Oxidation On Aluminium: Stop Mistaking It For Rust

Why Aluminum Oxidation Is Not the Same as Rust And Why It Matters

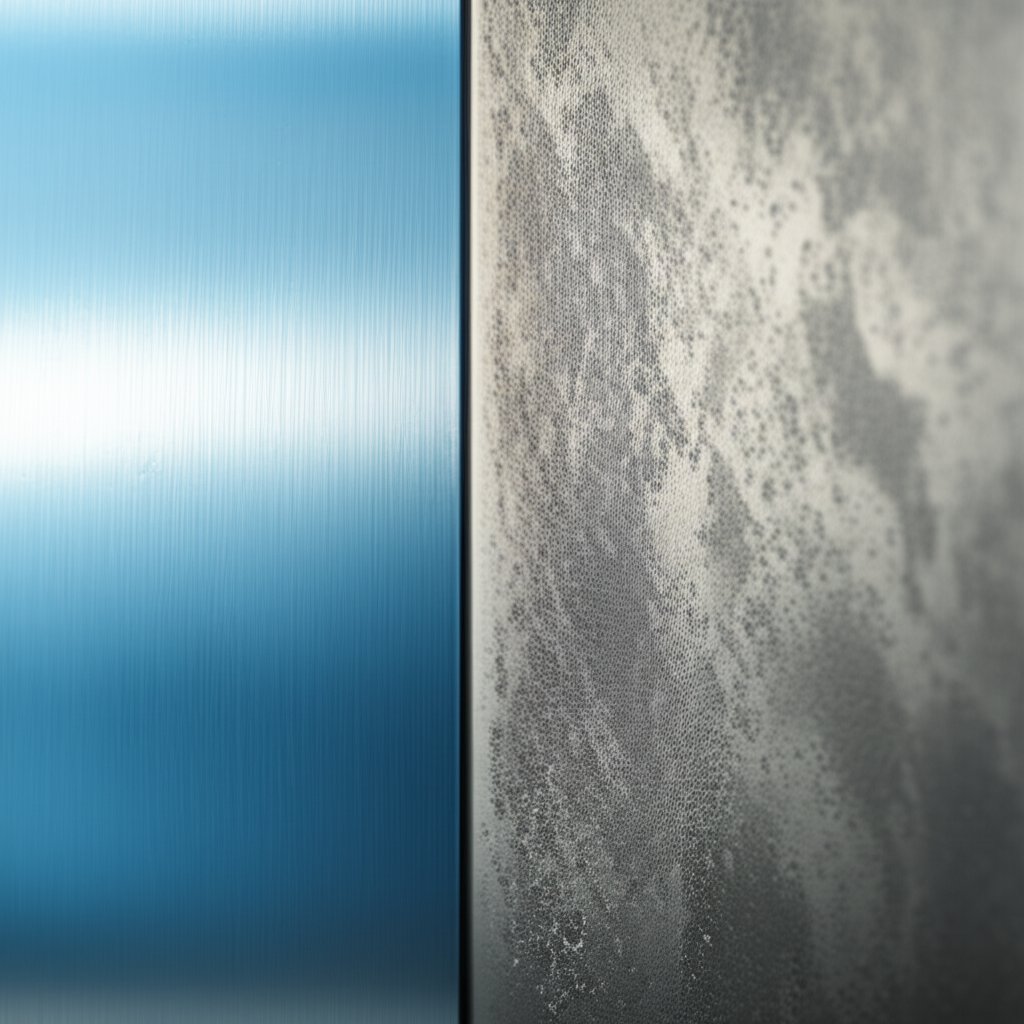

What oxidation on aluminium really means

Ever wondered, "Does aluminum rust?" or "Can aluminum rust like steel?" If you’ve seen a dull, whitish film on aluminum parts and worried about rust, you’re not alone. The confusion around oxidation on aluminium is common—and it’s easy to see why. Unlike iron or steel, aluminum doesn’t develop the flaky, reddish-brown rust we associate with corroded metal. Instead, it forms a thin, invisible layer of aluminum oxide (Al2O3) almost instantly when exposed to air. This passive film is what gives aluminum its well-known resistance to corrosion. But is aluminum rust-proof in every situation? Not quite.

Rust versus corrosion on aluminum

Let’s break down the basics. Rust is the specific name for iron oxide, which forms when iron or steel reacts with oxygen and moisture. Corrosion is a broader term for the gradual breakdown of any metal due to chemical reactions with its environment. Oxidation simply means a metal has reacted with oxygen. For aluminum, oxidation is actually what keeps the metal safe—most of the time. The process is called passivation: a self-forming, protective oxide film that shields the underlying metal from further attack. But when this passive film is damaged or dissolved—by aggressive chemicals, saltwater, or galvanic contact with other metals—corrosion can take hold, leading to pitting or more serious damage.

Common myths that cause costly mistakes

Let’s clear up some of the biggest misconceptions about aluminum and rust:

- Thinking aluminum "rusts" like steel (it doesn’t—rust is iron oxide, not aluminum oxide).

- Assuming the dull, whitish surface is always a problem (often, it’s the protective oxide layer, not damaging corrosion).

- Believing aluminum is rust-proof in every environment (chlorides, alkaline conditions, and dissimilar metal contact can still trigger corrosion).

- Confusing corrosion vs rust—all rust is corrosion, but not all corrosion is rust.

- Ignoring the risk of galvanic couples—aluminum in contact with more noble metals like stainless steel can corrode faster in wet, salty conditions.

Aluminum doesn’t form “rust” like steel, but it can corrode under certain conditions—especially if its protective oxide film is compromised.

Here’s the key: That thin, self-forming Al2O3 layer is usually invisible and tightly bonded to the surface. It acts as a barrier, slowing further oxidation and protecting the metal beneath. When intact, this passive film is your best friend for long-lasting aluminum components.

Why this guide matters

Understanding the difference between rust vs oxidation on aluminum can save you time, money, and headaches in the long run. This guide will walk you through:

- The chemistry behind aluminum’s passive film and what makes it so effective

- How different alloys and environments affect corrosion risk

- Inspection and maintenance strategies to prevent costly failures

- Step-by-step removal and cleaning methods for oxidation and corrosion

- Critical safety and waste handling tips

- How to choose the right treatment method for your application

Whether you’re managing architectural panels, marine hardware, or industrial machinery, knowing the real story behind aluminum oxidation helps you make smarter choices. Ready to separate myth from fact? Let’s dive in and master the science and practical realities of aluminum and rust, starting with the chemistry behind that all-important passive film.

The Protective Passive Film Explained Simply

How the Aluminum Oxide Film Forms in Seconds

When you leave a freshly cut piece of aluminum exposed to air, something remarkable happens—within seconds, a thin, invisible layer of aluminum oxide forms on the surface. This is known as the passivation of aluminum. The process is automatic and self-limiting: as soon as the oxide layer reaches a certain thickness, it blocks further oxygen from reaching the metal underneath. This is why, unlike iron, aluminum rarely shows the flaky, reddish corrosion we call rust. Instead, the metal appears to "tarnish," but this so-called aluminium tarnish is actually a sign that the protective film is doing its job.

Why the Film Is Self-Healing but Not Invincible

Sounds almost too good to be true? Here’s the science: The aluminum oxide film is dense, tightly bonded, and can "heal" itself if scratched or abraded. As long as oxygen is present—even in tiny amounts—any bare spot is quickly resealed by new oxide. This is why most oxidized aluminum surfaces remain protected, even after minor damage. But there are limits. The film’s stability depends on environmental factors: in highly alkaline conditions (pH above 9) or in the presence of aggressive chlorides (like road salt or seawater), the oxide can dissolve or become porous, opening the door to real aluminum corrosion [DST Chemicals].

The natural oxide film on aluminum acts as a barrier, protecting the metal beneath from further attack—unless harsh conditions break it down.

| Condition | Appearance | Risk Level | Common Triggers |

|---|---|---|---|

| Passive film intact | Smooth, dull gray or silver; no pitting | Low | Dry air, mild moisture |

| Passive film compromised | White powder, pitting, or dark spots | High | Salt, high pH, crevices, dissimilar metals |

When the Protective Layer Breaks Down

- Chlorides: Saltwater or deicing salts can penetrate and disrupt the oxide, leading to pitting corrosion.

- Alkaline environments: At pH above 9, the protective film dissolves, exposing the base metal.

- Crevices and deposits: Trapped moisture and contaminants in joints or under debris can locally break down the film.

- Dissimilar metals: Contact with more noble metals (like copper or stainless steel) in the presence of moisture can accelerate attack through galvanic corrosion.

So, will aluminum tarnish? Yes—but that’s usually just the oxide layer at work. Aluminium will rust only in the sense that it can corrode, but it never forms traditional rust. Instead, you’ll notice powdery white or gray deposits, or localized pitting, if the passive film is lost.

Technical Box: The Chemistry Behind the Barrier

- The natural oxide is primarily Al2O3 (aluminum oxide), which forms instantly in air.

- Recent studies show the passivation layer is a bilayer: an inner amorphous Al2O3 (stable) and an outer crystalline aluminum hydroxide (less stable) [Tribonet].

- Typical thickness is only a few nanometers, but it’s dense and adherent.

- The aluminum oxidation number in Al2O3 is +3, which makes the oxide chemically stable and difficult for most environments to attack.

It’s worth noting: Passivation of aluminum is why most architectural, automotive, and marine aluminum lasts for years with minimal visible change. But if you see white powder, deep pits, or dark spots, it’s time to investigate—those are signs the protective layer has failed and true aluminum corrosion is underway.

Now that you understand how the passive film works—and what can undermine it—let’s look at how different alloys and mixed-metal assemblies affect corrosion resistance in practice.

Alloys, Finishes, and Galvanic Traps You Must Know

Alloy Series at a Glance: Why Your Choice Matters

Imagine you’re specifying aluminum for a project exposed to the elements. Do you grab any alloy, or does your choice really change how long it will last? The answer is clear: not all aluminum alloys are created equal when it comes to resisting oxidation and corrosion. Each alloy family—distinguished by its main alloying element—offers a unique balance of strength, formability, and corrosion behavior. Let’s break down what you need to know before making a costly mistake.

| Alloy Series | Typical Uses | General Corrosion Behavior | Notes |

|---|---|---|---|

| 1xxx (Pure Al) | Electrical, chemical, enclosures | Excellent | Very high corrosion resistance; low strength |

| 3xxx (Mn) | Cookware, trim, heat exchangers, cans | Very Good | Good for general use; anodizes well; moderate strength |

| 5xxx (Mg) | Marine, structures, tanks, transport | Excellent | Top choice for marine and salt exposure; non-heat treatable |

| 6xxx (Mg + Si) | Architectural, automotive, extrusion | Good to Moderate | Versatile; moderate corrosion resistance; strong and formable |

| 2xxx (Cu) | Aerospace, high-strength parts | Low | Needs protective coating; prone to atmospheric corrosion |

| 7xxx (Zn) | Aerospace, sports equipment | Poor | Very strong; lowest corrosion resistance among common alloys |

When in doubt, alloys from the 5xxx series are your best bet for marine or deicing salt exposure, while 1xxx and 3xxx series offer excellent general corrosion resistance. However, high-strength alloys (2xxx, 7xxx) demand extra protection in harsh environments. Always match the alloy to your exposure conditions and performance needs.

Dissimilar Metal Contact: The Galvanic Trap

Ever wondered, "Does aluminum react with stainless steel?" The short answer: yes, especially when moisture is present. This is the classic scenario for galvanic corrosion aluminum. Here’s what happens in practice:

- Aluminum sits lower than stainless steel in the galvanic series, making it the anode (the metal that corrodes).

- When aluminum and stainless steel are joined in the presence of an electrolyte (like water or salt spray), the aluminum can corrode rapidly—especially at fastener sites or crevices.

- This stainless steel and aluminum reaction is a leading cause of premature failure in mixed-metal assemblies, particularly in marine or industrial environments.

But is it always a disaster? Not necessarily. The severity depends on the area ratio: large aluminum parts with small stainless fasteners are less vulnerable than the reverse. Still, the risk of stainless steel to aluminum corrosion grows dramatically with humidity, salt, or standing water. You’ll often see white powdery deposits or pitting around joints—classic signs of aluminum steel corrosion.

How to Prevent Galvanic Corrosion: Practical Steps

- Isolate the metals: Use plastic or rubber washers, gaskets, or sleeves to prevent direct contact.

- Apply compatible coatings: Epoxy, paint, or anodizing can slow the aluminum and steel reaction, but ensure coatings are intact, especially at drilled holes or cut edges.

- Seal and drain: Use sealants to block moisture entry, and design joints to shed water, avoiding crevice traps.

- Choose fasteners wisely: Stainless bolts in aluminum are safer than the reverse. Never use aluminum fasteners in large steel assemblies.

- Regular inspection: Catch early signs of galvanic attack before structural damage occurs.

Surface Finish, Anodizing, and Coatings: A Double-Edged Sword

Anodizing is a powerful tool for enhancing aluminum’s corrosion resistance. It thickens the natural oxide layer, making the surface harder and more resistant to attack. However, if the anodized layer is damaged—by scratching, drilling, or careless assembly—it can actually make galvanic corrosion worse by exposing small bare areas of aluminum as anodes against much larger stainless or steel cathodes [AluConsult]. Always specify careful handling and touch-up for any cut or drilled surfaces.

Checklist: Choosing Alloys and Finishes for Harsh Environments

- Is your application exposed to marine spray, road salts, or industrial fallout? Favor 5xxx or 1xxx alloys with anodized or coated surfaces.

- Are you using stainless steel fasteners? Always isolate contact points and seal joints.

- Will the assembly be cleaned or maintained regularly? Specify finishes that can withstand repeated cleaning without damage.

- Is drainage and ventilation adequate to avoid moisture traps?

- Are all cut edges and holes protected after fabrication?

By understanding alloy selection, galvanic risks, and the real-world behavior of finishes, you’ll make smarter decisions that keep oxidation on aluminium from turning into costly corrosion. Next up: how to spot early warning signs in the field and create a maintenance plan that prevents failure before it starts.

Field Inspection and Maintenance That Prevents Failure

What to Look for During Inspections

When you walk up to an aluminum structure—whether it’s a panel, extrusion, or assembly—do you know what to check first? Spotting early signs of corrosion or oxidation on aluminium is the key to preventing costly repairs. Here’s a step-by-step checklist to guide your inspection routine, whether you’re cleaning oxidized aluminum on a marine hull or maintaining architectural panels:

- Surface Condition: Scan for discoloration, dullness, or powdery white/gray spots. These may be harmless oxide films—or the first sign of trouble.

- Fastener Interfaces: Inspect around bolts, screws, and rivets for white bloom, pitting, or lifting paint. Galvanic corrosion often starts here.

- Crevices and Joints: Look inside seams, under gaskets, and at lap joints. Trapped moisture or debris can break down the protective film.

- Drainage Points: Ensure drain holes are open and free of blockages. Water accumulation accelerates corrosion.

- Coating Integrity: Check for chips, blisters, or peeling paint—especially near edges and welds. Damaged coatings expose bare metal.

- Aluminum Stains: Note any dark streaks, greenish deposits, or odd stains. These may indicate contact with other metals or environmental fallout.

Wondering what does aluminum corrosion look like? Unlike rust on steel, you’ll often see white powder, small pits, or a roughened surface rather than red flakes. In severe cases, you may find deep pits, flaking, or even lifted layers.

Severity Grading That Drives Action

| Symptom Appearance | Probable Cause | Recommended Action | Timeframe |

|---|---|---|---|

| Light, uniform film or dulling (no pitting) | Normal passivation or minor atmospheric exposure | Clean and monitor; document condition | Next scheduled review |

| White bloom, powder, or small pits (especially near fasteners) | Galvanic or crevice corrosion; loss of passive film | Clean, inspect for underlying damage, apply protective coating | Address within maintenance cycle |

| Flaking, deep pits, or underfilm corrosion | Film breakdown, aggressive environment, or prolonged neglect | Immediate remediation; consider part replacement or consult specialist | Immediate |

If you’re unsure whether you’re seeing harmless tarnish or something more serious, photograph and document the area. Regularly cleaning aluminium corrosion in its early stages is the best way to prevent structural loss.

A Simple Log to Track Issues Over Time

Consistent documentation helps spot trends and supports decisions on how to clean aluminum corrosion or escalate repairs. Here’s a practical inspection log format:

| Date | Location/Part ID | Environment | Observations | Photos Taken | Severity | Action | Next Review |

|---|---|---|---|---|---|---|---|

| -- | -- | -- | -- | Yes/No | -- | -- | -- |

- Frequency Guidance: Inspect after winter, following marine exposure, or per normal service intervals. High-risk environments may require more frequent checks.

- Photograph Before/After: Always capture the condition before and after cleaning oxidised aluminum. This helps you track effectiveness and catch recurring issues.

Small deposits in crevices or around fasteners often precede visible pitting—early intervention is crucial to stop deeper attack.

Best Practices for Preventive Maintenance

- Remove debris and rinse surfaces regularly—especially after salt or chemical exposure.

- Use only approved cleaners and soft brushes for cleaning oxidized aluminum. Avoid steel wool or harsh abrasives that can scratch and trap contaminants.

- After cleaning, dry thoroughly and inspect for new stains or corrosion. Promptly repair damaged coatings.

- For persistent or severe corrosion, consult standards or manufacturer guidelines for acceptance criteria and repair procedures.

By following this playbook, you’ll be able to answer not just how to clean corroded aluminum, but also how to prevent future issues and extend the life of your assets. Next, let’s walk through proven step-by-step methods to remove oxidation and keep it from coming back.

SOPs That Actually Remove Oxidation And Keep It Off

Mechanical Prep and Polishing SOP

When you spot that dull white or gray film on aluminum, your first instinct might be to grab some sandpaper and scrub away. But is that the best way to remove oxidation from aluminum? Let’s break down a repeatable, safe mechanical process that delivers consistent results—without risking new corrosion or damaging the base metal.

- Mask and Protect: Cover any areas you don’t want to abrade, especially adjacent materials or sensitive surfaces.

- Select the Right Abrasive: Use non-embedding media—fine-grit aluminum oxide sandpaper (start at 240–320 grit, finish with 800–1000 grit) or a nylon brush. Avoid steel wool, which can leave iron particles and trigger galvanic corrosion.

- Surface Cleaning: Before abrading, clean the area with soap and water to remove oils and debris. Dry thoroughly.

- Abrade in Stages: Sand or brush gently in overlapping motions, progressing from coarser to finer grit. Don’t rush; uneven pressure can create scratches or low spots.

- Dust Removal: Wipe away all dust with a microfiber cloth. Rinse with water and dry again to prevent residue.

- Visual Check: Inspect for a uniform, matte finish—no visible powdery corrosion, no dark smut, and no embedded debris.

Mechanical abrasion is effective for small to medium areas, but for intricate parts or heavy oxidation, you may want to consider chemical or laser-based aluminum oxide removal methods.

Chemical Cleaning and Neutralization SOP

Prefer a chemical approach for removing oxidation from aluminum? Here’s a step-by-step process that balances cleaning power with safety and surface quality:

- Choose the Cleaner: For light oxidation, use mild acids like diluted white vinegar, lemon juice, or cream of tartar. For industrial or heavy oxidation, select an approved acidic cleaner (e.g., phosphoric or sulfuric acid-based) or a commercial aluminum oxidation remover. Avoid aggressive acids like hydrochloric (muriatic) unless specifically authorized by OEM or process standards [KEYENCE].

- Test on a Small Area: Always test your chosen method on a hidden spot to check for unwanted reactions or discoloration.

- Application: Apply the solution by spray, soak, or brush—follow manufacturer instructions for dilution, dwell time, and agitation. For home methods, let the acid sit for 5–10 minutes, then gently scrub with a nylon brush.

- Rinse Thoroughly: Remove all chemical residues by rinsing with plenty of clean water. For industrial processes, immersion in a series of water baths may be required.

- Neutralize: If an acid was used, follow up with a neutralizing agent (such as a mild alkaline solution) to ensure the surface pH returns to neutral. This step is crucial before any further finishing or coating.

- Final Rinse and Dry: Rinse again and dry completely to prevent water spots or renewed oxidation.

- Water-Break-Free Test: Run a stream of water over the cleaned area. If the water sheets evenly (no beading or breaks), the surface is free of oils and residues—ready for coating or assembly.

Always dispose of chemical wastes per local regulations, and wear proper PPE. If in doubt, consult safety datasheets or process experts before attempting chemical aluminum corrosion removal.

Laser and Dry-Ice Cleaning: Advanced Options

Imagine a process that strips oxidation with zero chemicals and no abrasion—laser and dry-ice cleaning offer just that. Laser ablation uses a focused beam to vaporize the oxide layer, while dry-ice blasting removes it with frozen CO2 pellets. Both methods:

- Leave no chemical residue

- Are highly precise—ideal for intricate or sensitive parts

- Minimize risk of substrate damage when properly set up

However, these techniques require specialized equipment and trained operators. Always follow vendor or OEM parameters for safe, effective aluminum oxide removal.

Post-Clean Passivation and Protection SOP

Once you’ve achieved a clean, uniform finish, don’t stop there—protect your work to keep oxidation from returning:

- Inspect: Check for consistent sheen, absence of powdery deposits, and no visible smut or dark streaks.

- Apply Protective Coating: Use a clear coat, anodizing, or a corrosion-inhibiting polish to seal the surface and slow future oxidation.

- Maintain Regular Cleaning: Rinse and dry surfaces after exposure to salt, chemicals, or pollutants. Inspect coatings for chips or wear.

Following these steps ensures that your aluminum corrosion removal efforts last—and that future cleaning is easier and less invasive.

Acceptance Criteria and Common Failure Modes

- Uniform, matte or polished appearance—no powdery white corrosion or dark smut

- Consistent water break (water sheets evenly, no beading)

- No embedded grit, scratches, or residue

- Protective coatings fully intact

- No underfilm corrosion reappearing within days

- No uneven sheen or patchy finish after polishing

If you notice any of these failure modes after cleaning, rework may be needed—don’t ignore recurring oxidation or patchy results.

By sticking to these SOPs, you’ll master how to clean aluminum oxidation and remove corrosion from aluminum—and you’ll keep your assets looking and performing their best for years to come. Next, we’ll cover safety, neutralization, and waste handling to ensure every cleaning job is as responsible as it is effective.

Safety, Neutralization, And Waste You Can Trust

PPE and Site Controls Before You Start

Thinking about an aluminum acid wash or planning to use an acid for aluminium cleaning? Before you even open a bottle, ask yourself: Are you truly ready for the risks? Industrial acids like sulfuric or muriatic acid on aluminum can be highly effective, but they’re also hazardous. Protecting yourself and your team is non-negotiable.

- Gloves: Acid-resistant gloves (nitrile or neoprene) suited to the specific chemistry

- Eye/Face Protection: Safety goggles or a full face shield

- Respiratory Protection: Use a respirator if fumes may be present, especially in poorly ventilated areas

- Apron/Clothing: Chemical-resistant apron and sleeves; avoid cotton or synthetics that may react

- Ventilation: Work in a well-ventilated area or under a fume hood to control acid vapors

Always inspect PPE before and after use. Replace anything damaged immediately. Have an emergency eyewash and spill kit within arm’s reach—accidents can happen in seconds.

Neutralization, Rinsing, and Waste Handling

Once you’ve finished acid cleaning aluminium or performed an acid washed aluminum process, your job isn’t done. Proper neutralization and waste management are just as critical as the cleaning itself. Here’s a step-by-step flow to keep your process safe and compliant:

- Review the SDS: Always start by reading the Safety Data Sheet (SDS) for every aluminum cleaner acid you plan to use. This tells you exactly what hazards and first aid measures apply.

- Conduct a Spot Test: Test your chosen acid on a small, inconspicuous area to check for unwanted reactions or excessive etching—especially with strong acids like sulfuric acid on aluminum.

- Apply Per Label: Follow manufacturer instructions for dilution, application, and contact time. Never exceed recommended dwell times, as overexposure can damage the metal.

- Control Runoff: Prevent acid wash for metal from entering drains or soil untreated. Use containment trays or absorbent pads as needed.

- Neutralize Thoroughly: After cleaning, neutralize any remaining acid residue with a mild alkaline solution (such as baking soda in water), following SDS or manufacturer guidelines. Aim for a final pH between 5.5 and 9.5, unless local discharge rules specify otherwise (see Cornell EHS).

- Verify pH: Use pH strips or a meter to confirm the rinse water is within locally approved discharge limits before disposal.

- Collect and Dispose: Collect all waste solutions and rinses. Never mix different chemistries (e.g., don’t combine spent muriatic acid with sulfuric acid on aluminum). Label all containers clearly and store them securely until proper disposal.

Remember: Some acids, especially strong ones, may generate heat or even hydrogen gas during neutralization. Always add acid to water—never the reverse—to prevent dangerous splashing or reactions. Keep all ignition sources away from the work area.

| Cleaner Type | Approx. Dilution | Neutralizer Used | Final pH | Disposal Method | Authorization/Permit Ref. |

|---|---|---|---|---|---|

| Phosphoric acid cleaner | 1:10 | Baking soda solution | 6.5 | Drain (if local rules allow) | Permit #12345 |

| Sulfuric acid on aluminum | 1:20 | Sodium carbonate | 7.0 | Hazardous waste pickup | Authorization #67890 |

| Muriatic acid on aluminum | 1:15 | Baking soda solution | 6.0 | Hazardous waste pickup | Authorization #54321 |

If local rules specify pH or contaminant limits, document and cite them. Otherwise, always contact your environmental health and safety authority before disposal.

Documentation and Local Compliance

- Label every container with its contents and hazard class. Never use unmarked bottles for acid cleaning aluminium or neutralized waste.

- Keep a simple waste log, noting the type of aluminum cleaner acid, quantity, and disposal method for each job.

- Store acid cleaning wastes in compatible, sealed containers away from incompatible chemicals (e.g., keep acids away from bases, organics, or oxidizers).

- Retain disposal permits, pH logs, and training records as required by local regulations.

Training is key: Even experienced technicians should receive periodic refreshers on acid wash for metal procedures and emergency response. Make sure spill kits, neutralizers, and eyewash stations are always stocked and accessible (see GZ-Supplies).

Safe aluminum acid wash and neutralization start with the right PPE, clear procedures, and a commitment to responsible waste handling—never cut corners when it comes to chemical safety.

Following these steps ensures your acid washed aluminum process is not only effective but also safe for your team and the environment. Next, you’ll learn how to select the best treatment method for your specific alloy, finish, and application scenario.

Decision Matrix For Selecting The Right Treatment

Choose by Alloy, Finish, and Geometry

When facing oxidation on aluminium, how do you know which cleaning or protection method is right for your part? The answer depends on the alloy, surface finish, geometry, and the environment your aluminum will face. Choosing the wrong approach can shorten service life or even damage sensitive surfaces. Let’s make your decision easier with a practical selection matrix and some real-world tips.

| Alloy/Temper | Surface Finish | Geometry | Exposure | Constraints | Recommended Method | Notes |

|---|---|---|---|---|---|---|

| 1xxx, 3xxx (soft, pure Al, Mn) | Raw, lightly oxidized | Open, flat | Indoor, mild outdoor | VOC limits | Mechanical (soft cloth, mild polish) | Gentle cleaning preserves passive film; avoid harsh chemicals |

| 5xxx (Mg-rich) | Anodized | Extruded, open | Marine, deicing | No media embed | Chemical (mild alkaline wash, seal) | Use cleaner for aluminium with corrosion inhibitors for best aluminum corrosion protection |

| 6xxx (Mg+Si, extruded) | Painted or powder-coated | Thin-walled, decorative | Urban, industrial | Indoor-only | Mechanical (microfiber, non-abrasive) | Avoid aggressive abrasives; test before using any aluminium deoxidizer |

| 2xxx, 7xxx (Cu, Zn-rich) | Raw, painted | Creviced, fastened | Harsh, salt, industrial | No media embed, VOC limits | Chemical (phosphoric acid, rinse, coat) | Follow OEM or standard for aluminum corrosion treatment; inspect for galvanic risk |

| All alloys | Anodized, minor bloom | Open or creviced | Outdoor, marine | High appearance demand | Laser or dry-ice (advanced) | Best for sensitive or complex shapes; no residue, preserves finish |

Match Environment and Regulatory Constraints

Imagine you’re maintaining a marine railing or cleaning oxidized window frames. The right method for how to clean oxidation from aluminum is not always the same as for restoring painted trim in a city building. Regulatory limits on VOCs, waste disposal, or media embedment may also affect your choice. Always check if any standards (such as ASTM or OEM specs) apply to your application before proceeding.

Balance Speed, Cost, and Surface Quality

- If anodized with minor bloom, favor a mild alkaline wash and reseal for lasting aluminum corrosion protection.

- If you see white powder in creviced hardware, investigate galvanic isolation and select a chemical or laser method to prevent recurrence.

- If your part is thin-walled and appearance-critical, avoid aggressive abrasives—always test any aluminium deoxidizer on a hidden spot first.

Still unsure? Start with a small pilot on a concealed area. This helps confirm that your chosen method won’t harm the finish or reduce corrosion resistance.

Choosing the right aluminum corrosion treatment is about matching the method to your alloy, finish, and environment—never a one-size-fits-all answer.

With this matrix and these rules, you’ll confidently select the best approach for aluminum corrosion protection, extend service life, and know how to prevent aluminum corrosion before it starts. Next, we’ll tie these strategies to automotive extrusions and sourcing recommendations, so you can apply these lessons in real-world supply chains and high-performance applications.

Automotive Extrusions And Smart Sourcing Recommendations

Managing Oxidation on Automotive Extrusions

When you think about the longevity of automotive structures—frames, trim, or even wheels—oxidation on aluminium is more than just a cosmetic worry. Imagine an aluminum trailer left unwashed after a wet winter: you’ll likely spot dullness, streaks, or even powdery deposits. That’s not rust, but it can still undermine the vehicle’s appearance and, over time, its integrity. So, how do you keep oxidation at bay, especially in demanding automotive environments?

- Joint Design: Smart engineering minimizes crevices and traps where moisture can linger, reducing the risk of crevice corrosion or water staining. For example, using adhesive bonding instead of screws can help eliminate hidden pockets that collect grime and moisture.

- Drainage: Well-placed drainage holes and sloped surfaces ensure water and road salts don’t build up, especially after an aluminum trailer wash or during seasonal changes.

- Compatible Fasteners: Using isolation washers or sealants with stainless hardware prevents galvanic corrosion, especially where you have dissimilar metals in contact.

- Post-Clean Protection: After cleaning—whether you’re using the best aluminum trailer cleaner or a basic soap—apply a protective coating or ensure the anodized layer is intact. This step helps prevent the rapid return of oxidation, particularly after an acid wash aluminum trailer process.

Design-to-Clean Choices That Prevent Rework

Ever had to re-polish a wheel or re-clean a trailer just weeks after the last job? That’s often a sign the design didn’t account for maintenance realities. When you’re specifying or sourcing automotive extrusions, consider these practical, “design-to-clean” principles:

- Choose finishes that match your cleaning method: Polished aluminum needs gentler products, while unpolished can tolerate stronger cleaners, even a wheel acid wash for tough grime [Hydro-Chem Systems].

- Specify surface treatments like anodizing: These create a thicker, more durable oxide layer, making routine cleaning easier and reducing the need for aggressive chemicals or acid wheel cleaner aluminum products.

- Design for inspection access: Make sure critical joints and fasteners are visible and reachable, so early signs of oxidation or corrosion can be spotted and addressed before they become costly repairs.

- Standardize cleaning protocols: For fleets, using a consistent aluminum trailer wash process—ideally a touchless, two-step method—helps maintain the finish and prolongs the lifespan of both polished and unpolished parts.

For cast components, like engine covers or wheels, cleaning cast aluminum requires non-abrasive, aluminum-safe cleaners and soft brushes, as harsh acids or rough tools can lead to pitting or discoloration. Always test new products or techniques on a small, inconspicuous area first.

Trusted Sourcing for Precision Parts

Finding the right supplier for automotive aluminum extrusions means more than just price or lead time. You want partners who understand the challenges of oxidation on aluminium, offer robust finishing options, and provide reliable quality control. Here’s a quick resource guide to help you make informed decisions:

- Shaoyi Metal Parts Supplier – A leading integrated precision auto metal parts solutions provider in China. For engineered aluminum extrusion parts, verify corrosion control plans, isolation hardware, and finish specs align with your environment.

- Reputable local metal finishing shops – Look for those with documented aluminum processes, environmental compliance, and experience with automotive standards.

- Industry standards and technical bodies – Refer to the Aluminum Association and Sandia reports for up-to-date guidance on corrosion prevention, cleaning, and inspection best practices.

| Selection Criteria | Shaoyi Metal Parts Supplier | Local Finishing Shop | Industry Standards/Technical Bodies |

|---|---|---|---|

| Alloy Capability | Wide range, automotive focus | Varies by shop | Reference only |

| Tolerance Control | Precision, IATF 16949 certified | Depends on equipment | Reference only |

| Finishing Options | In-house anodizing, surface treatments | Often powder coat, anodizing | Guidelines/standards |

| QA/Traceability | Full documentation, traceable | Varies; ask for records | Reference only |

| EHS Compliance | Integrated, global standards | Check local certifications | Best practices |

Designing for passivation, easy inspection, and compatible hardware from day one saves time, reduces maintenance costs, and extends the lifecycle of every automotive aluminum part.

Whether you’re specifying a new extrusion or maintaining a fleet, understanding the nuances of aluminium how to clean, finish, and protect ensures your vehicles look sharp and perform reliably for years to come.

Frequently Asked Questions About Oxidation on Aluminium

1. Does aluminum rust like steel?

Aluminum does not rust in the way steel does. Instead of forming reddish-brown rust, aluminum develops a thin, protective oxide layer that shields it from further corrosion. However, in harsh environments or when exposed to salt, this layer can be compromised, leading to corrosion that appears as white powder or pitting rather than rust.

2. How can I remove oxidation from aluminum surfaces?

To remove oxidation from aluminum, use non-abrasive cleaning methods like mild acids (such as diluted vinegar or lemon juice) or specialized aluminum cleaners. For tougher oxidation, mechanical polishing with fine-grit sandpaper, or advanced methods like laser or dry-ice cleaning, can be effective. Always rinse thoroughly and apply a protective coating after cleaning to prevent recurrence.

3. What causes aluminum corrosion, and how can I prevent it?

Aluminum corrosion is mainly caused by breakdown of its natural oxide layer, often triggered by salt, alkaline environments, trapped moisture, or contact with dissimilar metals like stainless steel. Prevent corrosion by choosing the right alloy, applying protective coatings or anodizing, isolating aluminum from other metals, ensuring good drainage, and performing regular inspections and maintenance.

4. Is aluminum safe to clean with acids like muriatic or sulfuric acid?

While acids such as muriatic or sulfuric acid can remove oxidation, they must be used with caution. Always follow safety guidelines, use appropriate PPE, and neutralize residues after cleaning. Overuse or improper application can damage the aluminum or create hazardous waste. For most applications, milder acids or approved aluminum cleaners are safer choices.

5. What are the best practices for maintaining aluminum in automotive or marine environments?

For vehicles and marine equipment, choose alloys with high corrosion resistance, design joints to minimize moisture traps, use isolation hardware with fasteners, and apply protective coatings after cleaning. Partnering with suppliers like Shaoyi Metal Parts Supplier ensures you receive parts with robust surface treatments and quality control, reducing maintenance and prolonging service life.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —