductile iron offers a legitimate third path. For operations caught between gray iron's dampening and steel's toughness, SG iron delivers a balanced solution worth serious consideration.

Of course, some applications demand neither dampening nor balanced performance—they require maximum wear resistance above all else. That's where tool steel die sets enter the picture, commanding premium prices for extreme durability.

Tool Steel Die Sets for Maximum Wear Resistance

Some stamping applications punish tooling in ways that ordinary materials simply cannot withstand. When you're stamping abrasive high-strength steels, maintaining tolerances measured in microns, or pushing production runs into the tens of millions—standard die set materials reach their limits. This is where tool steel die sets justify their premium price tag.

In the steel vs cast iron debate, tool steel represents the extreme end of the hardness and wear resistance spectrum. What is stronger iron or steel? When it comes to resisting the grinding abrasion of advanced materials, tool steel wins decisively. Let's explore when investing in this premium material makes sound economic sense.

Tool Steel Die Sets for Extreme Wear Applications

Imagine stamping advanced high-strength steel automotive panels—materials with tensile strengths exceeding 1,000 MPa that would rapidly erode conventional tooling. Or picture a production run targeting 10 million blanks where every thousandth of an inch matters. These scenarios demand die set materials engineered for punishment.

Tool steel earns its reputation through carefully controlled metallurgy. Unlike standard carbon steels, tool steels contain precisely balanced alloys—chromium, molybdenum, vanadium, and tungsten—that form extremely hard carbide structures within the steel matrix. These carbides resist abrasive wear far better than anything the cast iron family offers.

The iron vs steel strength comparison becomes particularly relevant when discussing wear mechanisms. While cast iron's graphite structure excels at absorbing vibration, those same graphite inclusions create softer zones that abrasive materials attack. Tool steel presents a uniformly hard surface that resists material removal cycle after cycle.

Heat treatment flexibility represents another key advantage. You can specify tool steel die components at different hardness levels depending on their function. Wear surfaces might reach 60-62 HRC, while areas requiring toughness stay at 50-54 HRC. This tailored approach optimizes performance across the entire die set.

The Premium Choice for Abrasive Material Stamping

When does the significantly higher cost of tool steel actually pay off? Consider these specific scenarios where steel vs iron strength differences translate into real production advantages:

Stamping abrasive materials: Advanced high-strength steels, stainless steels, and materials with scale or surface coatings accelerate wear on conventional tooling. Tool steel's carbide-rich structure resists this abrasion, extending die life dramatically compared to softer alternatives.

Extremely tight tolerances: When your dimensional requirements leave zero margin for wear-induced drift, tool steel maintains cutting edges and forming surfaces across production volumes that would degrade other materials. Aerospace components often fall into this category.

Die set longevity as priority: Some applications justify maximum upfront investment to minimize changeovers and maintenance interventions. When production interruptions cost more than tooling premiums, tool steel makes economic sense.

For the most demanding applications, some manufacturers specify tungsten carbide inserts at critical wear points. While even more expensive than tool steel, tungsten carbide offers wear resistance approaching that of diamond—extending die life in applications where tool steel alone cannot survive.

Pros of Tool Steel Die Sets

- Exceptional wear resistance: Carbide-forming alloys create surfaces that resist abrasion from the most demanding materials

- Maintains precision over millions of cycles: Dimensional stability throughout extended production runs that would wear out softer materials

- Heat treatable for specific hardness: Customizable properties allow optimization for different die set components and applications

- Superior edge retention: Cutting and piercing components stay sharp far longer than standard steel alternatives

- Predictable wear patterns: Uniform hardness means consistent, manageable wear rather than unexpected failures

Cons of Tool Steel Die Sets

- Highest material cost: Premium alloys and specialized heat treatment significantly increase initial investment

- More difficult to machine: High hardness requires specialized cutting tools, slower speeds, and greater machining expertise

- Less vibration dampening than cast iron: Dense, uniform structure transmits rather than absorbs shock loads

- Repair complexity: Welding and modification require specialized procedures to maintain metallurgical integrity

- Longer lead times: Specialized materials and processing extend production schedules compared to conventional options

Ideal Applications for Tool Steel Die Sets

Tool steel's premium pricing means you should reserve it for applications where its unique properties deliver measurable returns. Consider tool steel die sets when your operation involves:

- Precision blanking dies: Applications where cutting edge sharpness directly impacts part quality and burr formation

- Stamping high-strength steels: Advanced automotive materials that rapidly wear conventional tooling

- Aerospace component production: Parts where tolerance specifications and material traceability justify premium tooling

- Ultra-high volume production: Runs exceeding 5-10 million cycles where die longevity becomes the dominant cost factor

- Abrasive material stamping: Coated materials, stainless steels, or parts with scale that accelerate wear

The what is stronger iron or steel question finds its clearest answer in tool steel applications. While cast iron offers superior dampening and gray iron excels at vibration absorption, nothing matches properly heat-treated tool steel for resisting the grinding abrasion that destroys other materials.

Of course, not every operation needs—or can justify—tool steel's premium pricing. For prototype work and short production runs, a more economical approach often makes better business sense. That's where mild steel die sets enter the conversation.

Mild Steel Die Sets for Budget-Conscious Operations

What if you're developing a new part and need tooling fast—without committing significant capital before validating the design? Or perhaps you're running a short production batch that doesn't justify premium materials? This is where mild steel die sets earn their place in the cast iron vs steel die sets conversation.

Mild steel won't outperform gray iron in dampening or match tool steel's wear resistance. But it delivers something equally valuable for the right applications: accessibility. When budget constraints drive decisions and flexibility matters more than longevity, mild steel offers a practical path forward.

Mild Steel Die Sets for Prototyping and Short Runs

Understanding the difference between steel and cast iron becomes especially relevant during product development phases. You're iterating designs, testing concepts, and refining geometry. Investing in premium die set materials at this stage often makes little sense—you might modify or scrap the tooling after just a few hundred parts.

Mild steel excels here because it machines quickly and modifies easily. Need to relocate a guide pin? Weld up the existing hole and redrill. Discover that your forming geometry needs adjustment? Mild steel accepts modifications that would be impractical or impossible with hardened tool steel or brittle cast iron.

The question of which is stronger iron or steel misses the point for prototype applications. Strength matters less when you're running dozens or hundreds of parts rather than millions. What matters is getting functional tooling into your press quickly so you can validate designs and move forward.

Is cast iron steel? No—they're fundamentally different materials. But for short-run applications, mild steel provides adequate performance at a fraction of the cost. You're trading longevity for accessibility, and that trade-off makes perfect sense when tooling won't see extended production use.

When Budget Constraints Make Mild Steel the Smart Choice

Every manufacturing operation faces resource constraints. Capital tied up in premium die sets can't fund other improvements. Mild steel die sets free up budget for the applications where premium materials actually deliver returns.

Consider production runs under 50,000 parts. At these volumes, the superior wear resistance of tool steel or the dampening benefits of cast iron rarely justify their higher costs. The die set will likely become obsolete due to design changes before it wears out from production use.

The cast iron and steel comparison reveals another practical consideration: lead time. Mild steel die sets ship faster because the material is readily available and machines without specialized tooling or heat treatment. When market windows demand rapid response, mild steel gets you producing while competitors wait for premium materials.

Pros of Mild Steel Die Sets

- Lowest initial cost: Material and machining expenses run significantly below cast iron or tool steel alternatives

- Readily available: Standard material grades stock at every steel supplier, eliminating sourcing delays

- Easy to machine and modify: Conventional tooling and standard shop practices handle all manufacturing operations

- Weldable and repairable: Modifications and repairs use straightforward welding procedures without special processes

- Fastest lead times: No foundry casting or specialized heat treatment extends your production schedule

Cons of Mild Steel Die Sets

- Faster wear: Lower hardness means guide surfaces and mounting areas degrade more quickly under production cycling

- Less dimensional stability: Material may shift or distort under repeated loading, affecting alignment over time

- Requires more frequent replacement: Shorter service life means higher long-term costs for extended production applications

- Poor vibration dampening: Transmits shock loads directly through the die set into press and parts

- Limited heat treatment options: Cannot achieve the hardness levels that extend life in demanding applications

Ideal Applications for Mild Steel Die Sets

Mild steel makes sense when circumstances favor speed and flexibility over ultimate performance. Consider this material when your situation involves:

- Prototype die sets: Initial tooling for design validation before committing to production-grade materials

- Short production runs: Batches under 50,000 parts where tooling cost dominates total part economics

- Frequent design changes: Products still evolving where tooling modifications occur regularly

- Secondary operations: Auxiliary tooling for operations that don't justify premium investment

- Training and setup: Die sets for operator training or process development where production quality isn't critical

The difference between cast iron and steel becomes most apparent over extended production. For short-term applications, mild steel delivers acceptable performance at accessible pricing. The key is matching material choice to application requirements—not over-engineering tooling for jobs that don't demand premium solutions.

With all die set material options now evaluated individually, how do you synthesize this information into clear decisions for your specific applications? The next section consolidates everything into a comprehensive comparison matrix designed for quick reference.

Complete Die Set Material Comparison Matrix

You've explored each material's strengths and limitations individually. Now comes the practical question: which one actually fits your operation? Rather than forcing you to flip between sections, this comparison consolidates everything into decision-ready formats you can reference whenever material selection questions arise.

Understanding what is the difference between cast iron and steel—and more specifically, what is the difference between cast iron and cast steel—becomes straightforward when you see the options side by side. Let's cut through the complexity with a direct comparison.

Side-by-Side Performance Comparison Across All Materials

This table captures the essential performance characteristics that determine which material suits your stamping application. Notice how the cast iron and steel difference shows up across multiple dimensions—not just strength, but dampening, cost, and optimal configurations.

| Material Type | Vibration Dampening | Wear Resistance | Cost Range | Best Die Set Configuration | Ideal Production Volume |

|---|---|---|---|---|---|

| Precision Steel | Low | High | $$-$$$ | Two-post, back-post for progressive dies | 100K-5M+ cycles |

| Gray Cast Iron | Excellent | Moderate | $$ | Four-post for blanking, large die shoe applications | 500K+ cycles |

| Ductile Iron | Good | Moderate-High | $$-$$$ | Two-post for forming operations | 100K-500K cycles |

| Tool Steel | Low | Excellent | $$$$ | Precision blanking, any configuration | 5M+ cycles |

| Mild Steel | Low | Low | $ | Any configuration for short runs | Under 50K cycles |

The die plate and die shoe components within each configuration interact differently depending on material choice. Gray iron die shoes excel at absorbing the repetitive shock of blanking, while precision steel die plates maintain the dimensional relationships that progressive dies demand.

Matching Die Set Material to Your Specific Operation

Which is stronger steel or iron? That depends entirely on what strength means for your application. Tensile strength favors steel. Vibration absorption favors cast iron. The real question isn't which material is universally better—it's which one solves your specific problem.

Use this decision framework to match materials to operations:

- Choose gray cast iron if: Your operation prioritizes vibration dampening, you're running high-volume blanking exceeding 500,000 annual cycles, you need thermal stability for large die shoes, or surface finish quality depends on minimizing transmitted shock.

- Choose precision steel if: Your application demands IATF 16949 certification, you're producing complex automotive components with tight tolerances, you need engineering support and CAE simulation backing, or your progressive dies require absolute dimensional consistency between stations.

- Choose ductile iron if: Your forming operations need more toughness than gray iron provides, you're running medium volumes between 100,000 and 500,000 cycles, your application involves occasional shock loading that would risk gray iron fracture, or you need balanced dampening and strength characteristics.

- Choose tool steel if: You're stamping abrasive high-strength materials, tolerances must hold across tens of millions of cycles, wear resistance justifies premium investment, or you're producing aerospace components with stringent requirements.

- Choose mild steel if: You're prototyping designs before committing to production tooling, production runs stay under 50,000 parts, budget constraints outweigh longevity concerns, or you need fast lead times and modification flexibility.

Matching Materials to Stamping Operations

Beyond production volumes, the type of stamping operation influences material selection. Here's how different operations align with material choices:

Blanking operations: The sudden shear and shock of material separation demands excellent vibration dampening. Gray cast iron dominates here, with its graphite flake structure absorbing energy that would otherwise transfer into your press and parts. For extreme volumes or abrasive materials, tool steel die components at cutting edges extend service life.

Forming operations: Draws, bends, and shapes impose sustained loading rather than sudden shock. Ductile iron's combination of strength and moderate dampening suits these applications well. Precision steel works for complex automotive forms where dimensional accuracy matters more than vibration control.

Drawing operations: Deep draws stress die sets differently than blanking—the material flows under continuous pressure rather than separating suddenly. Ductile iron handles these sustained forces while still providing some dampening benefit. Precision steel excels when draw depth and wall thickness tolerances drive quality requirements.

Progressive dies: Multi-station tooling combines blanking, piercing, and forming in a single die set. This mixed loading profile often favors precision steel for the die plate structure—maintaining station alignment—while individual stations may incorporate different materials based on their specific functions.

The right material choice balances your operation's technical requirements against economic realities. Premium materials pay dividends in demanding applications but waste resources when simpler solutions suffice. Match the material to the mission, and your die sets will deliver the performance your production demands.

Final Recommendations for Your Stamping Application

You've examined the technical properties, weighed the trade-offs, and compared materials across every critical dimension. Now comes the moment that matters most: translating this knowledge into decisions that improve your stamping operation. What is cast steel material best suited for? When does gray iron justify its investment? How do you use a die set selection process that consistently delivers results?

The answers depend on your specific manufacturing scenario. Let's synthesize everything into actionable recommendations you can apply immediately.

Your Die Set Material Decision Framework

After evaluating cast iron vs steel die sets across five performance dimensions, clear patterns emerge for different manufacturing contexts. Here's how to match your operation to the optimal material choice:

For automotive OEM work requiring certification and precision: Precision steel die sets with engineering support represent your best path forward. The combination of IATF 16949 certification, CAE simulation backing, and dimensional consistency across millions of cycles addresses everything automotive manufacturers demand. When your customer audits your tooling suppliers and expects documented quality systems, precision steel solutions from certified partners deliver both the performance and the paperwork you need.

Understanding how to use die set materials effectively means recognizing that automotive applications leave no room for compromise on quality systems. Your Tier 1 customers expect traceability, validated processes, and engineering support when problems arise.

For high-volume blanking operations: Gray cast iron remains the premier choice when vibration dampening drives your quality outcomes. Operations exceeding 500,000 annual cycles benefit from gray iron's exceptional shock absorption, thermal stability, and self-lubricating properties. The material's graphite flake structure does what steel simply cannot—it converts mechanical energy into heat rather than transmitting vibration into your parts and press.

Why is cast iron better for blanking? Because the sudden shear and shock of material separation creates exactly the kind of repetitive impact that gray iron absorbs most effectively. This isn't theoretical—it's why experienced stamping engineers consistently specify gray iron for their most demanding blanking applications.

For balanced forming applications: Ductile iron bridges the gap when your operation needs more toughness than gray iron provides but still values dampening that steel lacks. Medium-volume production between 100,000 and 500,000 cycles, forming operations with sustained loading, and applications with occasional shock events all favor ductile iron's balanced property profile.

For extreme wear resistance: Tool steel justifies its premium when you're stamping abrasive high-strength materials or targeting production runs in the tens of millions. What is cast steel compared to tool steel in these applications? Cast steel offers good general properties, but tool steel's carbide-rich structure resists abrasive wear at levels other materials cannot match.

For prototyping and short runs: Mild steel delivers accessibility when budget and lead time matter more than longevity. Reserve your premium material investments for production tooling—use mild steel to validate designs quickly and economically.

The right die set material isn't the strongest or most expensive option—it's the one that matches your specific application requirements while delivering the best total value across your production lifecycle.

Next Steps for Optimizing Your Stamping Tooling

Material selection represents just one element of die set optimization. The right engineering partner can maximize performance regardless of which material you choose. Here's how to move forward effectively:

Audit your current applications: Review your existing die sets against the decision framework above. Are you using premium materials where mild steel would suffice? Running gray iron in applications that demand precision steel? Identifying mismatches creates immediate optimization opportunities.

Quantify your requirements: Document production volumes, tolerance specifications, material types being stamped, and quality rejection rates. These specifics enable informed material selection rather than guesswork.

Engage qualified engineering support: Complex stamping applications benefit from partners who understand both material science and practical die design. CAE simulation, proper material specification, and manufacturing expertise combine to deliver tooling that performs from the first hit.

For manufacturers prioritizing precision steel solutions with full engineering backing, Shaoyi's automotive stamping die capabilities demonstrate what's possible when advanced simulation meets certified quality systems. Their 93% first-pass approval rate and rapid prototyping in as little as 5 days show how the right partner accelerates production rather than creating delays. When your application demands IATF 16949 certification and engineering expertise, working with specialists who deliver both makes the difference between tooling that struggles and tooling that performs.

Plan for the complete lifecycle: Initial material cost tells only part of the story. Factor in maintenance requirements, expected replacement intervals, and the production impact of any quality issues. Total cost of ownership often favors premium materials in demanding applications—but only when those applications actually demand premium performance.

The cast iron vs steel die sets decision ultimately comes down to honest assessment of what your operation actually requires. Match material properties to application demands, partner with qualified engineering support, and your stamping tooling will deliver the consistent performance your production depends on.

Frequently Asked Questions About Cast Iron vs Steel Die Sets

1. Which is better cast iron or steel for die sets?

Neither is universally better—the optimal choice depends on your application. Gray cast iron excels in high-volume blanking operations due to its superior vibration dampening from graphite flake structure. Steel die sets, particularly precision steel with CAE simulation support, lead for automotive stamping requiring tight tolerances and IATF 16949 certification. For forming operations needing balanced strength and dampening, ductile iron bridges both materials' benefits. Match your material to production volume, tolerance requirements, and shock loading conditions.

2. What is a disadvantage of cast iron die sets?

The primary disadvantage of gray cast iron die sets is brittleness under sudden shock loads. While the graphite flake structure provides excellent vibration dampening during normal operation, it creates stress concentration points that can cause cracking or shattering under unexpected impact. Cast iron die sets are also significantly heavier than steel alternatives, requiring more robust handling equipment. Additionally, gray iron has limited tensile strength compared to steel, restricting its use in applications with high peak forming loads.

3. What is the difference between cast iron and cast steel die sets?

Cast iron die sets contain graphite structures that absorb vibration and provide self-lubricating properties, making them ideal for high-volume blanking. Cast steel die sets offer higher tensile strength and better impact resistance, allowing them to bend under overload rather than fracture. Steel maintains tighter dimensional tolerances under sustained loading, while cast iron provides superior thermal stability. Steel die sets modify and weld more easily, whereas cast iron machines exceptionally well due to its graphite content acting as a natural lubricant.

4. When should I choose tool steel die sets over cast iron?

Choose tool steel die sets when stamping abrasive high-strength materials, maintaining micron-level tolerances across tens of millions of cycles, or producing aerospace components with stringent requirements. Tool steel's carbide-rich structure resists abrasive wear far better than cast iron's softer graphite inclusions. While tool steel costs significantly more and offers less vibration dampening, it justifies the investment when wear resistance and precision retention are paramount—particularly for advanced high-strength steel automotive panels or production runs exceeding 5-10 million cycles.

5. How do I choose the right die set material for my production volume?

For prototype work and runs under 50,000 parts, mild steel provides the most economical solution with fast lead times and easy modification. Medium volumes between 100,000-500,000 cycles suit ductile iron's balanced strength and dampening properties. High-volume blanking exceeding 500,000 annual cycles benefits from gray cast iron's superior vibration absorption. Precision steel with engineering support serves automotive OEM production requiring certification and tight tolerances. For ultra-high volumes over 5 million cycles stamping abrasive materials, tool steel's exceptional wear resistance delivers the best total value.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —