Stamped Steel Control Arms: A Brand Comparison for Your Car

TL;DR

When choosing a stamped steel aftermarket control arm, your decision hinges on the balance between cost and innovation. Premium brands like Moog and Mevotech are known for their “problem-solver” designs that often improve upon original equipment. For reliable, budget-friendly options that match OE specifications, brands such as Dorman and TrueDrive offer excellent value for daily drivers. The best choice ultimately depends on your vehicle's needs and your repair budget.

Understanding Stamped Steel vs. Other Control Arms

Before comparing brands, it’s essential to understand what a stamped steel control arm is and how it differs from other types. A stamped steel control arm is manufactured by pressing a sheet of steel into a specific shape. This method is cost-effective for mass production, making it a common choice for many passenger cars and light trucks directly from the factory. The process requires immense precision and specialized equipment to ensure each part meets strict tolerances for safety and performance.

The manufacturing of these components is a highly specialized field. For instance, companies in the automotive supply chain, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., provide comprehensive metal stamping solutions for the auto industry, handling everything from prototyping to mass production to meet IATF 16949 certification standards. This ensures that the parts forming the backbone of your vehicle's suspension are made with precision and reliability.

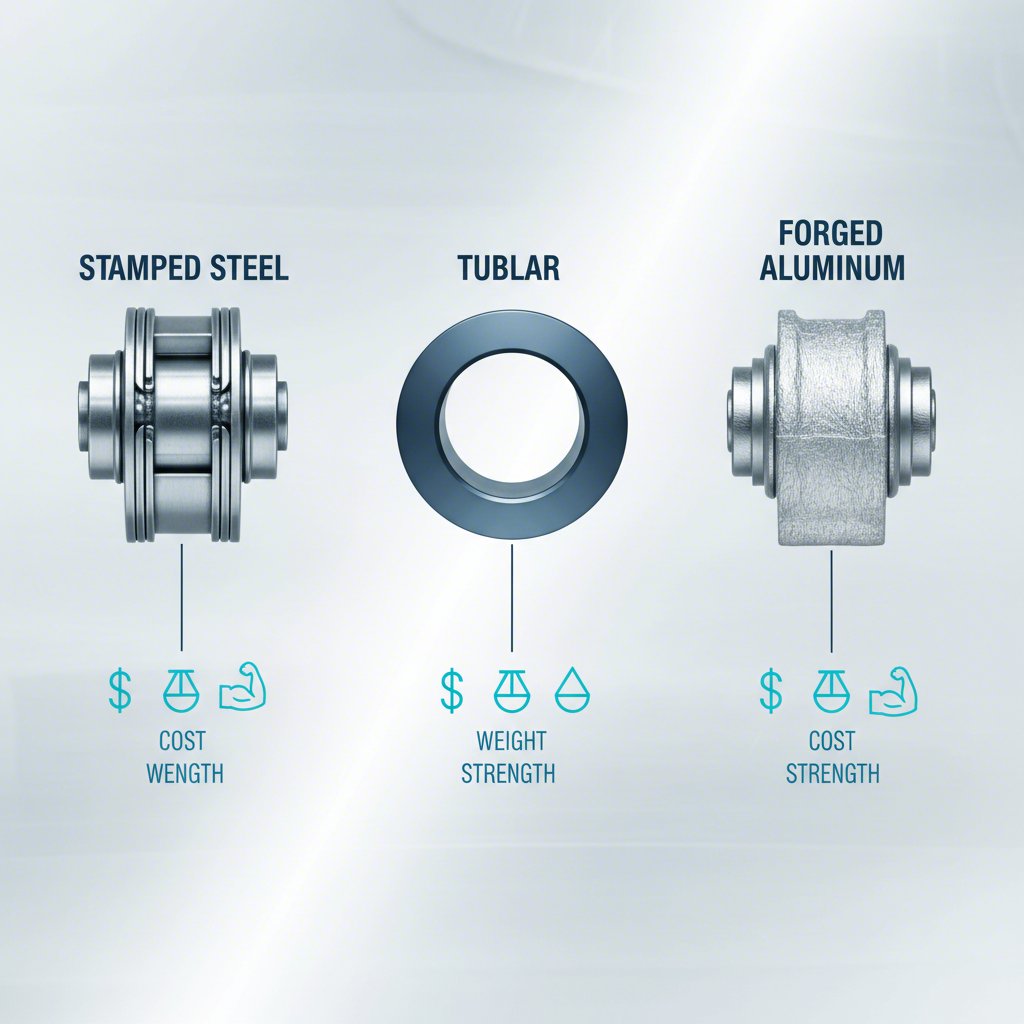

Stamped steel is not the only material used for control arms. The main alternatives are tubular steel and forged or cast aluminum/iron. Each type has distinct characteristics that make it suitable for different applications, from daily commuting to high-performance off-roading. Understanding these differences helps you decide whether sticking with a stamped steel replacement is the right call for your vehicle.

| Attribute | Stamped Steel | Tubular Steel | Forged/Cast Aluminum |

|---|---|---|---|

| Cost | Lowest | Moderate | Highest |

| Durability | Good for standard use but susceptible to rust without proper coating. | Very high strength-to-weight ratio; often used in performance/off-road applications. | Excellent strength, lighter weight, and naturally corrosion-resistant. |

| Weight | Moderate | Lighter than stamped | Lightest |

| Typical Use Case | OEM on most passenger cars and daily drivers. | Performance vehicles, lifted trucks, and off-road builds. | Luxury and performance vehicles where reduced unsprung weight is critical. |

For most drivers, a high-quality stamped steel aftermarket control arm is a perfectly suitable replacement. It restores the vehicle's original handling and performance characteristics without the high cost of performance-oriented upgrades. However, if your original part failed due to rust, look for an aftermarket brand that offers enhanced corrosion protection.

Top Aftermarket Stamped Steel Control Arm Brands: A Head-to-Head Comparison

Navigating the aftermarket landscape can be challenging, but several brands have established strong reputations for quality, innovation, and value. The leading names you'll encounter include Moog, Mevotech, Dorman, TrueDrive, Delphi, and TRW. Each brand targets a slightly different segment of the market, from DIYers on a budget to technicians seeking premium, enhanced components.

Moog is widely recognized for its "Problem Solver" line, which often re-engineers parts to be more durable than the original. Mevotech is another innovator, focusing on durability with features like sintered metal bearings and designs that make installation easier for technicians. On the other hand, Dorman is known for its vast catalog of OE-equivalent parts that provide a reliable, cost-effective repair. TrueDrive, a brand highlighted by retailers like CarParts.com, focuses on delivering a balance of durability and affordability. Finally, brands like Delphi and TRW bring decades of OE manufacturing experience to the aftermarket, ensuring high standards of quality and performance.

To help you make an informed decision, here is a breakdown of what each brand offers:

| Brand | Key Features & Specialty | Warranty | Best For |

|---|---|---|---|

| Moog | Problem Solver® designs with gusher bearings to reduce friction; heat-treated for strength. | Typically 3-Year Limited | Upgrading over OEM for enhanced durability. |

| Mevotech | Focus on durability (X-Factor) and easier installation; often includes pre-installed hardware. | Limited Lifetime | Daily drivers and technicians seeking long-lasting parts. |

| Dorman | Broad vehicle coverage; direct OE replacement with additional coatings for rust resistance. | Limited Lifetime | Budget-conscious repairs needing a reliable OE-fit part. |

| TrueDrive | Affordable yet durable; proprietary rust-inhibitive coating; manufactured to ISO/TS standards. | Typically 1-Year, Unlimited-Mileage | DIYers looking for the best balance of price and quality. |

| Delphi | OE heritage; undergoes extensive testing like 100% crack detection and ultrasonic flaw detection. | Varies by product line | Drivers who prioritize OE-level quality and testing. |

| TRW | Part of ZF Aftermarket with 100+ years of OE experience; focuses on safety and quality. | Varies by product line |

When comparing brands like Delphi and Dorman, the choice often comes down to priorities. As noted by industry experts, Delphi is positioned as a premium brand focused on matching OE material specifications and performance through rigorous testing. Dorman, while also committed to quality, excels in providing wide availability and value, making it a go-to for many common repairs.

OEM vs. Aftermarket Control Arms: Cost and Quality Analysis

One of the biggest decisions when replacing a control arm is whether to choose an Original Equipment Manufacturer (OEM) part or an aftermarket one. OEM parts are identical to the ones your vehicle was built with, offering a guaranteed fit and original performance. However, this assurance comes at a significant price premium. As seen in online forums, an OEM control arm from a dealer can cost hundreds of dollars more than a high-quality aftermarket alternative. For example, a Honda OEM part might be $325, while a comparable Moog or Mevotech part is around $80.

Aftermarket parts, on the other hand, are produced by various companies to fit and function like the original. The primary advantage is cost savings, but the benefits don't stop there. Many aftermarket brands, as discussed, aim to improve upon known weaknesses in the OEM design, offering greater durability or better features like greaseable joints for easier maintenance. According to a guide from PartsAvatar, aftermarket components can match or even exceed the performance of OE parts at a much more reasonable price.

Here’s a simple breakdown to help you decide:

OEM Control Arms

- Pros: Exact fit and finish guaranteed. Maintains vehicle originality. The safest choice for vehicles still under warranty.

- Cons: Significantly more expensive. No improvements over the original design, which may have known flaws.

Aftermarket Control Arms

- Pros: Much more affordable. Often engineered to be stronger or more durable than the original. Wide variety of options from value-focused to premium.

- Cons: Quality can vary between brands, so choosing a reputable manufacturer is crucial. Fitment issues are possible with low-quality brands.

For most out-of-warranty vehicles, a reputable aftermarket control arm offers the best combination of quality, performance, and value. The key is to select a trusted brand that invests in engineering and testing to ensure their parts meet or exceed industry standards.

Frequently Asked Questions

1. Who makes the best aftermarket upper control arms?

The "best" brand depends on your needs. For those seeking maximum durability and innovative designs that often improve upon factory parts, Moog and Mevotech are top contenders. For drivers focused on getting a reliable, OE-quality replacement at a great price, brands like Dorman and TrueDrive are excellent choices.

2. Is Delphi or Dorman better?

Both are reputable brands, but they target different market segments. Delphi is often considered a premium aftermarket brand with a strong OE heritage, focusing on rigorous testing to match original part specifications. Dorman is known for its vast catalog and providing affordable, reliable OE-equivalent parts, making them a practical choice for a wide range of common repairs.

3. Which brand of lower arm is best?

The same brands that excel in making upper control arms are generally the best for lower control arms as well. The choice follows the same logic: select Moog or Mevotech for premium durability and potential upgrades, or choose Dorman, TrueDrive, or another quality brand for a dependable, value-oriented replacement that meets OE standards.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —