How Forging Changes Anodizing Custom Forged Aluminum Results

Understanding Anodizing for Custom Forged Aluminum Components

When you think about protective finishes for aluminum, anodizing likely comes to mind. But here's the thing—anodizing custom forged aluminum is fundamentally different from treating cast, extruded, or sheet aluminum. The forging process transforms the metal's internal structure in ways that directly influence how the anodized coating forms, adheres, and performs over time.

So, what is anodized aluminum exactly? It's aluminum that has undergone an electrochemical process to create a durable oxide layer on its surface. This layer provides corrosion resistance, wear protection, and aesthetic appeal. However, the quality of this anodization depends heavily on the base material's characteristics—and forged aluminum brings unique advantages to the table.

What Makes Forged Aluminum Different for Anodizing

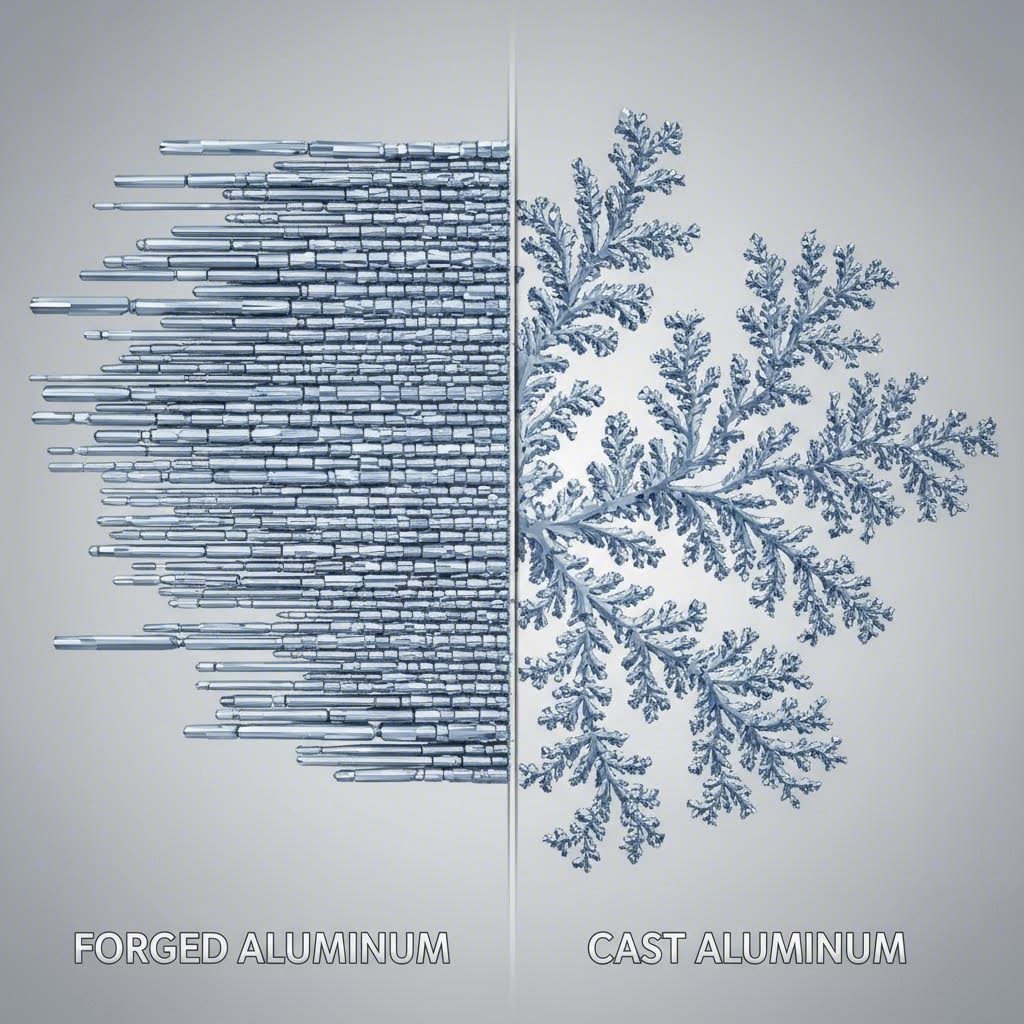

Forged aluminum stands apart because of how it's made. During forging, compressive forces reshape heated aluminum billets, aligning the metal's grain structure in a controlled, uniform pattern. This process eliminates the porosity and internal voids commonly found in cast aluminum, while creating a denser, more homogeneous material than extruded or sheet forms.

Why does this matter for anodizing? Consider these key differences:

- Grain structure uniformity: Forged aluminum's refined microstructure allows for consistent oxide layer formation across the entire surface.

- Absence of porosity: Unlike die cast aluminum, which contains trapped gas voids that disrupt the anodic coating, forged parts offer a solid foundation for uniform anodization.

- Lower impurity concentration: Forging alloys typically contain fewer elements that interfere with the electrochemical process, resulting in cleaner, more predictable finishes.

Cast aluminum, by contrast, often contains high silicon content (10.5-13.5%) and other alloying elements that produce gray, blotchy, or inconsistent oxide layers. The porosity inherent in casting creates weak spots where the anodic film fails to form properly.

Forging creates a refined grain structure that enhances both mechanical properties and anodizing outcomes. The aligned grain flow improves tensile strength and fatigue resistance, while the dense, void-free material enables the formation of a uniform, protective oxide layer that cast aluminum simply cannot achieve.

Why Custom Forging Demands Specialized Finishing Knowledge

Custom anodizing for forged components requires understanding this unique intersection of manufacturing processes. Engineers, procurement professionals, and manufacturers face specific challenges when specifying anodized finishes for forged parts.

The forging process itself introduces considerations that don't apply to other aluminum forms. Hot forging versus cold forging creates different surface characteristics. Die marks, parting lines, and forging scale must be addressed before anodizing can begin. Even the alloy selection during the forging design phase impacts what anodizing types and colors are achievable.

This article serves as your definitive resource for navigating these complexities. You'll learn how forging affects oxide layer formation, which alloys perform best for different anodizing types, and how to specify requirements that ensure your forged components receive the protective finish they deserve. Whether you're designing aerospace structural components, automotive suspension parts, or precision industrial equipment, understanding how forging changes anodizing results will help you make better decisions throughout your supply chain.

How Forging Affects Aluminum Grain Structure and Anodizing Quality

Ever wondered why two aluminum parts from different manufacturing processes look completely different after anodizing? The answer lies deep within the metal's internal structure. Understanding how the anodizing process interacts with forged aluminum's unique grain characteristics reveals why this combination produces superior results.

When you're working with forged aluminum, you're dealing with a material that has been fundamentally transformed at the microstructural level. This transformation directly impacts how aluminum is anodized and what outcomes you can expect in terms of uniformity, appearance, and long-term durability.

How Forging Grain Flow Impacts Oxide Layer Formation

During forging, compressive forces reorganize aluminum's crystalline structure. The metal's grains—the microscopic building blocks that determine material properties—become refined, elongated, and aligned in predictable patterns. This grain flow follows the contours of the forging die, creating what metallurgists call a fibrous microstructure.

How does anodizing work on this refined structure? The electrochemical process relies on consistent material properties across the surface. When current flows through the aluminum in an electrolyte bath, oxide grows perpendicular to the surface at a rate influenced by local grain orientation and alloy distribution. Forged aluminum's uniform grain structure means this growth occurs evenly across the entire part.

Consider the contrast with cast aluminum. Casting produces a dendritic grain structure with random orientations, segregated alloying elements, and microscopic porosity from trapped gases. According to research published in Coatings journal, alloying elements in cast materials often have significantly different electrochemical potentials compared to the aluminum matrix, leading to micro-galvanic coupling during anodization. This creates uneven oxide formation, discoloration, and weak spots in the protective layer.

Hot forging versus cold forging produces distinct surface characteristics that further influence anodizing outcomes:

- Hot forging occurs above aluminum's recrystallization temperature, allowing maximum material ductility and complex shape formation. The process enables better material flow and produces parts with excellent internal integrity. However, hot forging creates surface scale and may require more extensive surface preparation before anodizing.

- Cold forging happens at or near room temperature, resulting in work-hardened surfaces with finer grain structures and superior dimensional accuracy. Cold-forged surfaces typically require less preparation and can achieve tighter tolerances for the anodized coating thickness.

Both methods create the dense, aligned grain structure that supports quality anodizing—but understanding these differences helps you specify appropriate surface preparation for each.

Electrochemical Behavior of Dense Forged Aluminum

So, how do you anodize aluminum to achieve optimal results on forged parts? The process itself involves electrolysis anodizing—immersing the aluminum part as an anode in an acidic electrolyte while applying controlled electrical current. Oxygen ions migrate through the solution and combine with aluminum atoms at the surface, building an oxide layer from the outside in.

The electrochemical behavior differs significantly based on the base material's density and structure. Forged aluminum's characteristics create ideal conditions for this process:

- Consistent current distribution: Without the porosity found in cast parts, electrical current flows uniformly across the surface, producing even oxide growth.

- Predictable oxide thickness: The homogeneous grain structure allows precise control over anodizing parameters, resulting in consistent coating thickness within tight tolerances.

- Superior barrier properties: Dense base material enables the formation of a continuous, defect-free oxide layer with better corrosion resistance.

Research from Vrije Universiteit Brussel confirms that porous anodic layers form through a complex mechanism involving ion migration under high electric fields. The aluminum oxide grows at the metal/oxide interface as oxygen ions migrate inward, while aluminum ions migrate outward. In forged aluminum, this ionic migration occurs uniformly because there are no voids, inclusions, or compositional variations to disrupt the process.

The table below compares how different aluminum manufacturing methods affect grain structure and subsequent anodizing outcomes:

| Characteristic | Forged Aluminum | Cast Aluminum | Extruded Aluminum |

|---|---|---|---|

| Grain Structure | Fine, elongated, aligned with forging flow | Coarse, dendritic, random orientation | Elongated in extrusion direction, moderate uniformity |

| Material Density | High density, minimal porosity | Lower density, contains gas porosity and shrinkage voids | Good density, occasional internal voids possible |

| Alloy Distribution | Homogeneous, evenly distributed elements | Segregated, intermetallic phases at grain boundaries | Generally uniform with some directional segregation |

| Anodizing Uniformity | Excellent—consistent oxide layer across surface | Poor to fair—uneven thickness, blotchy appearance | Good—uniform in extrusion direction, may vary at ends |

| Color Consistency | Excellent—even dye absorption for consistent color | Poor—mottled appearance, color variations | Good—generally consistent when grain direction is controlled |

| Oxide Layer Durability | Superior—dense, continuous protective film | Limited—weak spots at porosity, prone to pitting | Good—performs well in most applications |

| Typical Applications | Aerospace structures, automotive suspension, high-performance components | Engine blocks, housings, decorative non-critical parts | Architectural trim, heat sinks, standard structural profiles |

Understanding how forging transforms aluminum's microstructure explains why this manufacturing method pairs so effectively with anodizing. The dense, uniform grain structure created through forging provides the ideal substrate for the electrochemical oxide formation process. This combination delivers anodized components with superior appearance, consistent properties, and enhanced durability—characteristics that become even more important when selecting the right alloy for your specific application.

Aluminum Alloy Selection for Optimal Anodizing Results

Choosing the right anodized aluminum material starts long before the part reaches the anodizing tank. The alloy you select during the forging design phase determines what finishes are achievable, how consistent your aluminum anodizing colors will appear, and whether the protective oxide layer meets your performance requirements.

Not all forging alloys behave the same way during anodization. Some produce brilliant, uniform finishes with excellent dye absorption. Others—particularly high-strength alloys with significant copper or zinc content—present challenges that require careful management. Understanding these differences helps you balance mechanical performance with finishing requirements.

Best Forging Alloys for Type II Decorative Anodizing

When your application demands consistent anodizing colors and a flawless clear anodized aluminum finish, alloy selection becomes critical. Type II sulfuric acid anodizing is the industry standard for decorative and protective finishes, but its results vary dramatically based on base material composition.

The 6xxx series alloys—particularly 6061 and 6063—represent the gold standard for aluminum anodizing. These magnesium-silicon alloys offer an excellent balance of forgeability, mechanical strength, and finishing characteristics:

- 6061 aluminum: The most widely used forging alloy for anodized applications. It produces a consistent, slightly gray-tinted oxide layer that accepts dyes uniformly. The magnesium and silicon alloying elements integrate smoothly into the oxide structure without disrupting formation.

- 6063 aluminum: Often called the "architectural alloy," 6063 produces the clearest, most aesthetically pleasing anodized finishes. While less common in heavy forging applications due to lower strength, it excels where appearance is paramount.

These alloys achieve their superior anodizing characteristics because their primary alloying elements—magnesium and silicon—form compounds that don't significantly interfere with the electrochemical oxide formation process. The result is a uniform, pore-free oxide layer that provides excellent corrosion protection and consistent aluminium anodizing colours across large production runs.

For applications requiring both good forgeability and decorative finishing, 6061 remains the preferred choice. Its T6 temper provides yield strengths around 276 MPa while maintaining excellent anodizing compatibility—a combination that satisfies both structural and aesthetic requirements.

High-Strength Alloys and Hardcoat Compatibility

What happens when your application demands maximum strength? High-performance forging alloys like 7075, 2024, and 2014 deliver exceptional mechanical properties, but their anodizing behavior requires special consideration.

The challenge with these alloys comes from their alloying elements:

- Copper (in 2xxx series): Copper doesn't oxidize at the same rate as aluminum during anodization. It creates discontinuities in the oxide layer, producing a darker, less uniform appearance. Copper-rich intermetallic particles can also cause localized pitting.

- Zinc (in 7xxx series): While zinc causes fewer finishing problems than copper, it still affects oxide layer consistency and can produce slightly yellowish tints in the anodized coating.

Despite these challenges, high-strength alloys can be successfully anodized—particularly with Type III hardcoat processes. The thicker oxide layers (typically 25-75 micrometers) help mask some of the color inconsistencies, and the primary goal shifts from appearance to functional performance.

Consider these specific alloy characteristics:

- 7075 aluminum: This zinc-alloyed workhorse of aerospace forging produces acceptable anodized finishes, though with slightly reduced color consistency compared to 6061. Its exceptional strength-to-weight ratio makes it the go-to choice for structural forgings where mechanical performance outweighs aesthetic concerns. Hardcoat anodizing works well on 7075, producing durable, wear-resistant surfaces for demanding applications.

- 2024 aluminum: High copper content (3.8-4.9%) makes 2024 one of the more challenging alloys to anodize attractively. The oxide layer tends toward darker, less uniform coloration. However, for aircraft structural components where strength and fatigue resistance take priority, 2024 remains widely used with functional anodized coatings.

- 2014 aluminum: Similar copper content to 2024 produces comparable anodizing challenges. This alloy sees extensive use in heavy-duty forged components where its excellent machinability and high strength justify the finishing limitations.

The table below provides a comprehensive comparison of common forging alloys and their anodizing characteristics:

| Alloy Designation | Primary Alloying Elements | Typical Forging Applications | Anodizing Compatibility | Expected Finish Quality |

|---|---|---|---|---|

| 6061-T6 | Mg 0.8-1.2%, Si 0.4-0.8% | Suspension components, structural frames, marine hardware | Excellent | Clear to light gray, excellent dye absorption, uniform appearance |

| 6063-T6 | Mg 0.45-0.9%, Si 0.2-0.6% | Architectural components, decorative hardware, thin-walled parts | Excellent | Clearest finish available, superior color consistency, ideal for bright dip |

| 7075-T6 | Zn 5.1-6.1%, Mg 2.1-2.9%, Cu 1.2-2.0% | Aerospace structures, high-stress automotive parts, sporting equipment | Good | Slightly darker gray tone, minor color variation possible, hardcoat recommended |

| 7050-T7 | Zn 5.7-6.7%, Mg 1.9-2.6%, Cu 2.0-2.6% | Aircraft bulkheads, wing skins, critical aerospace forgings | Good | Similar to 7075, excellent hardcoat response, stress corrosion resistant |

| 2024-T4 | Cu 3.8-4.9%, Mg 1.2-1.8% | Aircraft fittings, truck wheels, screw machine products | Fair | Darker oxide layer, less uniform color, functional rather than decorative |

| 2014-T6 | Cu 3.9-5.0%, Si 0.5-1.2%, Mg 0.2-0.8% | Heavy-duty forgings, aircraft structures, high-strength fittings | Fair | Similar to 2024, darker appearance, best suited for protective coatings |

| 5083-H116 | Mg 4.0-4.9%, Mn 0.4-1.0% | Marine forgings, pressure vessels, cryogenic applications | Very Good | Good clarity, slight yellowish tint possible, excellent corrosion resistance |

When specifying anodized aluminum colors for forged components, remember that the same dye applied to different alloys produces different results. A black anodize on 6061 appears deep and uniform, while the same process on 2024 may look mottled or uneven. For critical aesthetic applications, prototype testing with your specific alloy and anodizing process combination is essential.

The practical takeaway? Match your alloy selection to your finishing priorities. If consistent appearance and broad color options matter most, specify 6061 or 6063. When maximum strength is non-negotiable and you can accept functional finishes, 7075 or the 2xxx series alloys deliver the mechanical performance—just work with your anodizing partner to set appropriate expectations for finish quality. Understanding these alloy-specific behaviors during the design phase prevents costly surprises and ensures your forged components meet both structural and surface requirements.

Comparing Type I Type II and Type III Anodizing for Forged Parts

Now that you understand how alloy selection affects your finishing options, the next decision involves choosing the right anodizing type for your forged components. This choice directly impacts coating thickness, surface hardness, corrosion protection, and dimensional accuracy—all critical factors when specifying anodizing custom forged aluminum for demanding applications.

Military specification MIL-A-8625 defines three primary anodizing types, each serving distinct purposes. Understanding how these processes interact with forged aluminum's dense grain structure helps you make informed decisions that balance performance requirements with practical manufacturing constraints.

Type II vs Type III for Structural Forged Parts

For most forged aluminum applications, the decision comes down to Type II versus Type III anodizing. While Type I chromic acid anodizing still exists for specialized aerospace applications, environmental regulations and performance requirements have shifted the industry toward these two sulfuric acid-based processes.

Here's what distinguishes each anodizing type:

Type I - Chromic Acid Anodizing:

- Produces the thinnest oxide layer (0.00002" to 0.0001")

- Minimal dimensional impact—ideal for tight-tolerance forged parts

- Excellent paint adhesion base for subsequent coating operations

- Lower fatigue strength reduction compared to thicker coatings

- Limited to gray finish with poor dye acceptance

- Increasingly restricted due to hexavalent chromium environmental concerns

Type II - Sulfuric Acid Anodizing (MIL-A-8625 Type II Class 1 and Class 2):

- Conventional coating thickness range of 0.0001" to 0.001"

- Excellent balance of corrosion resistance and decorative options

- Accepts organic and inorganic dyes for broad color selection

- MIL-A-8625 Type II Class 1 designates undyed (clear) finishes

- MIL-A-8625 Type II Class 2 indicates dyed coatings

- Most cost-effective option for general-purpose protection

Type III - Hard Anodize (Hardcoat):

- Significantly thicker oxide layer (0.0005" to 0.003" typical)

- Exceptional hardness reaching 60-70 Rockwell C—approaching sapphire levels

- Superior abrasion and wear resistance for high-friction applications

- Performed at lower bath temperatures (34-36°F) with higher current densities

- Limited color options—naturally produces dark gray to black appearance

- May reduce fatigue life in highly stressed components

The type 2 anodizing process remains the workhorse for forged components requiring both protection and aesthetics. When you need decorative finishes with good corrosion resistance, Type II delivers consistent results on forged aluminum's uniform grain structure. The porous oxide layer absorbs dyes evenly, producing the color consistency that forging's homogeneous microstructure enables.

Hard anodize becomes essential when your forged parts face extreme operating conditions. Consider the hardness comparison: while bare 6061 aluminum measures approximately 60-70 Rockwell B, Type III hard anodize reaches 65-70 Rockwell C—a dramatic improvement that rivals the hardness of sapphire. This makes hardcoat anodizing ideal for forged gears, valve components, pistons, and sliding surfaces where wear resistance determines service life.

It's worth noting that anodizing steel isn't possible through this electrochemical process—aluminum's unique oxide formation chemistry makes it specially suited for anodization. When engineers need comparable surface hardness on steel components, they turn to different treatments like nitriding or chrome plating. This distinction matters when you're evaluating material choices for applications where hard anodize inc specifications might apply.

Dimensional Planning for Anodizing Layer Buildup

Here's where forging's precision becomes critical: anodizing changes your part dimensions. Unlike painting or plating that simply adds material to the surface, anodizing grows the oxide layer both outward and inward from the original aluminum surface. Understanding this growth pattern prevents tolerance stack-up problems in your forged assemblies.

The general rule? Approximately 50% of the total oxide thickness builds outward (increasing external dimensions), while 50% penetrates inward (converting base aluminum to oxide). This means:

- Outside diameters grow larger

- Inside diameters (holes, bores) become smaller

- Threaded features may require masking or post-anodizing tapping

- Mating surfaces need tolerance adjustments during forging design

For Type II anodizing, the dimensional change typically ranges from 0.0001" to 0.0005" per surface—manageable for most applications. Type III hardcoat presents greater challenges. A specification calling for 0.002" hardcoat thickness means each surface grows approximately 0.001", and critical features may need grinding or honing after anodizing to meet final dimensions.

The table below compares all three anodizing types with specifications relevant to forged component applications:

| Property | Type I (Chromic Acid) | Type II (Sulfuric Acid) | Type III (Hardcoat) |

|---|---|---|---|

| Oxide Thickness Range | 0.00002" - 0.0001" | 0.0001" - 0.001" | 0.0005" - 0.003" |

| Dimensional Growth (per surface) | Negligible | 0.00005" - 0.0005" | 0.00025" - 0.0015" |

| Surface Hardness | ~40-50 Rockwell C | ~40-50 Rockwell C | 60-70 Rockwell C |

| Corrosion Resistance | Excellent | Very Good to Excellent | Excellent |

| Wear/Abrasion Resistance | Low | Moderate | Excellent |

| Color Options | Gray only | Full spectrum with dyes | Limited (natural dark gray/black) |

| Fatigue Impact | Minimal reduction | Moderate reduction | Greater reduction possible |

| Process Temperature | ~95-100°F | ~68-70°F | ~34-36°F |

| Ideal Forged Component Applications | Fatigue-critical aerospace structures, paint base for aircraft skins | Suspension arms, architectural hardware, consumer products, marine fittings | Gears, pistons, valve bodies, hydraulic cylinders, high-wear surfaces |

| MIL-A-8625 Classes | Class 1 (non-dyed) | Class 1 (clear), Class 2 (dyed) | Class 1 (non-dyed), Class 2 (dyed) |

When designing forged parts destined for anodizing, incorporate these thickness considerations into your tolerance analysis. Specify whether dimensions on your drawings apply before or after anodizing—this single detail prevents countless manufacturing disputes. For precision fits, consider specifying post-anodizing machining of critical features, or work with your forging supplier to adjust pre-anodizing dimensions to hit final targets after coating.

The interaction between forged aluminum's dimensional stability and anodizing layer buildup actually works in your favor. Forging produces parts with consistent density and minimal residual stress, meaning the oxide layer grows uniformly without the warping or distortion that can affect cast or heavily machined parts. This predictability allows tighter tolerance control and more reliable assembly fit—advantages that become especially important when specifying hardcoat anodizing for precision forged components requiring both wear resistance and dimensional accuracy.

Surface Preparation Requirements for Forged Aluminum

You've selected the right alloy and specified the appropriate anodizing type—but here's a reality check. Even the best anodizing process cannot compensate for poor surface preparation. When you're finishing anodizing custom forged aluminum, the preparation phase often determines whether you achieve a flawless anodized finish or a part that reveals every hidden flaw in magnified detail.

Think of anodizing as a transparent amplifier. The electrochemical oxide layer doesn't hide surface imperfections—it highlights them. Every scratch, die mark, and subsurface defect becomes more visible after anodization. This makes pre-anodizing surface preparation absolutely critical for forged components, which present unique challenges compared to machined or extruded parts.

Removing Forging Scale and Die Marks Before Anodizing

Forged aluminum emerges from the dies with surface characteristics that require specific treatment before anodizing. Hot forging creates oxide scale on the aluminum surface, while the forging dies leave their own marks on every part they produce.

According to Southwest Aluminum's technical guidance, preparation before anodization includes processes of removing sharp edges, achieving smooth roughness, leaving certain machining allowance caused by coating layer thickness, designing special jigs, and protecting surfaces that don't require anodizing. This comprehensive approach ensures the anodized coating forms correctly and meets specification requirements.

Common forging surface conditions requiring attention include:

- Forging scale: The oxide layer formed during hot forging differs chemically from the controlled anodic oxide you want to create. This scale must be completely removed to ensure uniform oxide growth during anodization.

- Die marks and witness lines: Impressions from die surfaces transfer to every forged part. While some marks may be acceptable for functional applications, decorative finishes require mechanical removal or blending.

- Parting lines: Where die halves meet, a visible line or slight mismatch occurs. Flash removal often leaves rough edges that need smoothing before the part enters the anodizing tank.

- Flash remnants: Even after trimming, residual flash material can leave raised edges or burrs that disrupt uniform oxide formation.

The goal is creating a uniform surface where the electrochemical process can produce consistent results. Etched metal surfaces accept anodizing more uniformly than surfaces with varying textures or contamination levels. The etching process—typically using sodium hydroxide solutions—removes a thin layer of aluminum to create a matte, chemically clean surface ready for oxide formation.

Identifying Defects That Will Show Through Anodized Finish

Here's where experience becomes invaluable. Certain forging defects remain invisible on raw aluminum but emerge dramatically after anodizing. Catching these problems before parts enter the anodizing line saves significant rework costs and prevents delivery delays.

Research from industry sources identifies several common forging defects that impact anodizing outcomes:

- Laps: These occur when the metal surface folds over itself during forging, creating a seam that doesn't fully weld. Laps appear as dark lines or streaks after anodizing because the oxide layer forms differently at these discontinuities. The defects are most likely to form in sharp corners or areas with thin walls.

- Seams: Similar to laps, seams represent linear discontinuities in the metal structure. They may be nearly invisible before anodizing but become clearly defined afterward.

- Inclusions: Foreign material particles trapped within the aluminum during forging create localized disruptions in the anodized coating. These non-metallic particles don't anodize like the surrounding aluminum, producing spots or pits in the finished surface.

- Porosity: While less common in forged parts than castings, heavy sections or areas with complex material flow can develop small voids. Electrolyte trapped in these pores during anodizing leads to staining or corrosion issues.

- Cracks: Stress cracks from the forging process or thermal cycling become dramatically visible after anodizing. The oxide layer cannot bridge cracks, making them appear as dark lines in the finished coating.

Proper forging practices minimize these defects at the source. Using correct die lubricants, optimizing forging temperatures, reducing sharp corners in die design, and implementing proper material handling all contribute to defect-free forgings ready for quality anodizing.

Before committing parts to the anodizing process, thorough inspection identifies problems that require remediation. Visual examination under proper lighting reveals most surface defects, while dye penetrant testing can detect subsurface laps or seams that might otherwise go unnoticed until after anodizing.

The following workflow outlines the complete surface preparation sequence for cleaning anodized aluminum parts—from the moment they leave the forging dies through final pre-anodizing treatment:

- Post-forging inspection: Examine parts immediately after forging for obvious defects including laps, cracks, porosity, and dimensional conformance. Reject or segregate non-conforming parts before investing in further processing.

- Flash and burr removal: Trim excess material from parting lines and remove any flash using appropriate cutting or grinding methods. Ensure no raised edges or sharp burrs remain.

- Die mark remediation: Evaluate die marks against finish requirements. For decorative alu finish applications, mechanical blending or polishing may be necessary. Functional parts may proceed with acceptable die witness marks.

- Defect repair: Address repairable defects such as minor laps or surface porosity through localized grinding or machining. Document any repairs for quality records.

- Machining operations: Complete all required machining before anodizing. Remember to account for anodizing layer buildup in dimensional calculations for critical features.

- Degreasing: Remove all cutting fluids, lubricants, and handling oils using appropriate solvents or alkaline cleaners. Contamination prevents uniform etching and oxide formation.

- Alkaline cleaning: Immerse parts in alkaline solution to remove remaining organic contamination and prepare the surface for etching.

- Etching: Process parts through sodium hydroxide or similar etchant to remove the natural oxide layer and create a uniform, matte surface texture. Control etch time and temperature to achieve consistent results.

- Desmutting: Remove the dark smut layer left by etching using nitric acid or proprietary desmut solutions. This step reveals the clean aluminum surface ready for anodizing.

- Final rinse and inspection: Thoroughly rinse parts in deionized water and inspect for any remaining contamination, water breaks, or surface irregularities before loading into the anodizing tank.

Following this systematic approach ensures your forged components enter the anodizing process in optimal condition. The anodized coating will form uniformly across properly prepared surfaces, delivering the corrosion resistance, appearance, and durability your application demands.

Keep in mind that surface preparation requirements may vary based on the specific anodizing type and final finish requirements. Type III hardcoat applications often tolerate slightly rougher surface conditions since the thick oxide layer provides more coverage, while decorative Type II finishes demand meticulous preparation for consistent appearance. Discuss specific requirements with your anodizing service provider during the design phase to establish appropriate surface finish specifications for your forged components.

Design Considerations for Anodizing Custom Forged Components

Surface preparation gets your parts ready for the anodizing tank—but what about the decisions made months earlier during the design phase? The most successful anodized aluminum parts result from intentional design choices that account for finishing requirements from the very beginning. When you're engineering forged components destined for anodization, integrating these considerations early prevents costly modifications and ensures your anodized parts perform exactly as intended.

Think of it this way: every design decision—from alloy selection to tolerance specification to feature geometry—cascades forward to influence anodizing outcomes. Engineers who understand this relationship create drawings that manufacturing teams can execute efficiently, anodizing specialists can process correctly, and end users receive with confidence.

Tolerance Stack-Up Calculations for Anodized Forged Parts

Remember the dimensional growth we discussed earlier? This phenomenon demands careful attention during tolerance analysis. When designing forged components, you must decide whether your critical dimensions apply before or after anodizing—and communicate that decision clearly on your engineering drawings.

Consider a forged bearing housing with a 25.000mm bore requiring ±0.025mm tolerance. If you specify Type III hardcoat at 0.050mm thickness, the anodizing process will reduce that bore diameter by approximately 0.050mm (0.025mm growth per surface × 2 surfaces). Your machining target must compensate for this reduction if the final tolerance applies post-anodizing.

Critical design considerations for dimensional planning include:

- Define tolerance application point: Specify "dimensions before anodizing" or "dimensions after anodizing" in drawing notes to eliminate ambiguity.

- Calculate coating buildup: For Type II, plan for 0.0001"-0.0005" per surface. For Type III, budget 0.00025"-0.0015" per surface depending on specified thickness.

- Account for hole shrinkage: Internal diameters decrease by twice the per-surface growth. A 0.002" hardcoat reduces bore diameters by approximately 0.002".

- Consider mating features: Parts that assemble together need coordinated tolerance adjustments. A shaft and bore designed for interference fit may bind if both receive hardcoat anodizing without compensation.

- Specify corner radii: NASA's PRC-5006 specification recommends minimum radii based on coating thickness: 0.03" radius for 0.001" coating, 0.06" radius for 0.002" coating, and 0.09" radius for 0.003" coating.

For complex Type III applications, NASA's process specification recommends specifying both final dimensions and "machine to" dimensions on engineering drawings. This approach eliminates confusion and ensures machinists understand exactly what dimensions they need to achieve before the part goes to anodizing.

Early collaboration between forging engineers and finishing teams prevents the most common—and most expensive—anodizing failures. When anodizing requirements inform forging design from day one, parts arrive at the finishing line ready for processing without the rework, delays, and cost overruns that plague projects where finishing is an afterthought.

Specifying Anodizing Requirements on Forging Drawings

Your engineering drawing communicates critical information to everyone who touches your forged component. Incomplete or ambiguous anodizing callouts lead to incorrect processing, rejected parts, and production delays. Anodizing specialists need specific information to process your parts correctly.

According to NASA's anodizing specification, a proper drawing callout should follow this format:

ANODIZE PER MIL-A-8625, TYPE II, CLASS 2, COLOR BLUE

This simple callout communicates the governing specification (MIL-A-8625), process type (Type II sulfuric acid), class designation (Class 2 for dyed coatings), and color requirement. For undyed parts, specify Class 1. When selecting anodizing colors for aluminum, remember that achievable colors depend on your alloy—discuss options with your anodizing provider before finalizing specifications.

Essential drawing information for anodizing equipment operators includes:

- Specification reference: MIL-A-8625, ASTM B580, or applicable customer specification

- Anodizing type: Type I, IB, IC, II, IIB, or III

- Class designation: Class 1 (non-dyed) or Class 2 (dyed)

- Color callout: For Class 2, specify color name or reference AMS-STD-595 color number

- Coating thickness: Required for Type III; include tolerance (e.g., 0.002" ±0.0004")

- Surface finish requirements: Specify matte or glossy as needed

- Sealing requirements: Hot water seal, nickel acetate, or other specified method

- Electrical contact locations: Identify acceptable racking points

- Masking requirements: Clearly identify features requiring anodize masking

Masking deserves special attention for forged components. Industry experts emphasize that masking is essential when parts require electrical contact points or when anodic coating would cause dimensional issues. For threaded features, the decision depends on thread size and anodizing type.

Practical masking guidance for common forged part features:

- Threaded holes: For Type III hardcoat, mask all threads—the thick coating interferes with thread engagement. For Type II, consider masking threads smaller than 3/8-16 or M8. Larger threads may tolerate thin Type II coatings depending on fit class requirements.

- Bearing surfaces: Surfaces requiring precise fits or electrical conductivity need masking. Specify exact boundaries on drawings.

- Mating surfaces: When parts assemble together, determine whether both surfaces should be anodized, one masked, or both masked based on functional requirements.

- Electrical contact areas: Anodic oxide is an electrical insulator. Any surface requiring conductivity must be masked and may need subsequent chromate conversion coating for corrosion protection.

When masked areas require corrosion protection, NASA's specification notes that "if holes are masked, they should be conversion coated instead to ensure corrosion protection." Include this requirement in your drawing notes when applicable.

The geometry of masked boundaries matters too. Outside edges produce cleaner mask lines than inside corners, where achieving straight, neat mask boundaries becomes significantly more difficult. When possible, design mask boundaries along sharp external edges rather than internal corners or complex curved surfaces.

Finally, communicate with your anodizing provider during the design phase rather than after drawings are released. Experienced anodizing specialists can identify potential problems—from challenging geometries to alloy compatibility concerns—before you've committed to production tooling. This proactive collaboration ensures your forged components receive the quality anodized finish your application demands while minimizing the surprises that derail project timelines and budgets.

Industry Applications for Anodized Forged Aluminum

You've mastered the technical requirements—alloy selection, anodizing types, surface preparation, and design considerations. But where do these anodized forged components actually end up? Understanding real-world applications helps you appreciate why manufacturers invest in both forging and anodizing for their most demanding parts.

The combination of forging's superior mechanical properties with anodizing's protective and aesthetic benefits creates components that outperform alternatives across virtually every industry. From aircraft flying at 35,000 feet to the suspension components absorbing potholes on your daily commute, anodized metal forged from aluminum delivers performance that cast or machined parts simply cannot match.

Automotive Suspension and Drivetrain Forging Applications

The automotive industry's appetite for aluminum continues growing rapidly. According to the Aluminum Association, aluminum content in vehicles has grown consistently over the past five decades and is expected to reach over 500 pounds per vehicle by 2026—a trend that has only accelerated as manufacturers pursue weight savings for improved fuel efficiency and electric vehicle range.

Why choose forged and anodized aluminum for automotive applications? The answer lies in performance requirements that cast components cannot meet:

- Suspension control arms: These high-stress components experience constant fatigue loading from road impacts. Forging creates the aligned grain structure needed for fatigue resistance, while anodizing provides corrosion protection against road salt, moisture, and debris. Black anodized aluminum arms resist the cosmetic degradation that would make untreated parts unsightly within a single winter season.

- Steering knuckles: Critical safety components where failure is not an option. The combination of forging's superior strength-to-weight ratio and anodizing's corrosion barrier ensures these parts maintain their integrity throughout vehicle life.

- Wheel components: Forged aluminum wheels outperform cast alternatives in both strength and weight. Anodizing adds lasting protection against brake dust, road chemicals, and environmental exposure while maintaining the satin anodized aluminum finish that discerning customers expect.

- Transmission and drivetrain parts: Gears, shafts, and housings benefit from hardcoat anodizing's exceptional wear resistance. The dense forged substrate ensures uniform coating thickness, while the sapphire-hard surface reduces friction and extends component life.

- Brake components: Anti-lock brake system parts, caliper housings, and mounting brackets all benefit from anodized protection against the extreme heat cycling and corrosive brake dust environment.

The Aluminum Association notes that the transportation industry uses about 30 percent of all aluminum manufactured in the United States, making it the number one market for the metal. Anodizing plays a crucial role in this growth because it provides the durability, corrosion resistance, and aesthetic quality that automotive manufacturers demand.

Aerospace Structural Forgings Requiring Anodized Protection

Aerospace applications represent perhaps the most demanding environment for anodized forged aluminum. Components must withstand extreme temperature cycling, atmospheric corrosion, and continuous stress loading—often simultaneously. The anodizing industries serving aerospace maintain the strictest quality standards because failure is catastrophic.

Critical aerospace forging applications include:

- Structural bulkheads and frames: These primary load-bearing components carry the entire aircraft structure. Forged 7075 or 7050 aluminum provides exceptional strength-to-weight ratio, while Type I or Type II anodizing prevents corrosion that could compromise structural integrity over decades of service.

- Landing gear components: Subject to extreme impact loading during every landing, these forgings demand maximum fatigue strength. Anodizing protects against corrosion from hydraulic fluids, deicing chemicals, and runway contamination.

- Wing and control surface fittings: Attachment points for flaps, ailerons, and other movable surfaces experience complex loading in every flight regime. The combination of forging and anodizing ensures these critical connections maintain their strength throughout aircraft life.

- Engine mounting hardware: Extreme temperatures, vibration, and chemical exposure from combustion byproducts make this environment exceptionally harsh. Hardcoat anodizing provides the wear resistance and thermal stability these components require.

- Helicopter rotor components: Dynamic loading from rotary-wing flight creates unique fatigue challenges. Forged and anodized aluminum components provide the reliability needed for these life-critical applications.

Unlike painted or plated finishes, anodizing integrates with the aluminum substrate rather than simply adhering to it. This chemical bond eliminates the peeling, flaking, or delamination failures that could compromise safety in aerospace applications.

Electronics and Industrial Sector Applications

Beyond transportation, anodized forged aluminum serves critical functions across electronics and heavy industrial applications where performance, longevity, and appearance all matter.

Electronics and thermal management:

- Heat sinks and thermal solutions: Forged aluminum heat sinks with anodized finishes provide both thermal performance and electrical isolation. The anodic layer's insulating properties prevent short circuits while allowing efficient heat transfer.

- Electronic enclosures: Housings for sensitive equipment benefit from anodizing's EMI shielding enhancement and corrosion protection. Anodized aluminum trim on consumer electronics provides the premium appearance manufacturers demand.

- Connector housings: Precision forged connectors with anodized bodies resist wear from repeated insertion cycles while maintaining dimensional stability.

Industrial equipment and machinery:

- Hydraulic components: Cylinder bodies, valve housings, and pump components benefit from hardcoat anodizing's exceptional wear resistance. The dense forged substrate ensures uniform coating formation for consistent hydraulic sealing.

- Pneumatic actuators: Sliding surfaces require both hardness and dimensional precision that hardcoat anodizing on forged parts provides.

- Food processing equipment: Anodized aluminum's non-toxic, easy-to-clean surface makes it ideal for food contact applications where both hygiene and durability matter.

- Marine hardware: Cleats, fittings, and structural components endure constant saltwater exposure. Anodizing provides corrosion protection far superior to untreated aluminum, while forging ensures the strength needed for mooring and anchoring loads.

It's worth noting that while anodized copper exists for specialized applications, aluminum's unique oxide formation chemistry makes it far better suited for anodization. Copper anodizing produces different results with significantly more limited applications—another reason aluminum dominates when anodized finishes are required.

Why Anodize Instead of Leaving Parts Untreated?

Given the additional processing cost, why not simply use bare forged aluminum? The answer comes down to performance requirements that untreated parts cannot meet.

According to the Anodizing Industry, anodized finishes satisfy every factor that must be considered when selecting a high-performance finish:

- Cost effectiveness: A lower initial finishing cost combines with minimal maintenance requirements for unmatched long-term value.

- Durability: Anodizing is harder and more abrasion resistant than paint. The coating integrates with the aluminum substrate for total bonding and unmatched adhesion that won't chip or peel.

- Color stability: Exterior anodic coatings resist ultraviolet degradation indefinitely. Unlike organic coatings that fade and chalk, anodized colors remain stable for decades.

- Aesthetics: Anodizing maintains the metallic appearance that distinguishes aluminum from painted surfaces, creating a deeper, richer finish than organic coatings can achieve.

- Environmental responsibility: Anodized aluminum is fully recyclable with low environmental impact. The process generates minimal hazardous waste compared to alternative finishing methods.

For forged components specifically, anodizing protects the investment in precision manufacturing. The enhanced mechanical properties created through forging—improved fatigue life, higher strength, better impact resistance—would be compromised by corrosion if left unprotected. Anodizing preserves these properties while adding wear resistance that extends component service life.

The maintenance advantage deserves emphasis. Unlike stainless steel, anodized aluminum won't show fingerprints. The integral oxide layer cannot peel off and resists scratching during handling, installation, and cleaning. Simple rinsing or mild soap and water restores the original appearance—a practical benefit that reduces ongoing costs throughout product life.

Whether your application demands the precision of aerospace structures, the durability of automotive suspension components, or the reliability of industrial equipment, the combination of forging and anodizing delivers performance that alternative manufacturing and finishing methods cannot match. Understanding these application requirements helps you specify the right combination of alloy, anodizing type, and surface preparation for your specific needs—which brings us to the specifications and quality standards that govern these critical finishing processes.

Specifications and Quality Standards for Anodized Forgings

Understanding application requirements is only half the equation. When you're ordering anodized forged aluminum components, you need to speak the language of specifications—the technical standards that define exactly what you're buying and how quality will be verified. For engineers and procurement professionals, mastering these specifications ensures your parts meet requirements the first time, every time.

The anodizing service industry operates under well-established standards that govern coating thickness, hardness, corrosion resistance, and seal quality. Knowing which specifications apply to your application—and how to verify compliance—protects your investment and ensures your forged components perform as designed.

Military and Aerospace Anodizing Specifications for Forgings

MIL-A-8625 remains the foundational specification for anodized aluminum in demanding applications. Originally developed for military aerospace use, this specification now serves as the industry-wide reference for quality anodizing services across all sectors. When you specify "anodize per MIL-A-8625," you're invoking decades of refined requirements that define what constitutes acceptable anodized coatings.

The specification defines the three anodizing types we discussed earlier, along with specific requirements for each:

- MIL-A-8625 Type I: Chromic acid anodizing with coating weight requirements of 200-700 mg/ft². Primarily used where thin coatings are needed to minimize fatigue impact.

- MIL-A-8625 Type II: Sulfuric acid anodizing requiring minimum coating thicknesses of 0.0001" for Class 1 (clear) and 0.0002" for Class 2 (dyed) finishes.

- MIL-A-8625 Type III: Hardcoat anodizing with thickness requirements typically specified on engineering drawings, commonly ranging from 0.0001" to 0.0030" with 50% build and 50% penetration into the base aluminum.

Beyond MIL-A-8625, several complementary specifications govern anodized aluminum for forged aerospace components:

- AMS 2468: Hard anodic coating on aluminum alloys, specifying process requirements for aerospace applications.

- AMS 2469: Hard anodic coating treatment of aluminum alloys with specific thickness and hardness requirements.

- ASTM B580: Standard specification for anodic oxide coatings on aluminum, providing coating classifications and test requirements.

- MIL-STD-171: Finishing of metal and wood surfaces, referencing anodizing requirements within broader surface treatment contexts.

For architectural and commercial applications, AAMA 611 establishes performance requirements for anodized aluminum finishes. This specification defines two classes based on coating thickness and intended use: Class I requires minimum 0.7 mils (18 microns) for exterior applications with 3,000-hour salt spray resistance, while Class II specifies 0.4 mils (10 microns) for interior or light exterior use with 1,000-hour salt spray requirements.

When referencing an anodizing color chart for specification purposes, remember that MIL-A-8625 references AMS-STD-595 (formerly FED-STD-595) for color matching. This standard provides specific color chip numbers that ensure consistent results across different anodizing services providers.

Quality Testing and Acceptance Criteria

How do you know whether your anodized forged parts meet specification requirements? Quality testing provides objective verification that coating properties match what you specified. Understanding these tests helps you interpret test reports and communicate effectively with your anodizing service provider.

The AAMA 611 seal test represents one of the most critical quality verification methods. This procedure evaluates whether the anodic coating's porous structure has been properly sealed—a factor that directly determines long-term durability. The primary method uses the acid dissolution test outlined in ASTM B680, where a sample is weighed, immersed in controlled acid solution, and reweighed. Low mass loss indicates a high-quality seal that effectively closed the oxide layer's pores.

When comparing the acid dissolution test vs ASTM B 136, understand that both evaluate seal quality but through different mechanisms. ASTM B136 measures coating weight loss after exposure to phosphoric-chromic acid solution, providing data on seal integrity. The choice between methods often depends on specification requirements and testing laboratory capabilities.

Additional quality testing methods for anodized forgings include:

- Thickness measurement: Eddy current or microscopic cross-section analysis verifies coating thickness meets specification requirements.

- Salt spray testing: Per ASTM B117, samples undergo accelerated corrosion exposure to verify protective performance. Class I architectural finishes must pass 3,000 hours.

- Abrasion resistance: Taber abrasion testing measures coating durability under controlled wear conditions—particularly important for Type III hardcoat applications.

- Hardness testing: Rockwell or microhardness measurements confirm hardcoat achieves specified hardness levels (typically 60-70 Rockwell C).

- Dielectric testing: Verifies electrical insulation properties when electrical isolation is a functional requirement.

The table below summarizes common specifications with their requirements, testing methods, and typical applications for forged components:

| Specification | Key Requirements | Primary Testing Methods | Typical Forged Component Applications |

|---|---|---|---|

| MIL-A-8625 Type II | Min. 0.0001"-0.0002" thickness; Class 1 (clear) or Class 2 (dyed) | Thickness measurement, seal quality (ASTM B136), salt spray | Aerospace fittings, automotive suspension, marine hardware |

| MIL-A-8625 Type III | 0.0005"-0.003" thickness; 60-70 Rc hardness | Thickness, hardness (Rockwell C), Taber abrasion, salt spray | Gears, pistons, valve bodies, hydraulic components |

| AMS 2468/2469 | Aerospace-grade hardcoat with specific alloy compatibility requirements | Thickness, hardness, corrosion resistance, adhesion | Aircraft structural forgings, landing gear, engine mounts |

| ASTM B580 Type A | Hardcoat equivalent to MIL-A-8625 Type III | Thickness, hardness, wear resistance | Industrial machinery, precision equipment |

| AAMA 611 Class I | Min. 0.7 mils thickness; 3,000-hour salt spray | Thickness, seal test (ASTM B680), salt spray, color retention | Architectural forgings, exterior hardware, high-traffic components |

| AAMA 611 Class II | Min. 0.4 mils thickness; 1,000-hour salt spray | Thickness, seal test, salt spray | Interior applications, decorative forged components |

When ordering anodized forged aluminum parts, request documentation that demonstrates specification compliance. Reputable anodizing services providers maintain detailed process records and can furnish test reports, certificates of conformance, and material traceability documentation. For critical applications, consider requiring third-party laboratory verification of coating properties—especially for initial production runs or new supplier qualification.

Understanding these specifications and testing methods transforms you from a passive buyer into an informed customer who can evaluate supplier capabilities, interpret quality documentation, and ensure your forged components receive anodizing that meets your application's demanding requirements.

Selecting a Forging Partner for Anodizing-Ready Components

You've invested time understanding specifications, testing methods, and quality requirements. Now comes the practical question: who actually produces forged aluminum components that arrive at your anodizing provider ready for flawless finishing? The answer determines whether your anodized parts meet requirements on the first run—or whether you're chasing defects, rework, and delays.

Selecting the right forging partner isn't just about competitive pricing or lead times. When your forged components will be anodized, you need a supplier who understands how every upstream decision affects downstream finishing outcomes. Alloy consistency, surface quality, dimensional accuracy, and defect prevention all trace back to forging operations—and problems created at the forge become permanent features highlighted by the anodizing process.

Evaluating Forging Suppliers for Anodizing Compatibility

What separates forging suppliers who produce anodizing-ready components from those whose parts require extensive remediation? Look beyond basic manufacturing capability to evaluate these critical factors:

Alloy control and material traceability: Consistent anodizing results require consistent base material. Your forging supplier should maintain rigorous incoming material inspection using spectrometers to verify alloy composition before any billet enters production. Ask potential suppliers:

- Do they verify alloy chemistry for every heat lot received?

- Can they provide material certifications traceable to the original mill?

- How do they segregate different alloy grades to prevent mixing?

Surface quality management: The forging process inevitably creates surface characteristics—scale, die marks, parting lines—that must be controlled for quality anodizing. Suppliers with anodizing awareness design their tooling and processes to minimize defects that would show through the finished coating. According to industry guidance, the surface finish can be improved through secondary processing techniques, but choosing a supplier who minimizes defects at the source reduces your overall costs and lead times.

Dimensional precision: Remember that anodizing adds material to your parts. Forging suppliers who understand this provide components machined to dimensions that account for coating buildup on critical features. They know which tolerances apply before versus after anodizing—and they communicate proactively when drawing specifications create potential conflicts.

Defect detection capabilities: Laps, seams, and inclusions become dramatically visible after anodizing. Quality-focused forging suppliers implement inspection protocols—visual examination, dye penetrant testing, dimensional verification—that catch these defects before parts ship. Rejected parts at the forge cost far less than rejected parts after anodizing.

When searching for "anodizing companies near me" or "aluminum anodizing near me," you'll find many finishing providers. But finding a forging supplier who produces parts ready for those anodizers? That requires more careful evaluation of manufacturing capabilities and quality systems.

The Role of Quality Certifications

Certifications provide objective evidence of a supplier's quality management capability. For forged components destined for anodizing—particularly in automotive and aerospace applications—IATF 16949 certification stands as the gold standard.

What does IATF 16949 certification indicate about a forging supplier?

- Robust process control: Certified suppliers maintain documented procedures that ensure consistent results across production runs.

- Continuous improvement culture: The standard requires systematic identification and elimination of quality problems.

- Defect prevention focus: IATF 16949 emphasizes preventing defects rather than merely detecting them—exactly the approach needed for anodizing-ready forgings.

- Supply chain management: Certified suppliers extend quality requirements to their own material sources, ensuring alloy consistency from the original mill.

- Customer satisfaction orientation: The certification framework requires tracking and responding to customer feedback, creating accountability for quality outcomes.

Beyond IATF 16949, look for ISO 9001 as a baseline quality management indicator. For aerospace applications, AS9100 certification demonstrates compliance with the additional requirements specific to that demanding industry.

Streamlining the Forging-to-Finishing Supply Chain

The most efficient supply chains minimize handoffs and communication gaps between forging and finishing operations. When your forging supplier understands anodizing requirements, they can proactively address potential issues before parts leave their facility.

Consider the benefits of working with forging partners who offer:

- In-house engineering support: Engineers who understand both forging and finishing can optimize designs for manufacturability and anodizing compatibility. They identify potential problems during development rather than production.

- Rapid prototyping capability: The ability to produce prototype quantities quickly allows you to validate anodizing outcomes before committing to production tooling. Quick turn anodizing on prototype parts confirms that your alloy, design, and surface preparation approach will produce acceptable results.

- Integrated machining: Suppliers who machine forgings in-house control dimensional accuracy for critical features, eliminating the tolerance stack-up that occurs when multiple vendors handle the same part.

- Global logistics expertise: For international sourcing, suppliers located near major shipping ports streamline delivery and reduce lead times for anodizing services for OEMs operating global supply chains.

Shaoyi (Ningbo) Metal Technology exemplifies this integrated approach. As an IATF 16949-certified precision hot forging specialist, they understand how forging quality directly affects anodizing outcomes. Their in-house engineering team designs components like suspension arms and drive shafts with downstream finishing requirements in mind—accounting for coating buildup, specifying appropriate alloys, and controlling surface quality throughout production.

Their rapid prototyping capability—delivering prototype forgings in as little as 10 days—enables you to validate anodizing results before committing to high-volume production. Located near Ningbo Port, they provide efficient global delivery for aluminum anodizing service applications worldwide. For automotive applications requiring quality anodized finishes, their automotive forging solutions demonstrate the integration of forging expertise with finishing awareness that produces consistently anodizing-ready components.

Building Long-Term Supplier Relationships

The most successful anodized forging programs result from sustained partnerships between forging suppliers, anodizers, and end customers. These relationships enable:

- Process optimization: When your forging supplier understands your anodizing requirements, they can refine their processes to consistently produce compatible parts.

- Problem resolution: Issues that arise during anodizing can be traced back and addressed at the forging stage, preventing recurrence.

- Design collaboration: New product development benefits when forging and finishing expertise inform design decisions from the earliest stages.

- Cost reduction: Eliminating rework, reducing defects, and streamlining communication all contribute to lower total costs over time.

When evaluating potential forging partners, look beyond initial quotes to assess their willingness to understand your anodizing requirements and their capability to consistently meet them. Request case studies or references from customers with similar finishing needs. Ask about their experience with your specific alloys and anodizing types.

The investment in finding the right forging partner pays dividends throughout your product's lifecycle. Components that arrive at the anodizing line ready for processing—with correct alloy chemistry, controlled surface quality, appropriate dimensions, and freedom from hidden defects—flow through finishing without the delays, rework, and quality disputes that plague poorly managed supply chains.

Whether you're sourcing components for aerospace structures, automotive suspension systems, or industrial equipment, the principles remain consistent: select forging partners who understand that their work sets the foundation for everything that follows. When forging and anodizing work together as an integrated system, the result is superior components that meet your most demanding requirements.

Frequently Asked Questions About Anodizing Custom Forged Aluminum

1. Can forged aluminum be anodized?

Yes, forged aluminum can be anodized and actually produces superior results compared to cast aluminum. The forging process creates a dense, uniform grain structure without porosity, allowing the anodic oxide layer to form consistently across the entire surface. This results in better color uniformity, enhanced durability, and improved corrosion resistance. IATF 16949-certified forging partners like Shaoyi Metal Technology understand these advantages and produce components specifically optimized for quality anodizing outcomes.

2. What is the 720 rule for anodizing?

The 720 rule is a calculation formula used to estimate anodizing time based on desired oxide layer thickness. It helps anodizers predict how long aluminum parts need to remain in the electrolyte bath to achieve specific coating thicknesses. For forged aluminum, this calculation becomes more predictable due to the material's consistent density and uniform grain structure, allowing tighter control over final coating properties compared to cast or porous aluminum substrates.

3. Which aluminum alloys work best for anodizing forged parts?

The 6xxx series alloys, particularly 6061 and 6063, deliver the best anodizing results on forged components. These magnesium-silicon alloys produce uniform oxide layers with excellent dye absorption for consistent colors. High-strength alloys like 7075 work well for Type III hardcoat but may show slight color variations. Copper-rich alloys (2024, 2014) produce darker, less uniform finishes suitable for functional rather than decorative applications.

4. How does anodizing affect the dimensions of forged aluminum parts?

Anodizing grows the oxide layer approximately 50% outward and 50% inward from the original surface. Type II anodizing adds 0.0001-0.0005 inches per surface, while Type III hardcoat adds 0.00025-0.0015 inches per surface. Outside diameters increase, inside diameters decrease, and threaded features may require masking. Engineers should specify whether critical dimensions apply before or after anodizing to ensure proper tolerance planning.

5. What surface preparation is required before anodizing forged aluminum?

Forged aluminum requires thorough preparation including removal of forging scale, die marks, and flash remnants. The complete workflow involves post-forging inspection, degreasing, alkaline cleaning, etching to create uniform surface texture, and desmutting. Hidden defects like laps, seams, and inclusions must be identified and remediated before anodizing, as the oxide layer amplifies rather than hides surface imperfections.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —