Magnesium Alloy Stamping for Automotive: The Warm Forming Advantage Warm forming magnesium alloy sheet for lightweight automotive door panels

TL;DR

Magnesium alloy stamping represents the frontier of automotive lightweighting, offering components that are 33% lighter than aluminum and 75% lighter than steel. While standard cold stamping fails due to magnesium's hexagonal close-packed (HCP) crystal structure, warm forming technology (200°C–300°C) successfully activates non-basal slip systems to allow complex shaping. The industry standard alloy, AZ31B, is now being used for inner door panels, seat frames, and cross-car beams to extend electric vehicle (EV) range. This guide covers the critical process parameters, material selection, and feasibility data needed to transition from heavy castings to lightweight wrought stampings.

The Engineering Case: Why Stamp Magnesium?

In the race to maximize electric vehicle range, engineers have largely exhausted the easy wins with aluminum. Magnesium (Mg) is the next logical step. With a density of just 1.74 g/cm³ compared to aluminum’s 2.70 g/cm³, magnesium is the lightest structural metal available. Substituting steel components with magnesium stamping can yield weight reductions of up to 75%, while switching from aluminum saves roughly 33%.

Beyond pure mass reduction, magnesium sheet offers superior damping capacity—the ability to absorb vibration and noise. For Body-in-White (BIW) applications, this translates to improved NVH (Noise, Vibration, and Harshness) performance without adding heavy acoustic insulation. Unlike carbon fiber, which poses recycling challenges, magnesium is fully recyclable, aligning with circular economy mandates for automotive OEMs.

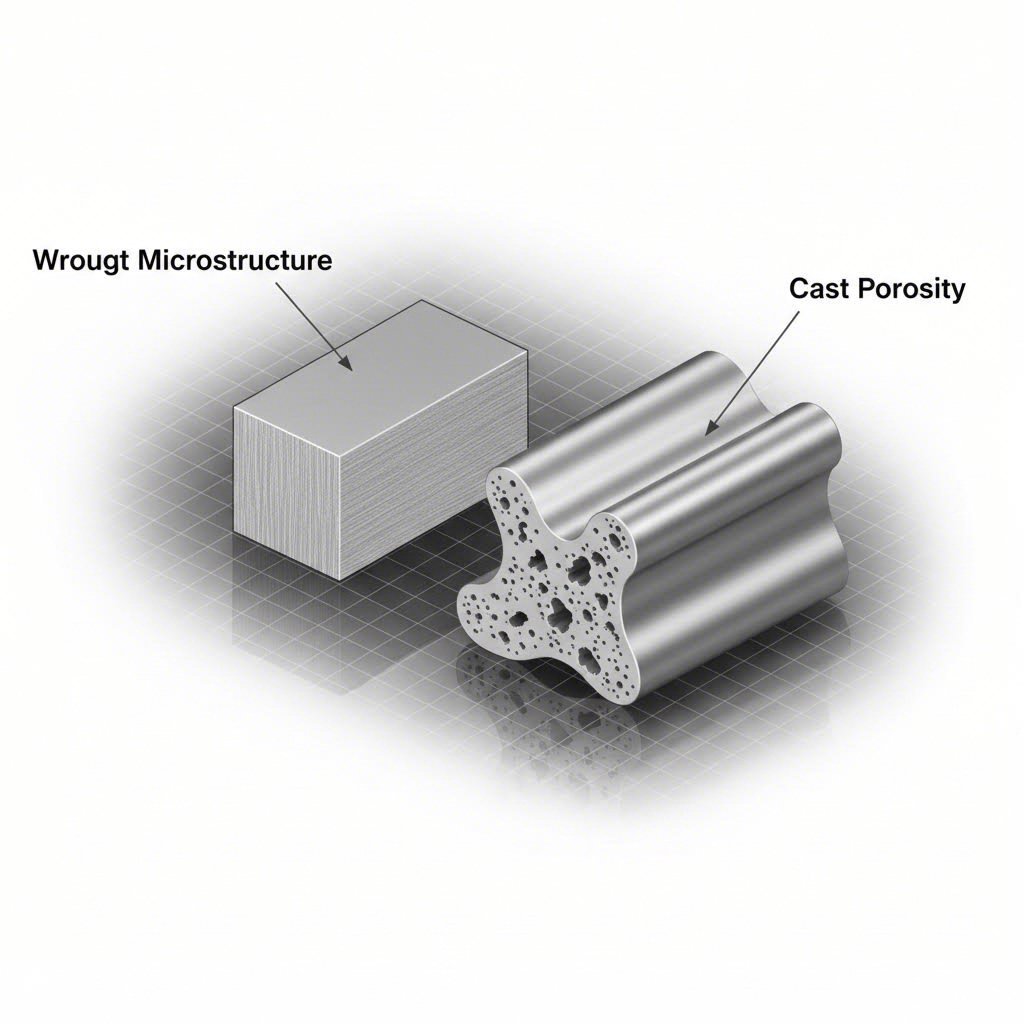

Historically, magnesium use was limited to die casting (engine blocks, transmission cases). However, stamped (wrought) magnesium parts offer significantly higher mechanical properties because they eliminate the porosity issues inherent in casting. This makes stamped magnesium ideal for large, thin-walled structural panels that require high specific strength.

The Critical Process: Warm Forming Technology

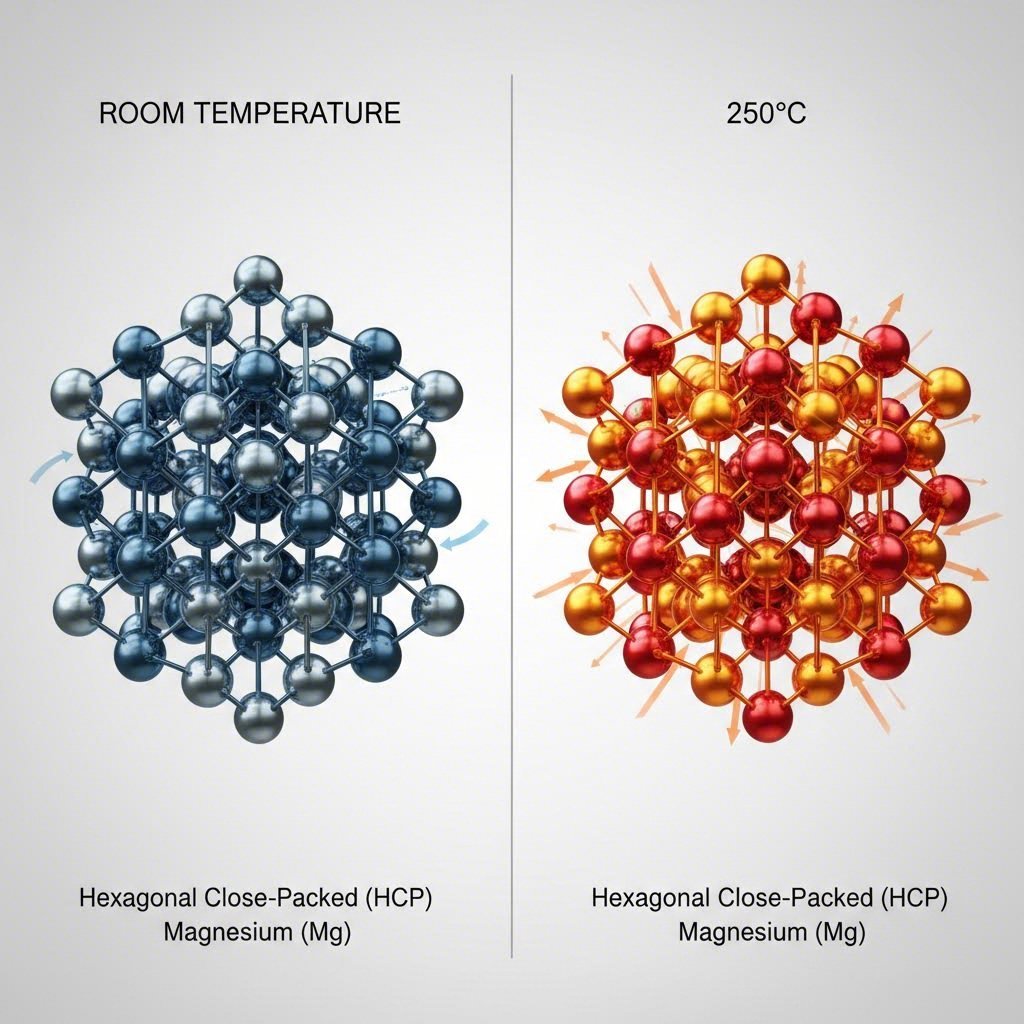

The primary barrier to stamping magnesium is its crystal structure. At room temperature, magnesium has a hexagonal close-packed (HCP) lattice with limited slip systems (primarily basal slip), making it brittle and prone to cracking during deformation. Standard cold stamping methods used for steel will cause immediate failure.

The solution is Warm Forming. By heating the magnesium sheet and tooling to a specific window of 200°C to 300°C (392°F–572°F), additional slip systems (prismatic and pyramidal) are thermally activated. This dramatically increases ductility, allowing for deep draws and complex geometries that are impossible at room temperature.

Key Process Parameters

- Temperature Control: Uniform heating is critical. A deviation of just ±10°C can lead to localized necking or fracture. Both the blank and the die are typically heated.

- Lubrication: Standard oil lubricants degrade at these temperatures. Specialized heat-resistant lubricants, often containing molybdenum disulfide (MoS2) or graphite, are required to prevent galling.

- Forming Speed: Unlike the high-speed stamping of steel, warm forming magnesium often requires slower press speeds (e.g., 20mm/s vs. hundreds of mm/s) to manage strain rates and prevent tearing, although recent R&D is improving cycle times.

Material Selection: AZ31B and Sheet Production

AZ31B (approx. 3% Aluminum, 1% Zinc) is the workhorse alloy for automotive magnesium sheet. It offers the best balance of strength, ductility, and weldability. Its yield strength typically hovers around 200 MPa, with a tensile strength of 260 MPa, making it competitive with mild steels and some aluminum grades.

A significant challenge has been the cost of producing magnesium sheet. Traditional rolling processes are expensive due to the need for multiple annealing steps. However, innovative extrusion-flattening techniques are emerging. This process extrudes a magnesium tube, splits it, and flattens it into a sheet, potentially reducing production costs by 50% compared to conventional rolling. This cost reduction is vital for making magnesium stamping commercially viable for mass-market vehicles rather than just luxury sports cars.

Comparative Analysis: Stamping vs. Die Casting

Automotive engineers often confuse magnesium die casting with stamping. While both use the same base metal, the applications and properties differ significantly.

| Feature | Magnesium Stamping (Warm Forming) | Magnesium Die Casting |

|---|---|---|

| Process State | Solid-state forming (Wrought) | Liquid injection (Molten) |

| Wall Thickness | Ultra-thin (0.5mm – 2.0mm) | Thicker walls (typically >2.0mm) |

| Porosity | Zero porosity (High integrity) | Prone to gas porosity |

| Geometry | Large surface areas, constant thickness (Panels, Roofs) | Complex 3D shapes, varying thickness (Housings) |

| Strength | Higher tensile/yield strength | Lower due to cast structure |

| Tooling Cost | Moderate (Heated dies required) | High (Complex molds required) |

Decision Matrix: Choose stamping for large, flat-ish structural components like door inners, hoods, and roofs. Choose die casting for intricate, blocky parts like steering column housings or gearbox casings.

From Prototype to Mass Production

Transitioning to magnesium stamping requires specialized partners who understand the thermal nuances of the material. It is not as simple as swapping a coil of steel for magnesium on an existing line. The tooling must accommodate thermal expansion, and the press parameters must be precisely controlled.

For OEMs and Tier 1 suppliers looking to validate this technology, working with an experienced fabrication partner is essential. Shaoyi Metal Technology offers comprehensive automotive stamping solutions that bridge the gap from rapid prototyping to high-volume manufacturing. With IATF 16949 certification and press capabilities up to 600 tons, they can deliver precision components like control arms and subframes while adhering to strict global standards. Whether you need to verify a warm-formed prototype or scale up production, their engineering expertise ensures the feasibility of complex lightweight designs.

Applications and Future Outlook

The adoption of magnesium stamping is accelerating. Current production applications include:

- Seat Frames: Replacing steel frames to save 5–8 kg per vehicle.

- Inner Door Panels: Using warm-formed AZ31B to create rigid, lightweight carriers.

- Cross-Car Beams: Integrating multiple parts into a single stamped magnesium structure.

- Roof Panels: Lowering the center of gravity for improved handling.

As EV battery weight continues to be a concern, the "lightweighting premium" automakers are willing to pay is increasing. We expect to see magnesium sheet costs drop as extrusion-flattening scales, making warm-formed magnesium a standard solution for the next generation of electric platforms.

The Lightweighting Frontier

Magnesium alloy stamping is no longer just an R&D curiosity; it is a viable, necessary technology for the future of automotive design. By mastering the warm forming process and selecting the right alloys like AZ31B, manufacturers can achieve weight savings that aluminum simply cannot match. The shift requires investment in heated tooling and process control, but the payoff—lighter, more efficient, and better-handling vehicles—is undeniable.

Frequently Asked Questions

1. What is the difference between magnesium stamping and die casting?

Stamping is a solid-state process that forms sheet metal into shapes, ideal for thin, large panels like car doors or roofs. It produces parts with no porosity and higher strength. Die casting involves injecting molten magnesium into a mold, which is better for complex, blocky 3D shapes like engine blocks but often results in lower structural integrity due to air pockets.

2. Why does magnesium require warm forming?

Magnesium has a hexagonal close-packed (HCP) crystal structure, which limits its flexibility at room temperature. Trying to stamp it cold usually causes cracks. Heating the material to 200°C–300°C activates additional "slip systems" in the crystal lattice, making the metal ductile enough to be formed into complex automotive parts without breaking.

3. How much lighter is magnesium compared to aluminum?

Magnesium is approximately 33% lighter than aluminum and about 75% lighter than steel. This significant weight reduction makes it the most effective structural metal for extending the range of electric vehicles.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —