Mastering Uniform Wall Thickness in Die Casting Design

TL;DR

Designing for uniform wall thickness is a foundational principle in die casting, essential for ensuring molten metal flows correctly, preventing defects, and controlling manufacturing costs. The primary goal is to maintain wall consistency throughout the part. Where thickness variations are unavoidable, they must be gradual to prevent stress concentrations, shrinkage, and porosity, ensuring a structurally sound and reliable final product.

The Critical Importance of Uniformity in Die Casting Design

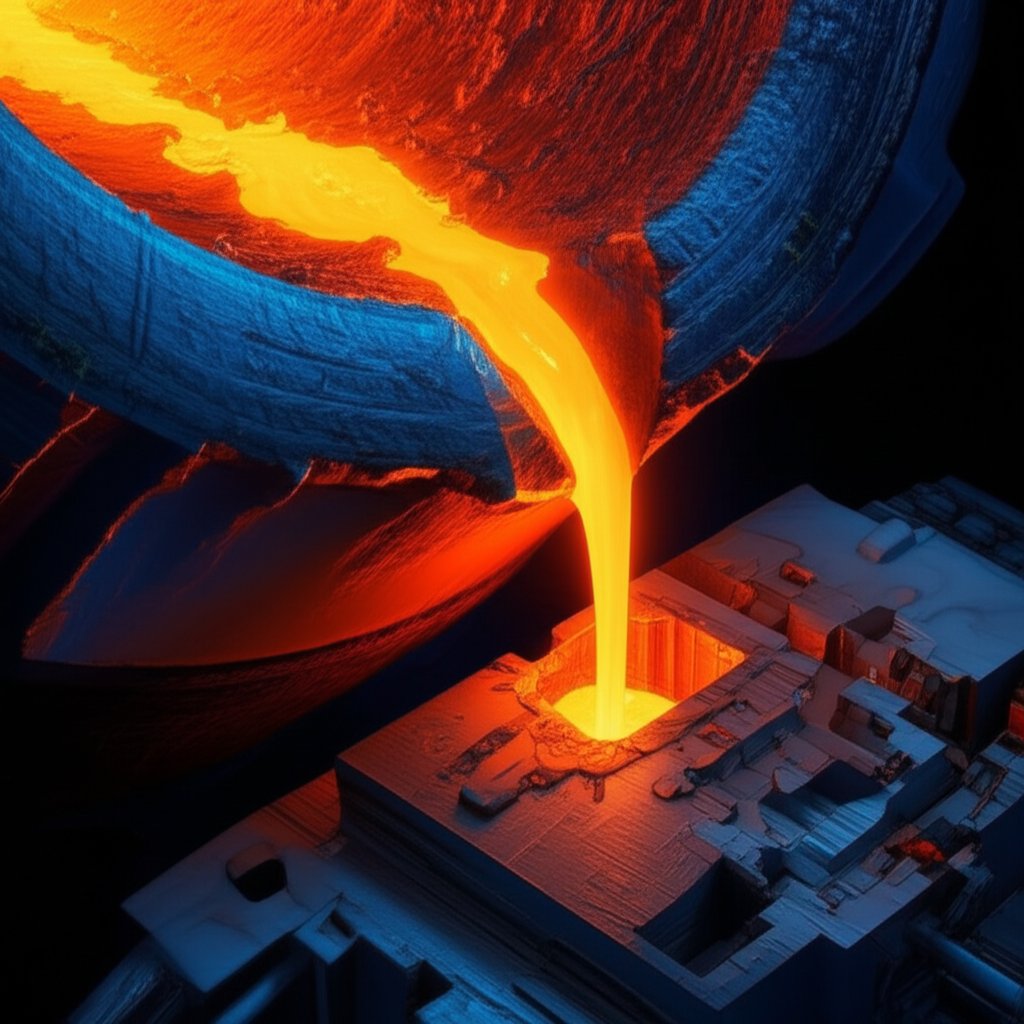

At its core, uniform wall thickness is a fundamental goal in die casting design that dictates the quality, performance, and manufacturability of a component. This principle involves keeping the cross-sectional thickness of a part as consistent as possible. While perfect uniformity is not always achievable, striving for it minimizes a host of production issues rooted in the physics of metal flow and solidification. When molten metal is injected into a die, it must fill the entire cavity before it begins to cool and harden. Consistent wall thickness ensures a smooth, predictable flow path and a controlled cooling rate across the entire part.

Abrupt changes in thickness disrupt this delicate process. Thicker sections act as heat masses, cooling much slower than adjacent thin sections. This differential cooling creates internal stresses, which can lead to warping, dimensional inaccuracies, and even cracks. Furthermore, as the thicker area solidifies, it shrinks and pulls material from the still-molten interior, creating voids known as shrinkage porosity. According to detailed analyses from Sunrise Metal, this is not just a cosmetic issue; it significantly compromises the part's mechanical integrity. In fact, their data shows that the tensile strength of an aluminum alloy can decrease by as much as 30% when wall thickness increases from 2mm to 6mm due to these internal defects.

Conversely, walls that are too thin present their own set of challenges. The molten metal may cool and solidify before completely filling the mold cavity, a defect known as a cold shut. Thin sections can also lead to poor surface finish and are more susceptible to cracking under stress. An ideal design balances the need for structural strength with the realities of the manufacturing process, avoiding the extremes of both thick and thin walls.

To better understand these trade-offs, consider the common defects associated with improper wall thickness:

- Too Thin Walls: Can cause incomplete filling (cold shuts), misruns, cracks, and low overall stiffness. The rapid cooling required for thin walls demands high injection speeds and pressures to ensure the mold is filled completely.

- Too Thick Walls: Often lead to shrinkage porosity, sink marks on the surface, longer cycle times (increasing cost), increased part weight, and reduced tensile strength due to a less dense microstructure upon cooling.

Ultimately, designing for uniformity is about controlling the manufacturing process to produce a predictable, cost-effective, and structurally sound component. As emphasized by casting experts at A&B Die Casting, the goal is to create a part that maximizes function while being produced efficiently with minimal defects and secondary operations.

Recommended Wall Thickness: Data, Materials, and Guidelines

While the principle of uniformity is universal, there are no absolute rules for wall thickness that apply to every project. The optimal thickness is a carefully calculated balance between the alloy being used, the part's size and complexity, and its functional requirements. However, industry best practices and material properties provide reliable guidelines for designers to use as a starting point. The choice of alloy is a primary driver, as different metals have distinct fluidity and cooling characteristics.

For instance, zinc alloys are known for their excellent fluidity, allowing them to fill extremely thin sections reliably. In contrast, aluminum and magnesium alloys require slightly thicker walls to ensure proper flow and prevent premature solidification. As a reference, CEX Casting provides clear benchmarks, noting that zinc can support wall thicknesses of less than 0.5mm, while aluminum is best suited for a range between 1.0mm and 5.0mm. Designing outside these ranges is possible but often requires specialized equipment and process controls, increasing complexity and cost.

The overall size of the part also plays a significant role. Larger parts naturally require thicker walls to maintain structural integrity and to facilitate metal flow over greater distances. The table below, synthesizing data from multiple industry sources, offers general recommendations based on the part's surface area and alloy type.

| Surface Area (cm²) | Aluminum Alloys | Zinc Alloys | Magnesium Alloys |

|---|---|---|---|

| ≤25 | 1.0 - 4.5 | 0.8 - 4.5 | 1.0 - 4.5 |

| >25-100 | 1.5 - 4.5 | 0.8 - 4.5 | 1.5 - 4.5 |

| >100-400 | 1.5 - 6.0 | 1.5 - 4.5 | 2.0 - 6.0 |

It is critical to understand that these figures are guidelines, not limitations. High-technology equipment can produce castings with dimensions that were previously impossible. However, pushing these limits should only be done when necessary to achieve a specific performance or economic advantage. For most applications, adhering to these established ranges will result in a more robust and manufacturable design. Always consult with your die casting partner to align your design with their specific capabilities and material expertise.

Core Design Strategies for Achieving Wall Thickness Uniformity

Achieving near-uniform wall thickness, especially in complex geometries, relies on a set of proven design strategies. These techniques help maintain structural integrity and manufacturability without simply adding mass, which can introduce defects and increase costs. By intelligently incorporating features like ribs, bosses, fillets, and coring, designers can create strong, lightweight, and high-quality die-cast parts.

1. Use Ribs and Gussets for Reinforcement

Instead of thickening an entire wall to increase strength or stiffness, it is far more effective to add ribs. Ribs provide support and rigidity while using minimal material, which helps maintain a consistent wall thickness and prevents the formation of thick sections prone to porosity. To be effective and avoid causing other defects, ribs must be designed correctly. A key guideline is to make the rib thickness approximately 0.5 to 0.7 times the thickness of the adjacent wall. This ratio, recommended by multiple casting experts, prevents sink marks from appearing on the opposite surface as the rib cools.

2. Implement Smooth Transitions with Fillets and Radii

Perfect uniformity is often impossible, and sections of different thicknesses must be joined. In these cases, abrupt changes are the enemy of good design. Sharp corners create stress concentrations and disrupt the flow of molten metal. The solution is to use generous fillets (inside corners) and radii (outside corners) to create a smooth, gradual transition between sections. This practice, universally advised by sources like the North American Die Casting Association (NADCA), allows the metal to flow more freely and reduces turbulence, minimizing the risk of porosity and cracks. Large radii also distribute stress more evenly across the part, enhancing its durability.

3. Core Out Thick Sections

When a design requires a thick, solid feature for functional reasons (like a mounting hub), it creates a mass of material that will cool slowly and cause shrinkage defects. The best practice here is to core out the section, removing unnecessary material from the interior to create a more uniform wall. This can be achieved by designing holes or hollows into the feature. Coring not only eliminates the risk of porosity but also reduces part weight and material cost without compromising the intended function of the feature.

4. Design Bosses Intelligently

Bosses, which are used as mounting points or stand-offs, are common features that can create thick sections. When designing bosses, it is important to blend them into the main wall with fillets and to core them out if they are large. They should also be connected to the nearest wall to avoid creating isolated hot spots in the die. Following these principles ensures that bosses are strong and functional without disrupting the overall thermal balance of the casting.

Advanced Considerations: Process Parameters and Managing Deviations

Even the most meticulously designed part depends on a well-controlled manufacturing process for success. The reality of complex engineering is that perfect wall uniformity is not always feasible. In these instances, success hinges on the interplay between smart design compromises and optimized die casting process parameters. Understanding these manufacturing variables allows designers to create parts that are not only theoretically sound but also practically manufacturable.

Key process parameters have a direct impact on the ability to fill thin-walled sections and ensure the integrity of thicker areas. For thin-walled designs (typically under 1.5mm), very high injection pressures and speeds are necessary. The molten metal must be forced into the cavity quickly before it has a chance to solidify. As detailed in technical guides, this can require a gate velocity exceeding 40 m/s and a filling time of less than 0.05 seconds. This aggressive process ensures that even the most intricate and thin sections of the mold are completely filled.

Managing deviations from uniformity is a balancing act. When a design must include a thicker section, its negative effects can be mitigated through careful mold design, including the strategic placement of cooling channels to draw heat away from the area more quickly. This helps equalize the solidification rate across the part, reducing the risk of shrinkage and porosity. The goal is to control the process to compensate for the necessary imperfections in the design.

Collaborating with a knowledgeable manufacturing partner is crucial for navigating these complexities, especially for demanding applications in sectors like automotive or aerospace. For instance, specialists in high-performance metal components bring deep expertise in process control and material science for precision parts. When preparing for production, it is vital to have a detailed discussion with your die caster. Use the following checklist to guide your conversation:

- Machine Capabilities: Confirm that their machines have the necessary clamping force, injection speed, and pressure controls for your part's specific geometry and wall thickness.

- Mold Design: Discuss their approach to gating, runner systems, venting, and cooling channels to ensure they can manage your part's unique thermal profile.

- Alloy Selection: Verify that the chosen alloy's fluidity and thermal properties are a good match for the design's thinnest sections and overall complexity.

- Simulation: Ask if they use mold-flow analysis software to predict and resolve potential filling or cooling issues before the tool is built, saving time and cost.

By considering both design principles and manufacturing realities, engineers can create robust, high-quality die-cast components that successfully meet both performance and production requirements.

Key Principles for Successful Die Casting Design

Mastering the design of die-cast components boils down to a few critical principles centered on controlling the flow and solidification of molten metal. By prioritizing uniform wall thickness, you lay the foundation for a part that is strong, lightweight, and free from costly defects. Where perfect uniformity isn't possible, the strategic use of smooth transitions, reinforcing ribs, and coring techniques allows you to manage variations effectively. Remember that every design choice has a direct impact on manufacturability, cost, and the final quality of the product. Successful design is not just about creating a functional shape; it's about creating a shape that is optimized for the die casting process itself. This holistic approach, combining thoughtful design with a deep understanding of manufacturing parameters, is the key to producing exceptional die-cast parts.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —