Identifying Top Metal Control Arm Manufacturer Options

TL;DR

Choosing the right metal control arm manufacturer involves evaluating top Original Equipment Manufacturer (OEM) suppliers and specialized aftermarket brands. Industry leaders like Mevotech and MOOG are renowned for engineering high-strength control arms from materials such as forged steel and lightweight aluminum. The key to optimal performance lies in understanding the differences in manufacturing processes—like stamping and CNC machining—and selecting a brand whose products match your vehicle's specific demands for durability and handling.

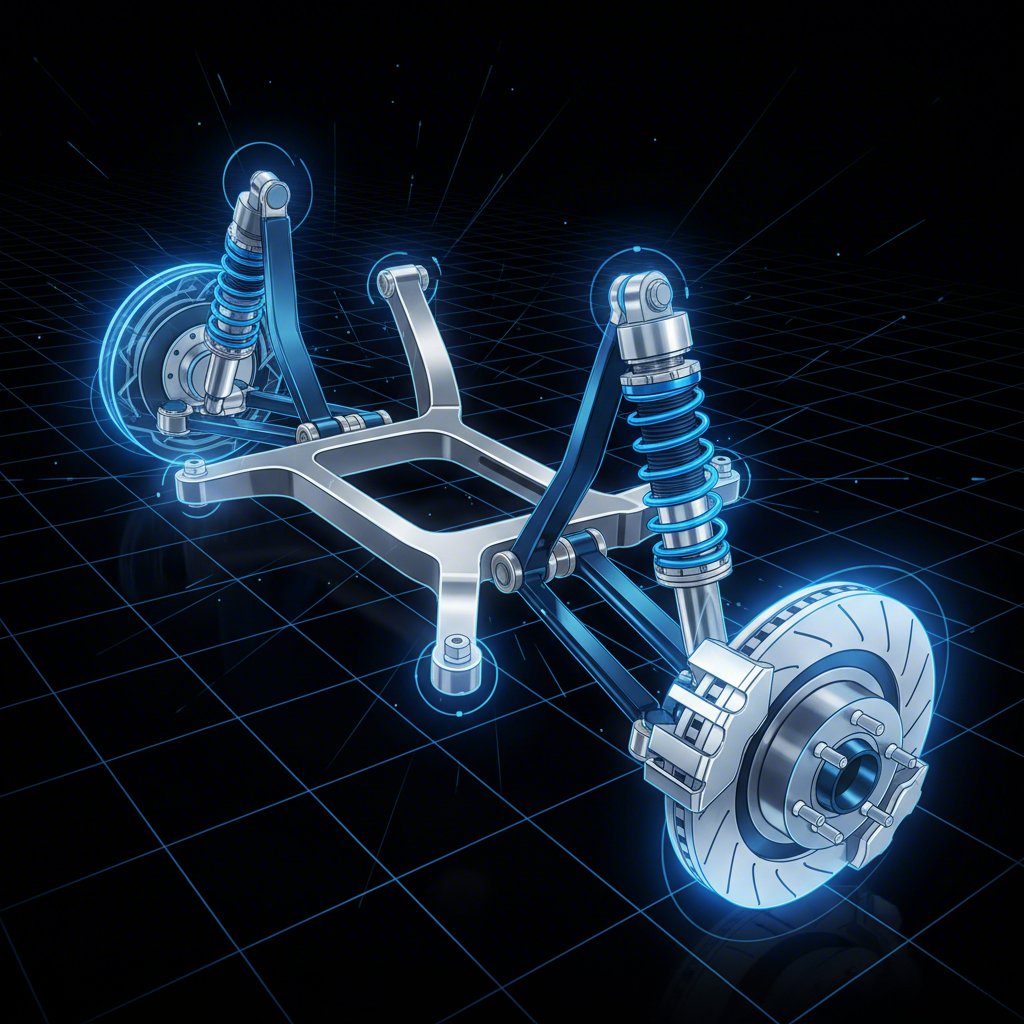

Understanding Control Arm Fundamentals: Materials and Manufacturing

A control arm is a critical, load-bearing component of a vehicle's suspension system. It acts as a hinged link between the chassis and the steering knuckle or axle, allowing the wheels to move up and down while maintaining proper alignment. The quality of a control arm directly impacts vehicle stability, steering response, and overall safety. Consequently, the materials and manufacturing methods used by a metal control arm manufacturer are paramount. The two dominant materials in control arm production are steel and aluminum, each offering distinct advantages.

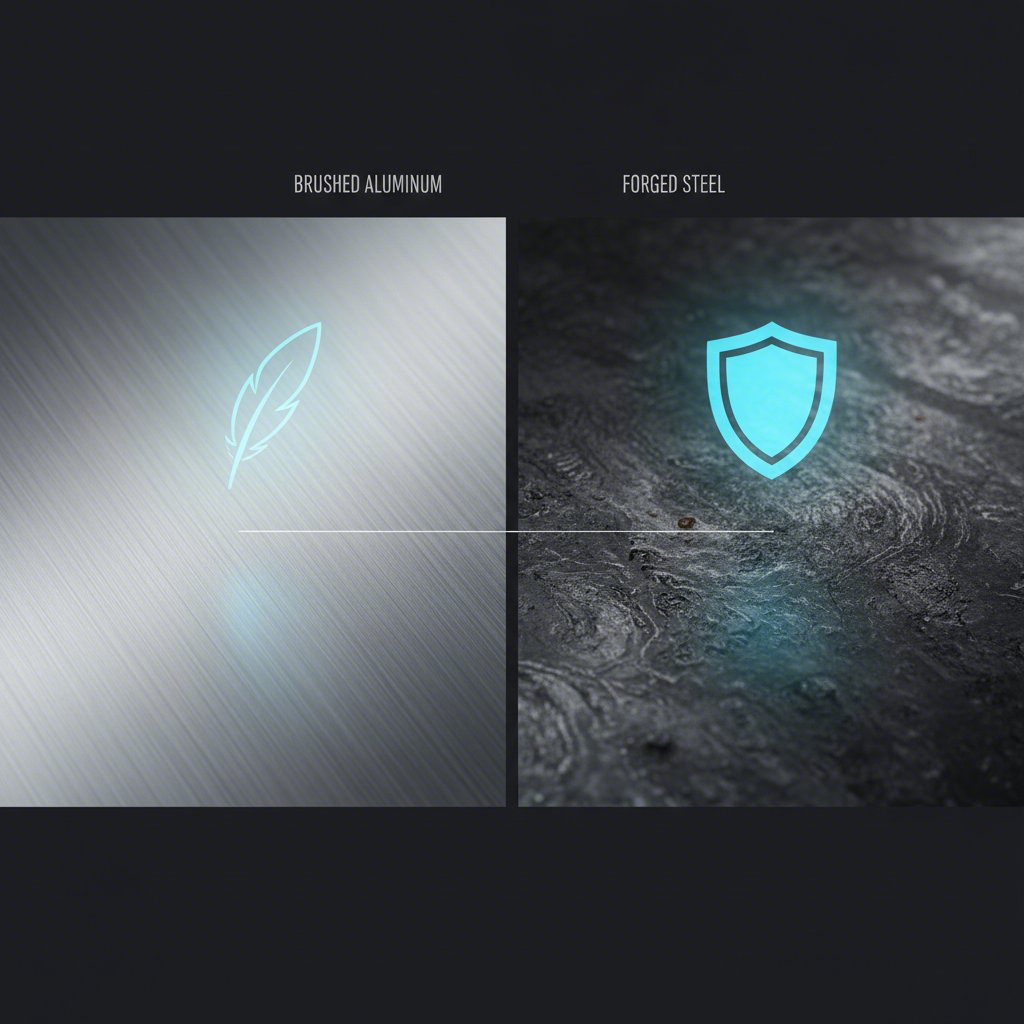

Steel is the traditional material of choice, prized for its exceptional strength, durability, and cost-effectiveness. It can withstand immense stress, making it ideal for heavy-duty applications like trucks, SUVs, and vehicles subjected to harsh conditions. Aluminum, a more recent innovation in suspension technology, offers a significant weight reduction. This lower "unsprung weight" allows the suspension to react more quickly to road imperfections, improving handling, agility, and ride comfort. While generally more expensive, aluminum is often the preferred material for performance and high-end vehicles.

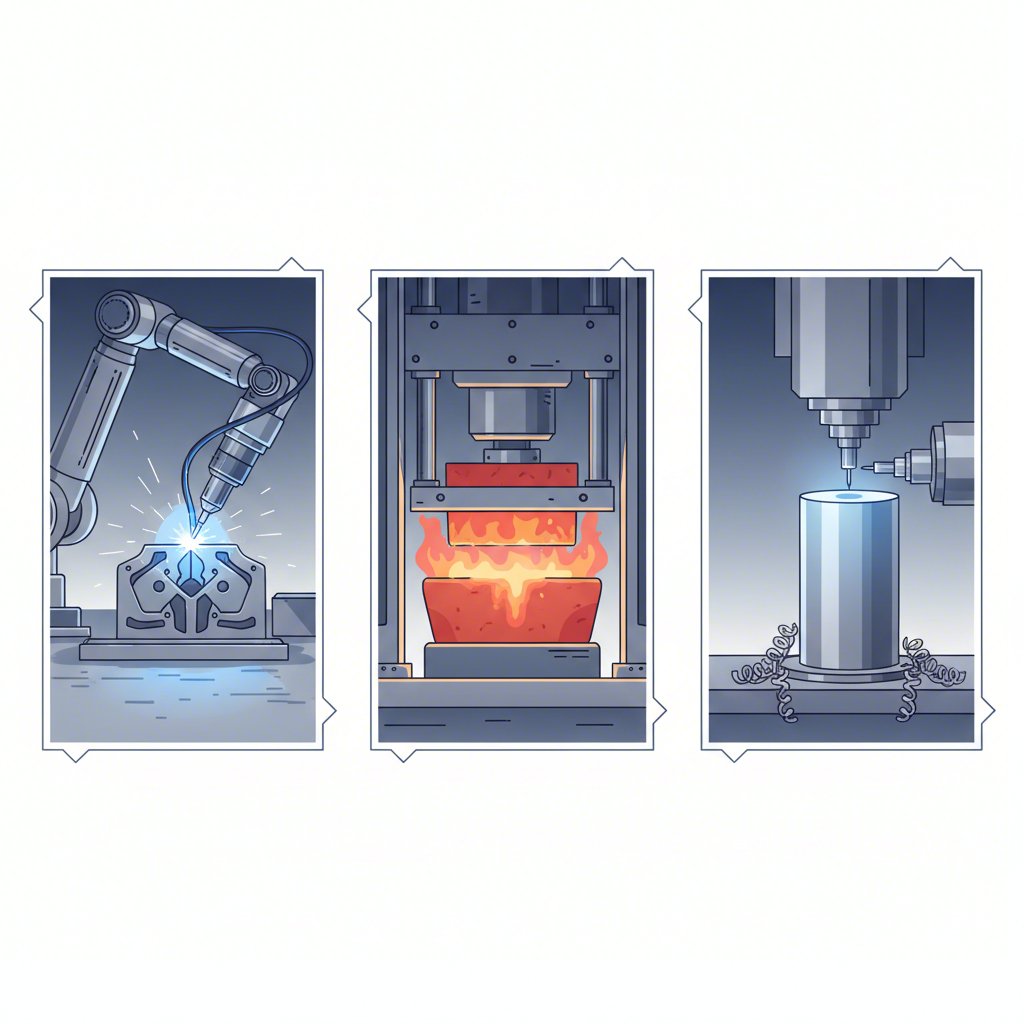

Manufacturing Processes and Their Impact

The method used to shape the metal is just as important as the material itself. Stamped steel control arms, created by pressing sheets of high-tensile steel into a specific shape, are common in mass-produced vehicles, offering a good balance of strength and manufacturing efficiency. For applications requiring even greater strength, manufacturers turn to forging, a process that shapes metal under extreme pressure to create a dense, robust component with superior fatigue resistance. On the other hand, CNC (Computer Numerical Control) machining offers unparalleled precision, carving control arms from solid blocks of metal to exact specifications, a method often used for high-performance and custom applications.

Leading component specialists and suppliers to OEMs often develop advanced, proprietary manufacturing techniques. For instance, Shaoyi (Ningbo) Metal Technology Co., Ltd. excels in creating custom automotive stamping dies and metal components, providing precision-engineered solutions for Tier 1 suppliers. Their expertise in advanced CAE simulations and IATF 16949-certified processes ensures that components meet the stringent quality standards required by modern vehicle manufacturers, from rapid prototyping to mass production.

The table below summarizes the key differences between the primary materials used:

| Feature | Steel Control Arms | Aluminum Control Arms |

|---|---|---|

| Strength & Durability | Excellent; highly resistant to stress and impact. Ideal for heavy-duty use. | Good strength-to-weight ratio, but can be less resilient to extreme impact than forged steel. |

| Weight | Heavier, which increases unsprung mass and can slightly dampen suspension responsiveness. | Significantly lighter, reducing unsprung weight for improved handling and ride quality. |

| Cost | More cost-effective to produce, making it standard for most passenger vehicles. | Higher material and manufacturing costs, typically found on premium or performance vehicles. |

| Corrosion Resistance | Requires protective coatings (e.g., E-coating) to prevent rust and corrosion. | Naturally resistant to corrosion, offering longer-lasting performance in harsh environments. |

| Best For | Trucks, SUVs, commercial vehicles, and budget-conscious daily drivers. | Performance cars, luxury vehicles, and applications where handling agility is a priority. |

Top Metal Control Arm Manufacturers in the Industry

The automotive aftermarket is populated by numerous manufacturers, each with a unique focus on engineering, materials, and target applications. From brands trusted by professional technicians for their durability to those specializing in off-road or racing performance, understanding the key players is essential for making an informed choice. These companies invest heavily in research and development to meet or exceed OEM specifications, often introducing innovations that enhance performance and simplify installation.

Several brands have established themselves as leaders through consistent quality and technological advancements. Mevotech, for instance, is a dominant supplier in North America, known for engineering parts specifically for technicians with features that save installation time. Similarly, MOOG Parts has a long-standing reputation for durability and innovation, offering premium and high-utilization designs that cater to vehicles under heavy loads or in challenging conditions. Other notable names include Delphi, TRW, and specialized manufacturers like JBA Offroad, which focuses on high-performance suspension for off-road vehicles. These companies form the backbone of the aftermarket, providing reliable solutions for nearly every vehicle type.

To aid in comparison, the following table highlights some of the industry's top manufacturers and their key attributes, based on information from industry analyses and brand documentation.

| Manufacturer | Key Features & Speciality | Primary Materials | Target Market |

|---|---|---|---|

| Mevotech | Engineered for technicians; features Labor Saver™ components for faster installation. Offers TTX line for extreme durability. | Steel, Aluminum, Aluminum, Aluminum, Aluminum | Professional Aftermarket, High-Utilization Vehicles |

| MOOG Parts | Focus on durability and problem-solving innovations. Carbon fiber-reinforced bearings and induction-hardened studs. | Steel | Professional Aftermarket, Daily Drivers, Heavy-Duty |

| Delphi Technologies | Global OE manufacturer with a focus on vehicle electronics and powertrain, extending to high-quality chassis components. | Steel, Aluminum | OEM, Professional Aftermarket |

| TRW | Long-standing global supplier known for safety systems and a wide range of OE-quality aftermarket parts. | Steel | OEM, Professional Aftermarket |

| Super Pro | Australian brand specializing in aftermarket solutions to improve handling and performance, particularly known for bushings. | Steel | Performance Enthusiasts, Aftermarket Upgrades |

| JBA Offroad | Specializes in aftermarket suspension parts for off-road vehicles, with a focus on lift kits and heavy-duty control arms. | Steel | Off-Road Enthusiasts |

Key Factors for Evaluating Control Arm Manufacturers

Selecting the right metal control arm manufacturer goes beyond simply matching a part number to a vehicle. To ensure long-term reliability and performance, it's crucial to evaluate manufacturers based on a set of technical and qualitative criteria. A superior control arm is the result of a deliberate combination of material science, precision engineering, and rigorous testing. Making a well-informed decision requires looking at the company's entire approach to creating these safety-critical components.

First and foremost is an assessment of material quality and engineering expertise. Reputable manufacturers are transparent about the materials they use, whether it's high-tensile stamped steel, forged steel, or lightweight aluminum alloys. Their engineering capabilities should be evident in their product designs, such as reinforced structures, advanced bearing technology, and corrosion-resistant coatings. As highlighted by manufacturers like GSW Auto Parts, geometric precision that matches OE specifications is non-negotiable for ensuring proper fitment and restoring the vehicle's original handling dynamics. A manufacturer that controls the entire assembly process, including the in-house production of bushings, often delivers a more integrated and reliable system.

Beyond the physical product, consider the manufacturer's range, reputation, and support. A broad product catalog indicates extensive experience across different vehicle platforms. Look for companies that follow stringent quality standards, such as IATF 16949 certification, which is a hallmark of commitment to quality in the automotive industry. Finally, factors like warranty coverage and customer support provide a safety net and indicate a manufacturer's confidence in their products. A comprehensive warranty and accessible technical assistance can be invaluable, especially when dealing with complex suspension repairs.

A Buyer's Checklist

- Material and Manufacturing Standards: Does the manufacturer specify the grade of steel or aluminum used? Do they adhere to industry standards like ISO or IATF certifications?

- Engineering and Design: Does the brand offer enhanced features over OEM parts, such as improved bearings, better corrosion protection, or reinforced designs for durability?

- Application Specificity: Does the manufacturer offer parts tailored for specific uses, such as heavy-duty, performance, or off-road applications?

- Component Integration: Are control arms sold as complete assemblies with high-quality, pre-installed ball joints and bushings? This often ensures better performance and saves installation time.

- Industry Reputation and Reviews: What is the consensus among professional technicians and end-users? Reviews and industry standing can provide insight into real-world performance and reliability.

- Warranty and Technical Support: Does the manufacturer stand behind their product with a solid warranty and provide accessible technical support for installation and troubleshooting?

Navigating Your Selection

Ultimately, the choice of a metal control arm manufacturer hinges on a balance of quality, application, and value. For a daily driver, a reputable aftermarket brand offering OE-equivalent parts provides a reliable and cost-effective solution. For trucks, commercial vehicles, or vehicles operating in harsh conditions, investing in a high-utilization or heavy-duty line from a manufacturer like MOOG or Mevotech ensures longevity and safety. For enthusiasts seeking to enhance their vehicle's handling, a performance-oriented brand specializing in lightweight aluminum or adjustable steel arms is the superior choice. By carefully considering the factors of material, engineering, and reputation, you can select a manufacturer that delivers the performance and peace of mind you require.

Frequently Asked Questions

1. What is the best metal for control arms?

The best metal depends on the application. Steel is favored for its strength and durability, making it ideal for trucks, SUVs, and situations demanding high resilience. Aluminum is prized for its light weight, which reduces unsprung mass and improves handling and ride comfort, making it a top choice for performance and luxury vehicles.

2. Who makes the best aftermarket upper control arms?

Several brands are highly regarded for their aftermarket upper control arms. MOOG is known for durability and engineering that often exceeds OEM standards. Mevotech is praised by technicians for its Supreme and TTX lines, which are designed for enhanced performance and easy installation. Other reputable brands include Dorman, Delphi, and specialized manufacturers for specific applications like off-roading.

3. Are MOOG parts better than OEM parts?

MOOG parts are engineered to meet or often exceed the standards of Original Equipment Manufacturer (OEM) parts. They frequently incorporate design improvements, such as greasable sockets and stronger materials, to solve common failure points in the original designs. While OEM parts are guaranteed to match the car's original specifications, many technicians prefer MOOG for its reputation for enhanced durability and longevity.

4. Is Delphi or Dorman better?

Both Delphi and Dorman are reputable aftermarket brands, but they often serve slightly different market segments. Delphi Technologies is a major OE supplier, and their aftermarket parts are known for their high quality and adherence to original specifications. Dorman offers a vast catalog of replacement parts, including many "OE FIX" solutions that redesign components to correct original flaws. Generally, Delphi is considered a premium brand, while Dorman is known for providing a wide range of reliable and accessible solutions.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —