Metal Stamping Outsourcing Pros and Cons: The Strategic Make-or-Buy Guide

TL;DR

Deciding between in-house production and contracting a supplier is a critical strategic move for manufacturers. The core trade-off in metal stamping outsourcing pros cons centers on control versus capital efficiency. Outsourcing converts high fixed costs (machinery, tooling, maintenance) into variable costs, offering immediate scalability and access to specialized expertise without the overhead. However, it introduces risks regarding supply chain visibility, intellectual property security, and reliance on partner solvency.

For high-volume production or specialized automotive components, outsourcing is often the superior financial choice due to economies of scale. Conversely, for rapid prototyping, highly sensitive IP, or stable long-run volumes where speed is paramount, maintaining in-house capacity may yield better long-term ROI. This guide analyzes these factors to help you make a data-driven decision.

The Case for Outsourcing: Strategic Advantages

For many B2B manufacturers, the decision to outsource is driven by financial agility and operational focus. Moving production to a dedicated specialist allows companies to offload the immense burden of heavy manufacturing while gaining access to technologies that would be cost-prohibitive to acquire internally.

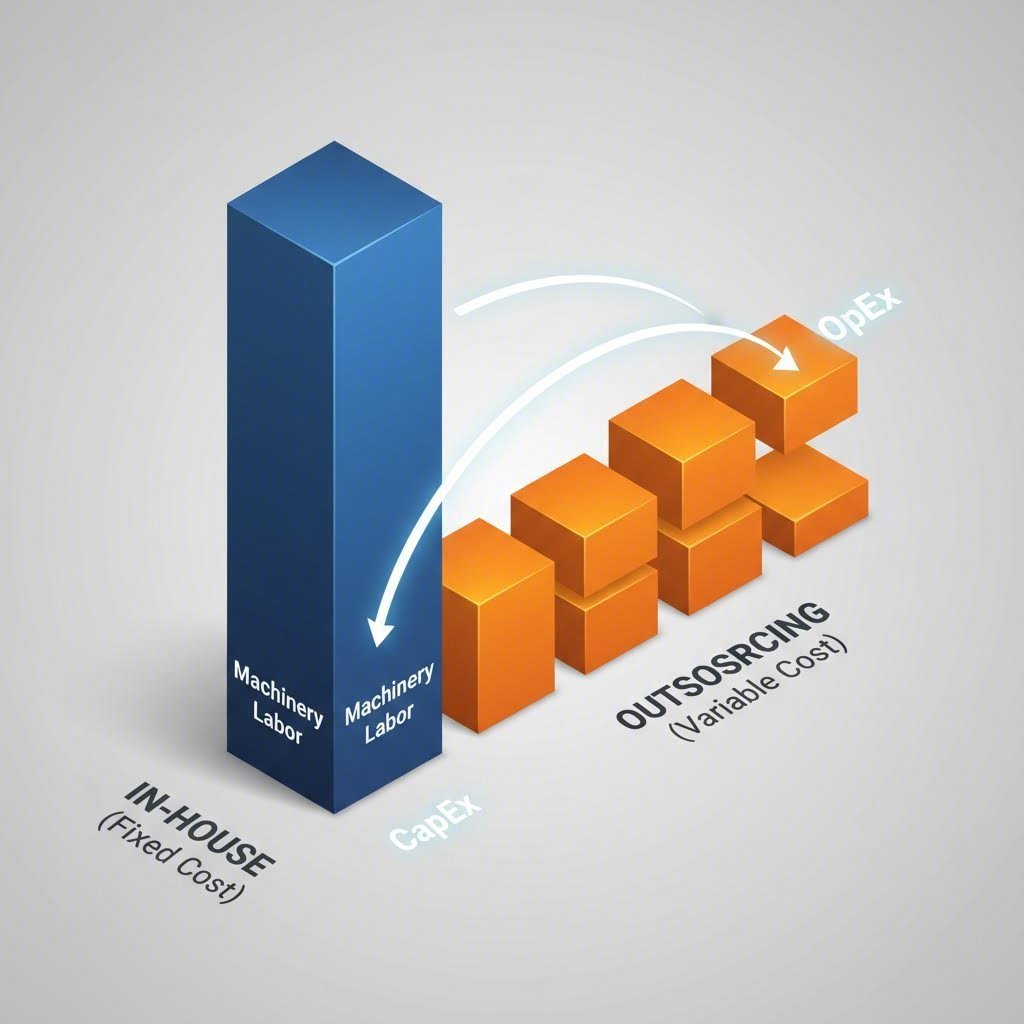

Financial Shift: From CapEx to OpEx

The most immediate impact of outsourcing is the shift from a fixed-cost model to a variable-cost model. Setting up an internal stamping line requires massive Capital Expenditure (CapEx). You are not just buying a press; you are funding:

- Heavy Machinery: High-tonnage presses cost hundreds of thousands to millions of dollars.

- Infrastructure: Reinforced concrete foundations, noise vibration control, and high-voltage power systems.

- Ancillary Equipment: Coil feeders, straighteners, and scrap handling systems.

By outsourcing, these become the supplier's sunk costs. You pay a per-part price (Operational Expenditure or OpEx), freeing up capital for R&D, marketing, and sales—areas that directly drive revenue growth.

Access to Specialized Expertise and Capacity

Metal stamping is a nuanced science involving metallurgy, die design, and lubricant tribology. A generalist manufacturer may struggle with complex geometries or high-strength steel alloys. specialized stamping houses possess the engineering depth to solve these problems efficiently.

Partnering with a dedicated specialist allows access to high-tonnage capabilities and industry certifications without the investment. For instance, suppliers like Shaoyi Metal Technology offer IATF 16949-certified automotive stamping and press capacities up to 600 tons, enabling manufacturers to scale from prototypes to mass production without buying a single machine. This access to advanced equipment ensures you can meet rigorous OEM standards immediately.

Risk Transfer: Safety and Labor

Stamping presses are inherently dangerous, involving high-speed automated movements and immense force. Operating an in-house line introduces significant liability and safety compliance costs (OSHA regulations, insurance premiums). Outsourcing transfers this operational risk to the vendor. Additionally, it insulates your company from the skilled labor shortage. Finding experienced tool and die makers is increasingly difficult; outsourcing shifts the burden of recruitment, training, and retention to your partner.

The Risks & Hidden Costs of Outsourcing

While the financial argument is strong, the operational reality of metal stamping outsourcing pros cons includes significant risks, particularly when sourcing offshore or selecting the wrong partner. A lower per-part price can quickly be negated by hidden costs and friction.

Loss of Control and Supply Chain Vulnerability

When you outsource, you surrender direct control over production scheduling. Your urgent order is one of many in the supplier's queue. If a larger customer demands capacity, your lead times may suffer. Furthermore, you become dependent on the supplier's financial health; a vendor bankruptcy can abruptly sever your supply chain, leaving you without parts or tooling.

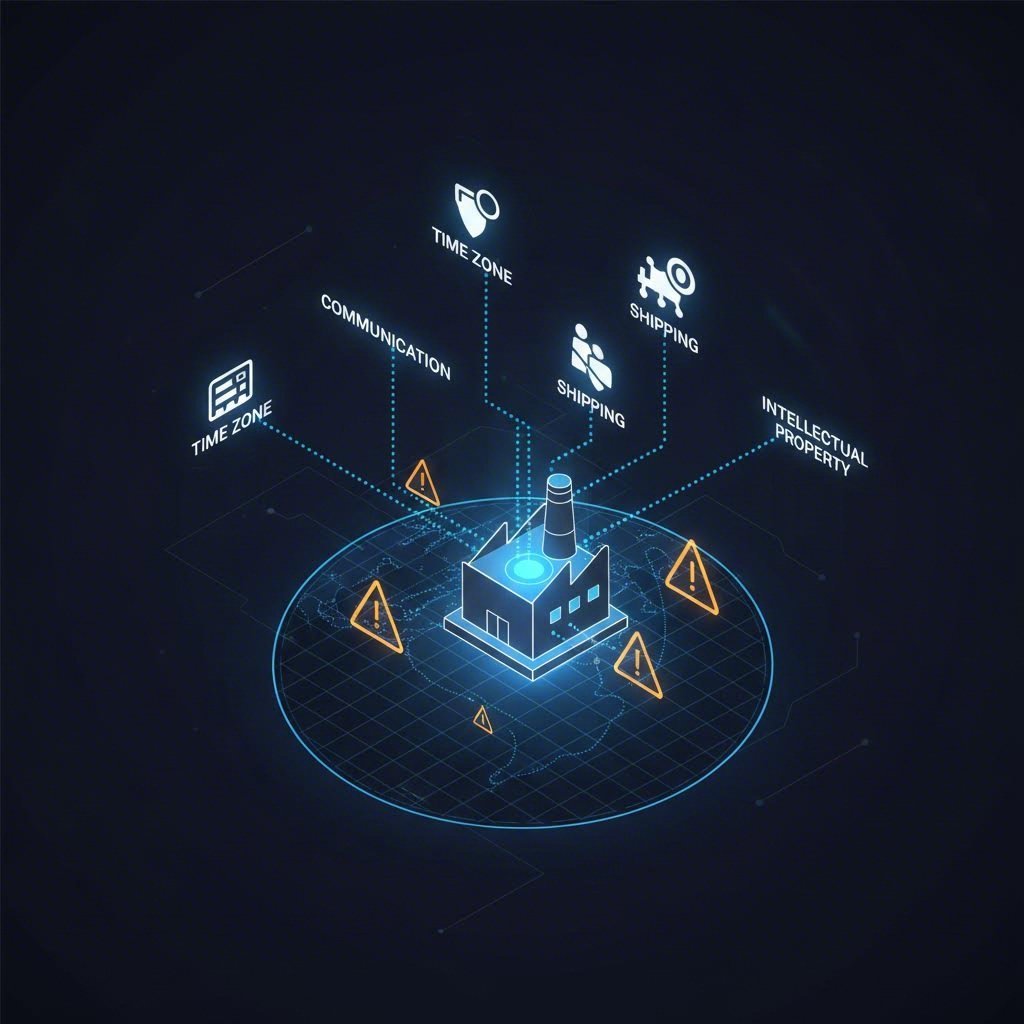

The "Offshore" Factor: Specific Challenges

Sourcing from overseas markets (e.g., Asia to the US/EU) adds distinct layers of complexity that often go uncalculated in the initial quote:

- Communication Breakdowns: Technical nuances can be lost in translation, leading to batches of parts that miss tolerance specifications.

- Time Zone Lags: A simple engineering query can take 24–48 hours to resolve due to lack of working hour overlap, slowing down iteration cycles.

- Logistics and Inventory: Long shipping times require you to hold higher safety stock (inventory carrying costs) to buffer against port delays or customs holds.

- Intellectual Property (IP) Risk: Patent protection varies by jurisdiction. In some regions, your tooling designs or production methods may not be legally protected, exposing your proprietary technology to theft or replication.

Quality Control at a Distance

Monitoring quality becomes exponentially harder as distance increases. An in-house quality manager can walk to the press and stop a defective run immediately. With an outsourced vendor, you may not discover a defect until thousands of faulty units arrive at your dock. Rectifying this requires expensive air freight for replacements and sorting fees, potentially stalling your assembly line.

The Case for In-House Stamping: When It Makes Sense

Despite the high costs, keeping metal stamping in-house is the correct strategy for specific business models. It offers intangible benefits that pure accountants might miss but engineers value highly.

Maximum Agility and Prototyping Speed

If your product is in a rapid iteration phase, in-house capabilities are unbeatable. You can stamp a part, test it, modify the tool, and stamp again in a single afternoon. Outsourcing this process could take weeks of shipping samples back and forth. For R&D-heavy companies, this speed to market is a competitive advantage that outweighs the equipment cost.

Total IP Protection

For defense contractors, aerospace firms, or innovators with trade secrets, the only way to guarantee 100% IP security is to keep the data and production within your own four walls. In-house production eliminates the risk of blueprints leaking to competitors or third-party vendors.

Volume Economics for Stable Products

For products with massive, predictable volumes (e.g., millions of units annually for 5+ years), the math often flips back to in-house production. Once the equipment is amortized, the variable cost of producing internally is often lower than a vendor's price, which includes their profit margin, shipping, and overhead. If you have the volume to run a press 24/7, owning the line yields the highest long-term ROI.

Critical Decision Factors: A Comparative Checklist

To make the final call, map your specific needs against this decision matrix. There is no one-size-fits-all answer; the right choice depends on your volume, budget, and risk tolerance.

| Factor | In-House Production | Outsourced Manufacturing |

|---|---|---|

| Upfront Investment | High (Machinery, Tooling, Facilities) | Low (Tooling only) |

| Cost Structure | High Fixed Costs, Low Variable Costs | Low Fixed Costs, Medium Variable Costs |

| Scalability | Limited by installed press capacity | High (Flexible across supplier's fleet) |

| Lead Time | Short (Immediate control) | Variable (Shipping + Queue times) |

| Quality Control | Immediate feedback loop | Delayed (Requires rigorous incoming inspection) |

| Maintenance | Internal responsibility (Staff + Spares) | Vendor responsibility |

Go/No-Go Guidance

- Choose Outsourcing if: Your volumes fluctuate, capital is tight, you lack specialized metallurgical expertise, or you need to scale production quickly without construction delays.

- Choose In-House if: You require daily design changes, your IP is highly sensitive, or you have stable, massive volumes that justify the capital depreciation.

Making the Strategic Cut

Ultimately, the decision to outsource metal stamping is not just about the price per part; it is about where your company adds value. If metal forming is a core competency that differentiates your brand, invest in it. If it is merely a step in the supply chain to get to your final product, outsourcing is likely the more efficient path.

Successful outsourcing requires treating the supplier not as a commodity vendor but as a strategic partner. Vet them rigorously for financial stability, quality certifications, and communication protocols. By balancing the metal stamping outsourcing pros cons, you can build a supply chain that is both resilient and cost-effective.

Frequently Asked Questions

1. What are the main disadvantages of metal pressing?

The primary disadvantage of metal pressing (stamping) is the high initial cost of tooling. Creating custom dies requires significant upfront investment and time, meaning there is a "downtime" period before production can begin. Additionally, because of these setup costs, metal pressing is generally not cost-effective for small production runs; other methods like laser cutting or fabrication are often better for low volumes.

2. What are the safety hazards associated with metal stamping?

Metal stamping environments are hazardous due to the use of heavy, high-speed machinery. Risks include severe crush injuries from presses, cuts from the sharp burrs on stamped metal edges, and eye injuries from flying debris or material shearing. High noise levels can also cause hearing damage over time. Outsourcing production shifts these safety liabilities and the need for strict OSHA compliance to the supplier.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —