Stamping Steering Column Components: Manufacturing & Materials Guide

TL;DR

Stamping is the dominant manufacturing process for high-volume, safety-critical stamping steering column components, including mounting brackets, rake adjustment mechanisms, and collapsible jackets. Compared to traditional casting methods, metal stamping using High-Strength Low-Alloy (HSLA) steels offers significant weight reduction and lower piece prices while maintaining rigorous crash-test standards. This guide examines the technical feasibility, material selection strategies, and supplier requirements (such as IATF 16949) necessary for engineering robust steering assemblies.

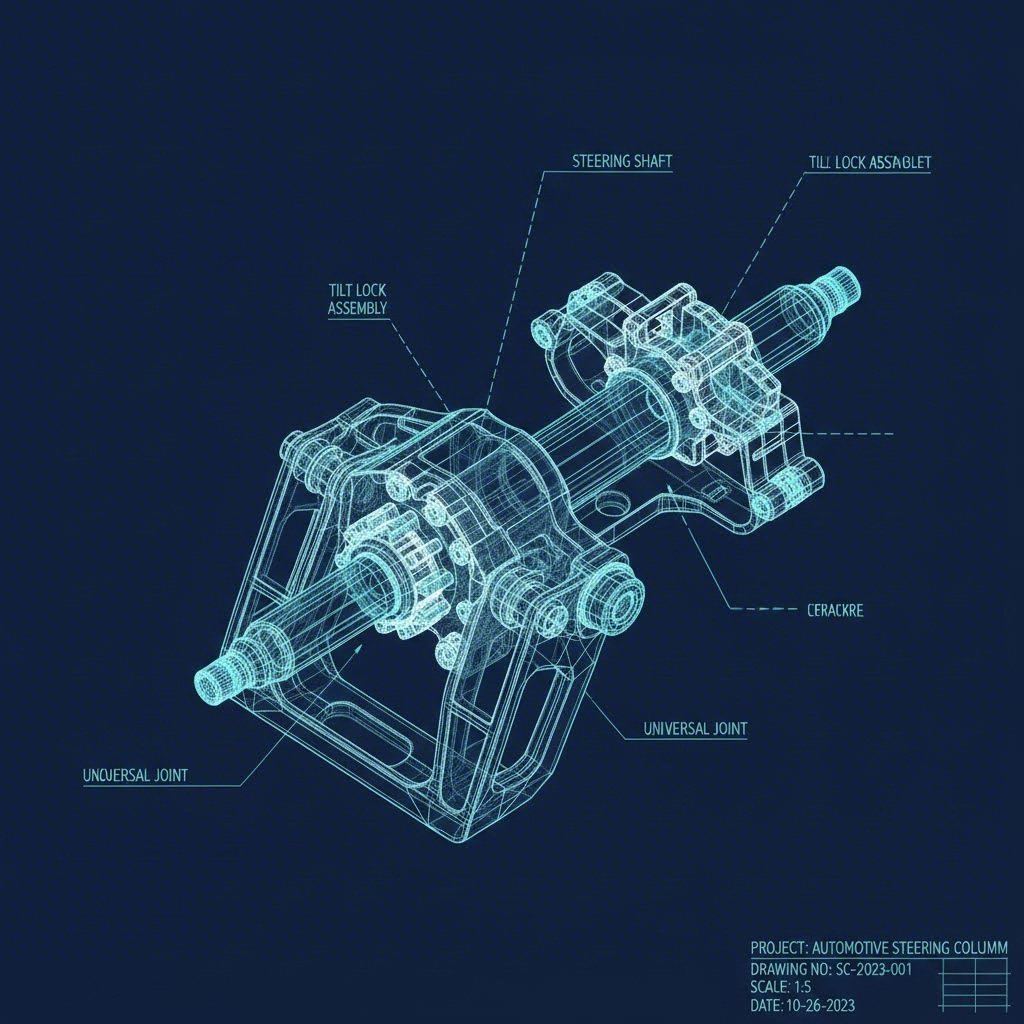

Critical Stamped Components in Steering Columns

Modern steering columns are complex sub-assemblies requiring high precision to ensure driver safety and comfort. Metal stamping allows engineers to produce intricate geometries with high repeatability. The following components are primary candidates for progressive and transfer stamping.

Mounting Brackets and Structural Supports

The steering column must be rigidly attached to the vehicle's cross-car beam or firewall to prevent vibration. Stamped mounting brackets are preferred over cast aluminum in many mass-market applications due to their superior strength-to-weight ratio. These brackets are typically formed from HSLA steel to withstand high static loads and dynamic operational forces without yielding.

Tilt and Rake Mechanisms

Driver ergonomics rely on the adjustment mechanisms for tilt (rake) and telescope (reach). The locking plates and teeth used in these systems are often stamped to near-net shape. Precision fine-blanking is frequently employed here to achieve the clean shear edges required for smooth locking engagement, eliminating secondary machining operations.

Collapsible Jackets and Safety Zones

In the event of a frontal collision, the steering column is designed to collapse, absorbing energy to protect the driver. This is often achieved through stamped and rolled energy-absorbing plates or mesh-style brackets that deform in a controlled manner. Manufacturers utilize specialized dies to create specific stress risers or corrugations in the metal, ensuring the component crumples predictably under a precise load.

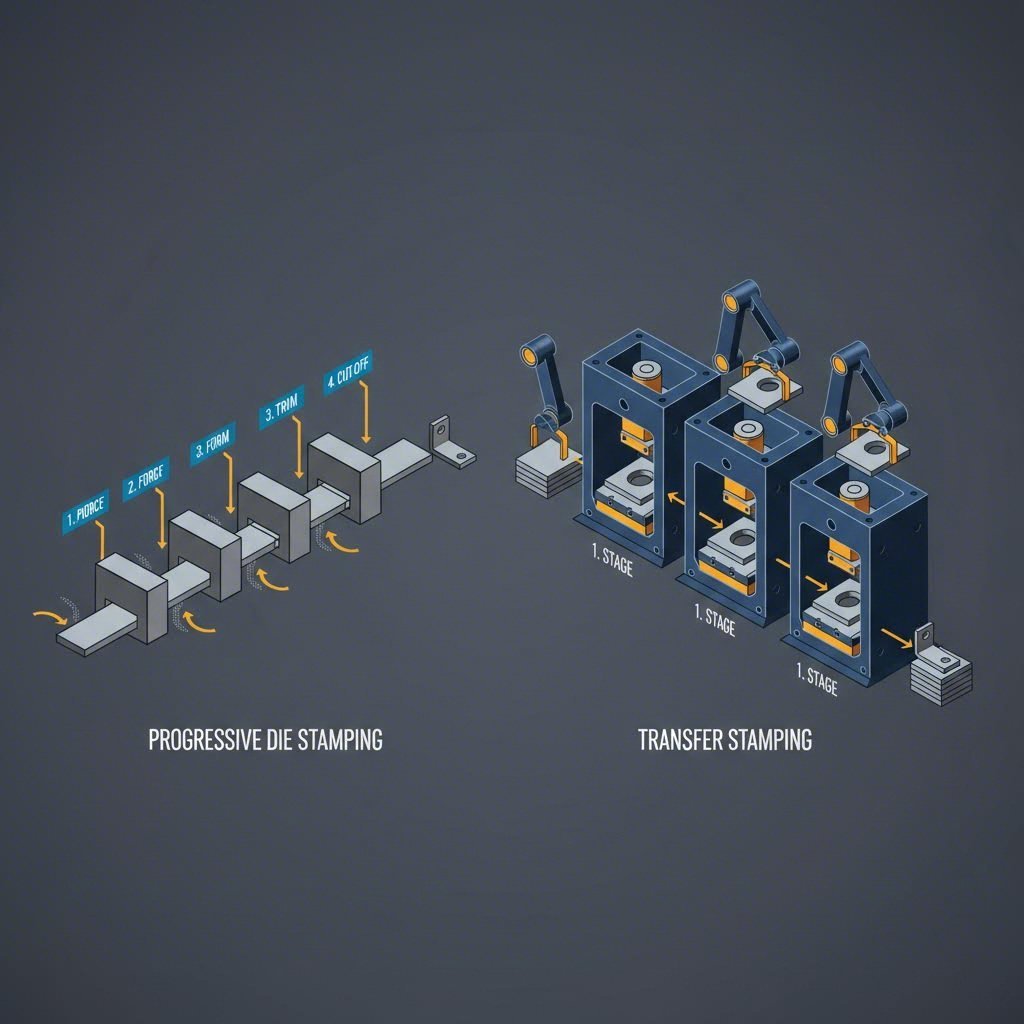

Manufacturing Processes: Progressive vs. Transfer Stamping

Choosing the correct stamping methodology is critical for balancing tooling investment with unit cost. For steering column components, the decision often lies between progressive die stamping and transfer stamping.

Progressive Die Stamping

For smaller, high-volume components like locking pawls, clips, and smaller brackets, progressive die stamping is the standard. In this process, a metal coil is fed through a single die with multiple stations. Each station performs a specific operation—cutting, bending, or piercing—as the strip moves forward. This method achieves high strokes per minute (SPM), significantly reducing the cycle time and piece price for high-volume automotive programs.

Transfer Stamping for Complex Geometries

Larger structural housings or components requiring deep draws often necessitate transfer stamping. Unlike progressive dies where parts remain attached to the strip, transfer stamping moves individual blanks between stations using mechanical fingers. This allows for more complex forming operations and better material utilization, which is essential when working with expensive automotive-grade steels.

From Prototype to Mass Production

Validating manufacturing feasibility early in the design phase is crucial. Automotive OEMs often require suppliers to demonstrate capability across the product lifecycle. Manufacturers capable of bridging the gap from rapid prototyping to mass production offer a strategic advantage. For instance, Shaoyi Metal Technology provides comprehensive stamping solutions that scale from initial prototypes to high-volume manufacturing, utilizing presses up to 600 tons to deliver critical components like control arms and subframes in adherence to IATF 16949 standards.

Engineering Challenges & Material Selection

Stamping safety-critical steering parts involves navigating complex metallurgical behaviors. Engineers must account for material properties that affect both manufacturability and final part performance.

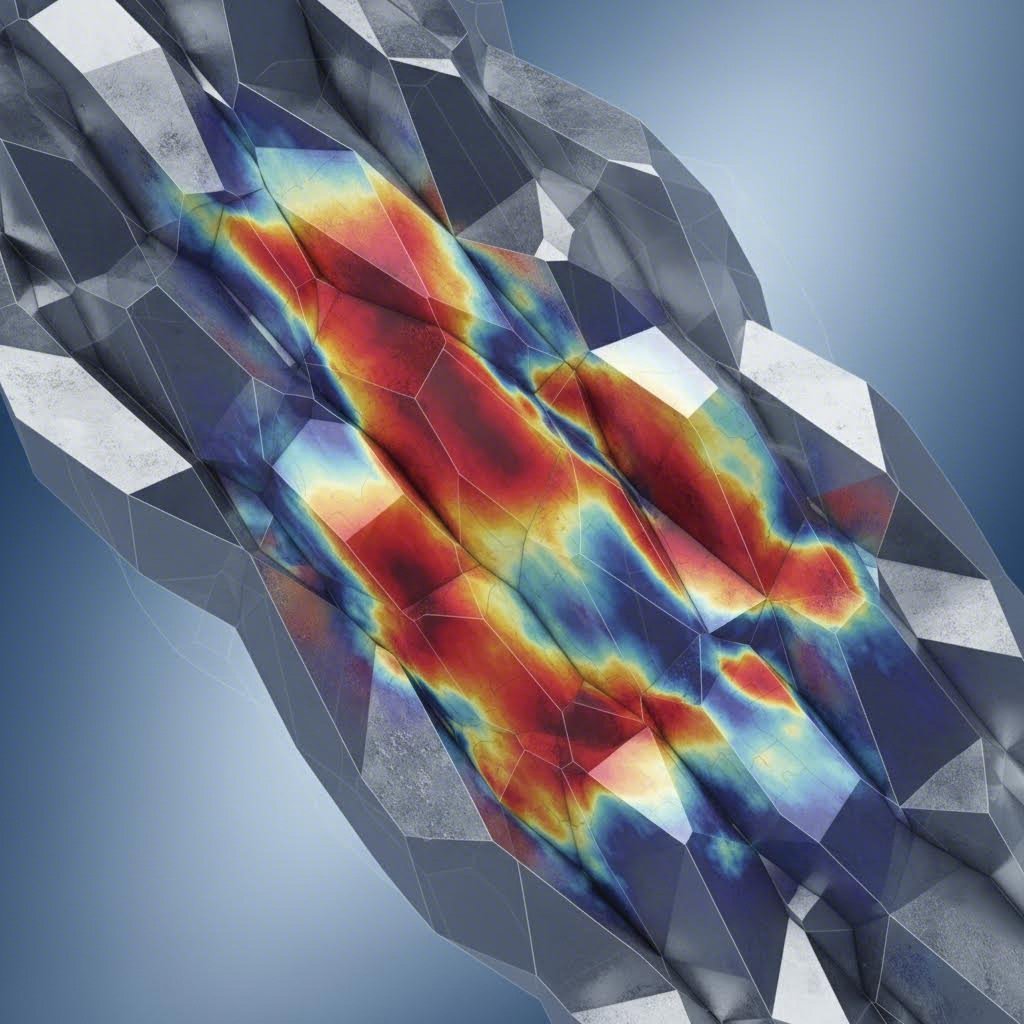

Managing Springback in HSLA Steels

To reduce vehicle weight, manufacturers increasingly rely on High-Strength Low-Alloy (HSLA) steels. While strong, these materials exhibit significant springback—the tendency of the metal to return to its original shape after forming. Compensation strategies in the die design phase, guided by Finite Element Analysis (FEA), are essential to maintain tolerances, particularly for mating parts in telescoping columns.

Tight Tolerances and Crashworthiness

Steering components operate with zero-play requirements to ensure steering precision. Stamped parts must hold tight tolerances (often within +/- 0.05mm) to prevent rattles or play. Furthermore, the material must maintain ductility to prevent cracking during the rapid deformation of a crash event. Selecting the right steel grade involves balancing yield strength for durability against elongation properties required for energy absorption.

Supplier Selection Criteria for Automotive Stamping

Procuring stamped steering components requires a vetting process that goes beyond price. The supplier's quality management system and technical capabilities are paramount.

- IATF 16949 Certification: This is the non-negotiable baseline for automotive suppliers, ensuring quality management systems are aligned with OEM requirements.

- In-House Tool & Die Capabilities: Suppliers with internal tooling departments can react faster to engineering changes and maintain dies more effectively, reducing downtime.

- Simulation and Co-Design: Top-tier suppliers use simulation software to predict forming issues before steel is cut. Look for partners willing to engage in co-design to optimize part geometry for the stamping process.

- Value-Added Assembly: Many steering components require secondary operations. Suppliers that offer in-line welding, staking, or assembly of brackets to tubes provide a more complete solution, reducing logistics complexity.

Summary of Manufacturing Feasibility

The shift from casting to stamping in steering column production is driven by the automotive industry's relentless pursuit of weight reduction and cost efficiency. By leveraging advanced processes like progressive die stamping and materials like HSLA steel, engineers can design components that meet stringent safety standards while optimizing production metrics. Success in this domain requires a deep understanding of material behavior and a partnership with capable, certified manufacturers.

Frequently Asked Questions

1. What are the main components of a steering system?

The primary components of a modern steering system include the steering wheel, the steering column (which houses the shaft and safety mechanisms), the steering gear (rack and pinion or recirculating ball), and the tie rods that transfer force to the steering knuckles at the wheels. In electric power steering (EPS) systems, an electric motor and ECU are also integrated into the column or rack.

2. What component transfers the steering force to the wheels?

Tie rods are the critical linkage components that transfer the lateral motion from the steering gear to the steering knuckles at the wheels. They are responsible for pushing and pulling the wheels to change their angle, ensuring the vehicle responds accurately to the driver's input.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —