Stamped Steel Control Arm Thickness: An Engineer's Guide

TL;DR

There is no single standard for stamped steel control arm material thickness. It typically ranges from 0.024 inches (0.6mm) to 0.250 inches (6.35mm), with most automotive applications falling under 5mm. The precise thickness is a critical engineering decision that balances the vehicle's weight, intended use, required structural strength, and manufacturing cost.

Understanding Stamped Steel Control Arm Thickness: A Technical Breakdown

A stamped steel control arm is a crucial suspension component that connects the vehicle's frame to the wheel hub, allowing for controlled movement. It's manufactured by pressing a sheet of steel into a specific shape using a die. The material's thickness is a primary factor in the part's strength, durability, and weight. A thicker arm is generally stronger but also heavier and more expensive, impacting fuel efficiency and production costs. Engineers must carefully calculate the minimum thickness required to handle the dynamic loads a vehicle will experience, from cornering forces to impacts from bumps and potholes.

The choice of thickness is a trade-off. For a light passenger car, a thinner, lighter arm may be sufficient and desirable for better fuel economy. However, a heavy-duty truck like a Ram 1500, which is expected to carry heavy loads and potentially go off-road, requires a much thicker and more robust control arm to prevent failure. According to a study in the International Journal of Science and Research, sheet metal operations for components like these are generally performed on steel sheets less than 5mm thick. This aligns with industry guides, which classify sheet metal as any metal under 0.25 inches (about 6.35mm).

The manufacturing process itself is a key consideration. Stamping is a fast and cost-effective method for mass production, making it ideal for original equipment manufacturers (OEMs). For automotive manufacturers seeking high-quality, precision-stamped components, specialized partners are essential. For example, companies such as Shaoyi (Ningbo) Metal Technology Co., Ltd. provide comprehensive solutions from prototyping to mass production, adhering to strict automotive standards like IATF 16949 to ensure reliability and cost-effectiveness in complex parts like control arms.

To provide a clearer picture, here is a summary of typical steel sheet thickness ranges used in manufacturing:

| Source/Standard | Typical Thickness Range | Notes |

|---|---|---|

| General Sheet Metal (Protolabs) | 0.024" - 0.250" (0.6mm - 6.35mm) | This represents the full range for sheet metal fabrication. |

| Automotive Stamping (IJSR) | < 5mm (~0.197") | Typical maximum for automotive sheet metal components. |

| Heavy-Duty Applications (Tripar Inc.) | 10-14 Gauge (0.0747" - 0.1345") | Used for structural parts and heavy-duty brackets. |

| General Industrial (Tripar Inc.) | 16-20 Gauge (0.0598" - 0.0359") | Common for general-purpose components and enclosures. |

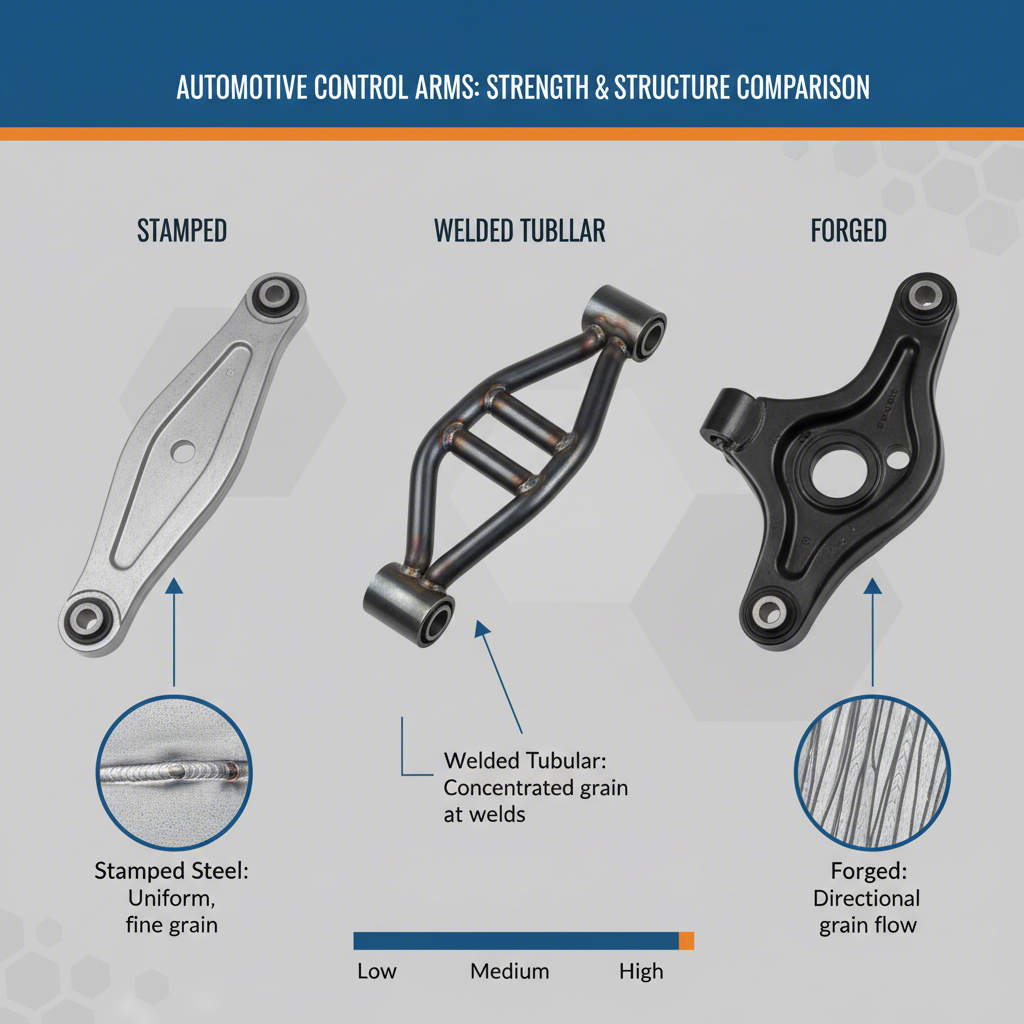

Comparison: Stamped Steel vs. Tubular vs. Forged Control Arms

When replacing or upgrading suspension components, you'll encounter three main types of control arms: stamped, tubular, and forged. Each has a distinct manufacturing process that results in different performance characteristics, costs, and ideal use cases. Understanding these differences is key to making an informed decision for your vehicle.

Stamped steel control arms are the most common type found in production vehicles. They are mass-produced by pressing sheets of steel into a desired shape. This method is highly cost-effective but can sometimes be perceived as less robust than other options, especially in performance applications. Tubular control arms are fabricated by welding sections of round or square steel tubing. This allows for greater design flexibility, a high strength-to-weight ratio, and improved suspension geometry, making them a popular aftermarket upgrade. Forged control arms are created by heating a solid billet of metal and pressing it into a die under extreme pressure. This process aligns the metal's internal grain structure, resulting in exceptional strength and fatigue resistance, making them suitable for heavy-duty or high-performance vehicles.

The choice between them often depends on your goals. For a daily driver, a quality stamped steel replacement is usually sufficient. For classic car restoration or performance street driving, tubular arms offer significant benefits in handling and durability. For extreme off-road or racing applications, the superior strength of a forged arm is often necessary.

Here’s a detailed comparison of the three types:

| Feature | Stamped Steel | Tubular Steel | Forged Steel/Aluminum |

|---|---|---|---|

| Manufacturing Process | Pressed from a single sheet of steel. | Welded from hollow steel tubes. | Shaped from a solid metal billet under heat and pressure. |

| Pros | Lowest manufacturing cost; lightweight; suitable for mass production. | High strength-to-weight ratio; customizable geometry; improved rigidity. | Superior strength and fatigue resistance; dense grain structure. |

| Cons | Can be less rigid; may flex under high loads; perceived as lower quality. | Higher cost than stamped; welds can be failure points if not done properly. | Highest manufacturing cost; often heavier than other types. |

| Typical Thickness/Spec | 0.6mm - 5mm sheet | ~.120" (3mm) wall D.O.M. tubing | Solid construction |

| Best Use Case | OEM replacement for daily drivers. | Performance street cars, classic car upgrades, light track use. | Heavy-duty trucks, off-road vehicles, professional racing. |

For example, a high-performance aftermarket supplier like Classic Performance Products specifies that their tubular arms use .120” wall D.O.M. (Drawn Over Mandrel) tubing, a high-quality material known for its uniform wall thickness and strength, highlighting the focus on durability for the performance market.

Material Specifications: Understanding Steel Gauges, Grades, and Tolerances

Beyond just thickness, the quality of a control arm is determined by the specific grade of steel used and the manufacturing tolerances. Not all steel is created equal, and understanding these details can help you identify a higher-quality component. Thickness is often measured in gauges, a system where a higher number corresponds to a thinner sheet of metal. This can be counterintuitive, so it's often clearer to refer to thickness in inches or millimeters.

It's important to know that a specific gauge number represents a different thickness depending on the type of metal. For instance, 14-gauge steel is not the same thickness as 14-gauge aluminum. Reputable manufacturers will provide precise measurements in their specifications. Furthermore, materials have inherent thickness tolerances. According to a guide from Tripar Inc., a sheet of 14-gauge steel with a nominal thickness of 0.0747 inches can have a production variance of ±0.007 inches. This means the actual material could be slightly thicker or thinner, which can be critical in high-precision applications.

Automotive applications use specific steel alloys designed for a combination of strength, formability, and durability. The IJSR paper mentions materials like Micro Steel Alloy (C45) for forged arms and Ferritic-Bainitic (FB) steels for stamped components, which offer high strength and good formability. When evaluating aftermarket parts, look for manufacturers who specify the grade of steel used, such as 1018 Mild Steel or the stronger 4130 Chromoly for tubular arms. This level of detail is often an indicator of a superior product.

Here is a simplified chart converting common steel gauges to more direct measurements:

| Gauge | Inches (Nominal) | Millimeters (Approx.) |

|---|---|---|

| 10 | 0.1345" | 3.42 mm |

| 12 | 0.1046" | 2.66 mm |

| 14 | 0.0747" | 1.90 mm |

| 16 | 0.0598" | 1.52 mm |

| 18 | 0.0478" | 1.21 mm |

Frequently Asked Questions

1. What is the difference between stamped and forged control arms?

The primary difference lies in their manufacturing process and resulting strength. Stamped control arms are made by pressing a sheet of steel into shape, which is cost-effective for mass production but can be less rigid. Forged control arms are made from a solid piece of heated metal that is compressed into a die, aligning the metal's grain structure with the part's shape. This process creates a component with superior strength and resistance to fatigue, making it ideal for heavy-duty or high-performance applications.

2. Are stamped steel control arms magnetic?

Yes, stamped steel control arms are magnetic. Steel is a ferrous metal, which means it contains iron and is attracted to magnets. This provides a simple way to distinguish between a steel control arm and an aluminum one, as aluminum is non-magnetic. If a magnet sticks to the control arm, it is made of either stamped steel or cast iron.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —