Vetting Your Next Forged Automotive Components Supplier abstract illustration of forged automotive components and precision engineering

TL;DR

Finding a reliable forged automotive components supplier requires evaluating companies based on their material expertise, custom capabilities, and critical quality certifications. The process involves identifying partners who can produce durable, high-performance parts like engine components, connecting rods, and structural frames. Key considerations include a supplier's production capacity, adherence to standards like IATF 16949, and their ability to deliver precision-engineered solutions for your specific automotive needs.

Understanding the Automotive Forging Landscape

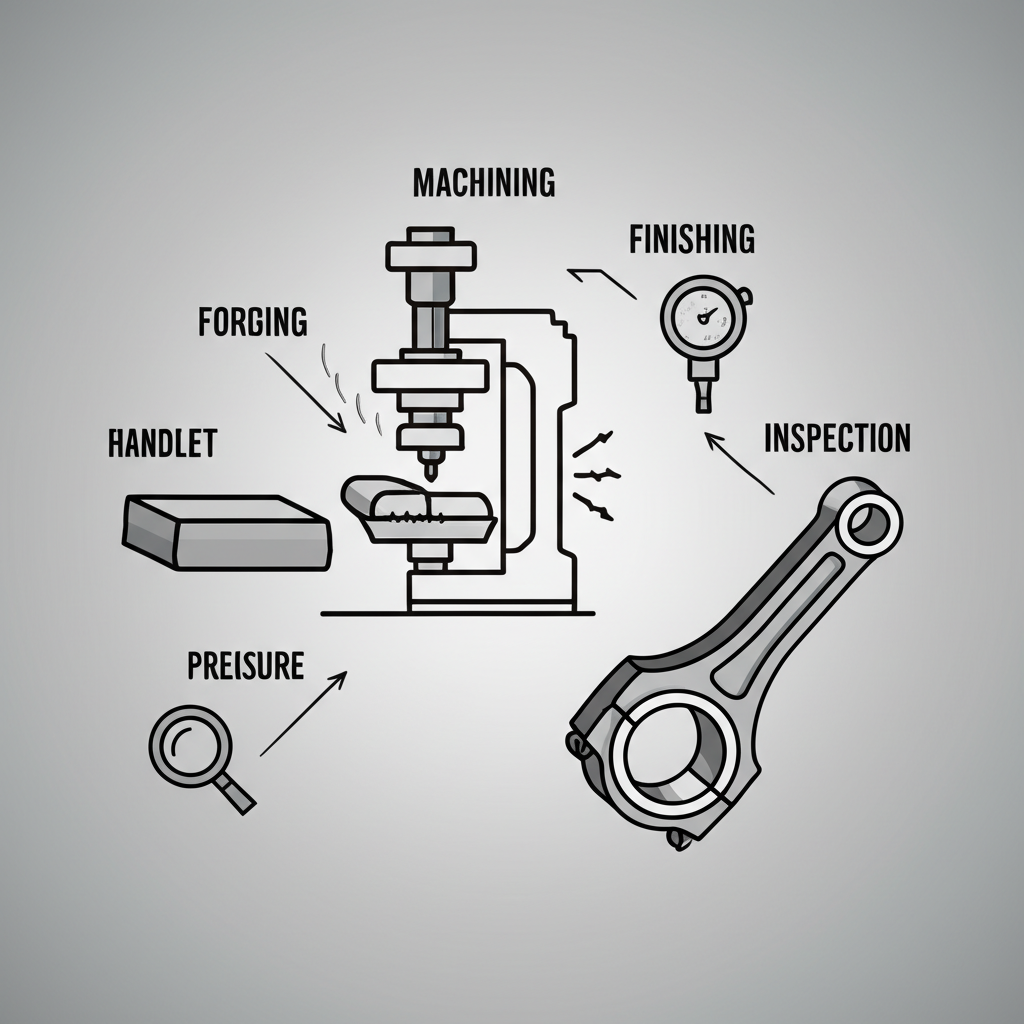

In the automotive industry, performance, safety, and efficiency are paramount. The forging process is critical to meeting these demands, as it produces metal components with superior strength and reliability compared to parts made by casting or machining alone. Forging involves shaping metal using localized compressive forces, which refines the grain structure of the material. This results in parts that are incredibly durable and resistant to impact and fatigue, making them essential for high-stress applications in vehicles.

Forged components are integral to nearly every major system in a modern vehicle. From engine and powertrain parts like crankshafts and connecting rods to chassis and suspension components like control arms and steering knuckles, forging ensures longevity and performance. The strength-to-weight ratio of forged parts is particularly beneficial as manufacturers strive to reduce vehicle weight for better fuel efficiency and lower emissions without compromising structural integrity.

A variety of materials are used in automotive forging, each chosen for its specific properties. The most common include:

- Carbon and Alloy Steels: Valued for their exceptional strength and wear resistance, these are commonly used for gears, axles, and powertrain components.

- Aluminum Alloys: Chosen for their lightweight properties, aluminum forgings help reduce overall vehicle mass. They are often used for suspension parts, brake calipers, and vehicle hubs.

- Micro-alloy Steels: These materials offer high strength with simplified heat-treatment processes, making them a cost-effective choice for parts like connecting rods.

The distinction between standard and custom forgings is also crucial. While standard components serve many needs, the increasing complexity of vehicle design often requires custom-forged solutions. Specialty suppliers work closely with OEMs and aftermarket manufacturers to design and produce parts tailored to unique performance requirements, from high-performance racing applications to innovative electric vehicle (EV) platforms.

Top Forged Automotive Component Suppliers: A Comparative Overview

Selecting the right supplier is a critical business decision. The ideal partner not only provides high-quality components but also functions as a strategic collaborator. Below is an overview of notable suppliers in the automotive forging sector, each with distinct specializations and capabilities.

Shaoyi Metal Technology

For businesses seeking a partner adept at both prototyping and mass production, Shaoyi Metal Technology offers robust and reliable custom forging services. Specializing in IATF 16949 certified hot forging, they cater specifically to the automotive industry's stringent quality demands. Their capabilities range from rapid prototyping for small-batch validation to full-scale production runs. With in-house die manufacturing, Shaoyi Metal Technology maintains tight control over the entire process, ensuring precision and efficiency from design to delivery.

thyssenkrupp Forged Technologies

As a global powerhouse, thyssenkrupp Forged Technologies is a diversified supplier of components and system solutions across numerous industries. For the automotive sector, they produce critical parts such as crankshafts, connecting rods, and front axles. Their extensive global network of manufacturing locations in North and South America, Europe, and Asia allows them to serve international markets effectively, providing state-of-the-art mechanical solutions and leveraging deep material and engineering competence.

Anchor Harvey

Specializing in precision and durability, Anchor Harvey has built a reputation for delivering high-performance components for specialty automotive applications. They are a trusted partner for OEMs, aftermarket manufacturers, and motorsports teams. Their expertise lies in creating custom-engineered aluminum forgings for parts like suspension components, brake calipers, and steering knuckles. By offering a fully integrated manufacturing solution—from forging and machining to finishing and inventory management—they help clients streamline their supply chain and ensure consistent quality.

Cerro Fabricated Products

Focusing on aluminum forgings and machined parts, Cerro Fabricated Products serves the automotive market with components like vibration dampening and suspension-related parts. While ISO 9001:2015 certified, they possess the capability to become IATF compliant for specific projects. Their in-house tool and die and heat-treating capabilities ensure quick lead times, a significant advantage for customers needing to bring products to market quickly. They typically work with 2000, 6000, and 7000 series aluminum alloys.

Modern Group

With over a century of experience, Modern Group supplies a wide variety of custom-forged automotive components for both high-volume OEM and low-volume service needs. Their product range includes engine parts, structural frame components, connecting rods, and tie rod ends. Modern Group utilizes a detailed Advanced Product Quality Planning (APQP) process and holds multiple certifications, including ISO 9001:2015 and AS9100, demonstrating a strong commitment to quality management systems.

Key Criteria for Selecting the Right Forging Partner

Choosing a forged automotive components supplier involves more than comparing price lists. It's about finding a partner that aligns with your technical requirements, quality standards, and production goals. A thorough evaluation process is essential to mitigate risks and build a successful, long-term relationship. Here are the key criteria to consider when vetting potential suppliers.

-

Technical Capabilities and Materials Expertise

A supplier's technical prowess is the foundation of a successful partnership. Evaluate their engineering capabilities, including their use of design and modeling software like AutoCAD, ProE, or Simufact. This indicates their ability to optimize die designs for efficiency and material yield. Furthermore, assess their expertise with the specific materials you require, whether carbon steel, aluminum alloys, or more specialized metals. A knowledgeable partner can provide valuable input on material selection to enhance performance and cost-effectiveness. -

Quality Certifications and Systems

In the automotive industry, quality is non-negotiable. The IATF 16949 certification is the international standard for automotive quality management systems, and it should be a primary requirement for any potential supplier. This certification demonstrates a commitment to continuous improvement, defect prevention, and the reduction of variation and waste in the supply chain. Ask for details about their quality control processes, such as CMM part validation, statistical process control (SPC), and Process FMEA's. -

Production Capacity and Scalability

The right supplier must be able to meet your volume demands, both now and in the future. Inquire about their production capacity, including the types of forging presses they operate (e.g., hammer, press) and their overall output capabilities. A supplier that can handle everything from small-batch prototypes to high-volume production runs offers valuable flexibility. This scalability ensures they can support your project from the initial development phase through its entire lifecycle. -

Customization and Specialization

Every automotive project has unique requirements. Look for a supplier that offers custom forging solutions rather than just off-the-shelf products. A partner with in-house tool and die capabilities can create custom tooling faster and more efficiently, reducing lead times for new components. Their experience with specialty parts, whether for electric vehicles, high-performance aftermarket upgrades, or heavy-duty trucks, can be a significant asset in developing innovative and competitive products.

Making an Informed Supplier Decision

Ultimately, selecting the right forged automotive components supplier is a strategic decision that impacts your product's quality, performance, and market success. By focusing on technical expertise, robust quality systems, production scalability, and a collaborative approach, you can identify a partner who will not only meet your specifications but also contribute to your long-term growth. A thorough vetting process based on these criteria will help you build a resilient and reliable supply chain.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —