T5 vs T6 Aluminum Temper: Which Is Right for Your Project?

T5 vs T6 Aluminum Temper: Which Is Right for Your Project?

TL;DR

The primary impact of temper on aluminum performance is that T6 is significantly stronger and harder than T5. This is due to T6 undergoing a more intensive heat treatment process involving solution heat treatment and rapid water quenching before artificial aging. While T6 offers superior mechanical properties for structural applications, T5 provides a more cost-effective solution with adequate strength for many architectural and decorative uses.

Understanding the Basics: What Are T5 and T6 Tempers?

When selecting an aluminum alloy, the material itself is only part of the equation. The temper designation, indicated by the 'T' followed by a number, reveals the specific heat treatment process the aluminum has undergone, which fundamentally alters its mechanical properties. Tempering is a controlled heating and cooling process used to achieve desired characteristics like strength, hardness, and ductility. For many common 6000 series alloys, the choice often comes down to the T5 vs T6 temper.

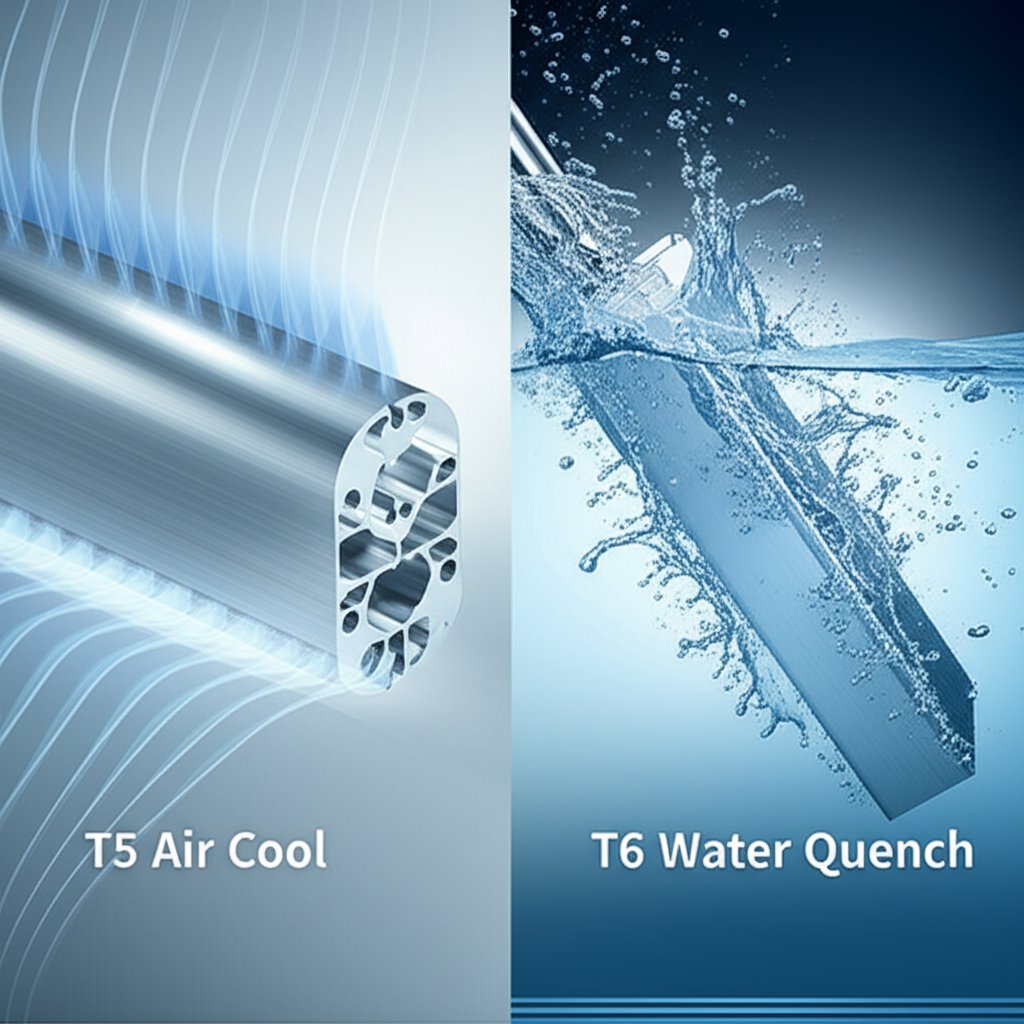

The T5 temper signifies that the aluminum profile has been cooled from an elevated temperature shaping process, typically via forced air, and then artificially aged. This process involves heating the material in an aging furnace for a set time to precipitate alloying elements, thereby increasing its strength and hardness. Because it cools more slowly after extrusion, the T5 process is simpler and less energy-intensive compared to T6.

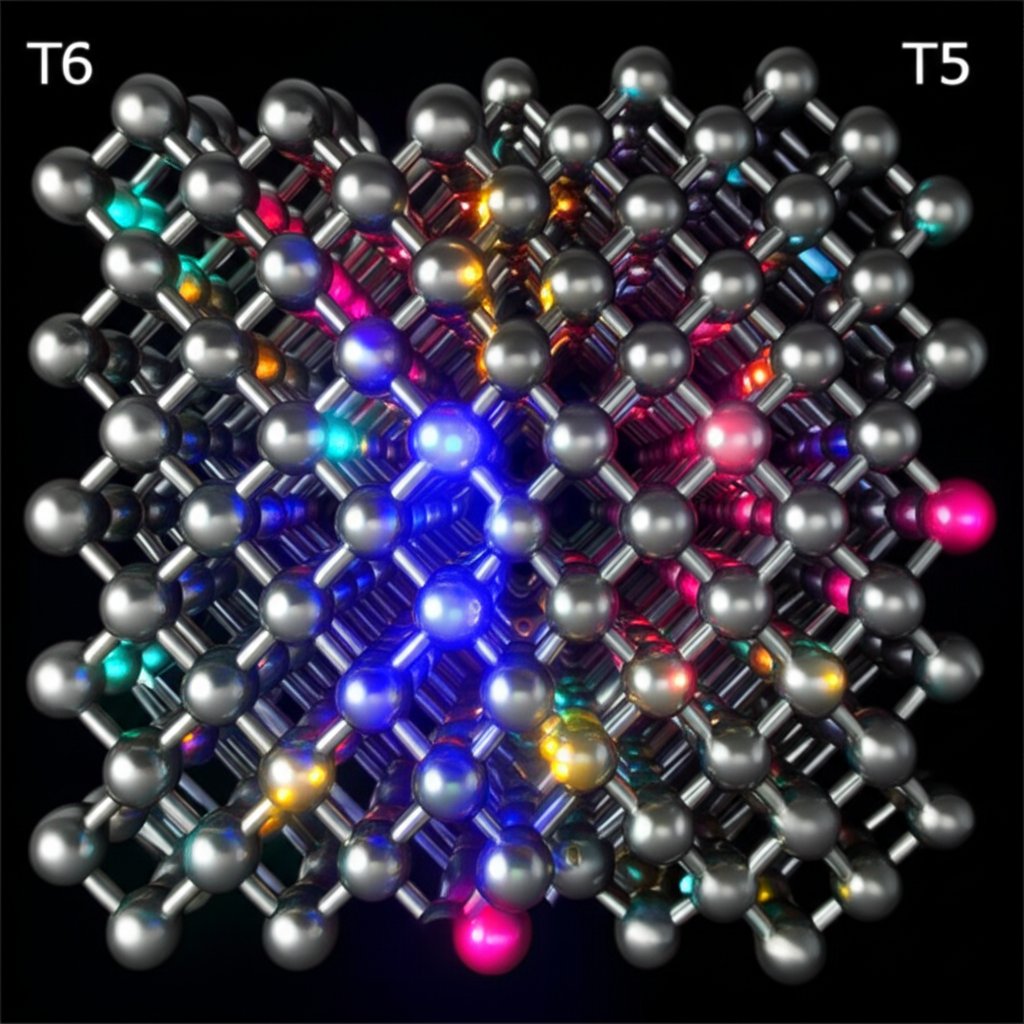

The T6 temper represents a more rigorous, multi-step heat treatment. First, the aluminum undergoes a solution heat treatment at a high temperature (around 980°F or 530°C) to dissolve the alloying elements into the aluminum matrix. It is then immediately and rapidly cooled, or quenched, in water. This rapid cooling 'locks' the elements in place. Finally, like T5, it is artificially aged in a furnace to achieve maximum strength and hardness. This solution heat treatment and rapid quench are the key steps that give T6 its superior properties.

Core Performance Metrics: A Head-to-Head Comparison

The difference in heat treatment directly translates to measurable differences in performance. For engineers, designers, and fabricators, understanding these distinctions is critical for material specification. The T6 temper consistently outperforms T5 in key mechanical properties, making it the choice for applications where performance cannot be compromised.

Strength (Tensile and Yield)

The most significant difference between the two tempers is strength. T6 aluminum exhibits substantially higher ultimate tensile strength (the maximum stress a material can withstand before breaking) and yield strength (the stress at which it begins to deform permanently). The solution heat treatment and rapid quenching of the T6 process create a finer and more uniform precipitation of alloying elements during aging, which is more effective at impeding dislocation movement within the metal's crystal structure. This results in a much stronger material. For example, 6063-T6 aluminum can have a tensile strength of at least 215 MPa, compared to around 175 MPa for 6063-T5.

Hardness

Following strength, hardness is another area where T6 has a clear advantage. Hardness measures a material's resistance to localized surface indentation and scratching. Due to its more robust internal structure, T6 aluminum is significantly harder than T5. On the Webster hardness scale, T6 typically measures 13.5 HW or higher, while T5 is generally in the 8-12 HW range. This increased hardness contributes to better durability and resistance to wear and abrasion in demanding applications.

Ductility and Formability

While T6 is stronger and harder, this comes with a slight trade-off in ductility and formability. T5 aluminum, being softer, is generally easier to bend, form, and machine without cracking. The increased strength of T6 makes it more rigid and slightly less forgiving during complex forming operations. However, it's important to note that even in the T6 temper, 6000 series alloys maintain good overall workability compared to many other high-strength metals.

Comparison Summary: 6063 Alloy

| Property | T5 Temper | T6 Temper |

|---|---|---|

| Typical Tensile Strength | ~160-175 MPa | ~195-215 MPa |

| Typical Yield Strength | ~110-130 MPa | ~160-170 MPa |

| Hardness (Webster) | 8-12 HW | 13.5+ HW |

| Formability | Good | Moderate |

| Cost | Lower | Higher |

Practical Applications: Choosing the Right Temper for Your Project

Translating these technical properties into real-world decisions depends entirely on the project's requirements. The choice between T5 and T6 is a classic engineering trade-off between performance, manufacturability, and cost.

When to Use T5 Temper

The T5 temper is an excellent choice when moderate strength is sufficient and cost is a significant factor. Its good balance of properties makes it ideal for a wide range of applications, including:

- Architectural Extrusions: Window frames, door frames, curtain walls, and trim are common uses where the corrosion resistance and adequate strength of T5 are perfect.

- Decorative Components: Its smooth surface finish and good formability lend themselves well to decorative trim and fixtures.

- General Fabrication: For projects that don't face high structural loads, T5 provides reliable performance without the added cost of T6 treatment.

When to Use T6 Temper

The superior strength and hardness of T6 make it indispensable for applications where structural integrity and durability are paramount. You should specify T6 temper for:

- Structural Components: Load-bearing applications such as roof rails, support beams, and chassis components demand the high yield strength of T6.

- Automotive and Aerospace Parts: In these industries, a high strength-to-weight ratio is critical. T6 is used for parts that must withstand significant stress and vibration while remaining lightweight.

- High-Performance Equipment: Bicycle frames, rock-climbing gear, and marine components are often made from T6-tempered aluminum for maximum reliability.

For example, in the automotive industry, projects demanding precision-engineered structural components often rely on T6 temper. For such specialized needs, custom aluminum extrusions from a trusted partner like Shaoyi Metal Technology can provide tailored solutions that meet strict quality standards like IATF 16949.

Beyond Performance: Factoring in Cost and Machinability

The final decision often involves practical considerations beyond mechanical specifications. Cost is a primary differentiator. The T6 temper is more expensive than T5 because its production process involves additional steps—namely the separate solution heat treatment and rapid water quenching—which consume more energy and time. This price difference can be significant in large-scale projects, making T5 a more attractive option if its performance is adequate for the application.

Machinability is another factor. While both tempers are readily machinable, the softer nature of T5 can sometimes allow for faster machining speeds or less tool wear. Conversely, the increased hardness of T6 can make it slightly more challenging to work with during complex forming or bending operations, as it is less forgiving. For fabricators, this can influence production time and costs, making it a crucial variable in the overall project budget.

Frequently Asked Questions

1. What is the difference between 5 series and 6 series Aluminium?

The primary difference lies in their main alloying elements. 5xxx series aluminum alloys use magnesium as their principal alloying element, which gives them excellent corrosion resistance (especially in marine environments) and good strength. 6xxx series alloys use both magnesium and silicon, which allows them to be heat-treated (like T5 and T6 tempers) to achieve significantly higher strength, making them more versatile for structural applications.

2. What is the difference between 6061 T5 and T6 aluminum?

While this article focuses on the general temper differences, the principles apply directly to specific alloys like 6061. 6061-T6 has undergone the full solution heat treatment and artificial aging process, resulting in much higher tensile and yield strength compared to 6061-T5. 6061-T6 is one of the most common aluminum alloys for structural applications due to its excellent combination of strength, weldability, and corrosion resistance.

3. Is T6 billet aluminum strong?

Yes, T6 billet aluminum, particularly an alloy like 6061-T6, is very strong. The 'billet' designation refers to the fact that the part is machined from a solid block of aluminum (a billet), rather than being cast into its final shape. When this high-quality starting material is given a T6 temper, the result is a component with excellent strength, structural integrity, and a premium finish, making it highly popular for high-performance automotive parts and other demanding applications.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —