Titanium Vs Steel Forged Valves: Which Material Survives Your Build?

The High-Stakes Decision Behind Forged Valve Selection

When you're building a high-performance engine, every component matters. But few choices carry as much weight as the valves controlling airflow in and out of your combustion chambers. Whether you're chasing peak horsepower on a naturally aspirated screamer or building a bulletproof forced induction setup, the material sitting in those valve seats directly determines how long your engine lives and how hard it can push.

Choosing between titanium valves and steel valves isn't just about picking a part off the shelf. It's a calculated decision that affects valve train dynamics, spring requirements, heat management, and ultimately, your engine's reliability under stress. Get it right, and you unlock performance potential. Get it wrong, and you're looking at premature wear, valve float, or catastrophic failure.

Why Valve Material Selection Makes or Breaks Performance Engines

Valves for engine applications operate in one of the most demanding environments imaginable. They open and close hundreds of times per second at high RPM, endure extreme temperatures on the exhaust side, and must seal perfectly every single cycle. According to industry experts at Williams Motowerx, a 250F engine running at 12,000 RPM creates dynamic forces of over 26 pounds per valve with stainless steel components. That stress multiplies across all four valves in a typical head, putting enormous strain on springs, retainers, and the valves themselves.

The stakes are clear: your valve material choice directly impacts engine longevity, power output, and reliability. A mismatched setup can lead to stretched valve stems, worn coatings, or valve float that robs power and risks piston contact.

The Weight-Strength Tradeoff Every Builder Must Understand

Here's where the titanium vs steel forged valves debate gets interesting. Both materials benefit enormously from the forging process, which aligns the metal's grain structure and dramatically improves fatigue resistance. However, their core properties create very different performance characteristics.

Titanium valves offer approximately 42% weight reduction compared to stainless steel equivalents, cutting dynamic valvetrain forces nearly in half at high RPM.

As Ferrea Racing Components explains, while titanium delivers exceptional weight savings, it comes with specific vulnerabilities around heat tolerance and coating durability. Steel valves, particularly forged stainless options, offer superior heat resistance and longevity but add mass that stresses the entire valve train at elevated engine speeds.

Throughout this guide, you'll find a ranked evaluation of top forged valve options across different applications. We'll break down when titanium makes sense, where steel holds the advantage, and which specialized materials like Inconel enter the conversation for extreme builds. By the end, you'll have the knowledge to match your valve selection to your specific build goals with confidence.

Our Evaluation Criteria for Ranking Forged Valves

With so many valve options on the market, how do you separate genuinely superior components from marketing hype? We developed a systematic evaluation framework that cuts through the noise and focuses on what actually matters when your engine is spinning at 8,000 RPM with aggressive cam profiles demanding precise valve control.

Our methodology weighs real-world performance factors against specific application requirements. A titanium valve that excels in a naturally aspirated drag motor might fail miserably in a turbocharged endurance build. Understanding these distinctions is what separates informed builders from those gambling with their engine investment.

How We Evaluated Each Valve Option

Every forged valve in our comparison went through the same rigorous assessment process. We examined manufacturer specifications, consulted with professional engine builders, and cross-referenced data from racing applications where these components prove themselves under pressure.

Here are the five core evaluation criteria we applied:

- Material Density and Weight Savings: How much mass reduction does each option deliver, and what does that mean for valvetrain inertia at your target RPM range?

- Heat Resistance and Thermal Conductivity: Can the valve maintain structural integrity and proper sealing under your application's exhaust gas temperatures?

- Fatigue Strength Under High-RPM Conditions: What's the realistic service life before inspection or replacement becomes necessary?

- Compatibility with Valve Spring Pressures: Does the valve material allow for optimized spring setups, or does it force compromises?

- Application Suitability: Is this valve engineered for naturally aspirated high-RPM use, forced induction heat loads, or dual-purpose street and strip duty?

Key Performance Metrics That Matter

When comparing stainless vs titanium valves, the numbers tell a compelling story. Ti-6Al-4V, the most common titanium alloy used in performance valves, has a density of approximately 4.43 g/cm³. Compare that to standard steel at around 7.8 g/cm³, and you immediately see where the 35-42% weight savings originates.

But density alone doesn't determine valve performance. Ti-6Al-4V delivers tensile strength around 1170 MPa with a yield strength of approximately 1100 MPa, making it exceptionally strong for its weight. However, its thermal conductivity sits at roughly 6.7 W/m·K, meaning it's a poor heat conductor. This becomes critical on exhaust applications where heat buildup can rapidly degrade titanium's mechanical properties.

On the stainless steel side, alloys like EV8 and 21-4N dominate intake applications, while EV16 and 23-8N handle exhaust duties. According to Engine Builder Magazine, these materials strike a proven balance between flow characteristics, heat tolerance, and durability that suits the majority of performance applications.

The thermal threshold difference is stark. Titanium exhaust valves struggle above 600°C (approximately 1,100°F), while stainless steel exhaust valves made from super alloys can withstand temperatures up to 2,400°F. This explains why many professional builds run a hybrid approach with titanium intake valves paired with stainless or Inconel exhaust valves.

Why Forging Quality Separates Winners from Failures

The forging process itself deserves close attention. Whether you're evaluating a valve titanium construction or a stainless alternative, how that metal was shaped determines its ultimate durability.

One-piece forged valves offer a continuous grain structure from stem to head, maximizing fatigue resistance where stress concentrations occur. This manufacturing method aligns the metal's internal structure along the natural load paths, creating valves that resist cracking under repeated high-cycle stress.

Two-piece inertia-welded valves, commonly used for bimetallic designs, join separate head and stem materials through friction welding processes. In inertia friction welding, one component connects to a flywheel that's declutched from its drive when the right speed is reached. On contact with the workpieces, friction at the weld interface generates both heat and braking force, creating a solid-phase joint without reaching the material's melting point. This produces a refined microstructure in the weld region with excellent reproducibility.

Both manufacturing methods can produce competition-worthy valves when executed properly. The critical factor is whether the manufacturer maintains consistent quality control throughout production. Variations in forging temperature, pressure, or cooling rates directly impact the finished valve's grain structure and performance envelope.

With this evaluation framework established, let's examine specific valve options and see how they perform across these criteria in real-world applications.

Shaoyi Precision Hot-Forged Valves for Automotive Excellence

When sourcing forged valves for titanium engine applications or stainless exhaust components, the manufacturer behind your parts matters as much as the material specification sheet. Quality inconsistencies in the forging process create weak points that no amount of premium alloy can overcome. This is where certified precision manufacturers separate themselves from commodity suppliers.

Shaoyi (Ningbo) Metal Technology represents a benchmark for what certified quality control delivers in forged valve production. Their precision hot forging solutions address the exact concerns performance builders face when specifying critical engine components.

What Sets Shaoyi Forged Valves Apart

The forging process fundamentally transforms metal's internal structure. As industry research confirms, forging refines the grain structure and aligns it along the shape of the valve through compressive forces applied with hammers or presses. Modern forging uses powerful machines with real-time monitoring to control pressure and temperature, helping reduce common defects such as cracks, voids, and laps.

Shaoyi's precision hot forging approach maximizes these benefits for both titanium exhaust system applications and steel valve production. The key differentiator lies in their process control. Optical microscopy and electron backscatter diffraction studies reveal that properly executed forging reduces grain size and improves alignment, which directly boosts durability and resistance to cracking under the cyclic stress valves endure.

Their in-house engineering team ensures components meet exact specifications before production begins. This matters enormously when you're ordering valves that must integrate with specific spring pressures, retainer geometries, and combustion chamber configurations. Getting the design dialogue right at the front end prevents costly mismatches downstream.

IATF 16949 Certification and Quality Assurance

Not all forging facilities operate under the same quality umbrella. IATF 16949 represents the international standard for automotive quality management systems, providing a standardized Quality Management System (QMS) that focuses on driving continuous improvement with emphasis on defect prevention and reduction of variation and waste in the automotive supply chain.

Why does this certification matter for your valve procurement? According to NSF International, IATF 16949 certification is required for most organizations in the automotive supply chain involved in the design, development, production, and servicing of automotive-related products. Most major automotive Original Equipment Manufacturers mandate this certification for their supply chain partners.

Organizations certified to IATF 16949 demonstrate:

- Improved consistency through documented processes and continual improvement protocols

- Better risk management through systematic identification of internal and external factors affecting quality

- Enhanced traceability enabling root cause analysis when issues arise

- Reduced defects through prevention-focused quality systems rather than inspection-based approaches

Shaoyi's IATF 16949 certification means every forged valve leaving their facility went through a validated process with documented controls. For racing teams and automotive manufacturers who can't afford batch-to-batch inconsistency, this certification provides confidence that part number 100 performs identically to part number 10,000.

Rapid Prototyping and Production Scalability

Development timelines in motorsport and performance automotive don't wait for slow suppliers. Shaoyi addresses this reality with rapid prototyping capabilities delivering functional components in as little as 10 days. This acceleration allows engine builders to test valve designs quickly, validate fitment, and move into production without extended development delays.

The same facility then scales to high-volume mass production while maintaining the consistency that prototyping established. This matters because many specialized forging shops excel at one-off work but struggle with repeatability at volume. Having both capabilities under one roof streamlines the path from concept to full production.

Their strategic location near Ningbo Port enables efficient global shipping, reducing lead times for international buyers who need consistent supply chains for their manufacturing operations.

Pros

- IATF 16949 certified quality control ensures automotive-grade consistency

- Rapid prototyping in as little as 10 days accelerates development cycles

- Precision hot forging creates superior grain structure in both titanium and steel applications

- In-house engineering validates component specifications before production

- Strategic Ningbo Port location enables fast global shipping

Cons

- Primarily serves OEM and high-volume buyers rather than individual consumers

- May require minimum order quantities for production runs

- Best suited for established manufacturers and racing teams with defined specifications

Best Applications for Shaoyi Forged Valves

Shaoyi's capabilities align best with specific buyer profiles. Automotive manufacturers requiring consistent quality at scale benefit from their certified processes and production capacity. Racing teams needing globally compliant components with documented traceability find value in their quality management systems. Builders seeking precision-forged valve blanks for custom applications appreciate their engineering consultation capabilities.

The precision hot forging expertise extends beyond just valves. Their manufacturing covers robust components like suspension arms and drive shafts where grain structure alignment and fatigue resistance determine service life. This breadth of experience with critical automotive components reinforces their understanding of what high-performance applications demand from forged parts.

For individual builders working on single-engine projects, the minimum order requirements may present challenges. However, for shop owners, racing organizations, or manufacturers with ongoing valve needs, the combination of certified quality and production scalability makes Shaoyi a compelling supply chain partner.

Understanding what certified precision manufacturing delivers provides context for evaluating all forged valve options. With this quality benchmark established, let's examine how specialized valve manufacturers like Ferrea approach the titanium performance segment.

Ferrea Titanium Valves for High-RPM Performance

When professional racing teams need titanium intake valves that can survive a full season of abuse, Ferrea Racing Components consistently appears on their spec sheets. This manufacturer has built a reputation through decades of motorsport competition, refining their titanium valve technology through real-world validation at the highest levels of racing.

But racing pedigree alone doesn't make a valve right for your build. Understanding exactly what Ferrea brings to the table helps you determine whether their premium titanium offerings match your application requirements or if you're paying for capabilities you'll never use.

Ferrea Titanium Valve Technology Breakdown

What separates Ferrea valves from generic titanium options starts at the surface. According to Ferrea's technical documentation, they coat their titanium valves in Chromium Nitride (CrN), a ceramic-based surface treatment that dramatically improves wear resistance and reduces friction against the valve guide.

This coating addresses one of titanium's fundamental weaknesses. Raw titanium has a tendency to gall against dissimilar metals under the sliding friction conditions present in valve guide interfaces. The CrN coating creates a hard, slippery barrier that prevents metal-to-metal contact while adding negligible weight to the valve.

Ferrea's engineering team takes this protection further with specific valve guide recommendations. As their technical experts explain, bronze guide materials like Ampco 45 or copper-bronze alloys work exceptionally well with their coated titanium valves. These bronze materials offer two critical advantages:

- Superior heat dissipation: Bronze conducts heat away from the valve stem more effectively than cast iron guides, helping keep temperatures within titanium's safe operating range

- Inherent lubricity: Bronze alloys naturally resist galling and provide a forgiving surface that protects the valve coating during break-in and normal operation

The 42% weight savings Ferrea titanium valves deliver over equivalent stainless steel components translates directly into reduced valvetrain inertia. At 8,000+ RPM, this weight reduction cuts dynamic forces nearly in half, allowing lighter springs, faster valve acceleration, and improved control at the ragged edge of engine speed.

When Ferrea Titanium Makes Sense

Not every high-performance build benefits from titanium. Ferrea's own experts are refreshingly honest about this reality. As Zeke Urrutia from Ferrea explains, the engine's power-making strategy determines whether titanium is appropriate, particularly on the exhaust side.

Forced induction applications typically create exhaust gas temperatures too high for titanium's thermal limits. However, there's an important exception. High-end race engines running methanol or other alcohol-based fuels generate significantly lower exhaust temperatures than their gasoline counterparts. In these specific applications, titanium can work on both intake and exhaust with valves surviving the heat load.

For gasoline-powered turbocharged or supercharged builds, Urrutia often recommends a hybrid approach: titanium intake valves paired with stainless steel or Inconel exhaust valves. This strategy captures the weight reduction benefits where heat isn't a limiting factor while maintaining durability where temperatures spike.

The valve spring pressure conversation becomes critical with any titanium valve installation. Titanium's lighter mass means the valvetrain accelerates faster, but it also means the valve stem sees different stress patterns than a heavier stainless component. Springs that worked perfectly with steel valves may need recalibration when switching to titanium.

Pros

- Proven racing pedigree with decades of professional motorsport validation

- Advanced Chromium Nitride coating protects against galling and wear

- Extensive application catalog covering most popular performance engine platforms

- Delivers full 42% weight savings over equivalent stainless steel valves

- Technical support team helps match valve specs to specific applications

Cons

- Premium pricing reflects racing-grade manufacturing and quality control

- Requires careful valve spring matching to optimize valvetrain dynamics

- Not ideal for all forced induction setups due to exhaust heat limitations

- Bronze valve guides recommended, adding potential cylinder head modification costs

- Regular inspection required to check for stem stretch and coating wear

Best Applications for Ferrea Titanium

Ferrea titanium valves shine brightest in specific scenarios. High-RPM naturally aspirated builds represent the ideal use case. Think professional drag racing engines spinning past 9,000 RPM, road racing applications where sustained high engine speeds punish heavy valvetrains, or weight-critical builds where every gram saved translates to competitive advantage.

Professional racing teams requiring consistent quality across multiple engines benefit from Ferrea's manufacturing standards. When you're building ten identical motors for a racing season, knowing each valve performs identically matters as much as the material properties themselves.

Weight-conscious street performance builds can also benefit, particularly on the intake side where exhaust with valves made from titanium isn't facing extreme heat. A naturally aspirated LS engine build, for example, gains significant valvetrain control by running titanium intakes even if the exhaust side stays stainless.

The maintenance considerations deserve attention before committing. Titanium valves require periodic inspection to verify the stem hasn't stretched under repeated high-RPM cycling and that the CrN coating remains intact. For racing applications with regular teardown schedules, this fits naturally into existing maintenance protocols. For street builds where the engine may run extended periods without inspection, the added maintenance requirements warrant consideration.

With Ferrea's titanium technology understood, the question becomes what happens when exhaust temperatures exceed even stainless steel's comfort zone. That's where Inconel enters the conversation as the extreme heat specialist.

Inconel Valves for Extreme Heat and Forced Induction

What happens when your exhaust gas temperatures climb past 1,500°F and keep rising? Turbocharged engines pushing serious boost, supercharged applications generating massive heat loads, and diesel performance builds all share a common challenge: conventional valve materials struggle to survive. This is where Inconel valves enter the conversation as the go-to solution for extreme thermal environments.

Inconel isn't just another stainless steel variant. It's a nickel-chromium superalloy engineered specifically for conditions that would destroy ordinary metals. When you're building an engine where the exhaust side sees temperatures that make titanium weaken and standard stainless steel approach its limits, Inconel offers the thermal headroom to keep your valves alive.

Why Inconel Dominates Extreme Heat Environments

The secret behind Inconel's heat resistance lies in its composition and molecular structure. According to Supertech Performance's technical analysis, Inconel exhibits exceptional resistance to high temperatures, making it an ideal material for exhaust valves in high-performance engines generating immense heat during combustion.

Consider the numbers. Titanium valves begin losing mechanical strength above approximately 600°F (315°C). Standard stainless steel exhaust valves can handle significantly more heat but still have practical limits around 1,400-1,500°F in sustained operation. Inconel? It retains its strength at extreme temperatures up to 2,000°F (1,093°C), giving you massive thermal margin in the most demanding applications.

This isn't just about surviving peak temperatures during wide-open-throttle pulls. Inconel excels at handling thermal cycling, the repeated heating and cooling that exhaust valves experience every time you get on and off the throttle. As Supertech's research confirms, Inconel exhaust valves can withstand the extreme temperatures and thermal cycling inherent to high-performance conditions, ensuring durability and prolonged lifespan.

Beyond raw heat tolerance, Inconel brings additional advantages to the intake engine valve and exhaust equation:

- Superior corrosion resistance: Exhaust valves face continuous exposure to corrosive gases, moisture, and combustion byproducts. Inconel's remarkable corrosion resistance provides reliable defense against oxidation and erosion.

- Excellent mechanical properties: High tensile strength, fatigue resistance, excellent creep resistance, and low thermal expansion keep valves performing under demanding conditions.

- Improved gas flow dynamics: Inconel's thermal conductivity facilitates effective heat dissipation, and its high-temperature strength enables thinner valve designs that enhance exhaust flow characteristics.

Inconel vs Titanium in Forced Induction Builds

Here's where the titanium vs steel forged valves debate gets nuanced. You've probably noticed titanium's 42% weight advantage mentioned repeatedly. So why would anyone choose heavier Inconel valves when weight reduction matters so much for valvetrain performance?

The answer comes down to where each material operates in your engine. Turbocharged and supercharged applications create exhaust conditions that fundamentally change the material selection equation.

When you're pushing 15, 20, or more pounds of boost, exhaust gas temperatures spike dramatically compared to naturally aspirated operation. According to SB International's technical documentation on valve operating conditions, spark-ignited engine exhaust valve temperatures typically run 1,450-1,500°F at the hottest points. Add forced induction, and those numbers climb even higher.

This creates a clear application divide:

- Intake side: Titanium valves work beautifully here. The incoming air/fuel charge cools the intake valve, keeping temperatures well within titanium's comfort zone. You capture the full weight savings benefit without thermal risk.

- Exhaust side: Inconel becomes the smart choice for serious forced induction. The thermal margin protects against the elevated exhaust temperatures that would compromise titanium's structure over time.

Many professional engine builders run exactly this combination. Titanium intake valves paired with Inconel exhaust valves gives you weight reduction where it's safe while maintaining durability where heat demands it. This hybrid approach has become standard practice in high-end turbo and supercharged builds.

The enhanced mechanical properties Inconel brings also matter in forced induction applications. These engines generate higher cylinder pressures, which translate to increased stress on exhaust valves during the combustion event. Inconel's superior tensile and fatigue strength handles these elevated loads reliably, reducing the risk of valve failure under extreme boost conditions.

Pros

- Exceptional heat resistance maintains structural integrity up to 2,000°F

- Outstanding corrosion resistance protects against exhaust gas degradation

- High tensile and fatigue strength handles forced induction stress loads

- Excellent creep resistance prevents valve stretch under sustained high temperatures

- Ideal for the exhaust side in turbocharged, supercharged, and diesel applications

Cons

- Heavier than titanium, increasing valvetrain inertia at high RPM

- Higher cost than standard stainless steel exhaust valves

- Overkill for naturally aspirated applications where stainless performs adequately

- Added weight may require stiffer valve springs to maintain control

Best Applications for Inconel Valves

Inconel valves make the most sense in specific high-heat scenarios where their thermal advantages justify the weight and cost penalties:

- Turbo builds: Any turbocharged engine pushing meaningful boost benefits from Inconel exhaust valves. The combination of elevated exhaust temperatures and extended high-load operation creates the exact conditions Inconel was designed to handle.

- Supercharged engines: Positive displacement and centrifugal superchargers both generate significant exhaust heat. Inconel provides the durability margin for aggressive street/strip and dedicated racing applications.

- Diesel performance: High-performance diesel applications generate substantial exhaust temperatures, particularly in towing and racing configurations. Inconel handles both the heat and the corrosive byproducts of diesel combustion.

- Any build exceeding standard exhaust temperature limits: If your datalog shows exhaust gas temperatures consistently pushing past 1,400°F, Inconel provides insurance against heat-related valve failure.

For naturally aspirated builds, even high-RPM racing applications, Inconel typically represents overkill. The weight penalty hurts valvetrain dynamics without providing benefits the application actually needs. Quality stainless steel or titanium valves handle naturally aspirated exhaust temperatures with appropriate margin.

With Inconel covering the extreme heat segment, what about builders who need better thermal management than standard stainless offers but can't justify exotic alloy pricing? Sodium-filled valve technology provides an interesting middle ground worth examining.

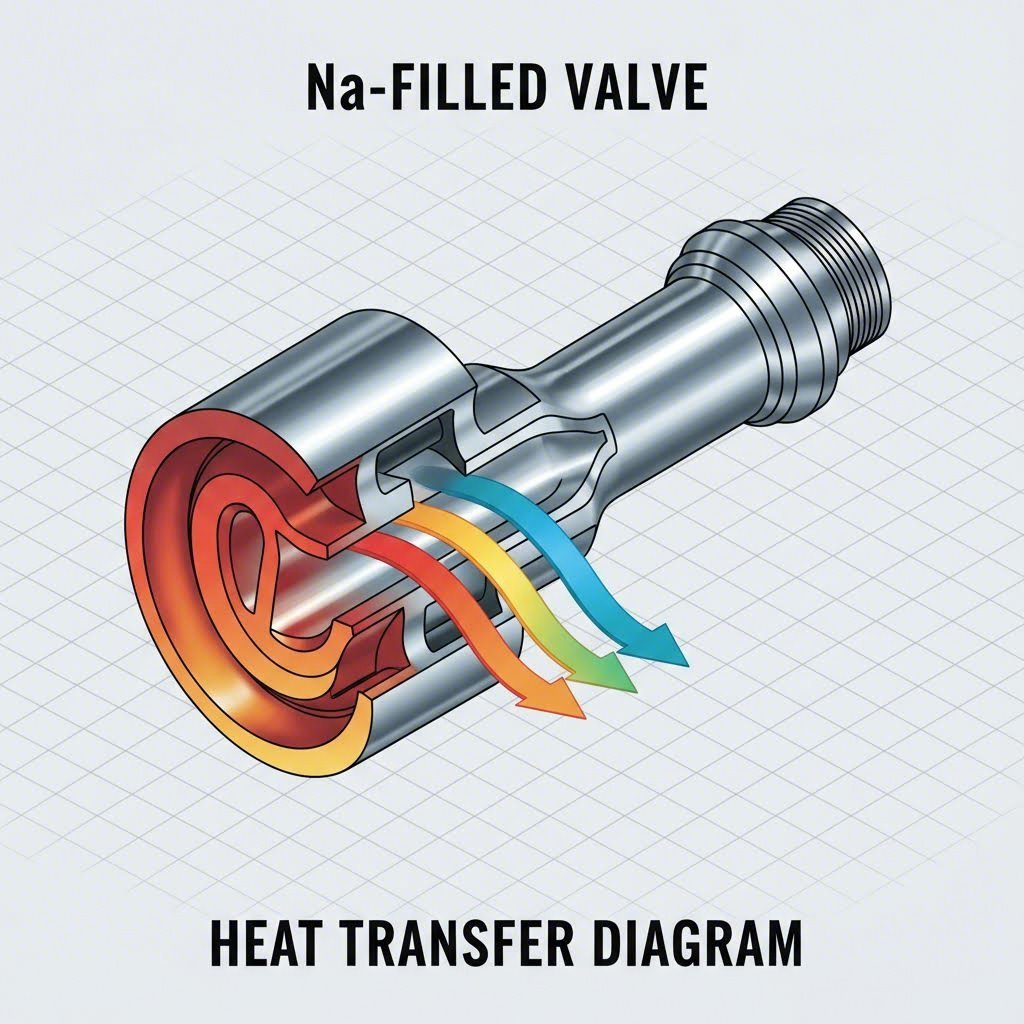

Sodium-Filled Stainless Valves for Heat Management

What if you need better heat management than standard stainless steel provides but can't justify the premium cost of Inconel or titanium? Sodium-filled valves offer a clever engineering solution that's been quietly solving thermal challenges in high-performance engines for decades. This technology bridges the gap between conventional v stainless steel valves and exotic materials by attacking the heat problem from a completely different angle.

Rather than relying solely on the valve material's inherent heat resistance, sodium-filled designs actively transfer thermal energy away from the hottest zones. Understanding what is engine valves technology at this level reveals why OEM engineers have trusted this approach in everything from aircraft engines to high-performance production vehicles.

How Sodium-Filled Valves Manage Extreme Heat

The genius behind sodium filled valves lies in their hollow construction and the unique properties of elemental sodium. According to SSV Valves' technical documentation, unlike traditional valves which are solid throughout, sodium-filled valves feature a hollow cavity inside the valve stem that's meticulously filled with elemental sodium, a remarkable conductor of heat.

Here's how the heat transfer magic works. When the valve operates, the sodium inside the hollow stem melts and becomes liquid at engine operating temperatures. As the valve opens and closes hundreds of times per second, this liquid sodium sloshes back and forth inside the cavity. Each time the sodium moves, it carries heat away from the valve head, where temperatures peak during combustion, and transfers it toward the cooler stem area where the valve guide can dissipate it into the cylinder head.

This innovative design allows for efficient heat transfer from the valve head to the sodium-filled stem, promoting superior cooling capabilities that passive material properties alone can't match. The result? Valve head temperatures drop significantly compared to solid valves of the same material, extending service life and reducing the risk of thermal-related failures.

The manufacturing process for these valves demands precision. As industry sources confirm, crafting sodium-filled valves involves precision forging and machining to shape the valve components to exact specifications, followed by a specialized sodium-filling process where the hollow cavity is carefully filled with elemental sodium to maximize heat transfer efficiency.

The Best Applications for Sodium-Filled Technology

Sodium-filled valve technology shines in applications where thermal management matters but the budget or weight constraints don't push you toward exotic alloys. These valves are typically constructed from high-temperature-resistant alloys such as stainless steel, giving you a proven material foundation enhanced by active cooling.

The versatility of sodium-filled valves makes them ideal for a wide range of high-performance engine applications. From racing cars and aircraft engines to high-performance motorcycles, this technology has earned trust across demanding environments. OEM engineers have specified sodium-filled exhaust valves in production vehicles for years, validating their reliability in real-world conditions.

Consider sodium-filled valves when your build falls into these categories:

- Street/strip dual-purpose builds: You need heat management for spirited driving and occasional track duty without the maintenance demands of titanium

- Forced induction on a budget: Your turbo or supercharged setup generates serious exhaust heat, but Inconel pricing doesn't fit the project scope

- High-heat applications where weight is secondary: The thermal benefits outweigh the mass penalty for your specific goals

- Endurance and reliability-focused builds: Maximum valve longevity matters more than shaving every possible gram

Pros

- Excellent heat dissipation through active thermal transfer technology

- More affordable than titanium or Inconel alternatives

- Proven technology validated in OEM and racing applications for decades

- Extends valve service life by reducing peak operating temperatures

- Works with standard valve spring setups and retainers

Cons

- Heavier than titanium valves, increasing valvetrain inertia at high RPM

- Requires careful handling during installation to avoid damaging the hollow construction

- Not suitable for extreme RPM applications where weight becomes critical

- Sodium is reactive and can be hazardous if the valve is damaged or improperly disposed

Best Applications for Sodium-Filled Valves

Sodium-filled technology hits its sweet spot in builds prioritizing reliability and heat management over absolute weight optimization. Street/strip dual-purpose engines benefit enormously since these valves handle the thermal cycling of daily driving combined with hard pulls at the drag strip without complaint.

Forced induction applications on a budget represent another ideal use case. If your turbocharged build generates exhaust temperatures that worry you but Inconel pricing makes you wince, sodium-filled stainless valves provide meaningful thermal protection at accessible price points.

High-heat applications where weight is less critical round out the target list. Think heavy vehicles, towing-oriented builds, or endurance racing where valve longevity trumps lap-time optimization. The enhanced cooling provided by sodium-filled valves contributes to increased durability and longevity, ensuring reliable performance in demanding environments.

Where sodium-filled valves don't make sense? Extreme RPM naturally aspirated builds where every gram of valvetrain mass matters. In these applications, the weight penalty hurts more than the thermal benefits help, and titanium becomes the smarter choice despite its higher cost.

With heat management options ranging from passive material selection to active sodium cooling covered, the question for many builders becomes platform-specific. Small block Chevrolet engines remain among the most popular performance platforms, and they bring their own valve selection considerations worth examining.

SBC Titanium Valves for Small Block Performance

Small block Chevrolet engines have dominated American performance building for over six decades. Whether you're refreshing a classic 350 or pushing a modern LS platform to its limits, the SBC titanium valves conversation eventually surfaces for anyone chasing serious power at high RPM. These legendary engine families respond exceptionally well to valvetrain weight reduction, making titanium a compelling upgrade path for the right applications.

But dropping titanium valves into your small block isn't a plug-and-play swap. The unique characteristics of SBC heads, combined with the specific demands different builds place on their valvetrains, require careful matching of valve sizing, spring pressures, and supporting hardware. Let's break down what makes titanium work in these platforms and how to avoid the common pitfalls.

Titanium Valve Options for Small Block Chevy Builds

The SBC platform spans an enormous range of applications. Traditional small blocks with iron heads running mechanical flat tappet cams have very different valve requirements than a boosted LS3 spinning to 7,500 RPM. Understanding where titanium valves sbc applications shine starts with recognizing the common thread: high-RPM operation where valvetrain mass becomes a limiting factor.

For traditional small blocks, titanium intake valves in the 2.02" to 2.08" range provide the weight savings that matter most. The intake side sees less thermal stress, making it the natural starting point for titanium conversion. Exhaust valves typically run 1.60" to 1.65" and face higher heat loads, so many builders pair titanium intakes with stainless or Inconel exhaust valves depending on the application.

LS-family engines open additional possibilities. The cathedral and rectangular port heads use different valve sizes and angles, but both respond well to titanium upgrades. The LY7 and similar engines benefit particularly from titanium intake valves when pushing past factory RPM limits. Finding the best valves for ly7 engine builds means matching valve diameter, stem length, and tip geometry to your specific head and cam combination.

Key sizing considerations for SBC titanium valves include:

- Valve diameter: Must match your cylinder head's valve seat diameter precisely for proper sealing

- Stem diameter: Standard 11/32" stems work for most applications; 5/16" stems save additional weight on dedicated racing builds

- Overall length: Critical for proper installed height and spring geometry

- Tip geometry: Must be compatible with your rocker arm style and lash adjuster

Matching SBC Titanium Valves to Your Build Goals

Valve spring compatibility represents the most critical consideration when switching to titanium valves sbc builds. The dramatic weight reduction changes the entire valvetrain dynamic equation. Springs that controlled a 100-gram stainless steel valve perfectly may be excessively aggressive with a 58-gram titanium replacement.

Here's where many builders make costly mistakes. Over-springing a titanium valve accelerates stem wear, stresses the valve tip, and can actually hurt performance by creating excessive friction and heat in the valvetrain. The goal is matching spring pressure to what the lighter valve actually needs for control, not what the original heavier valve required.

Retainer and lock requirements change with titanium as well. Standard steel retainers and locks can damage titanium valve stems through galling and accelerated wear. Titanium-compatible retainers, typically made from tool steel with specialized coatings or from titanium itself, protect the valve while maintaining proper lock engagement.

Spring pressure guidelines for titanium SBC applications typically look like this:

- Seat pressure: Reduce 15-20% compared to stainless steel valve specifications

- Open pressure: Maintain adequate control for your cam profile and RPM target

- Installed height: Verify correct geometry with titanium retainers which may differ from steel

Pros

- Significant weight reduction for high-RPM SBC builds, typically 40%+ savings per valve

- Improved valvetrain dynamics allow higher RPM potential before valve float

- Reduced valve float extends the usable powerband and protects against piston contact

- Lower spring pressures reduce camshaft and lifter wear

- Proven technology in professional SBC racing applications

Cons

- Requires titanium-compatible retainers and locks, adding to total investment

- Higher initial investment compared to quality stainless steel alternatives

- Demands precise spring pressure setup to avoid premature wear

- Periodic inspection required to check for stem stretch and coating condition

- Bronze valve guides recommended for optimal longevity

Best Applications for SBC Titanium Valves

High-RPM SBC racing builds represent the ideal titanium application. Drag racing small blocks pushing past 8,000 RPM, road racing engines that spend extended periods at high speed, and circle track motors where consistent valve control determines finishing position all benefit substantially from the weight reduction titanium provides.

LS engine performance applications have embraced titanium valves as the platform has matured. Modern LS builds targeting 7,000+ RPM with aggressive cam profiles need every valvetrain advantage available. Titanium intakes paired with appropriate exhaust valves give these engines the control they need without the mass penalty of all-stainless setups.

Weight-conscious street performance builds can also justify titanium, particularly on naturally aspirated applications. If you're building a weekend canyon carver or autocross competitor where every performance advantage matters, titanium intake valves offer real benefits. Just ensure your build actually reaches RPM levels where the weight savings translate to measurable improvement.

With platform-specific considerations for SBC engines covered, the broader question becomes how all these valve options compare when laid out side by side. A comprehensive comparison helps crystallize which material and construction approach matches your specific build requirements.

Complete Forged Valve Comparison by Material and Application

You've seen the individual breakdowns. Now comes the moment of clarity: how do all these forged valve options stack up when placed side by side? Whether you're weighing titanium piston and valve combinations for a high-RPM screamer or evaluating victory valves solutions for your forced induction build, this comprehensive comparison cuts through the complexity and delivers actionable intelligence.

Think of this section as your decision matrix. We've distilled everything from material density to failure modes into digestible formats that let you match your specific build requirements to the optimal valve solution. No more guessing. No more over-engineering or under-specifying. Just clear, data-driven guidance.

Material Properties Comparison at a Glance

When comparing titanium vs steel forged valves alongside specialized options like Inconel and sodium-filled designs, the property differences become strikingly clear. Each material brings distinct advantages and trade-offs that determine where it excels and where it falls short.

The following table consolidates the critical specifications you need for informed valve selection:

| Material Type | Weight (Relative) | Heat Resistance | Best Application | Price Range | Forging Quality Importance |

|---|---|---|---|---|---|

| Shaoyi Precision Hot-Forged (Steel/Titanium) | Varies by alloy | Excellent (material dependent) | OEM production, racing teams, high-volume applications | Competitive at volume | Critical - IATF 16949 certified process ensures consistency |

| Titanium (Ti-6Al-4V) | Lightest (~58% of steel) | Moderate (up to ~600°C/1,100°F) | High-RPM naturally aspirated, intake side applications | High ($$$) | Critical - grain structure alignment determines fatigue life |

| Stainless Steel (EV8, 21-4N) | Baseline (100%) | Good to Excellent (up to ~1,500°F) | General performance, street/strip, most exhaust applications | Low-Medium ($-$$) | Important - affects durability and heat resistance |

| Inconel (Nickel-Chromium Superalloy) | Heaviest (~110% of steel) | Exceptional (up to 2,000°F/1,093°C) | Forced induction exhaust, turbo/supercharged builds | Very High ($$$$) | Critical - superalloy forging requires precise temperature control |

| Sodium-Filled Stainless | Heavy (hollow but dense) | Excellent (active cooling) | High-heat budget builds, endurance applications | Medium ($$) | Important - hollow construction demands precision manufacturing |

Notice how Shaoyi's certified precision forging sits at the top as the quality benchmark. When you're sourcing valves at volume, that IATF 16949 certification ensures every component leaving the facility meets identical specifications. This consistency matters enormously when you're building multiple engines or supplying a racing team throughout a season.

The density differences deserve special attention. According to material property research, titanium runs approximately 4.5 g/cm³ compared to stainless steel at roughly 7.8 g/cm³ and Inconel at 8.4-8.7 g/cm³. These numbers translate directly into the valvetrain dynamics that determine your engine's RPM potential and reliability.

Choosing by Application Type

Material properties only tell half the story. Your specific application determines which trade-offs matter and which you can safely ignore. A naturally aspirated drag motor has fundamentally different valve requirements than a turbocharged endurance racer, even if both chase maximum performance.

Use this application-matched recommendation table to narrow your options:

| Application Type | Recommended Intake Valve | Recommended Exhaust Valve | Key Considerations |

|---|---|---|---|

| Naturally Aspirated High-RPM | Titanium (Ferrea or equivalent) | Titanium or Quality Stainless | Weight reduction critical; lower exhaust temps allow titanium exhaust in some cases |

| Forced Induction (Turbo/Supercharged) | Titanium | Inconel | Hybrid approach captures weight savings on intake; Inconel handles extreme exhaust heat |

| Street/Strip Dual-Purpose | Quality Stainless or Sodium-Filled | Sodium-Filled or Stainless | Balance of durability, heat management, and cost; titanium overkill for most street use |

| Endurance Racing | Sodium-Filled Stainless | Inconel or Sodium-Filled | Longevity trumps weight; active cooling extends valve life over extended race distances |

| Budget Performance | Quality Forged Stainless | Quality Forged Stainless | Proven reliability at accessible price points; proper forging quality still essential |

The hybrid approach showing up in forced induction recommendations reflects real-world professional engine building practice. Titanium intake valves capture the 42% weight reduction where thermal conditions allow, while Inconel exhaust valves handle the elevated temperatures that would compromise titanium over time.

Failure Modes and Warning Signs by Material

Understanding how each valve material fails helps you catch problems before catastrophic damage occurs. Different materials exhibit distinct failure patterns that experienced builders learn to recognize during inspections.

Titanium Valve Failure Modes

Titanium's sensitivity to improper spring pressure creates its most common failure pathway. Over-sprung titanium valves experience accelerated stem wear, tip damage, and coating degradation. Watch for these warning signs:

- Stem stretch: Measure valve overall length at each inspection; elongation indicates fatigue accumulation

- Coating wear: Visible wear-through of Chromium Nitride coating exposes raw titanium to galling

- Tip mushrooming: Deformation at the rocker contact point signals excessive valvetrain stress

- Guide wear patterns: Unusual wear in bronze guides may indicate coating failure or improper clearances

Titanium also struggles when exhaust temperatures exceed its thermal limits. Discoloration, softening, and eventual structural failure occur when heat exposure goes beyond approximately 1,100°F sustained.

Steel Valve Failure Modes

Stainless steel valves primarily fail through heat-related mechanisms. According to automotive technical resources, a burnt valve is a valve that has been damaged by excessive temperatures. The extreme heat will often cause the edges of the valve to burn away, or the valve may experience thermal shock causing a portion to crack or break off.

Common steel valve warning signs include:

- Margin erosion: The thin edge of the valve face wears away, creating sealing issues

- Seat recession: Repeated thermal cycling causes the valve seat interface to wear, affecting installed height

- Carbon buildup: Deposits on the valve face or stem indicate combustion issues that accelerate wear

- Compression loss: Burnt valves create poor cylinder sealing, detectable through compression or leak-down testing

Any issue that creates excessive heat in a valve or cylinder head can cause a valve to burn. Common causes include improper valve seating, cooling system problems, detonation, lean air-fuel mixtures, and pre-ignition.

Inconel Valve Considerations

Inconel rarely fails from heat exposure within its design envelope. Instead, its primary limitation involves the weight penalty affecting valvetrain dynamics:

- Valve float at high RPM: The additional mass requires stiffer springs to maintain control, which increases friction and wear throughout the valvetrain

- Increased camshaft and lifter loading: Heavier valves stress other valvetrain components more than lighter alternatives

- Spring fatigue: Higher required spring pressures accelerate spring fatigue, potentially requiring more frequent replacement

For naturally aspirated applications where exhaust temperatures stay moderate, Inconel's weight becomes a liability without delivering proportional benefits. Reserve this material for applications that genuinely need its extreme heat tolerance.

Quality Benchmarks Across All Materials

Regardless of which material you select, forging quality fundamentally determines valve performance and longevity. Premium alloys processed through substandard forging operations produce inferior results compared to properly forged standard materials.

When evaluating any forged valve supplier, look for these quality indicators:

- Grain structure documentation: Reputable manufacturers can provide metallurgical data confirming proper grain alignment

- Consistent dimensional tolerances: Batch-to-batch consistency indicates controlled manufacturing processes

- Certification credentials: IATF 16949 or equivalent quality management certification validates systematic process control

- Traceability: The ability to trace components back to specific material lots and production runs

Components like pro bolt fasteners and racetech titanium bolts in your valvetrain assembly deserve the same quality scrutiny as the valves themselves. The entire system works together, and a weak link anywhere compromises overall reliability.

With material properties, application matching, and failure modes now consolidated, the final step is translating this information into specific recommendations for your build. The conclusion ahead delivers ranked guidance based on everything we've examined.

Final Recommendations for Your Forged Valve Selection

You've absorbed the material science, examined the application-specific nuances, and reviewed the failure modes. Now comes the moment where all that knowledge crystallizes into actionable decisions. Whether you're specifying valves for a single build or sourcing components for an entire racing program, these ranked recommendations cut through the complexity and point you toward the right solution.

The titanium vs steel forged valves debate doesn't have a universal winner. Instead, the optimal choice depends entirely on your specific application, budget constraints, and performance priorities. Let's translate everything we've covered into clear guidance you can act on today.

Our Top Pick for Each Build Type

After evaluating material properties, manufacturing quality, thermal limits, and real-world performance across diverse applications, here's how the options rank for specific use cases:

-

For Certified Quality and Volume Production: Shaoyi Precision Hot-Forged Valves

When consistency across hundreds or thousands of components matters as much as individual piece quality, IATF 16949 certification becomes non-negotiable. Racing teams building multiple engines per season, automotive manufacturers requiring validated supply chains, and performance shops with ongoing valve needs benefit from Shaoyi's combination of rapid prototyping capabilities and high-volume production consistency. Their precision hot forging creates the grain structure alignment that determines fatigue life, while their location near Ningbo Port enables efficient global logistics. -

For High-RPM Naturally Aspirated Builds: Ferrea Titanium

When your engine regularly exceeds 7,500 RPM and every gram of valvetrain mass affects performance, Ferrea's Chromium Nitride-coated titanium valves deliver proven results. The 42% weight reduction translates directly into reduced valve float risk, faster valve acceleration, and the ability to run more aggressive cam profiles without compromising control. -

For Forced Induction Exhaust Applications: Inconel

Turbocharged and supercharged builds generating exhaust temperatures above 1,500°F demand Inconel's exceptional thermal tolerance. Pair Inconel exhaust valves with titanium intakes to capture weight savings where heat isn't a limiting factor while maintaining durability where temperatures spike. -

For Budget-Conscious Heat Management: Sodium-Filled Stainless

Active thermal transfer technology at accessible price points makes sodium-filled valves the smart choice for street/strip builds, mild forced induction applications, and any scenario where reliability matters more than ultimate weight optimization. The proven OEM pedigree provides confidence in long-term durability. -

For SBC-Specific Builds: Application-Matched Titanium

Small block Chevrolet and LS-family engines respond exceptionally well to titanium intake valves when pushing past factory RPM limits. Match valve diameter, stem size, and retainer compatibility to your specific head and cam combination for optimal results.

When to Invest in Premium Valve Materials

Premium valve materials justify their cost when specific performance thresholds enter the picture. According to industry experts at Engine Builder Magazine, a common rule of thumb for titanium valves is once an engine regularly exceeds 7,000 RPM. That's when the benefits of lighter weight outweigh the trade-offs in cost and lifespan.

Beyond RPM targets, consider premium materials when:

- Your cam profile pushes valvetrain dynamics to the edge of conventional valve control

- Competition rules don't restrict valve materials and every advantage matters

- Forced induction creates exhaust temperatures that standard stainless can't reliably handle

- The cost of engine failure exceeds the premium for appropriate valve materials

When NOT to Use Titanium

Knowing when titanium makes sense is only half the equation. Equally important is recognizing scenarios where titanium represents wasted money or, worse, a reliability risk:

- Low-RPM applications: Engines that rarely exceed 6,500 RPM don't generate the valvetrain dynamics where titanium's weight savings provide measurable benefit. Quality stainless steel handles these conditions reliably at a fraction of the cost.

- Extreme boost without proper cooling: Titanium exhaust valves in heavily turbocharged gasoline applications face temperatures beyond their safe operating range. The material loses strength rapidly above 1,100°F, creating unacceptable failure risk.

- Budget builds where stainless performs adequately: If your build doesn't push boundaries that demand exotic materials, investing in titanium diverts resources from other areas that might deliver more measurable improvement.

- Applications requiring extended service intervals: Titanium demands more frequent inspection and earlier replacement compared to stainless. If your engine runs extended periods between teardowns, the maintenance burden may not fit your program.

The Bottom Line: Forging Quality Determines Everything

Here's the truth that applies regardless of which material you select: manufacturing precision and forging quality ultimately determine valve performance and longevity. A perfectly specified titanium valve from a substandard manufacturer will fail before a properly forged stainless valve from a quality-focused supplier.

The forging process fundamentally transforms metal's internal structure. As manufacturing research confirms, forging alters the material's grain structure, making it stronger and more resilient to stress and fatigue. This enhanced strength comes from compressing and aligning the grain structure, giving forged parts superior durability for components subjected to high levels of stress.

When sourcing valves, prioritize suppliers who can demonstrate:

- Documented quality management systems with third-party certification

- Consistent batch-to-batch dimensional tolerances

- Metallurgical verification of proper grain structure

- Engineering support to match valve specifications to your application

For high-volume buyers, racing teams, and manufacturers requiring globally compliant components, partnering with an IATF 16949-certified precision forging specialist like Shaoyi provides the quality assurance that protects both your engines and your reputation. Their rapid prototyping capabilities accelerate development timelines while their mass production consistency ensures every valve performs identically.

Whether you ultimately choose titanium for its weight advantages, Inconel for extreme heat tolerance, sodium-filled stainless for active cooling, or quality forged stainless for proven reliability, the forging process that created your valves determines how well they'll perform under pressure. Invest in quality manufacturing, match materials to your specific application, and your valve selection will serve your build goals reliably mile after mile and lap after lap.

Frequently Asked Questions About Titanium vs Steel Forged Valves

1. Are titanium valves better than steel?

It depends on your application. Titanium valves offer approximately 42% weight reduction over stainless steel, making them ideal for high-RPM naturally aspirated builds exceeding 7,000 RPM where reduced valvetrain inertia prevents valve float. However, stainless steel valves provide superior heat resistance and durability for street performance and forced induction exhaust applications. Titanium weakens above 1,100°F, while quality stainless handles up to 1,500°F. For most street engines, stainless steel delivers proven reliability at lower cost, while titanium excels in professional racing where weight savings translate to competitive advantage.

2. What are the disadvantages of titanium valves?

Titanium valves come with several trade-offs. They're significantly more expensive than stainless steel alternatives and require specialized titanium-compatible retainers and locks to prevent stem damage. Titanium loses strength above approximately 600°C (1,100°F), making it unsuitable for exhaust valves in heavily turbocharged applications. They demand careful valve spring pressure matching, as over-springing accelerates stem wear and coating degradation. Regular inspection for stem stretch and coating condition is essential, and bronze valve guides are recommended for optimal longevity. These maintenance requirements may not suit engines with extended service intervals.

3. How long do titanium valves last?

With proper maintenance, titanium valves can last two to three racing seasons or longer. Longevity depends on maintaining fresh oil, proper cooling, correct valve adjustments, and appropriate spring pressures. Titanium valves require periodic inspection to check for stem stretch and Chromium Nitride coating wear. Unlike stainless steel valves that can often run indefinitely in street applications, titanium demands more frequent teardowns and earlier replacement schedules. For racing applications with regular engine inspections, this fits naturally into existing maintenance protocols.

4. What is the best material for engine valves?

The best valve material depends entirely on your build goals. For most street engines, quality stainless steel provides optimal durability and heat resistance at accessible prices. High-RPM naturally aspirated racing builds benefit from titanium intake valves for weight reduction. Turbocharged and supercharged applications often require Inconel exhaust valves, which withstand temperatures up to 2,000°F. Many professional builders use a hybrid approach: titanium intake valves paired with Inconel or stainless exhaust valves. IATF 16949-certified manufacturers like Shaoyi ensure consistent forging quality regardless of material choice.

5. Can you use titanium exhaust valves in turbocharged engines?

Titanium exhaust valves are generally not recommended for turbocharged gasoline engines due to extreme exhaust gas temperatures. Turbo applications can generate exhaust temps exceeding 1,500°F, well beyond titanium's safe operating range of approximately 1,100°F. However, there's an exception: high-end race engines running methanol or alcohol-based fuels produce significantly lower exhaust temperatures, allowing titanium on both intake and exhaust. For gasoline turbo builds, the recommended approach is titanium intake valves paired with Inconel exhaust valves, capturing weight savings where heat permits while maintaining durability where temperatures spike.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —