Stamped Window Regulators: Engineering Precision & Sourcing Guide

TL;DR

Stamped window regulators are automotive window lift mechanisms manufactured through precision sheet metal stamping, a process that ensures superior durability and exact Original Equipment (OE) fitment compared to cast or plastic alternatives. By using high-strength steel (typically SPCC or galvanized alloys) and progressive die stamping techniques, these components resist the bending and fatigue that often cause regulator failure. Whether you are sourcing components for mass production or restoring a vintage vehicle, stamped steel regulators offer the best balance of structural integrity, corrosion resistance (often zinc-plated), and cost-effectiveness. This guide explores the engineering behind these parts, how to identify quality stamping, and why they remain the industry standard for reliable window operation.

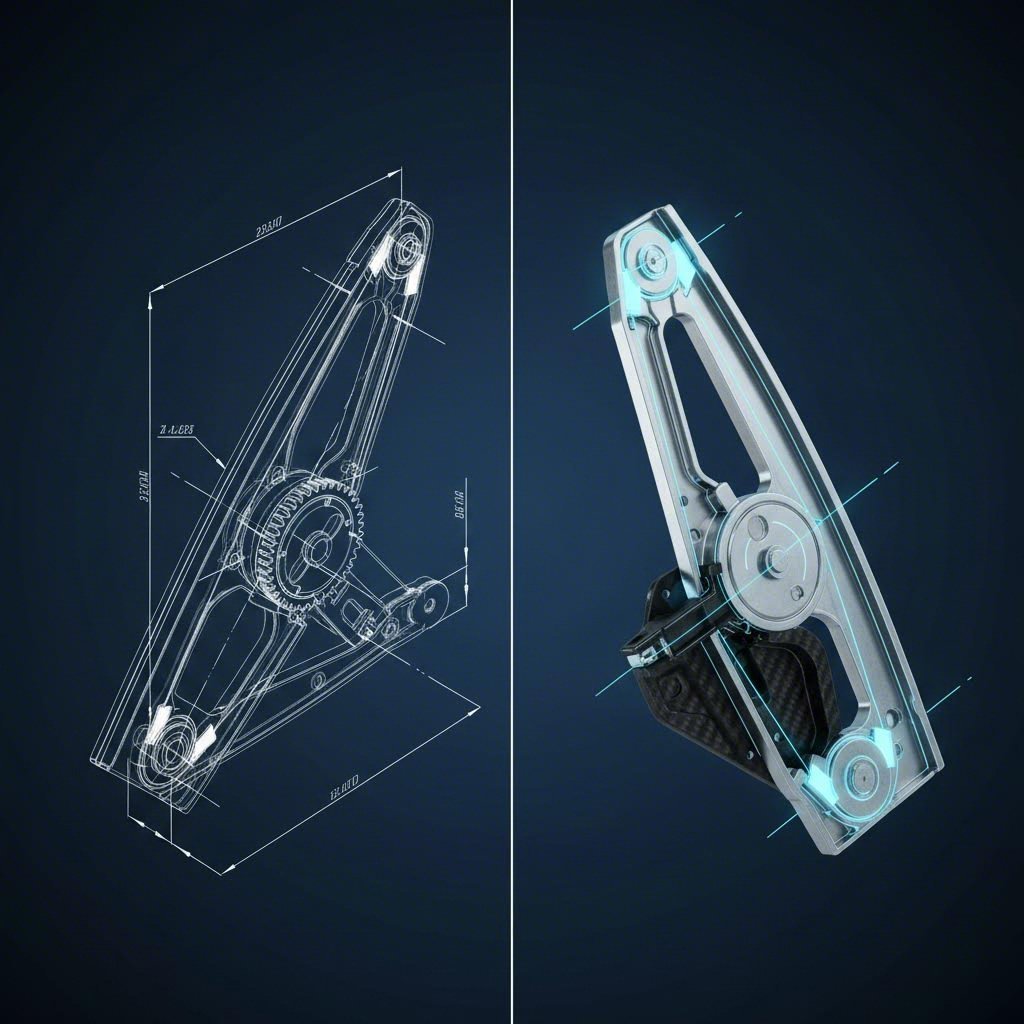

The Engineering Behind Stamped Window Regulators

The reliability of a window regulator—whether a classic scissor type or a modern cable assembly—begins with the manufacturing process. Unlike casting, which involves pouring molten metal into a mold, stamping uses extreme pressure to shape flat sheets of metal into complex three-dimensional forms. This process allows for tighter tolerances and higher material density, which are critical for parts that must endure thousands of up-and-down cycles.

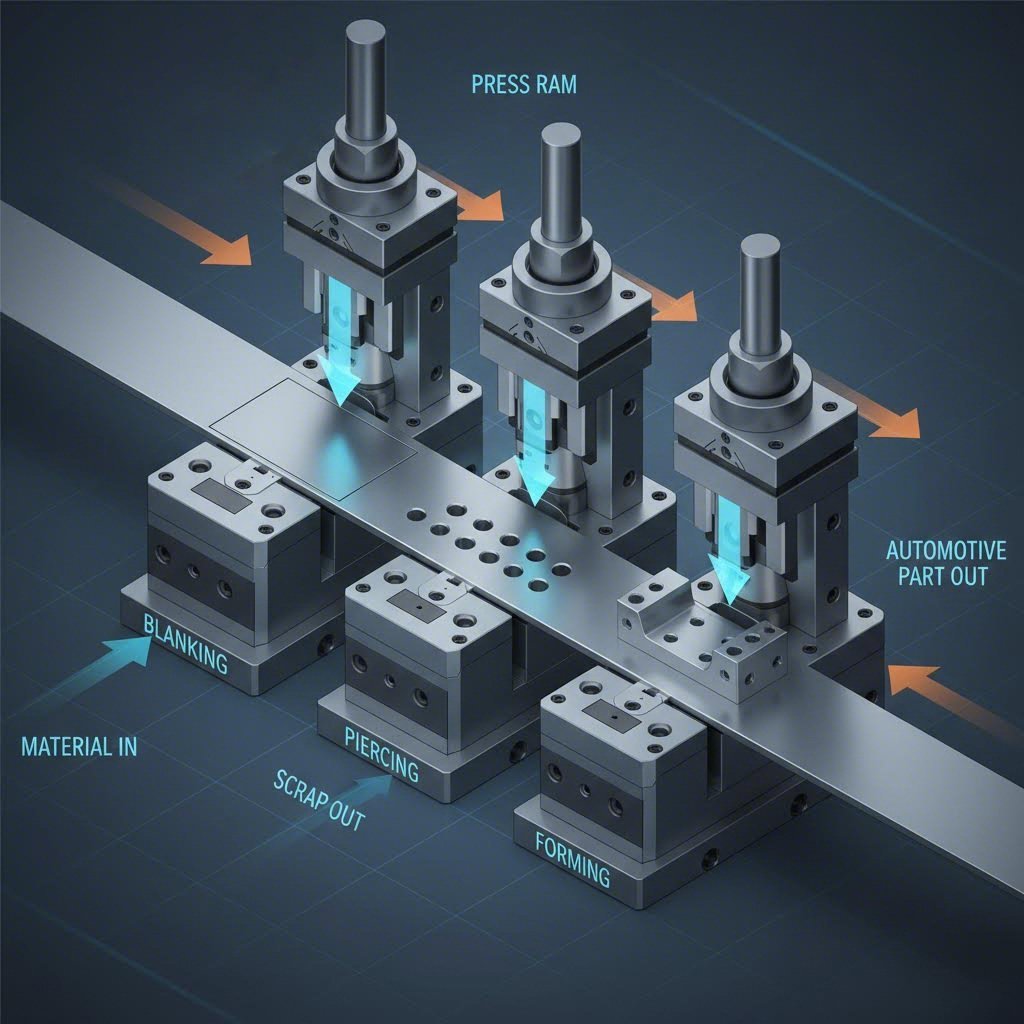

The production workflow typically follows a rigorous sequence: Blanking cuts the initial shape from a metal coil, Piercing creates precise mounting holes and gear pivots, and Forming bends the metal into rigid arms or tracks. For automotive applications, manufacturers often utilize progressive die stamping, where a metal strip moves through multiple stations with each press stroke. This ensures that every gear tooth and mounting point is identical to the millimeter, a crucial factor for smooth window operation.

High-volume manufacturing of these safety-critical components requires immense force. Advanced facilities often employ press capabilities up to 600 tons to stamp thick-gauge steel required for heavy glass support. For manufacturers seeking reliable partners, companies like Shaoyi Metal Technology offer IATF 16949-certified stamping solutions, bridging the gap from rapid prototyping to high-volume manufacturing with strict adherence to global OEM standards. This level of precision ensures that the regulator arms do not flex under load, preventing the window glass from binding or falling into the door panel.

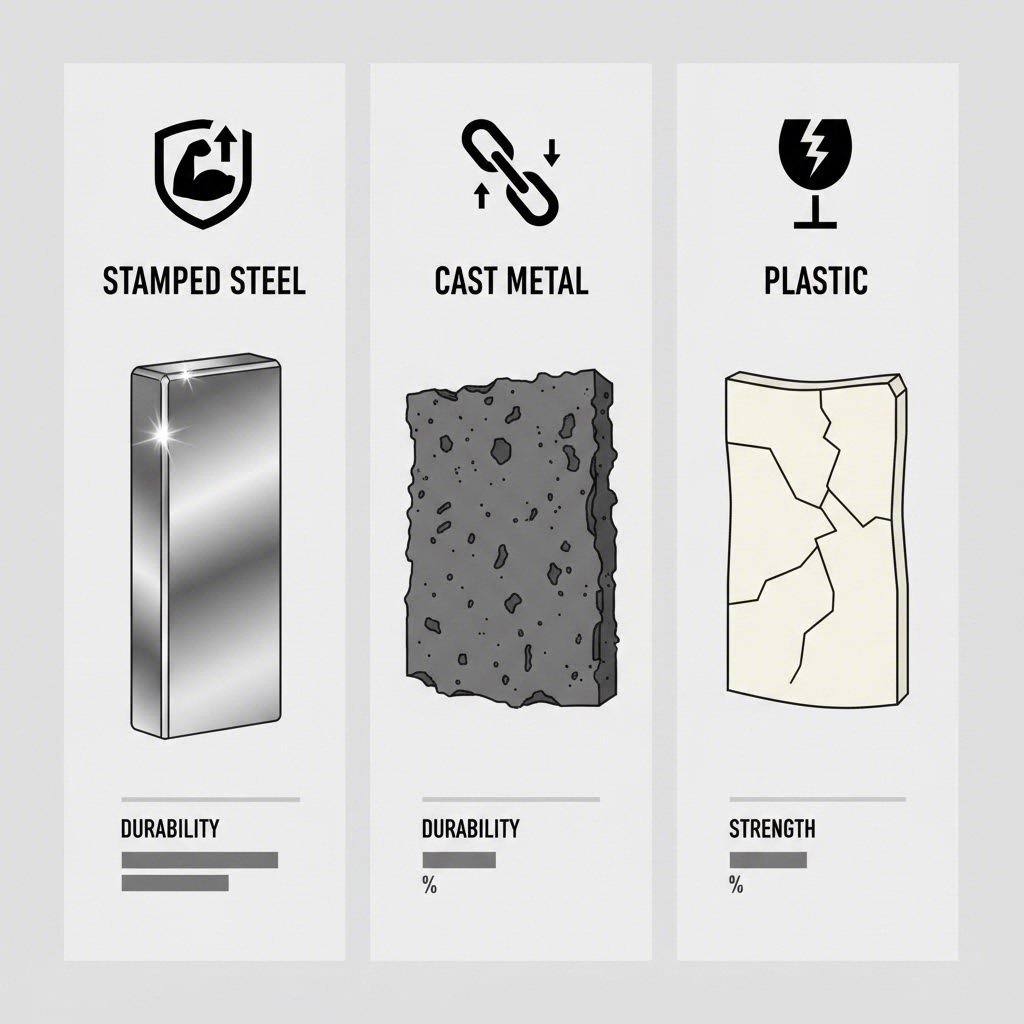

Material Selection: Stamped Steel vs. Alternatives

The choice of material is the single biggest predictor of a window regulator's lifespan. While modern economy cars frequently utilize molded plastic for clips and pulleys to save weight, stamped steel remains the superior choice for the structural arms and gear sectors. Steel provides the tensile strength necessary to lift heavy tempered glass, especially in larger trucks or vintage vehicles where glass weight is substantial.

Corrosion protection is equally important. Raw stamped steel is vulnerable to rust inside the moisture-prone environment of a car door. High-quality stamped regulators undergo secondary treatments immediately after fabrication. You will often see parts listed as Zinc Plated (offering a silver/gold finish) or E-Coated (black paint). These coatings bond to the metal surface to prevent oxidation.

| Material Type | Primary Use | Durability | Failure Mode |

|---|---|---|---|

| Stamped Carbon Steel | Scissor arms, Sector gears | High | Gradual rust (if untreated) |

| Cast Aluminum/Pot Metal | Housings, Pivot points | Medium | Brittle fracture/Cracking |

| Reinforced Plastic | Cable guides, Sliders | Low to Medium | Fatigue cracking/Snap |

When evaluating a replacement part, inspect the sector gear (the fan-shaped toothed area). A stamped steel gear with hardened teeth will outlast a cast alloy gear, which can strip or shear off under the torque of the window motor.

Types of Stamped Regulators & Mechanism Design

Stamping plays a different role depending on the regulator mechanism. Understanding these differences helps in diagnosing failures and selecting the right replacement.

Scissor-Type Mechanisms

Found commonly in vehicles from the 1940s through the 1990s, the scissor regulator relies almost entirely on stamped metal components. Two crossing arms, pivoting like scissors, lift the glass. The main sector arm is a heavy-gauge stamped piece with gear teeth on one edge. The durability of this design is legendary; however, the pivot points (often stamped rivets) can wear out over decades, causing the window to tilt.

Cable-Type Regulators

Modern vehicles predominantly use cable regulators to save weight and space. While the lifting mechanism uses cables and plastic pulleys, the guide rails (tracks) are almost always stamped steel. These tracks must be rigid enough to guide the glass without flexing. A cheap aftermarket part often uses thinner gauge steel for the track, leading to a noisy or wobbling window. Always look for stamped rails that match the thickness of the original part.

Sourcing & Identification: OE vs. Aftermarket Quality

For restoration experts and sourcing agents, identifying a high-quality stamped regulator involves looking for specific markers of precision. Original Equipment (OE) parts often feature identification numbers directly stamped into the metal arms. These "2-digit stamps" or production codes can help verify the production batch and compatibility, particularly for vintage restorations where model years might overlap.

OE Fitment is a term frequently abused in marketing, but in stamping, it has a literal meaning. It refers to the location of the mounting studs and the threaded nuts. On premium stamped regulators, the threaded mounting nuts are press-fitted (clinched) into the steel arm at the exact factory locations. Lower-quality reproductions may require you to fiddle with loose nuts or drill new holes because the stamping die was not calibrated to the original blueprint.

When examining a part, check the edges of the stamped metal. Fine blanking or quality stamping leaves a clean, smooth edge. Rough, jagged edges indicate worn tooling or poor manufacturing standards, which suggests the manufacturer may have also compromised on steel grade or assembly tolerance.

Conclusion: Ensuring Long-Term Reliability

The window regulator is a hidden workhorse of the vehicle, and its longevity depends entirely on the quality of its manufacturing. Stamped steel regulators offer a proven solution that combines the structural rigidity of metal with the economic efficiency of mass production. Whether you are replacing a failed unit in a daily driver or sourcing components for a new vehicle line, prioritizing high-strength stamped materials over cheaper plastic or cast alternatives is the only way to ensure smooth, silent, and reliable window operation for years to come.

Frequently Asked Questions

1. Who makes the best window regulators?

The "best" regulator depends on the application, but brands that prioritize stamped steel construction and OE-style manufacturing processes generally offer superior durability. For vintage and restoration markets, suppliers like United Pacific and Bob Drake are noted for high-quality stamped reproductions. For modern vehicles, manufacturers that adhere to ISO/IATF standards (like Dorman's premium lines or OE suppliers like AISIN) are recommended over unbranded generic parts.

2. How does a window regulator work?

A window regulator converts the rotary motion of a crank handle or electric motor into the vertical linear motion needed to move the glass. In stamped scissor systems, a gear rotates to open the metal arms, pushing the window up. In cable systems, the motor spools a cable that pulls a slider along a stamped metal track. Both systems rely on the rigidity of the metal framework to keep the glass stable.

3. What is the difference between a window regulator and a window motor?

The window regulator is the mechanical assembly (arms, gears, tracks, and cables) that physically moves and supports the glass. The window motor is the electrical component that powers the regulator. In many modern assemblies, they are sold as a single unit, but on older stamped regulators, the motor can often be replaced separately from the mechanical arms.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —