Tool And Die Stamping Decoded: From Raw Metal To Precision Parts

What Tool and Die Stamping Actually Means

Ever submitted a quote request only to realize you've been using "tool" and "die" interchangeably? You're not alone. This confusion costs manufacturers time, money, and countless headaches during supplier negotiations. Let's clear this up once and for all.

Tool and die stamping is a precision metal forming process where a complete tooling assembly (the "tool") containing specialized shaping components (the "dies") transforms flat sheet metal into finished parts through controlled force and deformation.

When you understand what is stamping at its core, you gain the vocabulary to communicate effectively with suppliers and make smarter sourcing decisions. The stamping process relies on this critical partnership between tools and dies working in perfect synchronization.

The Tool vs Die Distinction Explained

Think of it this way: the stamping tool is the entire machine that mounts into your press, while stamping dies are the custom-machined components inside that machine doing the actual shaping work. According to Prime Fabworks, the tool (also called a die set) includes the base, punches, strippers, and the dies themselves.

Here's what comprises a complete tool and die definition in practical terms:

- The Tool (Die Set): The complete assembly including upper and lower shoes, guide pins, bushings, fixtures, gauges, and all cutting instruments mounted as one unit

- The Dies: The specific hardened blocks within the tool that cut, bend, or form metal into your desired shape

- Supporting Components: Strippers, pressure pads, pilots, knockouts, and ejectors that ensure precise operation

A stamping die cannot function independently. It requires the complete tooling assembly to maintain alignment, apply force correctly, and produce consistent results. When suppliers discuss dies and stamping projects, they're referencing this integrated system where every component plays a critical role.

Why Terminology Matters in Metal Fabrication

Using correct terminology isn't just about sounding professional. It directly impacts your quotes, project timelines, and final part quality. When you define stamping requirements accurately, you eliminate the back-and-forth that delays production.

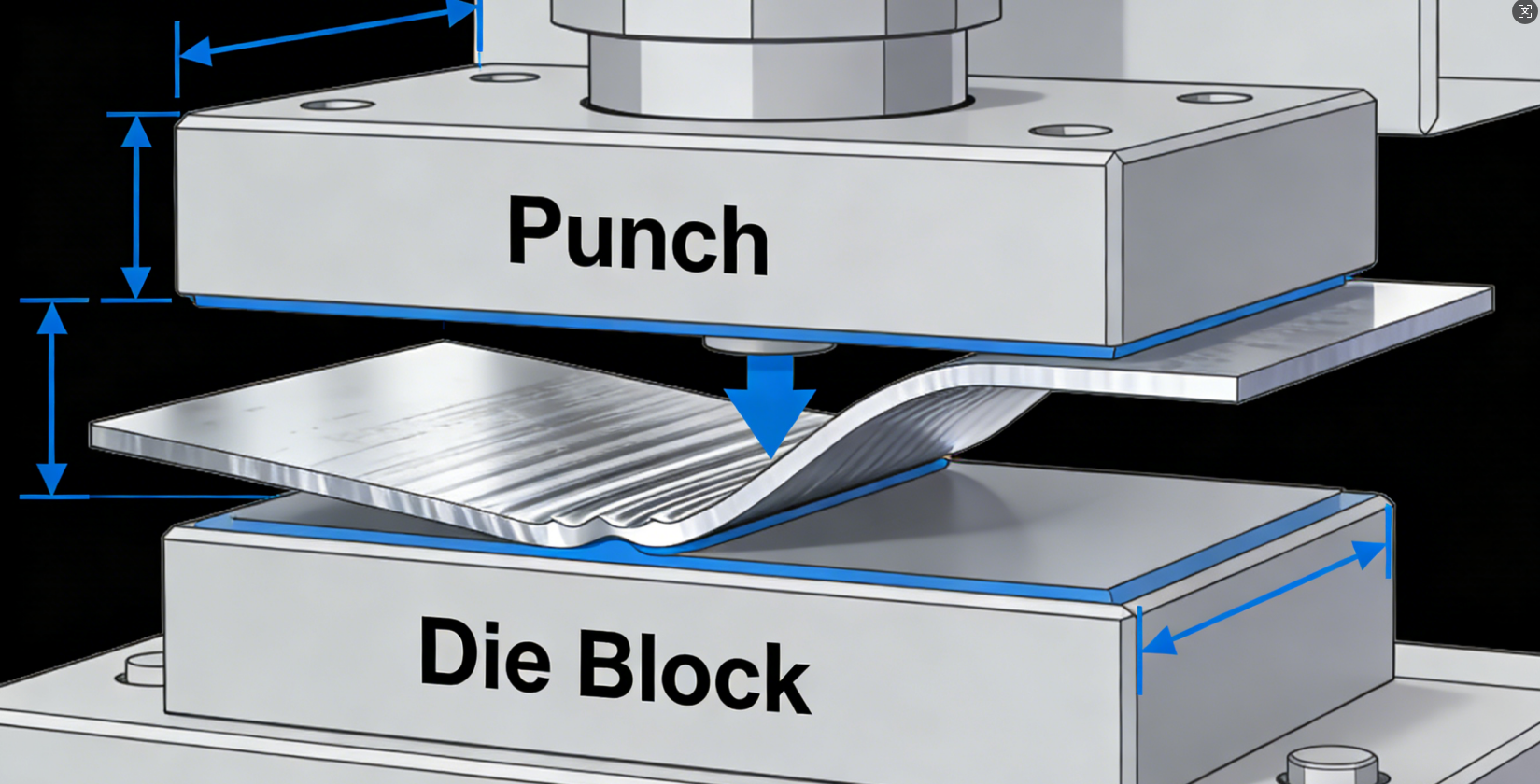

The eight fundamental die components work together in a precise sequence with tolerances measured in microns. These include:

- Die block - shapes the material with specific cavities

- Punch - forces material into the die cavity

- Guide pins and bushings - maintain alignment between upper and lower sections

- Strippers and pressure pads - hold and release workpieces

- Backup plates - prevent deformation under high pressure

- Pilots - ensure material positioning accuracy

- Springs and fasteners - control return motion and secure components

- Knockouts and ejectors - remove finished parts smoothly

Understanding this framework helps you evaluate supplier capabilities and ask the right questions. A die stamp operation might seem straightforward, but the engineering behind consistent, high-quality output requires mastery of each component's function. Throughout this guide, you'll discover how these elements work together to transform raw sheet metal into precision parts that meet your exact specifications.

How the Die Stamping Process Works Step by Step

Imagine feeding a flat sheet of metal into a machine and watching it emerge seconds later as a perfectly formed bracket, connector, or housing. That transformation happens through a carefully orchestrated die process that most suppliers mention but rarely explain in practical terms. Let's walk through exactly what happens from the moment raw material enters the press until a finished part drops into the collection bin.

The metal stamping process relies on controlled deformation. Unlike machining, which removes material, die stamping reshapes it through tremendous force. According to Aranda Tooling, this cold-forming technique uses no heat, though parts often exit hot due to friction between the metal and die surfaces. The force applied is measured in tons, giving you a sense of the power behind every stroke.

From Raw Sheet to Finished Part

The stamping process follows a predictable sequence whether you're running a simple blanking operation or complex multi-stage forming. Here's the complete workflow:

- Material Feeding: A continuous strip or individual blank enters the stamping machinery, typically fed from a coil through an automatic feeder. This step establishes the rhythm of production. The material must advance precisely, as even slight misalignment affects every downstream operation.

- Die Engagement: The upper die descends, guided by pins and bushings to maintain perfect alignment with the lower die. Metal stamping presses apply force ranging from a few tons for thin materials to thousands of tons for heavy-gauge steel or complex geometries.

- Forming Operation: This is where the actual transformation occurs. Depending on your part requirements, operations like blanking, punching, piercing, bending, or coining reshape the flat stock. The coining process, for example, uses extreme pressure to create fine details and tight tolerances by forcing metal to flow into die cavities.

- Part Ejection: Knockouts and ejectors push the formed component away from the die surface. Strippers hold the remaining strip or scrap in position while the punch withdraws. Proper ejection prevents damage and prepares the die for the next cycle.

- Quality Verification: Inspectors check dimensional accuracy, surface finish, and overall conformance. This happens throughout production, not just at the end. Rigorous quality control catches issues before they become costly problems.

Critical Stages in Die Stamping Operations

Understanding what happens at each station helps you communicate requirements effectively and troubleshoot issues when they arise. Die stamping operations typically include several forming techniques working in sequence:

- Blanking: Cuts the outer perimeter of your part from the strip. The blank becomes your workpiece for subsequent operations.

- Punching and Piercing: Creates internal holes and features. Punching removes material that becomes scrap, while piercing creates openings without removing a separate slug.

- Bending and Forming: Transforms flat blanks into three-dimensional shapes by forcing material around a radius or into a cavity.

- Drawing: Stretches material into cup-shaped or box-shaped components, common in automotive panels and housings.

- Coining: Applies extreme pressure to achieve fine surface details, sharp corners, and the tightest tolerances possible in stamping and pressing operations.

The stamping machinery you select directly impacts what's achievable. Mechanical presses excel at high-speed production, running anywhere from 20 to 1,500 strokes per minute according to Schaumburg Specialties. Hydraulic presses offer more control over pressure and stroke length, making them ideal for deep draws and complex forming. Servo presses combine speed with programmability for the most demanding applications.

Each cycle repeats with remarkable consistency. A well-designed die can produce millions of identical parts before requiring maintenance. That repeatability makes the stamping process exceptionally cost-effective for volume production, but it also means getting the die design right from the start is critical. The next section explores how different die types handle varying production requirements and part complexities.

Progressive vs Transfer vs Compound Die Types Compared

Choosing between progressive stamping, transfer die stamping, and compound die stamping feels overwhelming when you're facing production deadlines. Each method excels in specific scenarios, and selecting the wrong one can cost you thousands in tooling investment and production inefficiencies. Let's break down exactly when each die type makes financial and technical sense.

The progressive die stamping process keeps your workpiece attached to a continuous metal strip throughout production, advancing it through multiple stations with each press stroke. Transfer dies separate the blank early and mechanically move individual pieces between stations. Compound die stamping performs multiple operations simultaneously in a single stroke. Understanding these fundamental differences shapes every decision that follows.

| Characteristic | Progressive Die | Transfer Die | Compound Die |

|---|---|---|---|

| Operation Complexity | Multiple sequential stations; part stays on strip | Multiple stations; automated part transfer between each | Single stroke; all operations occur simultaneously |

| Part Size Suitability | Small to medium parts | Medium to large parts | Small flat parts |

| Production Volume Range | High volume (100,000+ parts) | Short to long runs (5,000-500,000 parts) | Medium to high volume |

| Typical Applications | Electrical connectors, brackets, automotive clips | Deep drawn housings, tubes, threaded components | Washers, wheel blanks, simple flat components |

| Relative Tooling Investment | High initial cost; lowest per-part cost at volume | Moderate to high; cost-effective for complex parts | Lower than progressive; efficient for simple shapes |

| Deep Draw Capability | Limited | Excellent | Not suitable |

Progressive Dies for High-Speed Production

When volume demands drive your project, progressive die and stamping systems deliver unmatched efficiency. According to Keats Manufacturing, progressive die stamping simultaneously shapes, bends, and punches parts from a continuous metal coil, saving time and reducing labor costs through fewer setup requirements.

Progressive stamping die design follows specific principles that maximize throughput:

- Station sequencing: Operations progress from simple to complex, with cutting operations early and forming operations later

- Strip retention: The workpiece remains connected to the carrier strip until the final station, eliminating transfer mechanisms

- Pilot accuracy: Precision pilots ensure perfect alignment at each station, enabling tolerances measured in thousandths of an inch

- Waste management: Scrap removal happens within the die, maintaining continuous operation

The ROI calculation favors progressive dies when your annual volumes exceed 100,000 parts. While initial tooling costs run higher than alternatives, the per-part cost drops dramatically as quantities increase. You'll also see reduced waste compared to compound die stamping, since material flows efficiently through sequential operations.

However, progressive stamping has limitations. Complex three-dimensional geometries requiring deep draws push beyond what this method handles effectively. Parts must remain small enough to fit the strip width, and highly intricate designs requiring workpiece rotation simply aren't feasible.

When Transfer Dies Outperform Progressive Systems

Transfer stamping shines where progressive dies struggle. When your part requires deep drawing, threading, ribs, or knurled features, transfer dies handle these complexities with precision. According to Worthy Hardware, this method separates the workpiece from the metal strip early in the process, allowing automation to transport and reorient individual parts through specialized stations.

Consider transfer die stamping when your project involves:

- Parts too large for progressive die strip widths

- Deep drawn components like cups, housings, or enclosures

- Designs requiring workpiece rotation between operations

- Tubes and cylindrical components

- Features on multiple surfaces that require repositioning

The flexibility of transfer dies comes with tradeoffs. Operational costs run higher due to complex automation and the skilled labor required for maintenance. Setup times extend longer than progressive systems, particularly for intricate part geometries. Yet for manufacturers producing large components or parts requiring specialized operations, transfer stamping remains the only practical choice.

Compound die stamping fills a different niche entirely. When you need flat parts like washers or simple blanks produced quickly with excellent dimensional consistency, a single-stroke compound operation delivers. The stamping die design for compound dies focuses on performing multiple cuts simultaneously, producing flatter parts than progressive dies typically achieve. Tooling costs stay lower, making this approach economical for simpler geometries.

Your decision ultimately comes down to part complexity, production volume, and budget constraints. High-volume simple parts favor progressive systems. Large or deeply formed parts demand transfer dies. Flat, straightforward components suit compound dies perfectly. Understanding these distinctions helps you request accurate quotes and select the manufacturing partner equipped to handle your specific requirements efficiently.

Material Selection for Dies and Stamped Parts

You've selected the right die type for your production volumes. Now comes a decision that directly impacts how long that die lasts, how often you're scheduling maintenance, and whether your parts meet specification: material selection. This choice operates on two levels. You need the right materials for constructing the dies themselves, and you need to understand how different workpiece materials behave during forming. Get either wrong, and you'll face premature die failure, inconsistent part quality, or both.

According to The Fabricator, tool steels fail in predictable ways: abrasive wear, adhesive wear, cracking, chipping, and plastic deformation. The goal is choosing a material that eliminates all failure types except wear, which you can manage through scheduled maintenance. This philosophy applies whether you're building metal stamping dies for high-volume automotive production or precision components for aerospace applications.

Selecting the Right Tool Steel for Die Longevity

Die and tooling material selection requires balancing two competing properties: toughness and wear resistance. Toughness allows the steel to absorb impact shock without cracking or deforming. Wear resistance prevents surface erosion during repeated cutting and forming operations. Finding the right balance depends on your specific application.

Here are the primary tool steel categories used in sheet metal die construction:

- D2 Tool Steel: High-carbon, high-chromium composition offering excellent wear resistance. Commonly chosen for steel stamping dies processing harder materials. However, D2 can experience adhesive bonding issues when forming stainless steel due to chromium compatibility.

- S7 Tool Steel: Known for exceptional toughness, making it ideal for applications involving severe impact shock. S7 absorbs the force of punch entry without cracking, particularly valuable in heavy-gauge blanking operations.

- M2 High-Speed Steel (HSS): Retains sharp cutting edges at elevated temperatures, making it excellent for high-speed stamping operations where friction generates significant heat.

- A2 Tool Steel: Offers good toughness with moderate wear resistance, providing a balanced option for general-purpose die applications.

- Powdered Metal (P/M) Tool Steels: Feature carbides evenly distributed throughout the microstructure, delivering both high wear resistance and good impact strength. These steels accommodate high-temperature coatings without softening, though they cannot be welded.

Carbide options enter the equation when wear resistance becomes paramount. Tungsten carbide inserts dramatically extend die life in high-volume applications, particularly when stamping abrasive materials. Some manufacturers apply carbide coatings through chemical vapor deposition (CVD) to existing tool steel dies. However, CVD processes require elevated temperatures that can soften steels with low tempering temperatures, potentially creating a soft substrate unable to support the thin coating.

Matching Die Materials to Production Demands

Your workpiece material dictates which die material performs best. The interface friction between tool steel and sheet metal during forming creates specific challenges that material pairing can solve or exacerbate.

Consider these precision metal stamping materials and their die requirements:

- Aluminum stamping: The aluminum stamping process demands dies with excellent surface finish to prevent galling. Aluminum's tendency to stick to tooling makes proper lubrication and die material selection critical. Grades like 5052-H32 offer excellent formability, while 2024 aluminum's higher strength requires more robust tooling.

- Stainless steel: Creates adhesive wear challenges when the chromium in the workpiece bonds with chromium in the die. Solutions include using alternative tool steels with different compositions or applying carbide coatings to prevent micro-welding.

- Carbon steels: Often contain hard particle oxides that erode die surfaces through abrasive wear. Higher-hardness tool steels counteract this erosion effectively.

- High-performance alloys: Materials like Inconel and titanium demand dies with exceptional hardness and heat resistance due to the extreme forces required for forming.

According to CMD PPL, dimensional stability becomes critical when precision tolerances are required. High-grade tool and alloy steels maintain their shape under mechanical stress and temperature variations, ensuring dies produce parts with consistent dimensions throughout production runs.

Cost considerations matter, but think in terms of total value rather than initial purchase price. As The Fabricator notes, some premium tool grades outperform traditional options two-to-one. The reduced downtime and extended maintenance intervals often justify higher material costs. A die constructed from appropriate materials requires less frequent replacement, maintains tighter tolerances longer, and produces higher-quality parts consistently.

The relationship between die design, material selection, and achievable tolerances becomes even more critical when specifications demand precision. Understanding these tolerance capabilities helps you communicate requirements effectively and evaluate whether a supplier can actually deliver what your application demands.

Precision Capabilities and Tolerance Standards

You've invested in quality die materials and selected the right die type for your volumes. But can your supplier actually hold the tolerances your application demands? This question separates precision stamped parts that perform flawlessly from components that fail during assembly or in the field. Understanding what tolerances are genuinely achievable helps you set realistic specifications and avoid costly back-and-forth with suppliers who overpromise.

High precision metal stamping isn't just about having good equipment. It's the intersection of stamping design decisions, material behavior, and process control working together. According to Komacut, tolerances in sheet metal fabrication divide into material tolerances (thickness and flatness variations in raw stock) and fabrication tolerances (the precision built into cutting, forming, and finishing processes). Both influence what you can realistically expect from your finished parts.

Achievable Tolerances in Precision Stamping

Different stamping operations deliver different levels of precision. Coining produces the tightest tolerances because extreme pressure forces metal to flow completely into die cavities, eliminating springback. Blanking and piercing operations depend heavily on die sharpness and clearances. Forming and drawing introduce more variables, making tight tolerances harder to maintain consistently.

Here's what metal precision stamping operations can realistically achieve:

| Operation Type | Standard Tolerance | High Precision Tolerance | Key Influencing Factors |

|---|---|---|---|

| Blanking/Piercing | ±0.10 to ±0.25 mm | ±0.05 to ±0.08 mm | Die clearance, punch sharpness, material thickness |

| Bending/Forming | ±0.25 to ±0.50 mm linear; ±1.0° | ±0.20 mm linear; ±0.5° | Springback compensation, bend radius, material elasticity |

| Drawing | ±0.25 to ±0.50 mm | ±0.12 to ±0.20 mm | Blank holder pressure, lubrication, draw depth |

| Coining | ±0.05 to ±0.10 mm | ±0.025 to ±0.05 mm | Tonnage applied, die surface finish, material flow |

Material thickness also affects achievable precision. According to Komacut's tolerance tables, thinner materials (0.5mm to 2.0mm) hold tighter tolerances of ±0.05mm, while heavier gauges (10.0mm to 20.0mm) expand to ±0.50mm for standard processes. Your sheet metal stamping design must account for these inherent limitations.

Design Factors That Affect Dimensional Accuracy

Achieving tight tolerances starts long before the press cycles. Metal stamping die design decisions made during engineering directly determine what's possible during production. Experienced suppliers use advanced 3D modeling software to visualize every component and catch potential dimensional issues before cutting metal, as noted by HT Tool & Die.

Several factors interact to determine final part precision:

- Die clearance settings: The gap between punch and die must match material thickness and type. Too tight causes excessive wear; too loose produces burrs and dimensional drift.

- Material springback: Elastic materials like stainless steel and high-strength alloys spring back after forming. Dies must over-bend to compensate, requiring careful calculation based on bend radius and material properties.

- Thermal expansion: High-speed production generates heat. Both die components and workpiece materials expand, affecting dimensions. Controlling temperature through proper lubrication and cycle timing maintains consistency.

- Press selection: Hydraulic presses offer superior control for precision drawing operations. Mechanical presses excel at high-speed blanking. Servo presses provide programmable stroke profiles for complex forming sequences.

- Tolerance stack-up: Multiple forming operations accumulate small variations. According to Approved Sheet Metal, experienced fabricators use statistical tolerance analysis and Monte Carlo simulations to predict cumulative effects and identify critical dimensions.

For demanding applications in automotive and aerospace, suppliers employ secondary machining operations after stamping to achieve the tightest specifications. While this adds cost, it enables tolerances that stamping alone cannot consistently deliver. Custom fixtures during assembly also help control and maintain precision in complex multi-part assemblies.

The key takeaway? Avoid over-tolerancing non-critical dimensions. Specifying unnecessarily tight tolerances increases manufacturing complexity and cost without adding functional value. Identify which dimensions truly matter for fit and function, then work with your supplier to determine realistic specifications for each. This collaborative approach prevents delays and keeps your project on budget while delivering parts that perform exactly as intended.

Troubleshooting Common Die Stamping Defects

You've selected the right die type, optimized your materials, and dialed in your tolerances. Then production starts, and defects appear. Burrs on your blanked edges. Wrinkles forming where they shouldn't. Parts springing back out of spec. These issues frustrate even experienced manufacturers, but understanding their root causes transforms reactive firefighting into proactive quality control.

According to HLC Metal Parts, most stamping defects trace back to six primary causes: excessive strain, improper material selection, worn cutting tools, unreasonable mold design, improper stamping parameters, and insufficient lubrication. The stamping manufacturing process introduces countless variables, but systematic diagnosis identifies problems quickly and points toward effective solutions.

Identifying Root Causes of Stamping Defects

Each defect type tells a specific story about what's happening inside your die. Learning to read these signs helps you pinpoint corrective actions without wasting time on trial-and-error approaches.

- Burring: Those rough edges and metal flakes forming on cut surfaces indicate problems with your stamping die components. When punch-to-die clearance exceeds optimal ranges or cutting edges become dull, material tears rather than shears cleanly. According to DR Solenoid, proper clearance should measure 8% to 12% of material thickness, with smaller values for mild steel.

- Wrinkling: When excess material bunches up during forming, you're seeing the result of insufficient blank holder pressure or improper material flow. Thin sheets and curved areas are particularly susceptible. The issue often stems from unbalanced stress distribution during the manufacturing stamping process.

- Springback: Elastic recovery after forming pushes your parts out of dimensional specification. High-strength steels and aluminum alloys exhibit pronounced springback behavior. The material's modulus of elasticity determines how much it wants to return to its original shape after the punch withdraws.

- Cracking: Splits appearing at corners, edges, or high-strain areas signal material being pushed beyond its ductility limits. This failure occurs when tensile stresses exceed what the metal can accommodate, particularly in localized stress concentration zones.

- Dimensional Drift: Parts gradually moving out of tolerance during production runs indicate progressive die wear, thermal expansion effects, or material batch variations. According to The Phoenix Group, poor stamping die maintenance causes quality defects during production, driving up sorting costs and increasing the likelihood of shipping defective parts.

The types of stamping dies you're running influence which defects you're most likely to encounter. Progressive dies face challenges with strip advancement accuracy affecting hole positioning. Transfer dies introduce part handling variables between stations. Compound dies may experience differential wear across simultaneously operating punches.

Preventive Measures for Consistent Quality

Catching defects after they occur costs significantly more than preventing them. Effective prevention operates across design, process control, and maintenance dimensions.

Start with design-stage interventions that eliminate defect-prone conditions:

- Use CAE simulation software to model material flow, springback behavior, and stress distribution before cutting steel

- Avoid sharp corners that concentrate stress; aim for radii at least three times material thickness

- Design springback compensation into forming surfaces based on material properties

- Specify appropriate punch-to-die clearances for your specific material and thickness

Process control during production maintains the conditions your design requires:

- Develop Standard Operating Procedures specifying acceptable ranges for blank holder force, press speed, and stroke settings

- Implement first-piece full-dimension inspection using coordinate measuring machines or 3D scanners

- Monitor press tonnage signatures to detect developing problems before defects appear

- Control lubrication application rates and coverage to ensure consistent friction conditions

Stamping die maintenance represents your most powerful defect prevention tool. According to The Phoenix Group, die maintenance involves routine inspections to identify wear, damage, or defects, followed by necessary repairs and adjustments. Preventive maintenance addresses potential issues before they cause production disruptions.

Effective stamping technology management includes:

- Establishing die life records tracking cycles between required maintenance

- Scheduling regular cutting edge inspections, with many manufacturers checking every 50,000 strokes

- Replacing wear components like punches, guide bushings, and springs on predetermined intervals

- Applying protective coatings such as TiAlN to extend wear resistance

- Using work order systems to document repairs and track recurring issues

The relationship between design decisions and manufacturing outcomes extends beyond the obvious. A die designed without considering maintenance accessibility becomes expensive to keep running. Stamping die components positioned for easy replacement reduce downtime. Proper documentation of original die specifications enables accurate restoration after wear-related corrections.

Quality problems often signal opportunities for continuous improvement rather than just repair needs. When defects appear, ask whether your current approach represents the best solution or simply the one you've always used. Sometimes alternative manufacturing methods deliver better results for specific part geometries or production volumes.

When to Choose Stamping Over Alternative Methods

Here's the honest truth most suppliers won't tell you: tool and die stamping isn't always your best option. Despite its efficiency at scale, this method requires significant upfront investment that simply doesn't make sense for every project. Understanding when stamping delivers value versus when alternative methods outperform it saves you money and prevents frustrating project delays.

Metal stamping and forming excels in specific scenarios. But CNC machining, laser cutting, 3D printing, and hydroforming each occupy niches where they outcompete traditional stamping. Your decision hinges on production volume, part complexity, material requirements, and budget constraints. Let's examine exactly where each method makes financial and technical sense.

| Factor | Tool and Die Stamping | CNC Machining | Laser Cutting | 3D Printing | Hydroforming |

|---|---|---|---|---|---|

| Optimal Volume Range | 10,000+ parts/year | 1-5,000 parts | 1-3,000 parts | 1-500 parts | 500-50,000 parts |

| Part Complexity | Medium to high (2D to moderate 3D) | Very high (complex 3D geometries) | 2D profiles only | Extremely high (internal features, lattices) | High (smooth complex curves) |

| Material Thickness Range | 0.1mm to 12mm typical | No practical limit | 0.5mm to 25mm | Limited by process | 0.5mm to 6mm typical |

| Tooling Investment | $3,000-$200,000+ | Minimal (fixtures only) | None (digital programming) | None | $5,000-$50,000 |

| Per-Part Cost at Volume | Lowest | High | Moderate | Very high | Low to moderate |

| Lead Time to First Part | 4-8 weeks (tooling) | Days to weeks | 24-48 hours | Hours to days | 2-4 weeks |

Volume Thresholds That Justify Die Investment

The economics of industrial metal stamping center on one critical question: at what volume does tooling investment pay off? According to Yeeshine Tech, the upfront tooling cost isn't worthwhile unless you plan to produce 10,000+ parts per year. Simple dies run $3,000 to $30,000, while complex progressive or transfer dies can reach $200,000 or more.

Here's the break-even calculation that drives decision-making:

(CNC cost per part – stamping cost per part) × volume – tooling cost = annual savings

Consider a practical example. Your CNC-machined part costs $12 each, but production metal stamping brings that down to $4. At 25,000 parts annually, you save $200,000 in processing costs. Subtract $40,000 for tooling, and you still net $160,000 in first-year savings. But at only 2,000 parts? The math doesn't work. You'd save $16,000 in processing but spend $40,000 on tooling.

High volume metal stamping advantages multiply as quantities increase:

- Cycle speed: Metal stamping machines produce parts in seconds, not minutes or hours

- Consistency: Once dialed in, dies produce identical parts across millions of cycles

- Material efficiency: Progressive dies optimize strip layouts, minimizing scrap

- Labor reduction: Automated feeding and ejection minimize operator intervention

Low volume metal stamping rarely makes sense unless you're prototyping for eventual high-volume production or the part geometry absolutely requires stamping processes. Even then, exploring alternatives first often reveals better options for initial runs.

When Alternative Methods Make More Sense

Understanding when NOT to use stamping protects your budget and accelerates time-to-market. Each alternative method occupies specific niches where it outperforms traditional metal stamping equipment.

Laser cutting dominates small batch production. According to Hotean's analysis, laser cutting delivers 40% cost reduction compared to stamping for batches under 3,000 units by eliminating $15,000+ tooling costs. You'll also achieve tighter tolerances—±0.1mm versus stamping's ±0.3mm typical—with immediate production capability. No 4-8 week wait for die fabrication. Parts ship within 24-48 hours of receiving digital files.

Choose laser cutting when:

- Production volume stays under 3,000 units

- You need rapid prototyping without tooling commitment

- Precision requirements demand ±0.1mm tolerances

- Designs change frequently between production runs

- Parts require complex 2D profiles without forming

CNC machining handles complexity that stamping cannot achieve. When your parts require 3D geometries with tight tolerances on multiple surfaces, machining delivers. There's no tooling investment—just fixtures and programming. Per-part costs run higher, but for quantities under 5,000, total project cost often comes in lower than stamping.

Hydroforming excels for complex curved surfaces and seamless tubular components. According to Larson Tool, hydroforming uses high-pressure hydraulic fluid to force metal into molds, creating smooth complex shapes without traditional punch-and-die tooling. Automotive manufacturers often choose hydroforming for structural components requiring specific strength-to-weight ratios and aerodynamic profiles.

3D printing serves prototyping and extremely low volumes where per-part cost matters less than speed and flexibility. While not suitable for production metal parts in most cases, additive manufacturing enables design validation before committing to any traditional manufacturing investment.

The decision matrix ultimately comes down to honest assessment of your actual needs:

- If volumes exceed 10,000 annually with stable designs, stamping wins on economics

- If you need parts fast without tooling delays, laser cutting or machining deliver

- If designs are evolving or quantities are uncertain, avoid tooling investment entirely

- If part geometry requires smooth complex curves, evaluate hydroforming

Smart manufacturers often combine methods. They laser-cut prototypes and initial production runs while tooling is fabricated, then transition to stamping once volumes justify the investment. This hybrid approach minimizes risk while positioning for efficient high-volume production when demand materializes.

Automotive applications represent the clearest case for stamping investment. When production volumes reach hundreds of thousands of parts annually, the per-piece economics make alternatives impractical. Understanding what automotive OEMs require from their stamping suppliers helps you evaluate whether your project fits this high-volume profile.

Automotive Stamping Applications and Industry Standards

When production volumes reach hundreds of thousands of units annually, automotive metal stamping becomes the only economically viable manufacturing approach. But high volume alone doesn't define automotive stamping. This sector operates under the most demanding quality standards in manufacturing, with tolerances sometimes as tight as 0.05mm and zero tolerance for defects that could compromise vehicle safety.

Whether you're stamping car parts for body panels, structural reinforcements, or intricate brackets, automotive OEMs expect perfection. A single defective component can trigger costly recalls, production line shutdowns, and reputational damage that far exceeds the part's value. Understanding these standards helps you evaluate whether your current capabilities meet automotive requirements or identify gaps that need addressing.

Meeting Automotive OEM Quality Standards

The automotive industry doesn't just prefer quality management systems. It mandates them. According to Master Products, IATF 16949:2016 certification creates a baseline for the quality you can expect when contracting out your automotive stamping projects. This certification harmonizes quality assessment systems across the global automotive supply chain, standardizing both production processes and results.

What makes IATF 16949 different from standard ISO 9001 certification? According to Plantmetal, the certification demands increased attention to customer-specific requirements, expectations, and concerns. Every step of the process must be documented, traceable, and proactively managed for risk.

Key requirements that any high volume stamping shop must meet include:

- Advanced Product Quality Planning (APQP): Structured methodology ensuring product quality through systematic planning before production begins

- Production Part Approval Process (PPAP): Comprehensive documentation proving manufacturing processes consistently produce parts meeting specifications

- Failure Mode and Effects Analysis (FMEA): Proactive identification of potential failure points and preventive measures before defects occur

- Statistical Process Control (SPC): Continuous monitoring of production parameters to catch variations before they produce out-of-spec parts

- Complete Traceability: Ability to track every component from raw material through final delivery

Progressive stamped automotive parts face particularly stringent scrutiny. Automotive stamping dies must maintain dimensional consistency across millions of cycles while producing components that meet both functional requirements and aesthetic standards for visible surfaces. The automotive stamping die itself becomes a critical quality factor, with die design directly influencing achievable tolerances and surface finishes.

From Prototyping to Production Volume

Automotive components progressive stamping projects don't jump directly to full production. The path from concept to volume manufacturing follows a structured progression designed to validate designs, prove processes, and minimize risk before committing to high-volume tooling.

Imagine you're developing a new structural bracket. The journey typically unfolds across these phases:

- Design Validation: CAE (Computer-Aided Engineering) simulation models material flow, springback behavior, and stress distribution before any metal is cut. This digital validation catches problems that would otherwise require expensive tooling modifications.

- Rapid Prototyping: Initial parts produced through soft tooling or alternative methods verify fit and function. Speed matters here. Suppliers capable of delivering prototype automotive stamping components in 5 days rather than 5 weeks accelerate your development timeline significantly.

- Process Validation: Pre-production runs using production-intent tooling confirm that manufacturing processes deliver consistent results. First article inspection verifies all dimensions against specifications.

- Production Launch: Full-volume manufacturing begins with ongoing monitoring to maintain quality throughout the production life cycle.

CAE simulation deserves special attention. According to Keysight, simulation allows engineers to optimize die designs before fabrication, reducing costly trial-and-error iterations. For automotive applications where tolerances may reach 0.05mm, this upfront analysis prevents expensive modifications later.

The combination of rigorous quality systems and advanced simulation capabilities distinguishes suppliers who consistently meet automotive requirements. For example, Shaoyi's automotive stamping die solutions demonstrate what this integration looks like in practice. Their IATF 16949 certification provides the quality framework, while CAE simulation enables defect-free results. Their 93% first-pass approval rate reflects how these systems work together, and 5-day rapid prototyping capability keeps development timelines on track.

When evaluating automotive stamping partners, look beyond basic capability claims. Ask about first-pass approval rates, prototyping speed, and specific quality certifications. Verify that suppliers can demonstrate APQP and PPAP compliance. Confirm they use simulation to optimize die designs before fabrication. These factors separate suppliers who consistently deliver from those who struggle with automotive's demanding standards.

The automotive sector's requirements may seem daunting, but they exist for good reason. When parts perform exactly as specified across millions of vehicles, the investment in quality systems and advanced engineering pays dividends in reliability, safety, and long-term manufacturing efficiency. Your next step involves evaluating whether your project demands these automotive-grade capabilities or whether standard industrial specifications meet your actual requirements.

Making the Right Tool and Die Stamping Decision

You've absorbed a lot of technical information about stamping tool and die processes, material selection, tolerance capabilities, and when stamping makes sense versus alternatives. Now comes the practical question: how do you pull all these factors together to make a confident decision for your specific project? The difference between a successful stamping project and a frustrating one often comes down to systematic evaluation before you commit.

According to KY Hardware, selecting the right stamping supplier is a critical decision that directly impacts your product quality, production timeline, and bottom line. Rushing this evaluation phase often leads to selecting a supplier who is a poor fit for your project's complexity or scale. Let's break down exactly what you need to assess.

Your Stamping Project Evaluation Checklist

Before reaching out to potential suppliers, complete this internal assessment. Having clear answers prevents miscommunication and ensures you're comparing suppliers on the right criteria.

- Volume Requirements: What's your Estimated Annual Usage (EAU)? Remember, stamping typically becomes economical above 10,000 parts annually. If you're below this threshold, revisit whether alternative methods like laser cutting or CNC machining deliver better total value.

- Part Complexity Assessment: Does your component require progressive stamping, transfer dies, or compound dies? According to Atlas Stamping, your stamping partner must be capable of simultaneous or continuous stamping, pressing, cutting, and forming of both two-dimensional and three-dimensional parts. Document critical-to-function features and any secondary operations needed like heat treating, plating, or assembly.

- Material Considerations: Specify exact material type, thickness, and temper requirements. Different materials behave differently in dies, so confirm potential suppliers have deep experience with your specific alloys. Per CEP Technologies, there are often highly suitable alternatives that improve manufacturability, are more readily available, or help lower production costs.

- Tolerance Needs: Are you requiring standard commercial tolerances or tighter precision die & stamping specifications? Be realistic. Over-tolerancing non-critical dimensions increases cost without adding functional value. Identify which dimensions truly matter for fit and function.

- Timeline Requirements: What are your prototyping needs and lead time expectations for first production runs? Consider long-term production forecasts that help partners plan capacity.

- Value-Added Services: Do you need finishing, assembly, or specialized packaging? A supplier offering these metal stamping components and services in-house simplifies your supply chain significantly.

Selecting the Right Manufacturing Partner

Once you've defined your requirements, evaluate potential suppliers against criteria that matter most for long-term success. The ideal partner does more than just produce parts. They offer engineering expertise and function as an extension of your team.

Consider these supplier evaluation criteria:

- Tool & Die Design Capabilities: Look for suppliers with in-house tool and die design expertise. According to KY Hardware, the best stamping suppliers provide engineering expertise, not just manufacturing capacity. Their early involvement can lead to significant cost savings and more robust part designs through Design for Manufacturability (DFM) analysis.

- Quality Certifications: A robust quality management system is non-negotiable. ISO 9001 represents baseline expectations. For automotive stamping applications, IATF 16949 certification demonstrates commitment to the most rigorous industry standards. These certifications validate third-party assessment of consistent, reliable processes.

- Equipment Capabilities: The type and tonnage of presses determine the size, thickness, and complexity of parts a supplier can produce. According to Atlas Stamping, stamping presses are available in a wide variety of sizes, tonnage capacities, stroke lengths, and operating speeds. Verify their metal stamping tooling aligns with your specific requirements.

- Prototyping Speed: Rapid prototyping capability accelerates your development timeline. Suppliers who can deliver prototype parts in days rather than weeks provide competitive advantages when time-to-market matters.

- Industry Experience: Look for proven track records within your industry. A company serving automotive understands PPAP requirements, while one focused on medical devices knows cleanliness and traceability standards. Ask for case studies, testimonials, or references from similar companies.

- Capacity and Logistics: Can they meet your volume demands today and scale with you tomorrow? Assess inventory management programs like Kanban or Just-in-Time delivery that reduce your on-hand stock and improve cash flow.

The lowest price per part rarely equals best value. As you evaluate potential partners, consider the less tangible aspects: responsiveness to questions, willingness to collaborate on design optimization, and transparency about capabilities and limitations.

For readers exploring precision stamping die solutions, particularly in automotive applications, Shaoyi's comprehensive mold design and fabrication capabilities exemplify the full-service approach worth seeking. Their engineering team delivers cost-effective, high-quality tooling tailored to OEM standards, with IATF 16949 certification backing their quality systems.

Create a weighted scorecard assigning importance levels to each criterion based on your priorities. Score each supplier objectively. This approach removes personal bias and clearly identifies partners best aligned with your most critical needs. The final decision should reflect a holistic view of capabilities, quality, support, and total cost of ownership, not just piece price.

By conducting thorough internal assessment, using this detailed checklist, and evaluating partnership potential systematically, you move beyond transactional relationships. The goal is finding a strategic partner committed to quality, offering valuable engineering expertise in stamping applications, and dedicated to helping you achieve manufacturing goals for years to come.

Frequently Asked Questions About Tool and Die Stamping

1. What is the difference between tool and die and stamping?

Tool and die refers to the custom-engineered components used in manufacturing, where the 'tool' is the complete assembly (including fixtures, gauges, and cutting instruments) and the 'die' is the specialized component that shapes metal. Stamping is the actual manufacturing process that uses these tools and dies to transform flat sheet metal into finished parts through controlled force. In essence, tool and die making creates the equipment, while stamping is the production process using that equipment. Suppliers like Shaoyi integrate both capabilities, offering comprehensive mold design and fabrication alongside high-volume stamping production.

2. How much does a metal stamping die cost?

Metal stamping die costs vary significantly based on complexity. Simple dies range from $3,000 to $30,000, while complex progressive or transfer dies can reach $200,000 or more. The investment becomes economical when producing 10,000+ parts annually. For automotive applications requiring IATF 16949 certification and CAE simulation for defect-free results, expect higher tooling costs that deliver superior quality and consistency. Many manufacturers find the per-part savings at volume quickly offset initial tooling investment.

3. What is the difference between die cut and stamping?

Die cutting is a subset of stamping focused specifically on cutting shapes from flat materials, while stamping encompasses a broader range of operations including cutting, bending, forming, drawing, and coining. Stamping transforms flat sheet metal into three-dimensional components through multiple operations, whereas die cutting typically produces flat, two-dimensional parts. Additionally, metal stamping is almost always a cold working process using sheet metal, while die casting (often confused with die cutting) uses molten metal poured into molds.

4. When should I choose stamping over laser cutting or CNC machining?

Choose tool and die stamping when production volumes exceed 10,000 parts annually and designs are stable. At high volumes, stamping delivers the lowest per-part cost despite higher upfront tooling investment. For volumes under 3,000 units, laser cutting offers 40% cost reduction by eliminating tooling costs. CNC machining suits complex 3D geometries in quantities under 5,000. Many manufacturers use a hybrid approach—laser cutting prototypes while stamping dies are fabricated, then transitioning to stamping for volume production.

5. What tolerances can precision metal stamping achieve?

Precision metal stamping tolerances vary by operation type. Blanking and piercing achieve ±0.05 to ±0.08mm at high precision levels. Bending and forming typically hold ±0.20mm linear and ±0.5° angular tolerances. Coining operations deliver the tightest tolerances at ±0.025 to ±0.05mm through extreme pressure that eliminates springback. Material thickness affects achievable precision, with thinner materials (0.5-2.0mm) holding tighter tolerances than heavy gauges. Automotive applications sometimes require tolerances as tight as 0.05mm.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —