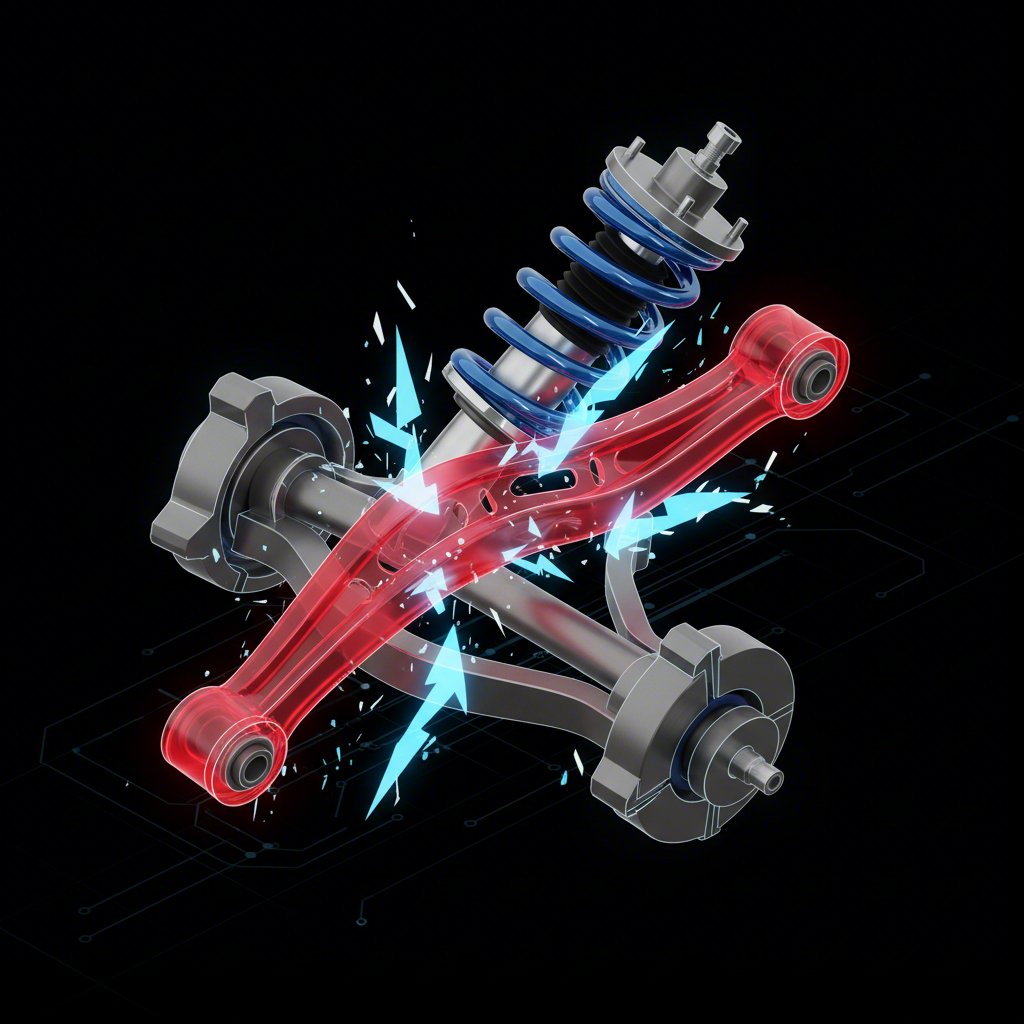

Eliminate Stamped Steel Control Arm Flex for Better Handling

TL;DR

Factory-issued stamped steel control arms are notorious for flexing under heavy loads from acceleration, braking, or cornering. This deflection absorbs engine power instead of transferring it to the wheels, leading to poor performance, wheel hop, and inconsistent handling. Upgrading to more rigid tubular or forged control arms with firmer bushings is the most effective solution to eliminate this weakness and significantly improve your vehicle's responsiveness and stability.

The Problem with Factory Stamped Steel Control Arms

On most production vehicles, the control arms that connect your wheel assembly to the chassis are made from stamped steel. This manufacturing method is cost-effective for automakers, involving cutting a shape from a sheet of metal and pressing it into a rigid form. However, this design has a significant drawback for performance applications: it is prone to flex. When you accelerate hard, brake aggressively, or take a sharp corner, the forces exerted on the suspension can cause these arms to bend or deflect. This is the core issue known as stamped steel control arm flex.

The problem isn't just with the metal itself. Original equipment manufacturers (OEMs) typically pair these arms with very soft rubber bushings. While excellent for absorbing road vibrations and providing a comfortable ride, these rubber bushings compress easily under load. The combination of a flexible steel arm and compressible rubber bushings creates a suspension system that deflects significantly, absorbing energy that should be used to move the car forward or maintain stability. As explained by experts at BMR Suspension, this deflection means power is wasted instead of being transferred to the tires. While some minor flex is intended in certain factory designs to prevent suspension binding, excessive flex becomes a major performance bottleneck.

For manufacturers focused on precision, the quality of stamped components is paramount. Companies specializing in automotive metal stamping, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., leverage advanced, IATF 16949-certified processes to produce complex parts that meet strict OEM standards for reliability and consistency. Even with high-quality manufacturing, the inherent design of a stamped arm is a compromise between cost and ultimate performance.

The negative consequences of this flex are numerous and tangible for any driver pushing their vehicle's limits. These issues compound, turning a predictable vehicle into one that can feel vague and unresponsive when it matters most.

- Power Loss: Energy from the engine is wasted on flexing the control arms and compressing bushings rather than spinning the tires.

- Wheel Hop: During hard launches, the rapid loading and unloading of the flexing arms can cause the tires to hop violently, killing traction.

- Inconsistent Handling: As the arms flex during cornering, suspension geometry like camber and toe can change, leading to a vague or unpredictable steering feel.

- Reduced Braking Stability: Under hard braking, flex can cause the suspension alignment to shift, potentially leading to instability.

Impact of Control Arm Flex on Vehicle Performance and Handling

The impact of control arm flex goes beyond a simple number on a dyno sheet; it fundamentally changes the way a car feels and reacts. Think of it like trying to sprint on a soft mattress versus a solid track. The mattress absorbs the energy from your legs, slowing you down, while the track transfers that energy directly into forward motion. Stamped steel control arms and soft bushings turn your car's suspension into that soft mattress, creating a spongy, inefficient link between the chassis and the road.

During acceleration, especially in powerful rear-wheel-drive cars, this flex is a primary cause of wheel hop. The control arms wind up like springs, and when they release that stored energy, the tires break and regain traction in a violent shudder. This not only prevents a quick launch but also puts immense stress on other drivetrain components. In cornering situations, the problem manifests as inconsistency. As you enter a turn, lateral forces cause the arms to deflect, altering the suspension geometry mid-corner. This can make the car feel unpredictable, forcing the driver to constantly make small corrections and undermining confidence.

Upgrading to rigid tubular arms provides a night-and-day difference. As highlighted in a guide by Speedway Motors, replacing flexible stamped steel arms with strong, non-flexing tubes adds crucial rigidity to the suspension. This ensures the suspension geometry remains stable and predictable under all loads, translating to a direct and responsive feel for the driver. The car becomes more planted, power is transferred efficiently, and handling becomes sharp and repeatable.

Are you experiencing issues related to control arm flex? Check for these common symptoms:

- Your car's rear end shudders or hops during hard acceleration.

- Steering feels vague or unresponsive during aggressive cornering.

- The vehicle feels unstable or “wanders” under heavy braking.

- You notice uneven or premature tire wear, which can indicate fluctuating suspension geometry.

Upgrade Guide: Comparing Stamped Steel, Tubular, and Forged Control Arms

When you decide to eliminate flex, you'll find several types of aftermarket control arms available. Understanding the differences in their construction and materials is key to choosing the right upgrade for your needs. The main alternatives to factory stamped steel are tubular steel and forged aluminum or steel arms, each with distinct advantages and disadvantages.

Stamped Steel: This is the OEM standard. Made by stamping and welding sheets of steel, they are cheap to produce but are the most prone to flex under load. They are perfectly adequate for daily driving and normal conditions but are the first component to show weakness in performance applications.

Tubular Steel: The most popular performance upgrade. These arms are constructed from welded steel tubes, often using a high-strength material like DOM (Drawn Over Mandrel) tubing. This design is inherently more rigid and resistant to bending and twisting forces than a stamped, open-channel design. They offer a massive improvement in strength and consistency with a moderate increase in cost, making them the best value for most street performance and drag racing applications.

Forged Aluminum/Steel: The premium option for high-end applications. Forging involves shaping metal under extreme pressure, which aligns the material's grain structure and creates an incredibly strong, dense part. Forged control arms offer the best strength-to-weight ratio and are highly resistant to fatigue, making them ideal for serious road racing or autocross where every ounce matters. However, they are also the most expensive option.

Here is a direct comparison to help guide your decision:

| Control Arm Type | Manufacturing Process | Key Advantage | Key Disadvantage | Best For |

|---|---|---|---|---|

| Stamped Steel | Pressed and welded sheet metal | Low manufacturing cost | High flex under load | Standard OEM daily driving |

| Tubular Steel (DOM) | Welded steel tubing | Excellent rigidity and strength | Weight is often lighter than stock, but can vary by design | Street performance, drag racing |

| Forged (Steel/Alum.) | Metal shaped under pressure | Superior strength-to-weight ratio | Highest cost | Professional racing, Pro-Touring |

Key Considerations for Your Control Arm Upgrade

Choosing the right type of control arm is only the first step. A successful upgrade requires paying attention to the supporting components that work with the arms, including bushings, adjustability, and hardware. Making the right choices here will ensure you get the full performance benefit from your new arms without unwanted side effects.

The single most important component after the arm itself is the bushing. Aftermarket control arms typically offer polyurethane bushings as an alternative to the soft OEM rubber. Polyurethane is a firmer material that resists deflection far better than rubber, ensuring that the control arm's rigidity is not compromised by spongy connection points. This transmits more feedback to the driver and ensures suspension geometry remains stable. However, because it's less compliant, it can transmit more noise, vibration, and harshness (NVH) into the cabin.

Here’s a breakdown of bushing materials:

- Rubber: Best for comfort and quietness. Poor for performance due to high deflection.

- Polyurethane: A great all-around performance upgrade. Offers a firm, responsive feel with a manageable increase in NVH. Many performance arms, like those from BMR, use upgraded bushings like polyurethane or Delrin to ensure reliable operation.

- Rod Ends (Heim Joints): Offer zero deflection for maximum performance and feedback. They allow for the most articulation but also transmit the most NVH and are best suited for track-only vehicles.

Another key consideration is adjustability. Many aftermarket control arms are available in fixed (non-adjustable) or adjustable versions. Non-adjustable arms are direct replacements that correct the flex issue and are perfect for most street cars with stock ride height. Adjustable arms allow you to change their length, which is crucial for fine-tuning suspension geometry. This is especially important for vehicles that have been lowered or lifted, as it allows you to correct angles like pinion angle in the rear or caster in the front to optimize traction and handling.

Before you finalize your purchase, use this checklist:

- Choose Your Arm Type: For most enthusiasts, tubular steel offers the best balance of performance and cost.

- Select Your Bushing: Polyurethane is the standard choice for street performance and occasional track use.

- Decide on Adjustability: If your car is at stock height, fixed arms are fine. If it's lowered, lifted, or used for serious competition, choose adjustable.

- Verify Component Quality: Ensure the kit comes with high-quality ball joints (if applicable) and consider purchasing new mounting hardware, as old bolts can be fatigued.

Frequently Asked Questions

1. What is the difference between stamped and forged control arms?

Stamped control arms are made by pressing and welding sheets of metal, a process that is cost-effective but results in a component prone to flexing under stress. Forged control arms are created by compressing heated metal into a die, which aligns the internal grain of the metal with the part's shape. This process creates a much stronger, denser, and more fatigue-resistant component with a superior strength-to-weight ratio, making it ideal for high-performance applications.

2. Are stamped steel control arms magnetic?

Yes, stamped steel control arms are magnetic. Steel is a ferrous metal, which means it contains iron and is attracted to magnets. This can be a simple way to distinguish a steel control arm from an aluminum one, as aluminum is non-magnetic.

3. Are control arms load bearing?

Yes, many control arms are load-bearing components. In most suspension designs, particularly the lower control arm, they support the vehicle's weight via the spring and shock absorber. They are also critical for managing the forces of acceleration, braking, and cornering, making their strength and rigidity essential for both safety and performance.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —