Mastering High-Volume Forging: Ensuring Consistency

TL;DR

Ensuring consistency in high-volume forging hinges on the rigorous control of key manufacturing variables. Repeatable quality is achieved through a combination of four essential pillars: stringent material selection, precise temperature management, robotic automation for procedural uniformity, and comprehensive quality control measures to prevent defects. Mastering these elements is critical for producing reliable, high-performance components at scale.

The Core Pillars of Forging Consistency

Achieving repeatable quality in high-volume forging is not a matter of chance but the result of a systematic approach built on several foundational pillars. Each element plays a crucial role in the final product's integrity, performance, and adherence to specifications. From the initial raw material to the final shape, controlling these variables is paramount for manufacturers in demanding sectors like automotive and aerospace.

It all begins with material selection. The chemical composition and internal structure of the initial steel, aluminum, or titanium alloy billet set the stage for the entire process. As detailed by experts at Cast & Alloys, using high-quality, uniform materials from reputable suppliers is a non-negotiable first step. Inconsistent alloying elements or internal flaws in the raw material can lead to unpredictable behavior under pressure and heat, resulting in defects and compromised mechanical properties. Therefore, a robust supply chain and rigorous incoming material inspection are critical for a stable production line.

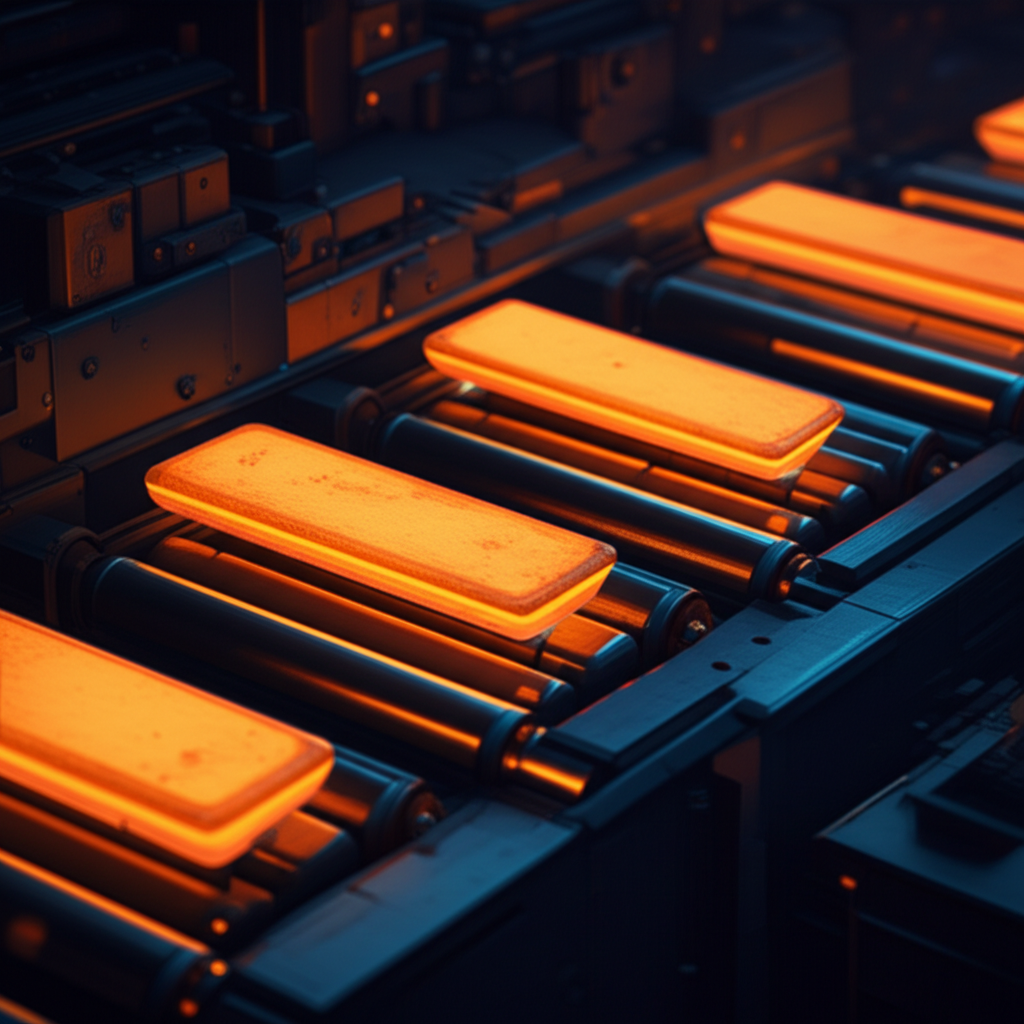

Equally important is precise temperature control. The temperature at which a metal is forged directly influences its malleability, grain structure, and final strength. Heating the billet too little results in poor material flow and potential damage to the forging dies, while overheating can cause undesirable grain growth or oxidation. Modern forging lines often use induction heating, which provides rapid, uniform, and controllable heat, ensuring each billet enters the die at the optimal forging temperature. This precision prevents defects like cracks and ensures the desired metallurgical properties are achieved consistently across thousands of parts.

The third pillar is optimized die design and maintenance. The die is the heart of the forging process, shaping the heated metal into its final form. A well-designed die, often created using computer-aided design (CAD) and finite element analysis (FEA), ensures smooth and uniform material flow. As highlighted in forging design considerations, elements like draft angles—slight slopes on the die walls—are essential for easy part removal without causing damage. Regular die maintenance is also crucial, as wear and tear can lead to dimensional inaccuracies. Proactive inspection, polishing, and refurbishment of dies are necessary to maintain tight tolerances over long production runs.

Leveraging Automation and Technology in High-Volume Production

In the context of high-volume production, minimizing human error and maximizing repeatability are essential for ensuring consistency. This is where automation and advanced technology become indispensable. Modern forging facilities increasingly rely on robotics and computer-controlled systems to execute repetitive tasks with a level of precision and endurance that is impossible to achieve manually. This technological integration is a key differentiator for industry leaders.

Robotic automation is a cornerstone of consistent high-volume forging. As noted by Southwest Steel Processing, equipping forging lines with material handling robots ensures repeatable and consistent quality. These automated systems are responsible for loading raw billets into heaters, transferring them between forging stations, and placing finished parts on cooling conveyors. By automating these movements, manufacturers can guarantee that every part follows the exact same process path and timing, eliminating variations that could affect temperature, material flow, and final dimensions. This leads to decreased dimensional variation and a significant increase in overall productivity.

The benefits of automation extend beyond just consistency. It significantly improves cycle times, allowing for higher output—sometimes up to 2,000 parts per day on a single line. Furthermore, it enhances workplace safety by removing human operators from the immediate vicinity of extreme heat and immense mechanical pressures. For industries like automotive manufacturing, where millions of identical, high-performance components are needed, this level of efficiency and reliability is crucial. For companies seeking robust and reliable components, specialized services are available. For instance, for robust and reliable automotive components, check out the custom forging services from Shaoyi Metal Technology. They specialize in high-quality, IATF16949 certified hot forging for the automotive industry, offering everything from rapid prototyping to full-scale mass production with in-house die manufacturing.

Beyond robotics, process monitoring and control systems are vital. Advanced sensors and data acquisition systems track key parameters like temperature, pressure, and deformation rates in real time. This data allows for immediate adjustments, ensuring the process remains within its designated control limits. This smart manufacturing approach, a tenet of Industry 4.0, transforms forging from a reactive to a proactive process, where potential deviations are corrected before they can result in defective parts.

Critical Quality Control Measures and Defect Prevention

While process controls are designed to ensure consistency, a robust quality control (QC) framework is essential to verify the outcome and prevent defects from reaching the customer. In high-volume forging, where even a small error rate can result in thousands of faulty parts, QC is not just a final step but an integrated part of the entire production process. Its importance is underscored by industry experts like Starpath Rail, who state that quality control is of the utmost importance for reliability.

Effective QC in forging employs a multi-layered approach. It begins with in-process checks, such as monitoring forging temperatures and press tonnage. This is followed by a variety of post-forging inspection methods. Visual inspection is the first line of defense, but for critical components, non-destructive testing (NDT) is employed to detect internal flaws. Common NDT methods include ultrasonic testing to find internal cracks and magnetic particle inspection for surface-level discontinuities in ferrous materials. Dimensional analysis using coordinate measuring machines (CMM) is used to ensure parts meet tight tolerances.

Understanding common forging defects is crucial for preventing them. Some of the most frequent issues include:

- Unfilled Section: This occurs when the metal does not completely fill the die cavity, often due to insufficient material volume or improper heating.

- Cold Shut: A defect where two streams of metal fail to fuse properly in the die, creating a weak spot. It is typically caused by low forging temperatures or poor die design that restricts metal flow.

- Surface Cracking: This can result from excessive stress during forging or from cooling the part too rapidly. The material's composition and temperature play a significant role.

- Die Shift: A misalignment of the upper and lower dies, resulting in a mismatched part where the two halves do not line up correctly.

Preventing these defects ties directly back to the core pillars of consistency. For example, precise temperature control and optimized die design are the primary countermeasures against cold shuts and unfilled sections. Strict die maintenance prevents die shift, while controlled cooling cycles, often part of post-forging heat treatment, mitigate the risk of surface cracking. By linking specific QC outcomes to process parameters, manufacturers can engage in continuous improvement, refining their operations to achieve near-zero defect rates.

The Impact of Forging Design on Consistency and Machinability

Long before the first piece of metal is heated, consistency in high-volume forging begins at the design stage. The principle of Design for Manufacturability (DFM) is critical, as choices made on the blueprint directly influence the efficiency, repeatability, and cost-effectiveness of the entire production run. A part that is designed with the forging process in mind will not only be stronger and more reliable but also easier to produce consistently and machine later.

According to insights from Presrite, an experienced engineer can design the process to ensure that grain flow, microstructures, and final mechanical properties create consistently stronger parts. The grain flow—the internal alignment of the metal's crystalline structure—is a unique advantage of forging. When designed correctly, the grain flow follows the contours of the part, creating superior strength and fatigue resistance at critical stress points. This is a significant advantage over casting (which has no grain flow) or machining from bar stock (which has a unidirectional grain flow that gets cut).

Several key design considerations directly impact forging consistency and subsequent machining. Among the essential best practices for forging success, as outlined by experts at Frigate, are:

- Generous Radii and Fillets: Sharp internal corners are difficult to fill with flowing metal and create stress concentrations in the final part. Designing with smooth, rounded corners facilitates better material flow and results in a stronger, more durable component.

- Proper Draft Angles: As mentioned earlier, incorporating a slight taper on vertical surfaces is crucial for allowing the forged part to be easily removed from the die. This simple design feature prevents damage to both the part and the tool, ensuring consistency.

- Consistent Wall Thickness: Abrupt changes in section thickness can impede material flow and cause defects. Where possible, designs should aim for uniform wall thickness to promote even cooling and reduce the risk of internal stresses.

- Minimize Machining Allowances: A well-designed forging is a near-net shape, meaning it is very close to the final dimensions. This minimizes the amount of material that needs to be removed through machining, which saves time, reduces waste, and lowers costs.

Ultimately, a collaborative approach between part designers and forging engineers is the most effective strategy. By considering the capabilities and limitations of the forging process early on, companies can develop components that are optimized for high-volume production, ensuring that consistency, strength, and cost-efficiency are built in from the very beginning.

Frequently Asked Questions

1. What are the 4 types of forging processes?

The four main types of forging processes are impression die forging (or closed-die forging), open-die forging, cold forging, and seamless rolled ring forging. Each method is suited for different part sizes, complexities, and production volumes.

2. Why is forging often done at high temperatures?

Forging high-strength materials like steel is usually done at elevated temperatures because the heat makes the metal more malleable and ductile. This allows it to be shaped with less force and enables the creation of more complex geometries that would be difficult or impossible to form when the metal is cold.

3. What are some common defects that can occur during the forging process?

Common forging defects include unfilled sections, where the metal fails to fill the die cavity; cold shuts, where metal streams don't fuse properly; scale pits from surface oxidation; die shift due to misalignment; and surface cracking caused by temperature issues or stress. These are typically prevented through careful process control.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —