Progressive Die vs Transfer Die: Which Stamping Is Right?

TL;DR

Progressive die vs transfer die stamping hinges on one key difference: how the metal is handled. Progressive die stamping forms parts from a continuous metal strip that moves through multiple stations within a single die, making it extremely fast and cost-effective for high-volume runs of smaller, intricate parts. In contrast, transfer die stamping first cuts a part (a 'blank') from the metal sheet and then uses a mechanical system to move this individual piece between separate stations or presses, offering greater versatility for larger, more complex components with features like deep draws or threads.

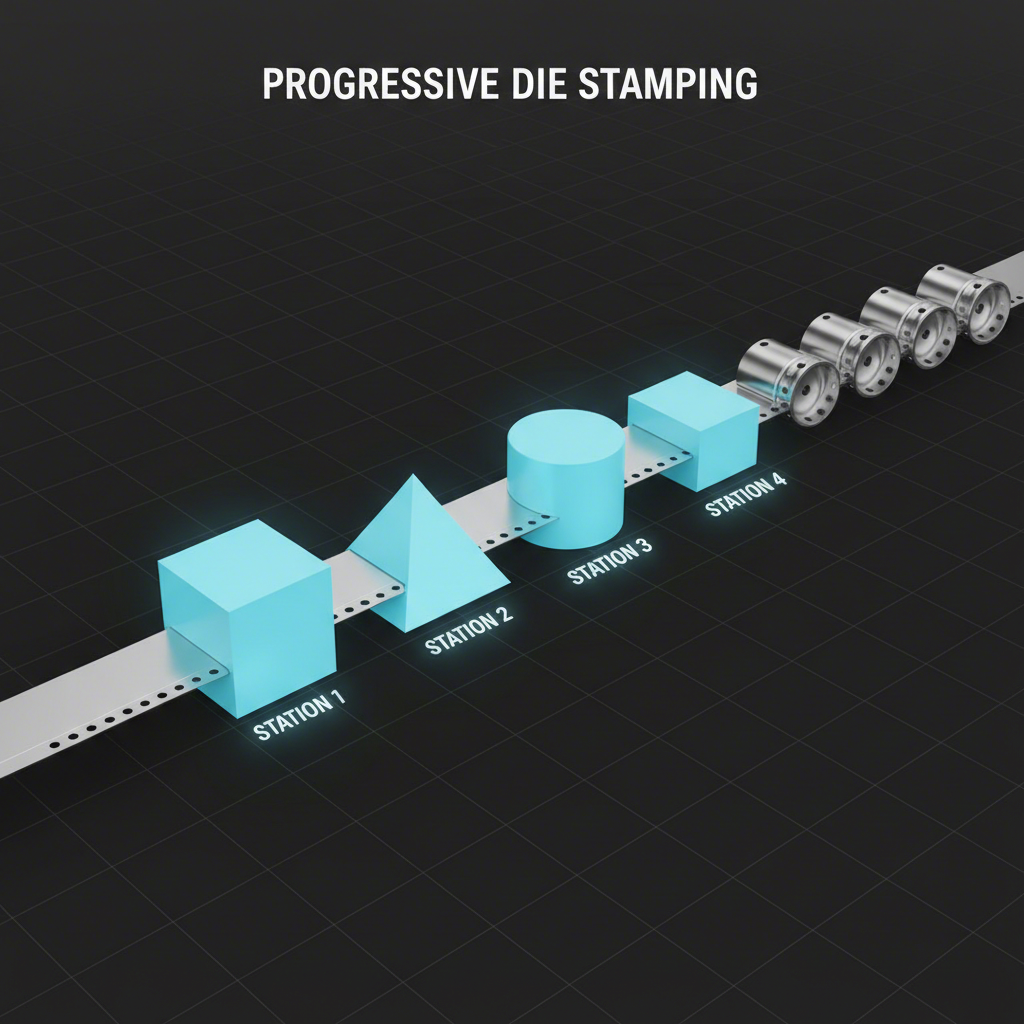

Understanding Progressive Die Stamping: Process and Principles

Progressive die stamping is a highly efficient metal forming process renowned for its speed and precision in high-volume production. The core of this method lies in its use of a continuous coil or strip of metal that is methodically fed through a single, multi-station die. Each station within the die performs a specific operation—such as punching, coining, or bending—in a sequential manner. The workpiece remains attached to this carrier strip as it advances, or 'progresses,' from one station to the next with each stroke of the press.

The integrity of the entire process depends on the precise alignment of the metal strip. To achieve this, conical pilots are often used. These pilots engage with pre-pierced holes in the strip to ensure it is perfectly positioned at each station, maintaining tight tolerances throughout the production run. This meticulous control is why progressive die stamping is ideal for producing complex parts that require a high degree of repeatability, such as components for the automotive and electronics industries. Only at the final station is the finished part separated from the carrier strip, which minimizes material waste.

The primary advantages of progressive die stamping are its remarkable speed and low per-part cost, especially for runs involving hundreds of thousands or millions of units. The automated nature of the process reduces labor requirements and allows for rapid production cycles. However, this method has its limitations. The initial tooling cost is substantial, as the complex, all-in-one die requires significant engineering. Furthermore, because the part is always attached to the strip, certain operations like deep drawing or creating features on multiple sides can be challenging or require secondary processes.

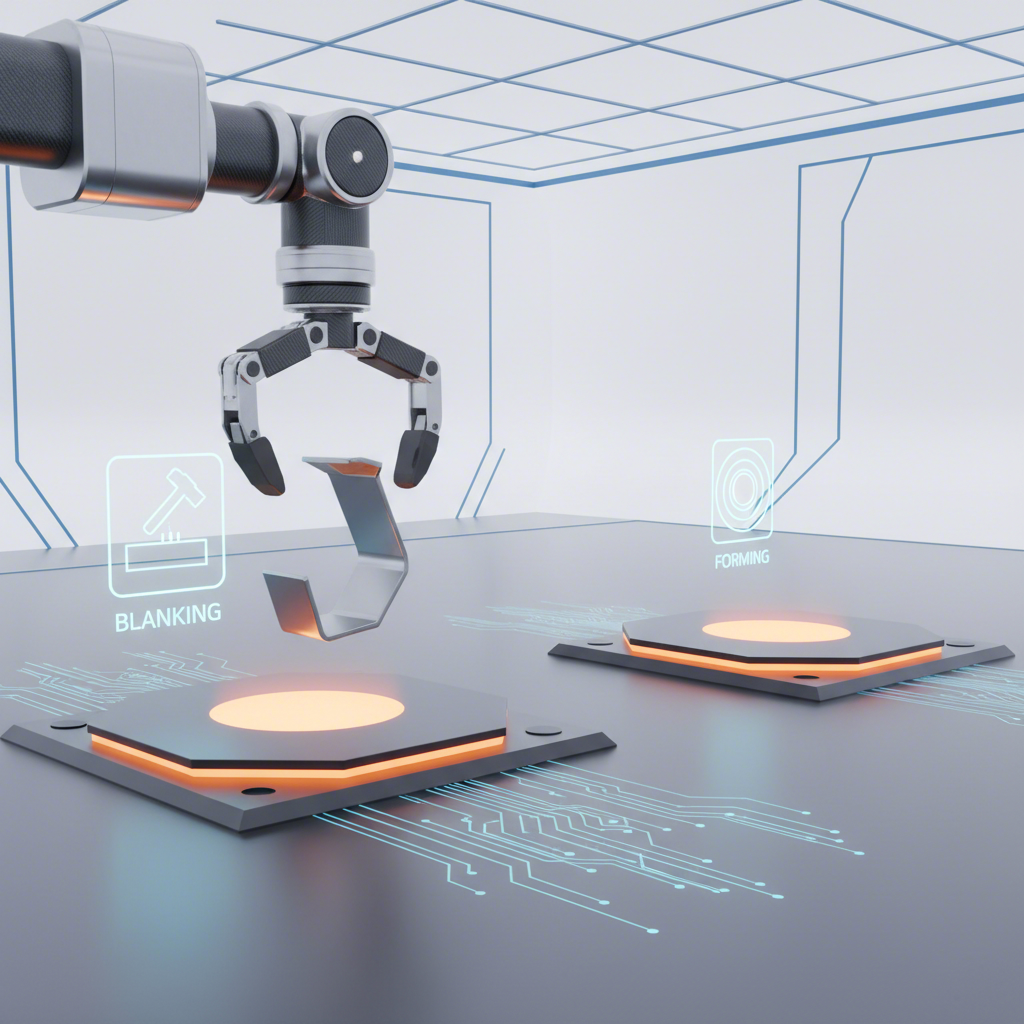

Understanding Transfer Die Stamping: Process and Principles

Transfer die stamping operates on a fundamentally different principle from its progressive counterpart. Instead of working with a continuous strip, the process begins by cutting an individual workpiece, known as a 'blank,' from the sheet metal. This freestanding part is then transferred between different dies or stations for subsequent operations. This transfer is managed by a mechanical transport system, often using 'fingers' or grippers that pick up the part, move it to the next station, and place it with precision.

This 'separate-then-move' approach is the source of transfer die stamping's main advantage: versatility. Because the part is not tethered to a carrier strip, it can be freely manipulated, lifted, rotated, and positioned at any angle. This freedom allows for the creation of complex features that are difficult or impossible to achieve in a progressive die. Operations like deep drawing, forming ribs or knurls, threading, and side piercing are well-suited for transfer dies. This makes the process ideal for manufacturing larger components such as automotive frames, structural parts, and deep shells.

While highly versatile, transfer die stamping is generally a slower process compared to progressive stamping. The mechanical transfer between stations adds time to each cycle. Tooling can also be complex and expensive, as it may involve multiple separate dies. However, it is often more economical for shorter production runs and can lead to better material yield since no carrier strip is required. For projects that demand intricate features on larger parts, the flexibility and capability of transfer die stamping often make it the superior choice.

Head-to-Head Comparison: Key Differences Between Progressive and Transfer Dies

Choosing the right stamping method is a critical decision that impacts production speed, cost, and final part quality. While both progressive and transfer die stamping transform sheet metal into precise components, they do so in fundamentally different ways. Understanding these distinctions across key criteria is essential for making an informed choice for your manufacturing project. The following table provides a direct comparison, followed by a deeper analysis of each factor.

| Criterion | Progressive Die Stamping | Transfer Die Stamping |

|---|---|---|

| Process Flow | A continuous metal strip moves through a single multi-station die. The part remains attached until the final operation. | An individual blank is cut first, then mechanically transferred between separate stations or dies. |

| Tooling | A single, complex die block contains all stations. Higher upfront engineering and cost. | Multiple, often simpler, individual dies are used. Can be more adaptable but overall setup is complex. |

| Production Speed | Very high speed, ideal for mass production. | Slower due to the part transfer time between stations. |

| Ideal Part Size | Best for small to medium-sized parts. | Excellent for medium to large parts (e.g., frames, shells). |

| Part Complexity | Limited; deep draws and features on multiple planes are difficult as the part is attached to the strip. | High versatility; ideal for deep draws, ribs, threads, and other complex features due to part freedom. |

| Production Volume | Best for high-volume runs (hundreds of thousands to millions). | More economical for short to medium-volume runs. |

| Cost | High initial tooling cost, but very low cost-per-part in long runs. More material scrap from the carrier strip. | Tooling costs can be high, but often lower than a complex progressive die. Better material yield. |

The most significant distinction lies in how the part is controlled. In progressive stamping, the continuous strip provides stability and rapid feeding, which is the source of its speed. However, this same strip restricts the part, limiting the types of forming operations possible. Conversely, transfer stamping liberates the part from the strip, as described by sources like Engineering Specialties, Inc. (ESI). This freedom allows for much greater complexity and is why it's the go-to method for deep-drawn components.

From a cost perspective, the choice is a trade-off. Progressive dies have a high initial investment but pay dividends over massive production volumes through lower per-part costs and reduced labor. Transfer dies might be more economical for smaller batches, as noted by Minifaber, and can save on material costs by eliminating the carrier web. Your budget and production forecast are therefore critical factors in the decision.

How to Choose the Right Stamping Process for Your Project

Selecting between progressive and transfer die stamping is not just a technical choice—it's a strategic business decision that directly affects your project's cost, timeline, and final quality. The optimal method depends on a careful evaluation of your part's specific characteristics and your production goals. The decision generally boils down to three primary factors: part intricacy, part size, and production volume.

First, consider part intricacy. If your component is relatively straightforward or its features can be formed while attached to a strip, progressive stamping is a strong candidate. However, if the design includes complex features such as deep draws, side holes, ribs, knurls, or threads, a transfer die is almost always the better choice. As detailed by Standard Die, these features often require the part to be free from the metal strip for proper manipulation, which is the core strength of the transfer process.

Next, evaluate the part size. Progressive die stamping excels at producing small to medium-sized components with high speed and repeatability. The mechanics of feeding a continuous metal strip become less practical and more wasteful for very large parts. Transfer die stamping, on the other hand, is specifically designed to handle larger and bulkier parts like automotive frames, shells, and structural components. The mechanical transfer system is more adept at moving these substantial blanks between stations.

Finally, analyze your production volume and budget. This is often the deciding factor. Progressive die stamping requires a significant upfront investment in tooling, but it delivers an exceptionally low cost-per-part on high-volume runs. If you anticipate producing hundreds of thousands or millions of units, the initial expense is easily justified by the long-term savings. For shorter or medium-volume runs, the more moderate tooling costs of a transfer die setup are often more economical. For complex projects, particularly in the automotive sector, partnering with a specialist can provide crucial guidance. For instance, companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. offer deep expertise in custom automotive stamping dies, helping clients navigate these decisions to optimize for both quality and efficiency.

To summarize, your choice can be guided by these scenarios:

- Choose Progressive Die Stamping if: You have a high-volume production run, the part is small to medium-sized, part complexity is moderate, and a low per-part cost is the primary goal.

- Choose Transfer Die Stamping if: Your part is large or has complex features like deep draws, the production volume is low to medium, and design flexibility is more important than maximum production speed.

Frequently Asked Questions

1. What is the difference between progressive dies and transfer dies?

The primary difference is how the material is handled. Progressive dies use a continuous strip of metal that advances through various stations in a single die, with the part remaining attached until the end. Transfer dies work with individual parts that are cut from the metal sheet first and then moved between separate die stations by a mechanical system. This makes progressive dies better for high-volume, smaller parts and transfer dies more suitable for larger, more complex parts.

2. What are the disadvantages of progressive die stamping?

The main disadvantages include high initial tooling costs, limitations on part design (deep drawing and certain features are difficult), and the potential for more scrap material due to the carrier strip. The tooling is also very specific to one part, making it inflexible for quick project changes. This integrated, multi-station design contributes to the tooling's overall complexity and cost.

3. What is a transfer die?

A transfer die is a type of stamping tool used for parts that require multiple operations and are handled individually. As explained by Larson Tool, the part is first cut into a blank and then moved between stations by a mechanical transfer system. This process is ideal for large or intricate components because the part is free from a metal strip, allowing for greater flexibility in forming complex shapes.

4. What is a progressive die used for?

A progressive die is used for the high-volume production of complex parts with tight tolerances. It is particularly effective for manufacturing smaller components quickly and cost-effectively. Common applications include producing parts for the automotive, electronics, and appliance industries where millions of identical parts are needed with high precision and repeatability.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —