The Right Stamped Steel Control Arm Bushing Material for Your Ride

TL;DR

When choosing a stamped steel control arm bushing material, your decision primarily comes down to rubber versus polyurethane. Standard rubber bushings offer a quiet, comfortable ride ideal for daily drivers by absorbing vibrations effectively. In contrast, polyurethane bushings provide enhanced responsiveness, improved handling, and greater durability, making them the preferred choice for performance-oriented vehicles and driving enthusiasts. While specialty materials like Delrin or PTFE exist for high-performance racing, they are generally too harsh for street use.

Understanding the Foundation: Stamped Steel Control Arms & Bushings

A control arm is a critical component of your vehicle's suspension system, acting as the link between the chassis and the wheel hub. Often called an A-arm, its job is to allow the wheels to move up and down in a controlled manner, ensuring stability and keeping the tires in contact with the road. While control arms can be made from cast iron or cast aluminum, stamped steel is a common choice for many modern cars due to its balance of strength and cost-effectiveness. The manufacturing of these components requires precision, and for automotive manufacturers seeking reliable metal stamping, providers like Shaoyi (Ningbo) Metal Technology Co., Ltd. deliver comprehensive solutions from prototyping to mass production, ensuring high-quality parts.

Housed within the control arm is the bushing, a small but vital part that serves as a pivot and insulator. Typically made of a flexible material, the bushing is mounted where the control arm connects to the vehicle's frame. Its primary role is to absorb road shock, dampen vibrations, and reduce noise from being transmitted into the vehicle's cabin. Think of it like cartilage in a joint; it allows for smooth, controlled movement without harsh metal-on-metal contact. This function is essential for both ride quality and predictable handling.

Over time, these bushings wear out due to constant stress, heat, and exposure to road contaminants. When a control arm bushing fails, the symptoms are often noticeable. You might experience a clunking noise when going over bumps, a shaky steering wheel, or uneven tire wear. A worn bushing allows for excessive movement in the suspension, which compromises handling, braking stability, and overall safety. This degradation is why selecting the right replacement bushing material is not just a matter of performance, but also of restoring your vehicle's intended ride characteristics and safety.

The Core Decision: Rubber vs. Polyurethane Bushings

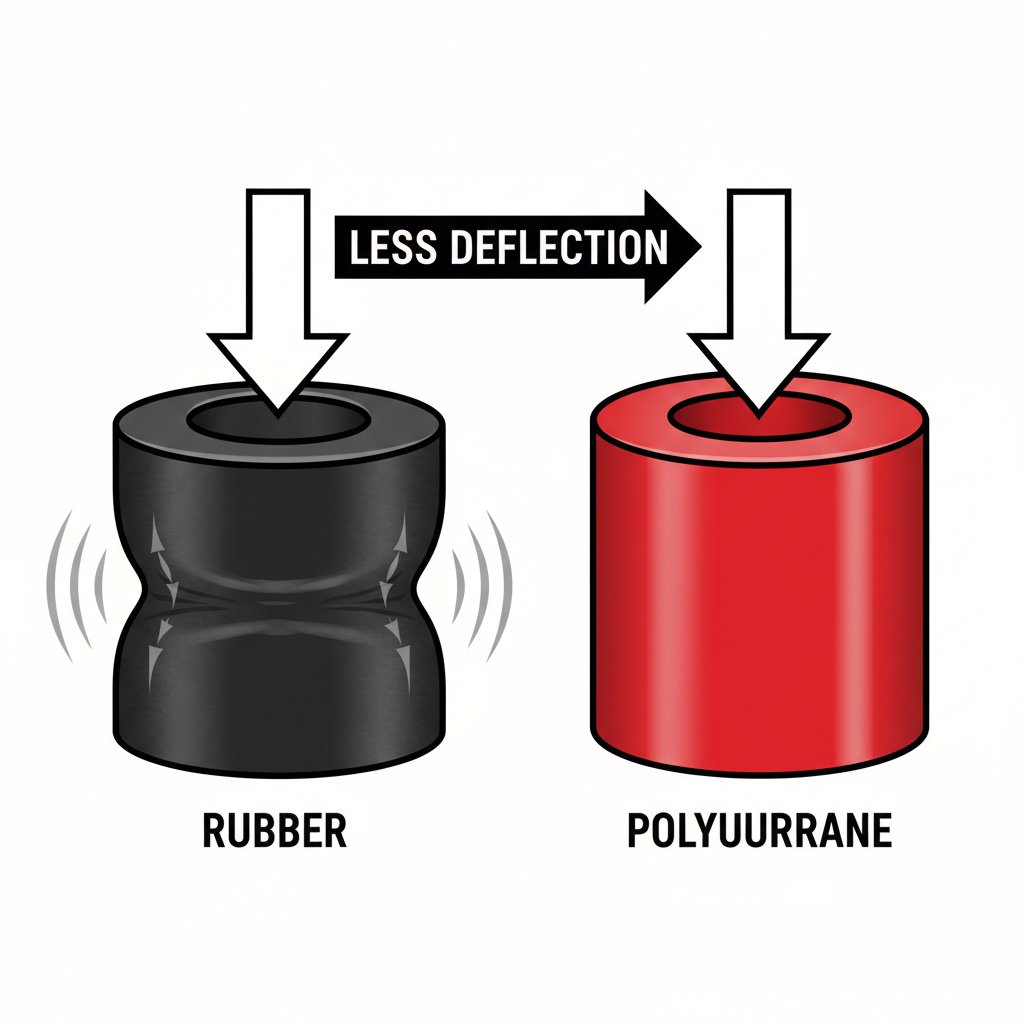

The most common dilemma for vehicle owners is choosing between traditional rubber and performance-oriented polyurethane bushings. Each material offers a distinct set of characteristics that cater to different driving needs and priorities. The original equipment (OE) choice for most vehicles is rubber, prized for its ability to provide a smooth, quiet ride. Its softness allows it to effectively absorb vibrations and impacts from the road, isolating the cabin from noise and harshness. This makes rubber the ideal choice for daily commuters and anyone who prioritizes comfort over raw performance.

On the other hand, polyurethane is a performance upgrade. It is a significantly firmer and more durable material than rubber. This firmness reduces the flex and deflection that occurs in the suspension during cornering and acceleration, resulting in sharper steering response, improved handling, and a more connected feel with the road. Because polyurethane is resistant to oil, chemicals, and degradation from stretching, it can often last the lifetime of the vehicle. However, this performance comes with a trade-off: its stiffness means more road noise and vibration are transferred into the cabin, leading to a harsher ride.

Another key difference is maintenance. Rubber bushings are generally a 'fit and forget' component. Polyurethane bushings, however, require periodic lubrication to prevent them from squeaking or binding. Many come with grease fittings to simplify this process, but it's a maintenance step that owners must be aware of. The choice ultimately depends on your vehicle's primary use. For a stock street car or cruiser, OE-style rubber is perfect. For a sports car, a weekend track vehicle, or anyone seeking to maximize handling, polyurethane is the superior option.

| Performance Factor | Rubber | Polyurethane |

|---|---|---|

| Road Noise | Less | More |

| Vibration | Less | More |

| Ride Quality | Smoother | Harsher |

| Steering & Suspension Feel | Less Feel, Less Responsive | More Feel, More Responsive |

| Durability | Wears out over time | Can last a lifetime |

| Maintenance | None | Regular lubrication required |

Advanced & Specialty Bushing Materials (For Demanding Applications)

While rubber and polyurethane cover the needs of most drivers, there is a third category of materials designed for extreme, high-performance applications. These specialty options, including Delrin, PTFE (Teflon), bronze, and nylon, are typically reserved for dedicated race cars or custom-built vehicles where performance is the only priority. These materials offer a level of rigidity and low friction that far exceeds even polyurethane, providing the most direct connection possible between the suspension and the chassis for maximum control and feedback.

Delrin, for example, is a high-strength plastic that offers extreme stiffness with minimal vibration absorption, making it a popular choice in competitive racing. It provides near-zero deflection, ensuring suspension geometry remains perfectly consistent under heavy cornering loads. Similarly, PTFE, especially when filled with materials like stainless steel, offers incredible wear resistance and can operate at very high temperatures. According to experts at GTeek, stainless steel-filled PTFE is particularly effective in steam or hot liquid service and is tough enough for demanding mechanical applications. Bronze and nylon also offer unique properties for specific, high-load scenarios.

However, the benefits of these advanced materials come with significant drawbacks for street use. Their extreme hardness means they transfer nearly all road imperfections directly into the vehicle's frame, resulting in a ride that is exceptionally harsh and noisy. The noise, vibration, and harshness (NVH) levels are far beyond what most drivers would find acceptable for daily driving. Therefore, unless you are building a dedicated track machine where every fraction of a second counts, these specialty materials are best viewed as a niche solution for professional-level performance needs.

How to Choose the Right Bushing Material for Your Vehicle

Synthesizing all this information into a final decision requires a clear assessment of your own needs and priorities. Choosing the right stamped steel control arm bushing material isn't about finding the 'best' option in a vacuum, but rather the best option for *your* specific situation. To make a confident choice, consider the following factors as a final checklist.

Start by evaluating your vehicle's primary use. Is it a daily driver where comfort and quiet are paramount? If so, OE-style rubber bushings are almost certainly the correct choice. They will restore the ride quality your car was designed to have from the factory. If your vehicle is a sports car that sees spirited driving or occasional autocross and track days, polyurethane offers a tangible upgrade in handling and responsiveness that you will immediately feel.

Next, be honest about your tolerance for performance trade-offs. Are you willing to accept a firmer, potentially noisier ride in exchange for enhanced steering feel and cornering stability? If the answer is no, stick with rubber. Also, consider your willingness to perform maintenance. Polyurethane bushings require periodic re-greasing to prevent squeaking, a task that rubber bushings do not. Finally, think about your budget. Rubber bushings are generally the most affordable, followed by polyurethane, with specialty materials like Delrin and PTFE being the most expensive. For most standard street cars, exotic materials are overkill and represent a point of diminishing returns. Once you've identified your ideal material, the final step is to verify the correct part number and fitment for your vehicle's specific make and model.

Frequently Asked Questions

1. What is the best material for control arm bushings?

There is no single 'best' material, as the ideal choice depends on your vehicle's use. For most daily driven street cars, rubber is best because it provides a smooth, quiet ride. For performance applications like sports cars or track vehicles, polyurethane is superior due to its firmness, which improves handling and steering response, though it results in a harsher ride.

2. What is the best bushing material for stainless steel?

For applications involving stainless steel, especially in high-temperature or demanding mechanical environments, PTFE (Teflon) filled with stainless steel is an excellent option. This composite material offers high wear resistance, can withstand high temperatures, and provides the strength needed for industrial uses like steam or hot liquid service.

3. Is Delrin a good bushing material?

Yes, Delrin is an excellent bushing material for high-performance and racing applications. Its high strength and low-friction properties provide maximum suspension rigidity and responsiveness. However, it is generally not recommended for street cars because it transfers a significant amount of noise and vibration, resulting in a very harsh ride.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —