Carbon Fibre vs Aluminium: Strength, Weight, and Design Trade-Offs

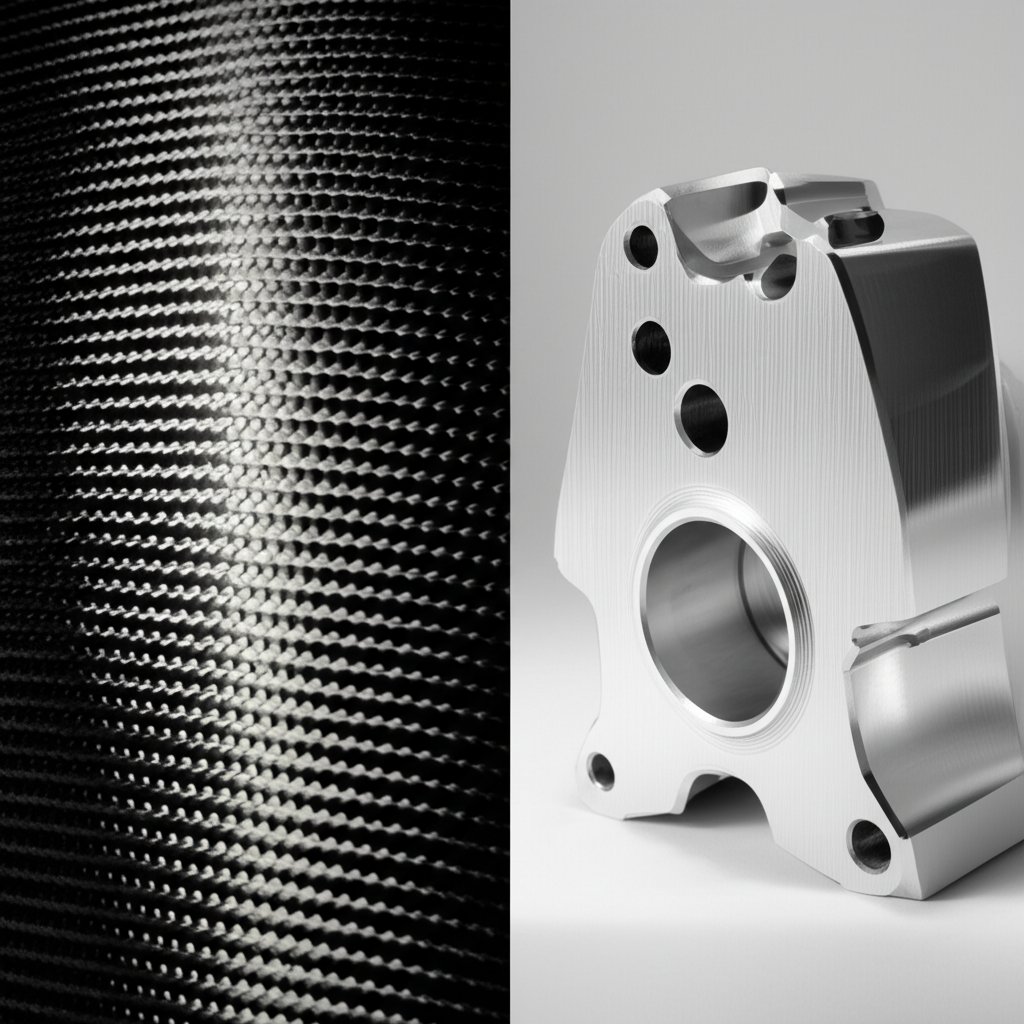

Foundations of Carbon Fibre and Aluminium

When you compare carbon fibre vs aluminium, you’re really weighing two very different material families—each with unique strengths, behaviors, and design implications. So, what makes engineers so often debate aluminum vs carbon fiber for everything from bike frames to aircraft wings? Let’s break it down with clear definitions and practical context.

What carbon fibre is made of

Imagine a bundle of ultra-strong, hair-thin carbon filaments, all embedded in a tough resin—this is what is known as a carbon fiber composite. Technically, what is carbon fiber composite? It’s a material where high-strength carbon fibers (made mostly from polyacrylonitrile or pitch) are combined with a polymer matrix, usually epoxy. The result is a lightweight, highly stiff structure with strength that depends on fiber type, orientation, and how well the fibers bond to the resin. These composites are not metals—so if you’ve ever wondered, is carbon fiber a metal? The answer is no; it’s a non-metallic composite material designed for specific performance needs (ScienceDirect).

How aluminium and its 6xxx alloys behave

Aluminium, on the other hand, is a metallic element that’s prized for its low density, ductility, and versatility. When alloyed with elements like magnesium and silicon—as in the popular 6xxx series (e.g., 6061)—it becomes even stronger and more useful for engineering applications. The properties of aluminium alloys are defined by their composition and heat treatment ("temper"), enabling precise control over strength, formability, and weldability (Wikipedia: 6061 Aluminium Alloy).

Anisotropy vs isotropy explained

Here’s where the real design trade-offs begin. Aluminium is considered isotropic: its mechanical properties—like strength and stiffness—are the same in all directions. That means you can predict how it will behave under any load, making it straightforward for engineers to design with confidence.

Carbon fibre composites, however, are anisotropic. Their properties vary depending on the direction of the fibers. Lay the fibers along the length of a bike frame, and you get maximum stiffness and strength in that direction—but much less across it. This directional behavior lets designers "tune" a part for specific loads, but it also means analysis and manufacturing are more complex. In the composite vs aluminum debate, this anisotropy is both a powerful tool and a challenge.

Choosing by performance not hype

So, how do you decide between aluminium vs carbon fibre for your application? It all comes down to matching the material to the job. Consider:

-

Material definitions:

– Carbon fiber composite: High-strength, lightweight, anisotropic material made from carbon filaments in a resin matrix.

– Aluminium alloy: Isotropic metal, properties controlled by alloying and temper. -

Typical use-cases:

– Carbon fibre: Aerospace fairings, high-end automotive panels, bike frames, sporting goods.

– Aluminium: Structural beams, automotive chassis, aircraft skins, general-purpose extrusions. -

Design implications:

– Carbon fibre: Tailorable stiffness, low weight, but requires careful layup and quality control.

– Aluminium: Predictable properties, tight tolerances, easier to form and machine, robust supply chains.

Composite layups can be tailored for directional stiffness, while aluminium delivers predictable isotropic behavior and tight tolerances.

In summary, carbon fibre vs aluminium is not about one being "better" than the other. It’s about understanding the science behind what is carbon fiber composite and how isotropic metals like aluminium behave, then choosing the best fit for your performance, cost, and manufacturing needs. As we move into measurable properties like strength, density, and cost, you’ll see how these foundational differences shape real-world decisions in automotive, aerospace, and cycling design.

Mechanical Properties That Drive Design Choices

When you’re sizing up carbon fibre vs aluminium for your next project, the numbers matter. But which numbers? And how do you translate those stats into real-world design? Let’s break down the most important mechanical properties—tensile strength, yield, modulus, and density—so you can make informed, apples-to-apples comparisons between these two engineering staples.

Tensile and Yield Fundamentals

Imagine you’re stretching a bike frame or loading an aircraft spar—tensile and yield strengths tell you how much load the material can bear before it stretches permanently or breaks. For carbon fiber tensile strength, unidirectional laminates tested along the fiber direction can reach values around 1220 MPa (megapascals), while cross-ply and quasi-isotropic layups show lower numbers, often between 360–860 MPa—all depending on fiber orientation, resin, and layup.

For 6061 aluminum yield strength, typical values for the T6 temper are about 276 MPa, with ultimate tensile strength around 310 MPa. The yield stress of aluminum 6061 t6 is well-documented and predictable, making it a go-to choice for designs needing reliable, repeatable performance.

Modulus and Stiffness Targets

Stiffness—how much a material resists bending or stretching—is governed by its modulus. Here’s where the tensile modulus of carbon fiber shines. In the fiber direction, carbon/epoxy laminates can reach Young’s modulus values of 98–115 GPa for unidirectional layups, while cross-ply and quasi-isotropic layups typically fall between 43–74 GPa.

Compare this to young's modulus for 6061-t6 aluminum, which is about 69–72 GPa—and crucially, this value is the same in every direction (isotropic). That means aluminium’s stiffness is easy to predict and design for, while carbon fiber’s stiffness depends on how you orient the fibers and build the laminate.

Density and Specific Strength Comparisons

Weight is often the deciding factor in carbon fiber vs aluminum debates. For carbon fiber density, typical values are 1.6–1.8 g/cm³, while density aluminum 6061 t6 is about 2.70 g/cm³ (Performance Composites). That’s a 30–40% weight savings for carbon fiber composites, before even optimizing the structure for directional strength.

But “specific strength”—strength divided by density—tells a more complete story. Carbon fiber’s high strength at low weight delivers exceptional specific strength, especially in unidirectional applications. Aluminium’s advantage is its consistent, well-understood behavior in all directions and under a wide range of loading conditions.

| Property | Carbon Fibre Composite* | 6061-T6 Aluminium | Units / Standard |

|---|---|---|---|

| Tensile Strength (0° UD) | ~1220 MPa | ~310 MPa | ASTM D3039 / ASTM E8 |

| Tensile Strength (Quasi-iso) | ~360–860 MPa | ~310 MPa | ASTM D3039 / ASTM E8 |

| Yield Strength | N/A (brittle, no yield) | ~276 MPa | ASTM D3039 / ASTM E8 |

| Young’s Modulus (0° UD) | 98–115 GPa | 69–72 GPa | ASTM D3039 / ASTM E111 |

| Young’s Modulus (Quasi-iso) | ~43–74 GPa | 69–72 GPa | ASTM D3039 / ASTM E111 |

| Density | 1.6–1.8 g/cm³ | 2.70 g/cm³ | ASTM D792 |

*Values depend strongly on fiber type, matrix, layup, and test direction.

Why Laminate Schedules Matter

Sounds complex? Here’s the key: with carbon fiber, the way you stack and orient the plies—known as the laminate schedule—dramatically changes the mechanical properties. A unidirectional layup delivers maximum performance in one direction, while cross-ply or quasi-isotropic layups sacrifice some peak strength for better performance in multiple directions (MDPI: Ogunleye et al.).

For aluminium, the story is simpler. The alloy and temper (like 6061-T6) define the mechanical properties, and the numbers you see on a datasheet apply in every direction. That’s why young's modulus of aluminum 6061 and 6061 aluminum yield strength are so widely used in engineering calculations.

-

Testing direction matters for composites:

- Properties are highest along the fiber direction (0° UD)

- Strength and stiffness drop off-axis or in multi-directional layups

-

Aluminium is isotropic:

- Properties are the same in all directions

- Design calculations are straightforward

“For carbon fibre, the stacking sequence and fiber orientation can be tailored for specific loads, but always check the test direction and layup details. For aluminium, rely on published values for your alloy and temper, and confirm with ASTM/ISO test standards.”

In summary, when comparing carbon fibre vs aluminium, you’ll notice that the mechanical properties you see on spec sheets are just the starting point. For composites, always specify the laminate schedule and test direction. For metals, confirm the alloy and temper. This sets you up for the next step: translating these numbers into practical weight and stiffness estimates for your real-world design.

Weight and Stiffness Sizing Made Simple

Ever wondered why a carbon fiber bike frame feels feather-light compared to an aluminum one? Or puzzled over how engineers estimate the weight and stiffness of a part before it’s ever built? Let’s walk through practical, repeatable steps for sizing and comparing carbon fiber vs aluminum weight, and see how these calculations shape real-world design choices.

Quick Weight Estimate Method

Imagine you’re designing a flat panel or a simple beam. To estimate how heavy is aluminum or carbon fiber for the same size part, you’ll need just two things: the material’s density and the part’s volume.

-

Calculate the part’s volume:

For a rectangular plate, that’s length × width × thickness. -

Find the material’s density:

- Aluminum (6061): about 2.7 g/cm³

- Carbon fiber composite: about 1.55–1.6 g/cm³ (typical for 70/30 fiber/resin layups)

-

Multiply volume by density: This gives the weight for each material. For example, a 1 m² panel at 6 mm thick:

- Volume = 1 m² × 0.006 m = 0.006 m³

- Weight (aluminum) = 0.006 m³ × 2,700 kg/m³ = 16.2 kg

- Weight (carbon fiber composite) = 0.006 m³ × 1,550 kg/m³ = 9.3 kg

So, for the same dimensions, carbon fiber is lighter than aluminum by about 42%.

That’s the basic workflow for answering, “how much does aluminum weigh” and “how much does carbon fiber weigh” for a given part size.

Stiffness Sizing Walkthrough

But weight isn’t everything—your part also needs to be stiff enough. Here’s a simple method for sizing thickness based on stiffness targets:

- Define your load case: What force or deflection must your part withstand?

- Select a safety factor and target maximum deflection.

-

Use the material’s modulus (stiffness):

- Aluminum 6061-T6: Young’s modulus ≈ 69–72 GPa

- Carbon fiber composite: Varies; for quasi-isotropic layups, 43–74 GPa; for unidirectional, up to 98–115 GPa

- Apply the beam or plate stiffness formula: For a simply supported beam, deflection δ = (Load × Length³) / (48 × Modulus × Moment of Inertia). For a plate, similar formulas apply.

- Iterate thickness: Increase thickness until calculated deflection is within your target. For carbon fiber, remember to align fibers with the primary load for best results.

Match stiffness in the load direction for composites; check buckling for thin aluminium sections.

When Aluminium Wins on Size

While carbon fiber often wins on weight, aluminum can sometimes be the better choice when:

- You need very thin walls (aluminum extrusions can be made reliably thin, while carbon fiber has minimum ply counts)

- The load is multi-directional and isotropic properties are a must

- Manufacturing constraints or joining requirements favor metal

-

Common pitfalls to avoid:

- Ignoring off-axis loads in composites (stiffness drops fast away from fiber direction)

- Overlooking fastener-bearing and edge stresses

- Assuming all carbon fiber layups are equally light—resin-rich or thick laminates can add weight

- Not accounting for manufacturability: carbon fiber needs minimum ply counts; aluminum extrusions have minimum wall thicknesses

In summary, estimating the weight of carbon fiber vs aluminum is straightforward with density and volume, but matching stiffness and manufacturability requires careful attention to layup, thickness, and structural geometry. As you move from “pencil math” to a viable design, remember: always validate your estimates with real material samples and consider manufacturing constraints early. Next, we’ll look at how production realities—like forming, joining, and tolerances—shape your final material choice.

Manufacturing Methods and Trade-Offs

When you’re weighing carbon fibre vs aluminium for your next part, it’s not just about material specs—it’s about how each is made, and what that means for cost, quality, and speed. Ever wondered why a carbon fiber composite sheet can be so expensive, or why aluminum extrusions dominate in mass production? Let’s break down the real-world manufacturing methods that drive your design—and your bottom line.

Composite Layups and Curing Options

Imagine you’re building a custom bike frame or a race car panel. Carbon fiber composite manufacturing starts with laying up sheets or fabrics of carbon fiber, saturating them with resin, and then curing them into a solid, lightweight part. But the method you choose changes everything:

| Method | Tolerance Capability | Tooling Cost | Cycle Time / Sensitivities | Common Defects |

|---|---|---|---|---|

| Hand Layup / Open Molding | Low (±1–2 mm) | Low | Long cure, room temp | Voids, resin-rich zones |

| Vacuum Bagging / Infusion | Moderate (±0.5–1 mm) | Moderate | Moderate, sensitive to leaks | Voids, dry spots, warping |

| Autoclave Cure (Prepreg) | High (±0.2–0.5 mm) | High | Long, high temp/pressure | Delamination, porosity |

| Resin Transfer Molding (RTM) | High (±0.2–0.5 mm) | High | Moderate, resin flow control | Incomplete fill, voids |

Hand layup is perfect for prototypes or unique shapes but comes with looser tolerances and longer cycle times. Vacuum bagging and infusion improve fiber compaction and reduce voids, making them ideal for medium-volume, complex parts. Autoclave curing—often used for aerospace-grade carbon fiber composite sheets—delivers the best consistency and strength, but at a much higher cost and longer lead times.

Extrusion, Machining, and Welding for Aluminium

Switch gears to aluminum, and the story is about speed, precision, and scalability. The most common route for 6xxx alloys like 6061 is extrusion—forcing heated aluminum through a shaped die to create long, consistent profiles. Need a custom bracket or enclosure? CNC machining carves complex shapes from billet or extruded stock with tight tolerances. Welding and forming let you join or bend aluminum into finished assemblies.

| Method | Tolerance Capability | Tooling Cost | Cycle Time / Sensitivities | Common Defects |

|---|---|---|---|---|

| Extrusion | High (±0.1–0.5 mm) | Moderate | Fast, die wear, temp-sensitive | Distortion, surface lines |

| CNC Machining | Very High (±0.02–0.1 mm) | Low per part, high for complex | Fast, tool wear, chip control | Tool marks, burrs |

| Welding | Moderate (±0.5–1 mm) | Low | Fast, heat-affected zone | Distortion, cracks |

| Forming / Bending | Moderate (±0.5–1 mm) | Low | Fast, springback | Wrinkling, thinning |

Aluminum’s 6061 tensile strength and 6061 t6 aluminum shear modulus remain stable through forming and machining, but welding can reduce local strength. The aluminum melting point 6061 (about 580–650°C) also sets limits for joining and heat treatment.

Joining and Bonding Choices

How do you assemble your parts? For carbon fiber, adhesives and mechanical fasteners are common, but require careful design to avoid crushing the laminate. Specialized bonding is often used for carbon fiber veneer trims and panels. For aluminum, welding, riveting, and bolting are proven, scalable methods—just keep an eye on heat input and joint design to preserve strength.

Defects, Tolerances, and Lead Times

Sounds complex? Here’s a quick scan of what can go wrong and how to catch it early:

-

Carbon Fiber Composite Manufacturing:

- Voids and porosity from poor resin flow or trapped air

- Delamination from improper cure or impact

- Dimensional warping from uneven cure or fiber tension

- Inspection cues: tap tests, ultrasound, visual checks for surface finish

-

Aluminum Processing:

- Distortion from forming or welding heat

- Cracks at welds or sharp corners

- Surface defects from die wear or poor machining

- Inspection cues: dye penetrant for welds, dimensional checks, hardness tests

“Manufacturing isn’t just about making a shape—it’s about hitting the right tolerances, minimizing defects, and keeping your project on schedule and on budget.”

In short, the choice between carbon fiber composite sheet and aluminum isn’t just about performance specs. It’s about process realities: how fiber orientation, resin system, and cure cycle affect quality and repeatability for composites, and how die design, chip control, and thermal management steer aluminum outcomes. Always check process capability charts, validate with coupons, and consult supplier datasheets to ensure your design survives the leap from CAD to production floor. Next up, we’ll explore how these manufacturing choices play out over the life of your part—through fatigue, environment, and maintenance.

Durability, Fatigue, and Environmental Performance

Fatigue and Long-Term Stress: How Each Material Holds Up

When you’re designing for the long haul, the question isn’t just “is carbon fiber stronger than aluminum?”—it’s how each material stands up to years of vibration, loading, and environmental exposure. Let’s dig into how carbon composites and aluminum behave under repeated stress and real-world conditions.

-

Carbon Fibre Pros (Fatigue & Environment):

- Exceptional fatigue resistance in fiber direction—critical for aerospace and automotive parts under cyclic loading.

- Does not rust; immune to traditional red-oxide corrosion, answering the common question: does carbon fiber rust? Not in the way metals do.

- Highly resistant to most chemicals and environmental degradation.

- Low carbon fiber thermal expansion; dimensional stability across a wide temperature range.

-

Carbon Fibre Cons (Fatigue & Environment):

- Matrix (resin) can degrade with prolonged UV, moisture, or heat exposure—especially if not properly protected.

- Susceptible to impact delamination and damage in resin-rich or off-axis zones.

- Fatigue life is excellent along the fiber, but joints, cutouts, and resin-dominated regions can limit durability.

-

Aluminium Pros (Fatigue & Environment):

- Predictable fatigue behavior; well-understood crack initiation and growth patterns.

- Resists many corrosive environments, especially with protective coatings or anodizing.

- Stable mechanical properties across a wide range of temperatures.

-

Aluminium Cons (Fatigue & Environment):

- Can corrode, especially in saltwater or when in electrical contact with carbon composites.

- Fatigue cracks can grow from notches or welds if not carefully managed.

- Higher thermal expansion than carbon fiber, which can affect assemblies exposed to temperature swings.

Carbon composites don’t rust but can be vulnerable to matrix-driven degradation and impact delamination; aluminium resists many environments but needs corrosion control especially with carbon contact.

Temperature and Moisture: Heat Resistance and Expansion

Ever wondered about carbon fiber heat resistance or the melting point of carbon fiber? While the carbon fibers themselves can withstand temperatures above 3000°C, the actual carbon fiber melting temperature is dictated by the resin matrix—typically limiting use to below 200°C. Aluminium, by contrast, is robust up to its melting point (around 580–650°C for 6061 alloys), but can soften and lose strength at elevated temperatures. Both materials are stable under most cycling conditions, but composites need careful resin selection for high-heat environments.

Galvanic Corrosion: What Happens When Carbon and Aluminium Meet?

Here’s a scenario many engineers face: you want to use both materials in the same assembly. But when carbon fiber (an electrical conductor) and aluminium (anodic metal) are joined and exposed to moisture, galvanic corrosion can occur. This accelerates corrosion of the aluminium, especially in salty or wet environments (Corrosionpedia).

-

Mitigation steps:

- Apply barrier films or non-conductive coatings between materials

- Use primers and sealants to block moisture ingress

- Control fastener stacks with insulating washers or sleeves

- Regularly check and re-torque fasteners to maintain isolation

Inspection and NDT Strategies: Catching Problems Early

How do you spot issues before they become failures? Both materials benefit from proactive inspection:

- Carbon Fibre: Visual checks for surface cracks or delamination, tap tests (listening for dull spots), and ultrasound or thermography to detect internal voids or defects (CompositesWorld).

- Aluminium: Visual inspections for corrosion or cracking, dye penetrant testing for welds, and regular audits of joint tightness and fit.

For both, always follow validated standards and supplier guidance—don’t rely on generic thresholds, especially when it comes to temperature, moisture, or aggressive environments.

In summary, when you compare carbon fibre vs aluminium for durability and environmental performance, you’ll see each has unique strengths and vulnerabilities. Carbon fiber’s resistance to rust and fatigue (in the fiber direction) is a huge win, but it needs careful resin and layup choices to avoid matrix or joint failures. Aluminium offers robust, predictable performance but must be protected from corrosion—especially when paired with carbon composites. Next, we’ll see how these durability factors play into lifecycle cost, repairability, and sustainability.

Lifecycle Costs, Sustainability, and ROI

When you’re choosing between carbon fiber and aluminum, the sticker price is only the start. Have you ever wondered why a carbon fiber part can cost many times more than its aluminum equivalent, or how those upfront costs balance out over a product’s lifetime? Let’s break down the real costs, from raw materials and processing to maintenance, repair, and what happens at the end of the road.

Raw Material and Processing Costs

First, let’s tackle the big question: how much is carbon fiber? The answer: it depends on grade, process, and volume, but carbon fiber is consistently more expensive than aluminum. According to industry references, aluminum typically costs around $1.50 to $2.00 per pound, while carbon fiber price per pound—especially for aerospace-grade—ranges from $10 to $20 or more. That means carbon fiber cost per pound is roughly five to ten times higher than aluminum.

But that’s just the start. Processing costs for carbon fiber are higher too. Manufacturing carbon fiber components involves labor-intensive layup, resin infusion, and curing—sometimes in energy-hungry autoclaves. In aerospace, labor can account for up to 40% of the total composite part cost, compared to 25% for aluminum. Automated fiber placement and other advanced methods are helping, but carbon fiber’s complexity still drives up the price.

| Cost Element | Carbon Fiber Composite | Aluminum | Notes / Uncertainty |

|---|---|---|---|

| Raw Material | $10–$20+/lb | $1.50–$2.00/lb | Carbon fiber price varies by grade and supplier |

| Processing / Labor | High (manual layup, curing, QA) | Low–Moderate (extrusion, machining) | Composites need skilled labor, longer cycles |

| Tooling | High (precision molds, autoclave) | Moderate (dies, jigs) | Tooling cost scales with volume |

| Scrap & Rework | High (defects, limited rework) | Low–Moderate (recyclable scrap) | Composite scrap is harder to reclaim |

| Maintenance | Moderate–High (specialized repair) | Low–Moderate (simple weld/patch) | Composites often require expert repair |

| End-of-Life (EoL) | Limited recycling, high disposal cost | Highly recyclable, low EoL cost | Aluminum retains value at EoL |

Repair vs Replacement Decisions

Imagine you’re managing a fleet of aircraft or high-end bikes. If a carbon fiber component is damaged, repair can be complex and costly—sometimes requiring full replacement or expert intervention. For example, in aerospace, a CFRP rotor blade repair may cost three times that of an aluminum blade for similar damage. Aluminum, by contrast, is more forgiving: dents can be hammered out, cracks welded, and parts patched quickly and affordably. This difference can lead to unexpected downtime and higher lifecycle costs for carbon fiber, especially in high-use or impact-prone environments.

End-of-Life Recyclability and Recovery

Sustainability matters more than ever. So, what happens when your part reaches the end of its useful life? Aluminum shines here—about 75% of all aluminum ever produced is still in use, thanks to efficient recycling that recovers up to 95% of the original energy investment. Recycling aluminum is straightforward and widely available.

Carbon fiber recycling is still in its infancy. Only about 30% of CFRP waste is recycled, and the process (often thermal recycling) is energy-intensive and yields fibers that may only be suitable for lower-grade applications. The price of carbon fiber at end-of-life is low, and disposal can add cost rather than recover value.

ROI Workflow: Making a Smart Decision

Sounds complex? Here’s a step-by-step approach to compare options and estimate true ROI:

- Define your performance target: Weight, stiffness, durability, or cost?

- Shortlist materials: Compare carbon fiber cost and aluminum cost for your specific application.

- Estimate part count and learning curve: High volumes reduce per-part tooling and labor costs—especially for aluminum.

- Factor repair downtime: How much will unexpected repairs or replacements cost in lost productivity?

- Run a sensitivity analysis: Adjust for changes in fuel savings, maintenance, or recycling value to see which option holds up best over time.

"Composites can deliver weight savings that lower operating costs, but repair complexity and cure time can offset those gains. Aluminum often offers faster iteration, easier repair, and proven recycling streams."

-

Tips for cost-effective sourcing:

- Request multiple quotes and detailed breakdowns from suppliers.

- Validate assumptions with pilot runs and coupon testing.

- Consider total lifecycle cost, not just upfront price.

- Include maintenance, repair, and end-of-life in your cost model.

In summary, while carbon fiber cost is higher up front, its weight savings may justify the investment for applications where every gram counts—think aerospace or racing. For most general-purpose engineering, aluminum’s lower price, ease of repair, and recyclability make it the more cost-effective and sustainable choice. As you move to application-specific decisions, keep ROI and full lifecycle impacts front and center—your budget and your sustainability goals will thank you.

Choosing Carbon Fibre or Aluminium for Cars, Planes, and Bikes

Ever wondered why some automotive parts are aluminum while others are carbon fiber? Or why pro cyclists debate aluminium vs carbon bike frames so passionately? Let’s break down how the trade-offs between carbon fibre vs aluminium play out in three critical sectors: automotive, aerospace, and cycling. You’ll see exactly where each material shines—and where it might fall short.

Automotive Structures and Trims

In modern vehicles, the choice between carbon fiber and aluminum is rarely about hype—it’s about matching performance, manufacturability, and cost. For body-in-white reinforcements, crash rails, and battery enclosure frames, aluminum extrusion parts are the go-to. Aluminum’s isotropic properties, tight tolerances, and robust supply chain make it ideal for high-volume, safety-critical structures. Suppliers like Shaoyi Metal Parts Supplier—A leading integrated precision auto metal parts solutions provider in China—help streamline DFM (Design for Manufacturability), tolerance control, and PPAP documentation for automotive OEMs.

But carbon fiber isn’t out of the race. It dominates in premium trims, hoods, roofs, and performance panels where weight savings and custom shapes are prized. For high-end sports cars or electric vehicles seeking maximum range, a carbon fiber car chassis or select CFRP panels can deliver a unique edge.

Aerospace: Primary vs Secondary Use

When you step onto a carbon fiber airplane, you’re experiencing the material’s greatest strengths—exceptional fatigue resistance, corrosion immunity, and the ability to tailor stiffness for wings, fuselages, and fairings. Carbon fiber’s light weight and strength-to-weight ratio are critical for fuel efficiency and emissions reduction in aerospace.

Aluminum still leads in secondary structures, skins, and areas where fast, cost-effective manufacturing is a must. Its proven history, ease of inspection, and recyclability keep it a mainstay in aerospace supply chains—especially for components that must meet tight tolerances and rigorous certification standards.

Bike Frames and Components

If you’re choosing between aluminum versus carbon fiber bikes, you’ll find each material has a distinct personality. Carbon fiber frames, forks, and even carbon fiber seatpost upgrades deliver unmatched weight savings and vibration damping—key for racers and enthusiasts. The ability to tune frame stiffness and geometry gives carbon an edge in high-performance cycling (Market Prospects).

But don’t count out aluminum. For everyday riders, aluminium vs carbon bike frame debates often come down to durability, repairability, and cost. Aluminum frames are tough, affordable, and forgiving under rough use. And when it comes to carbon vs aluminum rims, the choice hinges on weight, ride feel, and price—carbon for race-day speed, aluminum for all-weather reliability.

| Sector | Component Type | Preferred Material | Rationale | Manufacturing Route | Notes on Inspection |

|---|---|---|---|---|---|

| Automotive | Chassis, Crash Rails, Battery Frames | Aluminum | High volume, tight tolerance, crash energy absorption | Extrusion, stamping, welding | Visual, dimensional, weld checks |

| Automotive | Hoods, Roofs, Trims | Carbon Fiber | Weight savings, premium aesthetics | Laminating, autoclave, RTM | Ultrasound, tap test, visual |

| Aerospace | Wings, Fuselages, Fairings | Carbon Fiber | Fatigue resistance, lightweight, corrosion proof | Prepreg layup, autoclave | Ultrasound, thermography |

| Aerospace | Skins, Secondary Structures | Aluminum | Proven, easy to inspect, repairable | Sheet forming, riveting | Dye penetrant, visual |

| Cycling | Frames, Forks, Seatposts | Carbon Fiber | Minimal weight, tuned stiffness, ride comfort | Layup, molding | Tap test, visual |

| Cycling | Frames, Rims | Aluminum | Affordability, durability, ease of repair | Extrusion, welding | Visual, straightness, weld checks |

Decision Checkpoints for Buyers and Engineers

-

Automotive:

- Weight vs crash repairability

- Tolerance and fit-up (aluminum excels for mass production)

- Tooling and supply chain maturity

-

Aerospace:

- Fatigue life and certification requirements

- Environmental exposure (carbon for corrosion-prone zones)

- Inspection and NDT compatibility

-

Cycling:

- Performance (weight, stiffness, damping)

- Budget and repair needs

- Preference on aluminium vs carbon bike frame for longevity vs speed

In summary, the carbon fibre vs aluminium decision is never one-size-fits-all. Whether you’re designing a carbon vs aluminum road bike or specifying crash rails for a new EV, always weigh performance, cost, manufacturability, and inspection needs. And if you’re sourcing automotive structures, consider trusted partners for aluminum extrusion parts to ensure quality and efficiency from design to delivery.

Next, let’s equip you with the standards, testing protocols, and specification tips you’ll need to specify, test, and source the right material with confidence.

Standards, Testing, and a Spec-Ready Checklist

When you’re ready to move from comparing carbon fibre vs aluminium on paper to actually specifying, testing, and sourcing parts, the details matter. Sounds complex? It doesn’t have to be—if you know what standards to reference, what language to use, and how to qualify your suppliers. Let’s break down the essentials for a confident, spec-driven approach.

Key ASTM and ISO Methods for Carbon Fiber and Aluminum

Imagine you’re reviewing a carbon fiber stress strain curve or checking the 6061 aluminum tensile strength on a datasheet. To ensure apples-to-apples comparisons and reliable results, always specify recognized standards for each property. Here’s a quick list of go-to standards for both materials:

-

Carbon Fiber Composites:

- ASTM D3039 – Tensile properties of polymer matrix composites

- ASTM D7264 – Flexural properties

- ASTM D2344 – Short-beam shear strength

- ISO 527 – Tensile testing of plastics and composites

- Documentation of layup schedule and test direction (critical for yield strength of carbon fiber)

-

Aluminum Alloys (e.g., 6061):

- ASTM E8/E8M – Tension testing of metallic materials (for ultimate tensile strength of aluminium 6061 and 6061 aluminum tensile strength)

- ASTM E111 – Young’s modulus determination

- ASTM E18 – Hardness testing

- ASTM B209 – Aluminum and aluminum-alloy sheet and plate

- Weld procedures, if relevant: AWS D1.2/D1.2M for aluminum

Supplier Qualification Criteria and a Practical Procurement Checklist

Imagine you’re sourcing a new part. How do you ensure your supplier can deliver consistent quality, whether you need high shear modulus of aluminum 6061 or a complex composite layup? Use this step-by-step flow:

- Shortlist suppliers with relevant certifications (e.g., ISO 9001, IATF 16949 for automotive).

- Request datasheets and process capability statements for your specific alloy, layup, or geometry.

- Define coupon testing requirements: Align tests to ASTM/ISO standards—specify orientation for composites, temper for aluminum.

- Run pilot builds or first-article inspections to validate performance and tolerance.

- Confirm inspection and traceability protocols: Ask about barcode tracking, QA/QC automation, and defect reporting (AddComposites).

-

Procurement checklist:

- Reference all applicable ASTM/ISO standards in your RFQ/spec

- Specify test direction (composites) and temper (aluminum)

- Request recent test reports and QA documentation

- Define acceptance criteria for key properties (e.g., ultimate tensile strength of aluminium 6061, yield strength of carbon fiber, 6061 aluminum young's modulus, poisson's ratio of aluminum 6061)

- Include inspection and NDT requirements

Specify directionality for composite tests and temper for aluminium to avoid apples-to-oranges.

Sample Spec Wording to Reduce Ambiguity

Ever seen a spec that led to confusion or rework? Here’s how to write clear, actionable requirements:

- “Carbon fiber laminate to be tested per ASTM D3039, [0°/90°] layup, with minimum yield strength of carbon fiber [specify value] in the primary load direction.”

- “6061-T6 aluminum plate to meet ASTM B209, with 6061 aluminum tensile strength not less than [specify value] and Young’s modulus per ASTM E111.”

- “All test data to be provided with traceable lot numbers and QA documentation.”

Final Recommendations and Sourcing Tips

Imagine you’re sourcing automotive structures and want confidence in both quality and manufacturability. Early alignment with suppliers who excel at DFM (Design for Manufacturability) and process control can save you time and money. For aluminum extrusion needs, consider aluminum extrusion parts from trusted partners like Shaoyi Metal Parts Supplier, known for integrated precision and robust QA systems. Their expertise in automotive aluminum extrusions streamlines early design reviews and ensures your specs are met from pilot to production.

In summary, moving from carbon fibre vs aluminium theory to real-world success means locking in standards, clear language, and supplier diligence. Always cite datasheets and peer-reviewed research, and use precise spec patterns to lock in test methods, tolerances, and acceptance criteria. With the right approach, you’ll confidently navigate the trade-offs and deliver parts that perform as designed—every time.

Frequently Asked Questions: Carbon Fibre vs Aluminium

1. Is carbon fiber stronger than aluminum?

Carbon fiber can offer higher specific strength and stiffness than aluminum, especially when fibers are aligned with the primary load. However, aluminum provides consistent, isotropic strength in all directions, making it favorable for parts requiring uniform performance and easy manufacturability. The choice depends on the application, required durability, and design constraints.

2. Why is carbon fiber more expensive than aluminum?

Carbon fiber's higher price comes from its costly raw materials, manual or specialized manufacturing processes, and longer production cycles. Unlike aluminum, which benefits from established mass production and recycling infrastructure, carbon fiber requires skilled labor and energy-intensive curing, resulting in a higher cost per pound and increased fabrication expenses.

3. What are the main differences in durability between carbon fiber and aluminum?

Carbon fiber resists corrosion and fatigue well in the fiber direction, but its resin matrix can degrade with UV, moisture, or impact. Aluminum is robust against many environments and is easily repaired or recycled, but it can corrode, especially when in contact with carbon composites. Both materials require proper design and maintenance for long-term durability.

4. Which material is better for automotive parts: carbon fiber or aluminum?

Aluminum is often preferred for automotive structural parts due to its predictable properties, cost-effectiveness, and manufacturing scalability. Carbon fiber is used for premium, lightweight trims or high-performance components where weight reduction is critical. Services like Shaoyi's automotive aluminum extrusions offer custom, high-quality solutions for mass-produced automotive parts, making aluminum a practical choice for most applications.

5. How do carbon fiber and aluminum compare in terms of recyclability?

Aluminum is highly recyclable and retains most of its value at end-of-life, making it a sustainable option for large-scale manufacturing. Carbon fiber recycling is less developed, with most waste currently downcycled or disposed of, which limits its sustainability benefits compared to aluminum.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —