Magnetic Aluminum Or Not? Reliable Home And Lab Tests Inside

Magnetic Aluminum Basics

Is aluminum magnetic explained

Have you ever tried sticking a fridge magnet to an aluminum pan and wondered why it slides right off? Or maybe you’ve seen a video where a magnet seems to float slowly through an aluminum tube. These real-life puzzles get to the heart of a common question: is aluminum magnetic?

Let’s set the record straight. Pure aluminum is not magnetic in the way iron or steel is. Technically, aluminum is classified as a paramagnetic material. This means it only shows a very weak, temporary response to magnetic fields—so faint you’ll never notice it in daily life. You won’t see an aluminum magnet sticking to your baking sheets, nor will a standard magnet cling to your aluminum window frame. But there’s more to the story, and it’s worth understanding why.

When magnets seem to stick to aluminum

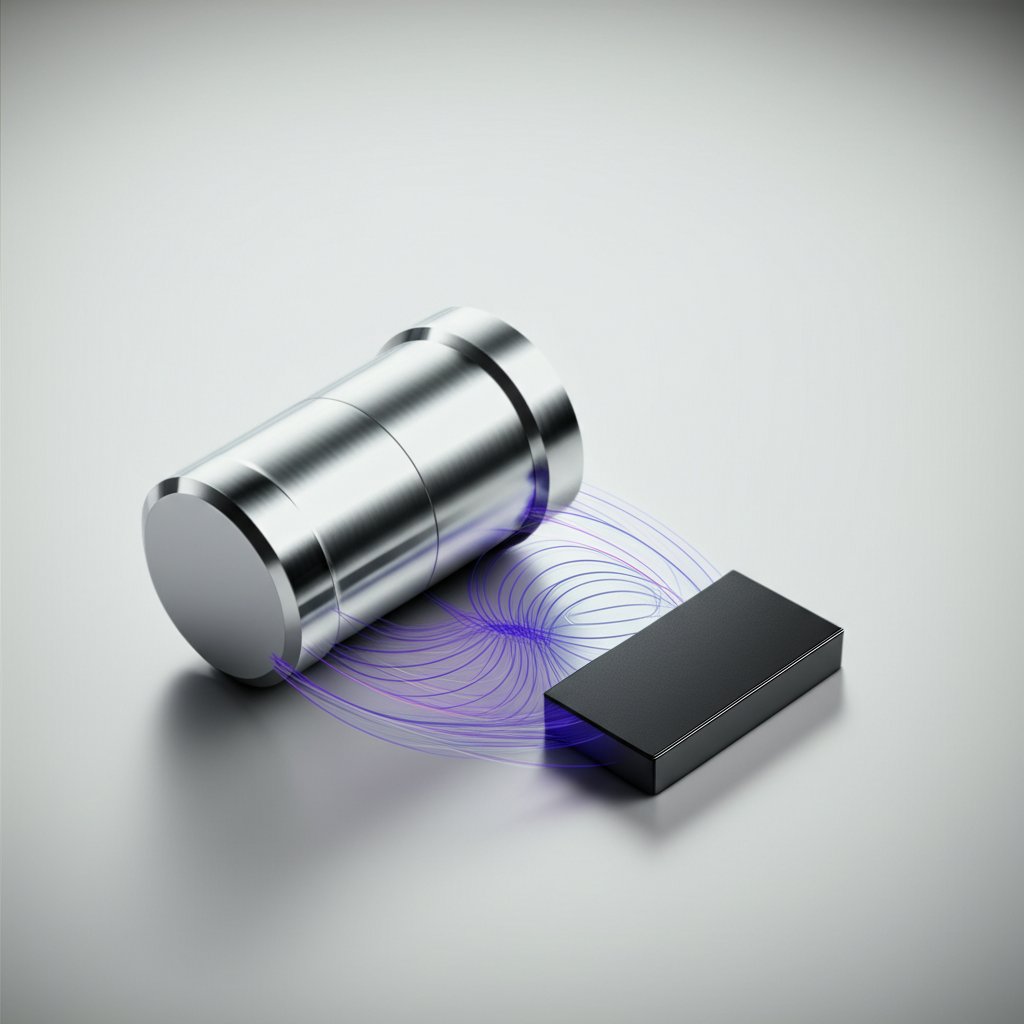

So, why do some magnets move strangely around aluminum, or even appear to slow down as they pass through it? This is where the physics gets interesting. When a magnet moves near aluminum, it creates swirling electrical currents in the metal—called eddy currents. These currents, in turn, create their own magnetic fields that oppose the movement of the magnet. The result? A drag force that can slow the magnet down, but not attract it. That’s why a magnet falls slowly through an aluminum tube, but if you just hold the magnet against an aluminum surface, nothing happens. If you’re asking, will magnets stick to aluminum, the answer is no—but they can interact in motion.

Common myths about magnetic aluminum

-

Myth: All metals are magnetic.

Fact: Many metals, including aluminum, copper, and gold, are not magnetic in the traditional sense. -

Myth: Aluminum can be magnetized like iron.

Fact: Aluminum cannot retain magnetization and does not become a permanent magnet. -

Myth: If a magnet drags or slows on aluminum, it’s sticking.

Fact: Any resistance you feel is from eddy currents, not magnetic attraction. -

Myth: Aluminum foil can block all magnetic fields.

Fact: Aluminum can shield some electromagnetic waves, but not static magnetic fields.

Why this matters for design and safety

Understanding magnetic aluminum is more than a science curiosity—it shapes real engineering decisions. For example, in automotive electronics, using non-magnetic aluminum helps prevent interference with sensitive sensors and circuits. In recycling plants, eddy currents in aluminum are used to separate cans from other materials. Even in product design, knowing that do magnets stick to aluminum (they don’t) can impact choices for mounting, shielding, or sensor placement.

When designing with aluminum extrusions—such as for electric vehicle battery enclosures or sensor housings—it’s crucial to consider both the non-magnetic nature of aluminum and its ability to interact with moving magnetic fields. For automotive projects, working with a specialized supplier like Shaoyi Metal Parts Supplier can make a difference. Their expertise in aluminum extrusion parts ensures your designs account for both structural and electromagnetic requirements, especially when precise sensor placement and EMI shielding are priorities.

Aluminum is not ferromagnetic, but it does interact with magnetic fields through weak paramagnetism and eddy currents.

In summary, if you’re searching for a clear answer to “is aluminium magnetic,” remember: pure aluminum will not stick to a magnet, but it can interact with magnetic fields in unique ways. This distinction is at the core of countless design, safety, and manufacturing choices, from your kitchen to advanced automotive systems.

Why Aluminum Doesn’t Act Like Iron Near Magnets

Ferromagnetic versus paramagnetic materials

Ever tried to stick a magnet to an aluminum soda can and wondered why nothing happens? Or noticed that iron tools snap to a magnet, but your aluminum ladder doesn’t budge? The answer lies in the fundamental difference between ferromagnetic and paramagnetic materials.

- Ferromagnetic materials (like iron, steel, and nickel) have regions where their electrons’ spins align, creating strong, permanent magnetic fields. This alignment allows them to be powerfully attracted to magnets—and to become magnets themselves.

- Paramagnetic materials (like aluminum) have unpaired electrons, but their spins only align weakly and temporarily with an external magnetic field. The effect is so slight you’ll never feel it in everyday life.

- Diamagnetic materials (such as copper and gold) actually repel magnetic fields, but this effect is even weaker than paramagnetism.

So, is aluminum paramagnetic? Yes—but the effect is so faint that aluminum is not magnetic in any practical sense. That’s why aluminum is not magnetic like steel or iron.

Why aluminum is not magnetic like steel

Let’s dig deeper: why isn’t aluminum magnetic in the way steel is? It comes down to atomic structure. Ferromagnetic materials have “magnetic domains” that remain aligned even after a magnetic field is removed, allowing them to stick to magnets. Aluminum lacks these domains. When you bring a magnet close to aluminum, you might get a barely detectable, temporary alignment of electrons—but as soon as you pull the magnet away, the effect vanishes.

This is why is aluminum ferromagnetic has a clear answer: no, it’s not. Aluminum doesn’t retain magnetization, nor does it display any significant attraction to a magnet under normal conditions.

Role of magnetic permeability

Another way to understand this is through magnetic permeability. This property describes how well a material can “conduct” magnetic field lines. Ferromagnetic materials have high permeability, which is why they concentrate and amplify magnetic fields. The magnetic permeability of aluminum is nearly the same as air—very close to one. This means aluminum does not concentrate or amplify magnetic fields, so it doesn’t behave like a typical “magnetic” metal.

| Phenomenon | What you’ll observe with aluminum |

|---|---|

| Attraction (magnet sticks) | No attraction—aluminum is not magnetic, so magnets won’t stick to it |

| Drag (motion slows) | When a magnet moves past or through aluminum, you’ll notice a slow-down due to eddy currents, not magnetic attraction |

| Shielding (blocks fields) | Aluminum can shield some electromagnetic waves, but not static magnetic fields—its effect is limited compared to steel |

Eddy currents explain apparent magnetic effects

But what about those times when a magnet seems to “float” or slow down near aluminum? This is where eddy currents come in. When a magnet moves past aluminum, it induces swirling electrical currents in the metal. These currents create their own magnetic fields, which oppose the motion of the magnet. The result is a resistive force—drag—not attraction. This is why aluminum is not magnetic, but can still interact with moving magnets in surprising ways.

The strength of this effect depends on:

- Conductivity: Aluminum’s high electrical conductivity makes eddy currents strong enough to notice.

- Thickness: Thicker aluminum produces more drag, as there’s more metal for currents to flow through.

- Magnet speed: Faster motion creates stronger eddy currents and more noticeable drag.

- Air gap: A smaller gap between magnet and aluminum increases the effect.

But remember: this is not magnetic attraction—aluminum is not magnetic in the way most people expect.

Temperature effects on aluminum magnetic response

Does temperature change anything? Temperature changes slightly affect aluminum's paramagnetism. According to Curie's law, the magnetic susceptibility of a paramagnetic material is inversely proportional to the absolute temperature. Therefore, increasing temperature generally weakens its weak paramagnetism. However, aluminum does not exhibit ferromagnetism at any practical temperature.

In summary, why is aluminum not magnetic? Because it’s paramagnetic, with a magnetic permeability near unity—so weak you’ll never see a magnet stick to it. Yet, its conductivity means you’ll notice drag from eddy currents when magnets move nearby. This is crucial knowledge for engineers and designers working with sensors, EMI shielding, or sorting systems.

If it’s stationary and there’s no changing field, aluminum shows almost no effect; when fields change, eddy currents create drag, not attraction.

Next, let’s see how these principles translate into reliable home and lab tests for magnetic response—so you can be sure what you’re working with, every time.

Reliable Tests for Magnetic Response at Home and in Labs

Simple consumer magnet test protocol

Ever wondered, "does a magnet stick to aluminum" or "can a magnet stick to aluminum"? Here’s an easy way to find out for yourself. This at-home test is quick, requires no special equipment, and helps eliminate confusion caused by contamination or coatings.

- Gather your tools: Use a strong neodymium magnet and a clean aluminum object (like a soda can or foil).

- Clean the surface: Wipe the aluminum thoroughly to remove dust, grease, or any metallic debris. Even a tiny steel shaving can give a false result.

- Check your magnet: Test your magnet on a known ferromagnetic object (like a steel spoon) to confirm it’s working. This baseline ensures your magnet is strong enough for the test.

- Remove fasteners and coatings: If the aluminum piece has screws, rivets, or visible coatings, remove them or test on a bare spot. Paint or adhesives can dull the feel of the test.

- Test for static attraction: Gently place the magnet against the aluminum. You should feel no pull and the magnet will not stick. If you notice any attraction, suspect contamination or non-aluminum parts.

- Test for drag: Slide the magnet slowly across the aluminum surface. You may feel a faint resistance—this is not attraction, but the effect of eddy currents. It’s a subtle drag that only occurs when the magnet is moving.

Outcome: In everyday conditions, "does magnets stick to aluminum" or "will aluminum stick to a magnet"? The answer is no—unless the object is contaminated or contains hidden ferromagnetic parts.

Lab-grade Hall or gauss meter measurement

For engineers and quality teams, a more scientific approach helps document results and avoid ambiguity. Lab-grade protocols can confirm that aluminum is not magnetic in the traditional sense, but can interact with magnetic fields dynamically.

- Sample preparation: Cut or select a flat aluminum coupon with clean, deburred edges. Avoid areas near fasteners or welds.

- Instrument setup: Zero your Hall or gauss meter. Verify calibration by measuring a known reference magnet and background field.

- Static measurement: Place the probe in direct contact with the aluminum, then at 1–5 mm above the surface. Record readings for both positions.

- Dynamic test: Move a strong magnet past the aluminum (or use an AC coil to create a changing field) and observe any induced response on the meter. Note: Any signal should be extremely weak and only present during motion.

- Document results: Fill out a table with setup details, conditions, readings, and notes for each test.

| Setup | Conditions | Readings | Notes |

|---|---|---|---|

| Static, direct contact | Aluminum coupon, probe touching | (Insert reading) | No attraction or field change |

| Static, 5 mm gap | Probe 5 mm above | (Insert reading) | Same as background |

| Dynamic, magnet moving | Magnet slid across surface | (Insert reading) | Transient signal from eddy currents |

Eliminating contamination and false positives

Why do some people report that magnets stick to aluminum? Often, it’s due to contamination or hidden ferromagnetic components. Here’s how to avoid misleading results:

- Use adhesive tape to remove steel swarf or filings from the aluminum surface.

- Demagnetize tools before testing to prevent stray particles from transferring.

- Repeat tests after cleaning. If the magnet still sticks, inspect for embedded fasteners, bushings, or plated areas.

- Always test on multiple areas—especially away from joints, welds, or coated zones.

Remember: Paint layers, adhesives, or even fingerprints can affect how the magnet slides, but these do not create real magnetic attraction. If you ever find that "will magnet stick to aluminum" or "do magnets stick on aluminum" in your tests, double-check for non-aluminum parts or contamination first.

Static attraction indicates contamination or non-aluminum parts—aluminum itself should not ‘stick.’

By following these protocols, you’ll reliably answer whether "do magnets work on aluminum"—they don’t stick, but you may feel a subtle drag in motion. Next, we’ll show how these effects become visible through hands-on demonstrations and what they mean for real-world applications.

Demonstrations That Make Aluminum and Magnets Interactions Visible

Falling Magnet in an Aluminum Tube Demo

Ever wondered why a magnet seems to move in slow motion when dropped through an aluminum tube? This simple demonstration is a favorite in physics classrooms and perfectly illustrates how aluminum and magnets interact—not by attraction, but through something called eddy currents. If you’ve ever asked, “does aluminum attract magnets” or “can magnets attract aluminum,” this hands-on test will clear things up.

- Gather your materials: You’ll need a long, clean aluminum tube (with no steel or magnetic inserts) and a strong magnet (like a neodymium cylinder). For comparison, also have a similar-sized non-magnetic object, such as an aluminum rod or a coin.

- Set up the tube: Hold the tube vertically, either by hand or propped securely so nothing blocks the ends.

- Drop the non-magnetic object: Let the aluminum rod or coin fall through the tube. It should drop straight down, hitting the bottom almost instantly under gravity.

- Drop the magnet: Now, drop the strong magnet into the same tube. Watch closely as it descends much more slowly, almost floating down the length of the tube.

- Observe and time: Compare the time it takes for each object to exit the tube. The magnet’s slow fall is a direct result of eddy currents in the aluminum, not magnetic attraction.

What to Expect: Slow Versus Fast Motion

Sounds complex? Here’s what’s really happening: As the magnet falls, its magnetic field changes relative to the aluminum tube. This changing field induces swirling electrical currents—eddy currents—in the tube wall. According to Lenz’s Law, these currents flow in such a way that they create their own magnetic field, which opposes the magnet’s motion. The result is a drag force that slows the magnet down. No matter how strong your magnet is, you won’t get a magnet that sticks to aluminum—you’ll only notice resistance when the magnet is moving.

If you’re testing this at home or in a lab, keep an eye out for these outcomes:

- The magnet falls slowly, while the non-magnetic object drops quickly.

- No static attraction—magnets that stick to aluminum simply don’t exist in this context.

- The drag effect is more noticeable with thicker tube walls or a tighter fit between the magnet and tube.

If your magnet drops at normal speed, check these troubleshooting tips:

- Is the tube really aluminum? Steel or coated tubes won’t show the effect.

- Is the magnet strong enough? Weak magnets may not induce noticeable eddy currents.

- Is there a large air gap? The closer the magnet fits to the tube walls, the stronger the effect.

- Does the tube have a non-conductive coating? Paint or plastic can block current flow.

Eddy currents oppose change, so motion slows without any ‘pull’ toward the aluminum.

Real-World Uses: From Braking to Sorting

This demonstration isn’t just a science trick—it’s the principle behind several important technologies. For example, physics demos show how eddy currents provide non-contact braking in amusement park rides and high-speed trains. In recycling facilities, eddy current separators use rapidly rotating magnetic fields to kick non-ferrous metals like aluminum off conveyor belts, separating them from other materials. The same effect is harnessed in lab equipment for speed sensors and non-contact braking systems.

To recap, if you’re ever asked, “do magnet stick to aluminum” or see a magnet aluminum demonstration, remember: the interaction is all about motion and induced currents, not magnetic attraction. This knowledge is essential for engineers designing equipment that involves moving magnetic fields and non-magnetic metals.

- Induction braking: Non-contact, wear-free braking using eddy currents in aluminum discs or rails.

- Non-ferrous sorting: Eddy current separators eject aluminum and copper from waste streams.

- Speed sensing: Conductive shields and plates in sensors exploit eddy-current drag for precise measurement.

Understanding these interactions helps you make better choices in material selection and system design. Next, we’ll explore how different aluminum alloys and processing steps can affect apparent magnetic behavior, so you can avoid false positives and ensure reliable results in every application.

How Alloys and Processing Change Apparent Magnetic Behavior

Alloy Families and Expected Responses

When you test a piece of aluminum and unexpectedly notice a magnet sticking—or feel a stronger drag than expected—it’s easy to wonder: can aluminum be magnetized, or is this some special kind of aluminium magnetic effect? The answer almost always comes down to alloying, contamination, or processing—not a fundamental change in the nature of aluminum itself.

Let’s break down the most common alloy families and what you should expect from each:

| Alloy Series | Typical Conductivity | Expected Magnetic Response | Contamination/False Positive Risk |

|---|---|---|---|

| 1xxx (Pure Al) | Very high | Aluminum non magnetic; only faint paramagnetic response | Low, unless surface is contaminated |

| 2xxx (Al-Cu) | Moderate | Still non magnetic aluminum; slightly lower conductivity, but no ferromagnetism | Moderate—may contain iron-rich inclusions if not carefully controlled |

| 5xxx (Al-Mg) | High | Aluminum non magnetic; eddy-current effects similar to pure Al | Low, unless fabricated with steel tooling |

| 6xxx (Al-Mg-Si) | Good | Remains aluminium non magnetic; commonly used in extrusions | Moderate—watch for fastener or insert contamination |

| 7xxx (Al-Zn-Mg) | Moderate | Aluminium magnetic response remains weak (paramagnetic only) | Moderate—possible inclusions or surface residues |

| Specialty alloys (e.g., Alnico, Al-Fe) | Varies | May exhibit strong magnetic behavior, but only due to iron/cobalt content—not true aluminum magnetism | High—these are engineered for magnetic use |

In summary, standard aluminum alloys—even those with magnesium, silicon, or copper—do not become ferromagnetic. Their aluminum magnetism is always weak, and any significant magnetic attraction points to something else at play.

Contamination, Coatings, and Fasteners

Sounds complex? It’s actually a common source of confusion. If a magnet seems to stick to your aluminum part, check for these culprits first:

- Steel or magnetic stainless inserts: Helicoils, bushings, or reinforcement rings can cause local attraction.

- Machining swarf or embedded steel shot: Tiny steel particles left from fabrication can cling to the surface and mislead tests.

- Fasteners: Screws, rivets, or bolts made of steel can create the illusion of a magnetic aluminum part.

- Coatings and platings: Anodized aluminum magnetic behavior is unchanged, but nickel or iron-based platings can add magnetic spots.

- Paints or adhesives: These don’t make the base metal magnetic, but can mask or alter the feel of a sliding magnet test.

Before concluding you have a magnetic aluminum part, always document construction details and inspect thoroughly. In industrial settings, nondestructive inspection systems (like thin film magnetic sensors) are used to identify embedded magnetic contaminants in aluminum castings, ensuring product integrity (MDPI Sensors).

Cold Work, Heat Treatment, and Welding Effects

Processing steps can subtly affect how aluminium is magnetic or non magnetic in tests. Here’s what to watch for:

- Cold working: Rolling, bending, or forming can alter grain structure and conductivity, slightly changing eddy-current strength—but will not make the material ferromagnetic.

- Heat treatment: Alters microstructure and may redistribute alloying elements, with minor effects on paramagnetic response.

- Weld zones: Can introduce inclusions or contamination from steel tools, leading to localized false positives.

Ultimately, if you observe strong magnetic attraction in an area that should be non magnetic aluminum, it’s almost always due to contamination or the presence of non-aluminum parts. True aluminum magnetism remains weak and temporary. Even after significant processing, aluminum non magnetic behavior is preserved unless new ferromagnetic components are introduced.

- Check for visible fasteners or inserts before testing.

- Inspect welds and adjacent areas for embedded steel or tool marks.

- Use adhesive tape to remove surface swarf before magnet tests.

- Document alloy series, coatings, and fabrication steps in quality records.

- Repeat tests on bare, cleaned surfaces and away from joints or coatings.

Aluminum alloys remain non-magnetic, but contamination, coatings, or inserts can create misleading results—always verify before drawing conclusions.

Understanding these details ensures you don’t misclassify aluminium is magnetic or non magnetic behavior in your projects. Next, we’ll dig into the key data and comparisons engineers need when selecting materials for magnetic and non-magnetic environments.

Comparing Aluminum’s Magnetic Properties to Other Metals

Key Parameters for Magnetic Comparisons

When you’re choosing materials for a project involving magnets, the numbers matter. But what exactly should you look for? The main parameters that define whether a metal is magnetic—or how it will behave around magnets—are:

- Magnetic susceptibility (χ): Measures how much a material becomes magnetized in an external field. Positive for paramagnetic, strongly positive for ferromagnetic, and negative for diamagnetic materials.

- Relative permeability (μr): Shows how easily a material supports a magnetic field compared to a vacuum. μr ≈ 1 means the material does not concentrate magnetic fields.

- Electrical conductivity: Affects how strongly eddy currents are induced (and thus how much drag you’ll feel in motion).

- Frequency dependence: At high frequencies, permeability and conductivity can change, affecting eddy-current effects and shielding properties (Wikipedia).

Engineers often turn to trusted sources like ASM Handbooks, NIST, or MatWeb for these values, especially when precision matters. For traceable measurements of magnetic susceptibility, the NIST Magnetic Moment and Susceptibility Standard Reference Materials program sets the gold standard.

Interpreting Low Susceptibility and μr ≈ 1

Imagine you’re holding a piece of aluminum and a piece of steel. When you ask, “is steel a magnetic material?” or “does magnet stick to iron?” the answer is clearly yes—because their relative permeability is much greater than one, and their magnetic susceptibility is high. But for aluminum, things are different. The magnetic permeability of aluminium is almost exactly one, just like air. This means it neither attracts nor amplifies magnetic fields. That’s why aluminum magnetic properties are described as paramagnetic—weak, temporary, and only present when a field is applied.

On the other hand, copper is another metal people often wonder about. “Is copper a magnetic metal?” No—copper is a diamagnetic material, meaning it weakly repels magnetic fields. This effect is physically distinct from the weak paramagnetism (attraction) of aluminum, and both are difficult to observe with everyday magnets under normal conditions. Both copper and aluminum are considered what metals are not magnetic in the traditional sense.

Comparative Table: Magnetic Properties of Key Metals

| Material | Magnetic Susceptibility (χ) | Relative Permeability (μr) | Electrical Conductivity | Eddy-Current Behavior | Source |

|---|---|---|---|---|---|

| Aluminum | Paramagnetic (very weak, positive χ) | ~1 (almost identical to air) | High | Strong drag in changing fields, no static attraction | Wikipedia |

| Iron/Steel | Strongly ferromagnetic (high positive χ) | Much greater than 1 (varies by alloy and field) | Moderate | Strong attraction, can be magnetized | Wikipedia |

| Copper | Diamagnetic (weak, negative χ) | ~1 (slightly less than 1) | Very high | Strong eddy-current drag, no attraction | Wikipedia |

| Stainless Steel (Austenitic) | Paramagnetic or weakly ferromagnetic (varies by grade) | ~1 to slightly above 1 | Lower than Al/Cu | Usually non-magnetic, but some grades show weak attraction | Wikipedia |

Caption: Editors—insert only sourced values; leave numeric cells blank if not available from reference.

How to Cite Authoritative Sources

For engineering documentation or research, always cite values for aluminum magnetic properties or magnetic permeability of aluminium from respected databases. The NIST Magnetic Moment and Susceptibility program is a trusted reference for susceptibility measurements (NIST). For broader material property data, ASM Handbooks and MatWeb are widely used. If you can’t find a value in these sources, describe the property qualitatively and note the reference used.

High conductivity plus μr near 1 explains why aluminum resists motion in changing fields yet stays non-attractive.

Armed with these facts, you can confidently select materials for your next project—knowing exactly how aluminum stacks up against iron, copper, and stainless steel. Next, we’ll translate this data into practical design tips for EMI shielding, sensor placement, and safety decisions in real-world applications.

Design Implications for Aluminum and Magnets in Automotive and Equipment Applications

EMI Shielding and Sensor Placement

When you’re designing electronic enclosures or sensor mounts, have you ever wondered what sticks to aluminum—or more importantly, what doesn’t? Unlike steel, aluminum won’t draw in a magnetic field, but it still plays a crucial role in electromagnetic interference (EMI) shielding. Sounds counterintuitive? Here’s how it works:

- Aluminum’s high conductivity allows it to block or reflect many types of electromagnetic waves, making it a go-to material for EMI shielding in automotive, aerospace, and consumer electronics.

- However, because aluminum is not a magnetic receptive sheet, it cannot shunt static magnetic fields the way steel can. This means if your device relies on magnetic shielding (not just EMI), you’ll need to look elsewhere or combine materials.

- For sensors that use magnets—like Hall effect or reed switches—keep a defined air gap from aluminum surfaces. Too close, and eddy currents in the aluminum can dampen the sensor’s response, especially in dynamic systems.

- Need to fine-tune this effect? Engineers often slot or thin aluminum shields to reduce eddy-current damping, or use hybrid enclosures. Always consider the frequency of the interference you’re combating, since aluminum is more effective at higher frequencies.

Remember, if your application calls for a magnetic receptive sheet—such as mounting magnetic sensors or using magnetic fasteners—plain aluminum will not suffice. Instead, plan for a layered approach or select a steel insert where magnetic attachment is required.

Eddy-Current Inspection and Sorting

Ever seen a recycling line where aluminum cans seem to leap off the conveyor? That’s eddy-current sorting in action! Because aluminum is highly conductive, moving magnets induce strong eddy currents that push non-ferrous metals away from ferrous streams. This principle is used in:

- Recycling facilities: Eddy-current separators eject aluminum and copper from mixed waste, making sorting efficient and contact-free.

- Manufacturing quality assurance: Eddy-current testing quickly detects cracks, changes in conductivity, or improper heat treatment in aluminum auto parts (Foerster Group).

- Calibration standards are critical—always use reference samples to ensure your inspection system is dialed in for the specific alloy and condition.

Safety Notes for MRI, Shop Floors, and Automotive Maintenance

Imagine rolling equipment into an MRI suite, or reaching for a tool near a powerful industrial magnet. Here’s where aluminum’s non-magnetic properties really shine:

- MRI rooms: Only non-ferrous carts, fixtures, and tools are allowed—aluminum is the preferred choice since it won’t be attracted to the MRI’s strong magnetic field, reducing risk and interference.

- Shop floors: Aluminum ladders, workbenches, and tool trays won’t suddenly jump toward stray magnets, making them safer in environments with large or moving magnetic fields.

- Automotive maintenance: If you’re used to relying on an oil pan magnet to catch ferrous debris, take note: in an aluminum oil pan, the magnet for aluminum won’t work. Instead, use high-quality filtration and maintain regular oil change intervals, since aluminum pans offer no magnetic capture.

- Magnet health and safety: Always keep strong magnets away from sensitive electronics and medical devices. Aluminum enclosures help by preventing direct contact, but remember, they do not block static magnetic fields (Magnet Applications).

Quick Do’s and Don’ts by Application

| Application Area | Do | Don’t |

|---|---|---|

| EMI Shielding | Use aluminum for high-frequency EMI; slot or thin shields to tune eddy-current effects | Rely on aluminum as a magnetic receptive sheet for static fields |

| Sensor Placement | Keep magnetic sensors at a controlled distance from aluminum | Place sensors flush against thick aluminum without testing damping |

| Manufacturing QA | Calibrate eddy-current testers with reference samples | Assume all alloys or tempers behave identically |

| Recycling | Use eddy-current separation for non-ferrous metals | Expect magnetic sorting to remove aluminum |

| Safety | Choose aluminum for MRI, shop, and cleanroom settings | Use oil pan magnets in aluminum pans |

Use aluminum for non-attractive structures near magnets, but account for eddy-current effects in moving-field systems.

By understanding these sector-specific nuances, you’ll make better choices when specifying magnets for aluminum housings, selecting the right magnet for aluminum, or ensuring that your equipment is safe and efficient in any environment. Next, we’ll provide a plain-language glossary so everyone on your team—from engineers to technicians—can follow the key terms and concepts involved in magnetic aluminum applications.

Plain Language Glossary

Foundational Magnetism Terms in Plain English

When you’re reading about magnetic aluminum or trying to decide which metals are attracted to a magnet, all the jargon can get confusing. Is metal magnetic? What about aluminum? This glossary breaks down the most important terms you’ll encounter—so you can follow every section, whether you’re a seasoned engineer or new to the topic.

- Ferromagnetic: Materials (like iron, steel, and nickel) that are strongly attracted to magnets and can become magnets themselves. These are the classic magnetized metals you see in everyday life. (Think: why does a magnet attract metal? This is why.)

- Paramagnetic: Materials (including aluminum) that are weakly attracted to magnetic fields, but only while the field is present. The effect is so slight you won’t feel it—aluminum is in this group.

- Diamagnetic: Materials (such as copper or bismuth) that are weakly repelled by magnetic fields. If you’re wondering what metal is not magnetic at all, many diamagnetic metals fit this description.

- Magnetic susceptibility (χ): A measure of how much a material will become magnetized in an external magnetic field. Positive for paramagnetic, strongly positive for ferromagnetic, and negative for diamagnetic materials.

- Relative permeability (μr): Describes how easily a material supports a magnetic field compared to a vacuum. For aluminum, μr is almost exactly 1—meaning it doesn’t help concentrate or amplify magnetic fields.

- Eddy currents: Swirling electrical currents induced in conductive metals (like aluminum) when exposed to changing magnetic fields. These create a drag force that opposes motion—responsible for the “floating magnet” effect in aluminum tubes.

- Hysteresis: The lag between changes in magnetizing force and the resulting magnetization. It’s significant in ferromagnetic materials, but not in aluminum.

- Hall effect sensor: An electronic device that detects magnetic fields and is often used to measure the presence, strength, or movement of a magnet near a metal part.

- Gauss: A unit of magnetic flux density (strength of the magnetic field). A gauss meter measures this value—useful for comparing how different materials respond to magnets. (Magnet Expert Glossary)

- Tesla: Another unit for magnetic flux density. 1 tesla = 10,000 gauss. Used in scientific and engineering contexts for very strong fields.

Units You Will See in Measurements

- Oersted (Oe): A unit of magnetic field strength, often used in material property tables.

- Maxwell, Weber: Units for measuring magnetic flux—the total “amount” of magnetic field passing through an area.

Test and Instrument Vocabulary

- Gauss meter: A handheld or benchtop device that measures the strength of a magnetic field in gauss. Used to test if a material is magnetic or to map field strength.

- Flux meter: Measures changes in magnetic flux, often used in research or quality control labs.

- Search coil: A coil of wire used with a flux meter to detect changing magnetic fields—helpful in advanced testing setups.

Aluminum’s paramagnetism means nearly no attraction in static fields, but notable eddy-current effects in changing fields.

Understanding these terms helps you interpret results and explanations throughout this guide. For example, if you read about why does a magnet attract metal, remember that only certain metals—mainly ferromagnetic ones—respond this way. If you’re curious, is a magnet metal? The answer is no—a magnet is an object that produces a magnetic field, and it can be made from metal or other materials.

Now that you’re familiar with the vocabulary, you’ll find it easier to follow the technical details and testing protocols in the rest of this article. Next, we’ll point you to trusted resources and design checklists for sourcing aluminum parts near magnets—so your projects stay safe, reliable, and interference-free.

Trusted Resources and Sourcing for Aluminum Near Magnets

Top resources for aluminum near magnetic systems

When you’re designing with aluminum in environments where magnets or electromagnetic fields are present, sourcing the right information and partners is essential. Whether you’re verifying if is aluminum a magnetic material or ensuring your extrusion supplier understands the nuances of EMI, the following resources will help you make informed, reliable decisions.

- Shaoyi Metal Parts Supplier – aluminum extrusion parts: As a leading integrated precision auto metal parts solutions provider in China, Shaoyi offers custom, non-magnetic aluminum extrusions with deep experience in automotive applications. Their expertise is particularly valuable for projects where sensor placement, EMI shielding, and eddy-current effects are critical. If you’re asking, “will a magnet stick to aluminium?” or “is aluminum magnetic yes or no,” Shaoyi’s technical support ensures your designs leverage aluminum’s non-magnetic properties for optimal performance.

- Aluminum Extruders Council (AEC) – Automotive Technical Resources: A hub for best practices, design guidance, and technical papers on the use of aluminum extrusions in vehicle structures, including considerations for magnetic fields and multi-material integration.

- Magnetstek – Science and Applications of Magnets on Aluminum Alloys: Detailed technical articles on how aluminum alloys interact with magnetic fields, including real-world case studies and sensor integration tips.

- KDMFab – Is Aluminum Magnetic?: Plain-language explanations of aluminum’s magnetic and non-magnetic behavior, including alloy and contamination effects.

- NIST – Magnetic Moment and Susceptibility Standards: Authoritative data for engineers who require traceable measurements of magnetic properties.

- Light Metal Age – Industry News and Research: Articles and white papers on aluminum’s role in automotive, electronics, and industrial design.

Design checklist for extrusions around magnets

Before finalizing your aluminum structure—especially for automotive, electronics, or sensor-heavy assemblies—run through this checklist. It’s designed to help you avoid common pitfalls and maximize the benefits of aluminum’s non-magnetic properties.

- Confirm that your extrusion alloy is standard non-magnetic aluminum (e.g., 6xxx or 7xxx series) and not a specialty magnetic alloy.

- Specify wall thickness and cross-sectional geometry to balance structural needs with minimal eddy-current drag in dynamic magnetic fields.

- Consider slotting or thinning extrusion walls near sensors to reduce unwanted eddy-current effects if rapid field changes are expected.

- Segregate fasteners: Use non-magnetic stainless or aluminum fasteners near critical sensors; avoid steel inserts unless absolutely necessary.

- Document all coating and anodizing processes—these won’t make aluminum magnetic, but could affect sensor readings or surface conductivity.

- Map and record all sensor offsets and air gaps to ensure reliable operation and avoid unexpected damping or interference.

- Always test for contamination or embedded ferromagnetic components before final assembly (remember, even a small steel particle can create a false positive if you’re checking “does a magnet stick to aluminium?”).

When to consult a specialist supplier

Imagine you’re launching a new EV platform or designing a sensor array for industrial automation. If you’re unsure whether your design will meet strict EMI, safety, or performance criteria, it’s time to engage a specialist. Consult your extrusion partner early—especially if you need guidance on alloy selection, eddy-current mitigation, or integrating magnetic sensors in close proximity to aluminum structures. A supplier with both automotive and electromagnetic experience can help you answer “is aluminum magnetic yes or no?” for your specific application and avoid costly redesigns down the line.

| Supplier/Resource | Core Focus | Magnetic/EMI Expertise | Automotive Experience |

|---|---|---|---|

| Shaoyi Metal Parts Supplier | Custom automotive aluminum extrusion parts | Sensor placement, EMI, and eddy-current design support | Extensive (IATF 16949 certified, rapid prototyping, integrated solutions) |

| AEC Automotive Technical Resources | Industry-wide extrusion standards and technical papers | General guidance, best practices | Broad, including BEV and multi-material integration |

| Magnetstek | Magnetic materials and sensor solutions | Detailed technical resources | Multiple sectors, including automotive and industrial |

Choose extrusion partners who understand magnetism-related design constraints, not just alloy availability.

In summary, the question “is aluminium magnetic material” or “does a magnet stick to aluminium” is more than a curiosity—it’s a design and sourcing imperative. By leveraging these resources and following the checklist above, you’ll ensure your aluminum structures are safe, interference-free, and ready for tomorrow’s automotive and electronic challenges.

Frequently Asked Questions about Magnetic Aluminum

1. Is aluminum magnetic or non-magnetic?

Aluminum is considered non-magnetic under normal conditions. It is classified as a paramagnetic material, which means it only exhibits a very weak and temporary response to magnetic fields. Unlike ferromagnetic metals like iron or steel, aluminum will not attract or stick to a magnet in everyday situations.

2. Why do magnets sometimes interact with aluminum if it is not magnetic?

Magnets can appear to interact with aluminum due to a phenomenon called eddy currents. When a magnet moves near aluminum, it induces electrical currents in the metal, which create opposing magnetic fields. This results in a drag force that slows the magnet's movement, but does not cause attraction. This effect is noticeable in demonstrations like a magnet falling slowly through an aluminum tube.

3. Can aluminum be magnetized or made to stick to a magnet?

Pure aluminum cannot be magnetized or made to stick to a magnet. However, if an aluminum object is contaminated with ferromagnetic materials (like steel filings, fasteners, or inserts), a magnet may stick to those areas. Always clean and inspect aluminum parts to ensure accurate magnetic testing results.

4. How does aluminum's lack of magnetism benefit automotive and electronic design?

Aluminum's non-magnetic nature makes it ideal for applications where electromagnetic interference (EMI) must be minimized, such as EV battery enclosures, sensor housings, and automotive electronics. Suppliers like Shaoyi Metal Parts offer custom aluminum extrusion parts that help engineers design lightweight, non-magnetic structures, ensuring optimal performance and safety for sensitive electrical systems.

5. What is the best way to test if an aluminum part is truly non-magnetic?

A simple home test involves using a strong magnet on a clean aluminum surface; the magnet should not stick. For more precise results, lab-grade instruments like Hall or gauss meters can measure any magnetic response. Always check for contamination, coatings, or hidden steel parts, as these can give false positives.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —