Stamped Steel Control Arm Manufacturing: A Technical Guide

TL;DR

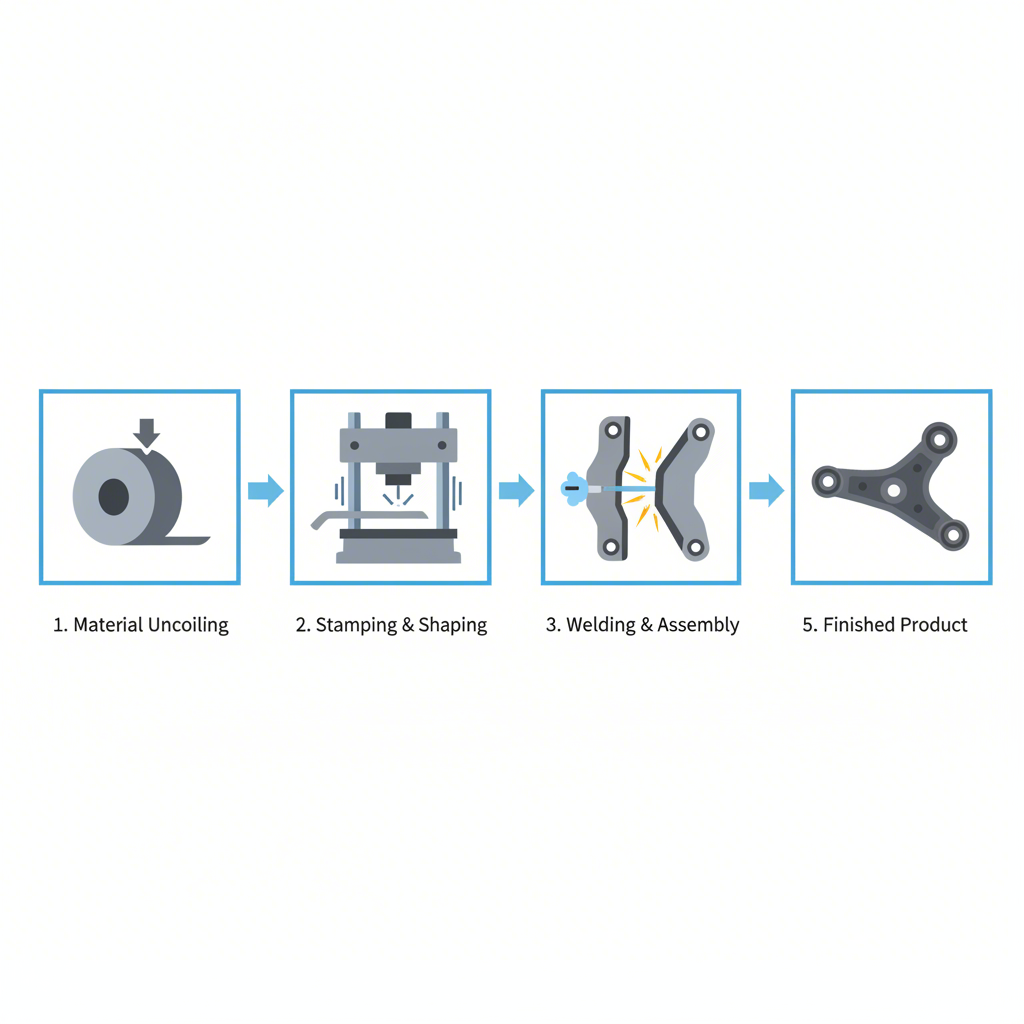

The manufacturing process for stamped steel control arms is a multi-stage industrial method centered on forming and fabrication. It begins with selecting high-tensile steel sheets, which are then cut and pressed into two symmetrical halves using powerful stamping machines. These halves are precisely welded together to create a single, hollow, and structurally rigid component. The final steps involve applying a protective coating for corrosion resistance and installing bushings for articulation within the vehicle's suspension system.

The Stamped Steel Manufacturing Process: A Step-by-Step Breakdown

The creation of a stamped steel control arm is a precise and highly engineered process designed for mass production, balancing strength, weight, and cost. This method has become an industry standard for original equipment manufacturers (OEMs) due to its efficiency and the reliable performance of the final product. Each stage, from raw material handling to the final inspection, is critical for ensuring the component can withstand the demanding conditions of a vehicle's suspension. The process transforms a flat sheet of steel into a complex, three-dimensional part responsible for vehicle stability and handling.

The entire manufacturing sequence can be broken down into several key phases:

- Material Selection and Preparation: The process starts with large coils of high-tensile steel. This material is chosen for its excellent strength-to-weight ratio and durability. According to automotive parts manufacturer Carico, specifications such as black iron plate or high-tension plate are selected based on the specific design requirements, including material hardness and thickness. The steel is uncoiled, flattened, and cut into blanks of the appropriate size for the stamping press.

- Sheet Metal Stamping: The prepared steel blanks are fed into large mechanical or hydraulic stamping presses. These machines use custom dies to cut, bend, and form the flat sheet into the intricate shape of one half of the control arm. As described in a patent for the process, the separate details of the arm are stamped from sheets and pressed into their desired shape. This is repeated to create a matching second half, resulting in two pieces that will form the hollow upper and lower sections of the arm.

- Assembly and Robotic Welding: The two stamped halves are brought together in precise alignment using specialized jigs and fixtures. Robotic welding arms then execute a series of welds along the seams to join the two pieces into a single, hollow structure. This automated process ensures consistency and strength in every weld. For automotive suppliers, achieving perfect alignment for single-pass assembly is crucial for Tier 1 quality standards. For manufacturers seeking partners with proven expertise in this area, specialized firms like Shaoyi (Ningbo) Metal Technology Co., Ltd. offer advanced automated facilities and IATF 16949 certified processes, ensuring high precision from prototyping to mass production.

- Finishing and Coating: Once welded, the control arm is typically treated to enhance its durability and resistance to corrosion. This often involves an e-coating (electrophoretic coating) or powder coating process, which applies a uniform, protective layer across the entire surface. This finishing step is essential for protecting the steel from moisture, salt, and road debris that can cause rust and degradation over the component's lifespan.

- Bushing and Ball Joint Installation: In the final manufacturing stage, rubber or polyurethane bushings are pressed into designated openings in the arm. These bushings are the pivot points that allow the control arm to move up and down with the suspension. Depending on the design, a ball joint may also be installed, which allows for rotational movement and connects the control arm to the steering knuckle.

Material Science: Why High-Tensile Steel Is the Industry Standard

The choice of material is fundamental to the performance and safety of any suspension component. For stamped control arms, high-tensile steel has long been the material of choice for OEMs. This is not by accident; it represents a carefully calculated balance of mechanical properties, manufacturability, and economic viability. High-tensile steel provides the necessary strength to handle immense forces from acceleration, braking, and cornering while being malleable enough to be formed through the stamping process.

The advantages of using high-tensile steel are significant. Its primary benefit is providing high strength with less material, which allows for lighter components compared to traditional mild steel without compromising on durability. This weight reduction contributes to better fuel efficiency and improved vehicle handling by reducing unsprung mass. Furthermore, the manufacturing processes themselves alter the material's properties. Research shows that processes like stamping and welding introduce micro-structural modifications that can alter the fatigue resistance of the steel, a critical factor for a part that endures millions of stress cycles. The fibrous microstructure of elongated ferrite and pearlite grains, typical of high-strength low-alloy (HSLA) steels, is key to its robust performance.

While stamped steel is the OEM standard, other materials are used in different contexts, particularly in the aftermarket and performance sectors. Each material offers a unique set of trade-offs.

| Material | Weight | Strength | Cost | Common Use |

|---|---|---|---|---|

| Stamped Steel | Moderate | High | Low | OEM, Standard Replacement |

| Forged Aluminum | Low | High | High | Performance, Luxury Vehicles |

| Tubular Steel | Low-Moderate | High (Customizable) | Moderate-High | Aftermarket, Racing, Off-Road |

The Machinery and Tooling Behind the Process

The production of stamped steel control arms is an operation of industrial scale, relying on massive, specialized machinery to achieve the required precision and volume. The high capital investment in this equipment is a primary reason why this manufacturing method is best suited for high-volume OEM production lines. The quality and safety of the final component are directly linked to the precision and capability of the tooling and machines used throughout the process.

Several key pieces of equipment are essential to the manufacturing workflow:

- Stamping Presses: These are the heart of the forming process. Ranging from hundreds to thousands of tons in capacity, these presses use immense force to shape the steel blanks. Progressive stamping lines can perform multiple forming and cutting operations in a single pass, dramatically increasing efficiency.

- Robotic Welding Cells: To ensure each control arm is identical and meets strict strength requirements, automated welding cells are used. These cells contain robotic arms programmed to perform precise welds at specific speeds and temperatures. They are often integrated with fixtures that hold the stamped halves in perfect alignment, eliminating human error and ensuring consistent quality.

- Laser Cutting Machines: While dies handle the primary shaping, automated 2D laser cutters are often used for creating initial blanks or for more complex, low-volume production runs. As noted by Carico Auto Parts, this technology offers flexibility, reduces the need for expensive custom molds for every variation, and minimizes material waste through optimized computer calculations.

- Industrial Coating and Curing Systems: For corrosion protection, control arms pass through automated finishing lines. These systems may include chemical cleaning baths, electrophoretic deposition (e-coating) tanks where an electrical charge adheres paint to the metal, and large ovens to cure the protective coating.

The integration of these systems into a cohesive production line is what allows for the efficient and reliable manufacturing of millions of control arms annually. The precision of the machinery and the quality of the tooling are non-negotiable, as they directly impact the safety and performance of the vehicle's suspension.

Frequently Asked Questions

1. What is the best metal for control arms?

For most standard passenger vehicles, high-tensile stamped steel is considered the best overall metal due to its excellent balance of strength, durability, and low cost. It is the standard for most original equipment manufacturers (OEMs). However, for performance or luxury applications where weight reduction is a top priority and cost is less of a concern, forged aluminum is often superior. For custom, racing, or off-road applications, tubular steel offers high strength and design flexibility.

2. What is the control arm process?

The term "control arm process" can refer to either manufacturing or replacement. The manufacturing process, as detailed in this article, involves stamping steel sheets into two halves, welding them together to form a hollow arm, applying a protective coating, and installing bushings. The replacement process, on the other hand, is a mechanical repair that involves safely lifting the vehicle, removing the wheel, disconnecting the old control arm from the chassis and wheel hub, installing the new component, and performing a wheel alignment.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —