How Automation in Automotive Die Manufacturing Drives Innovation

TL;DR

Automation in automotive die manufacturing leverages robotics, advanced sensors, and intelligent software to transform the production of metal components. By integrating multiple complex steps like stamping and welding into a single, streamlined die casting process, this technology dramatically increases production speed, reduces manufacturing costs, enhances part quality, and improves worker safety. It is a cornerstone of modern vehicle production, enabling innovations like large, single-piece underbodies and lightweighting for electric vehicles.

What Is Die Casting Automation and Why Is It Revolutionizing Automotive Manufacturing?

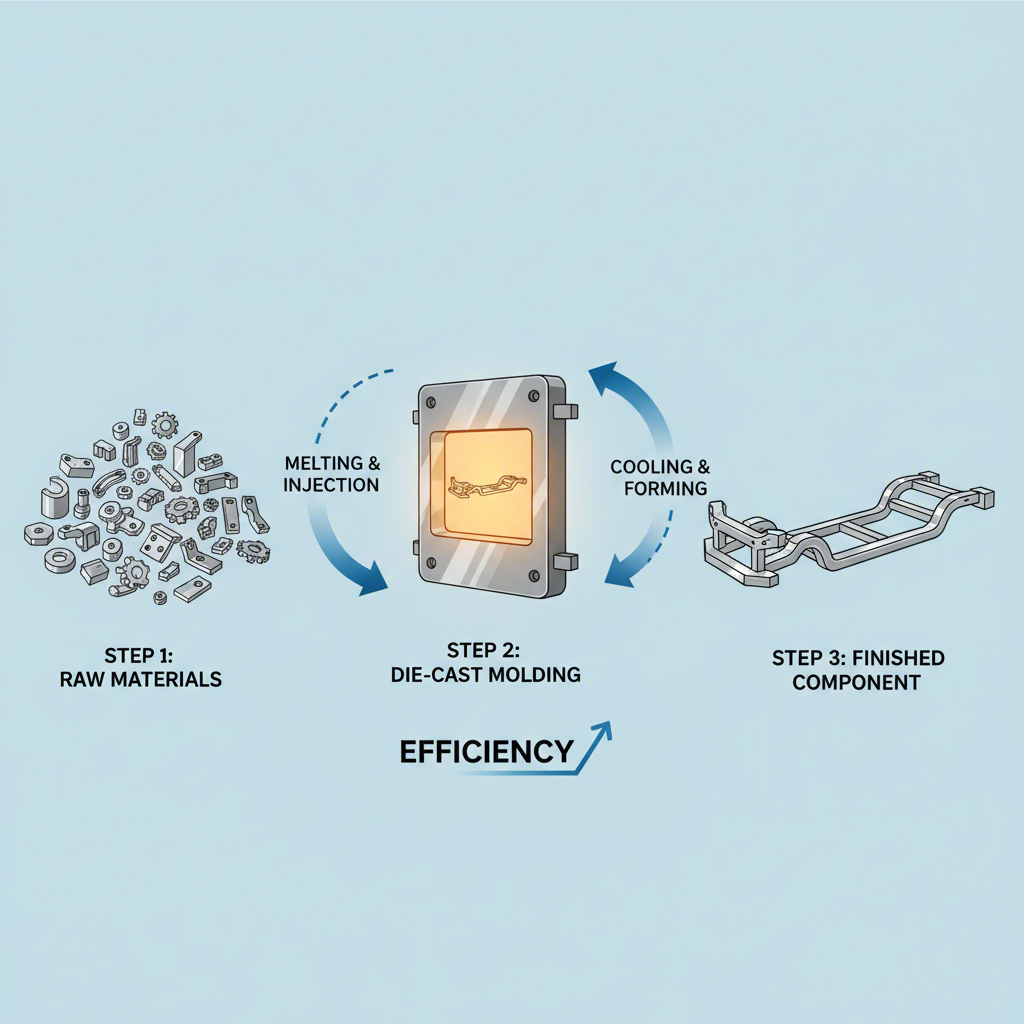

Die casting automation is the strategic use of robotic systems, sensors, and sophisticated software to streamline every stage of the die casting process, from handling molten metal to final quality inspection. This integration marks a fundamental departure from traditional automotive manufacturing, which has long relied on a sequence of separate stages: stamping individual metal sheets, welding them together with hundreds of robots, painting, and final assembly. Automation collapses this complex, multi-stage workflow into a more efficient, unified operation.

The revolutionary impact of this technology is best exemplified by the concept of "giga casting," pioneered by automakers like Tesla. Instead of welding dozens of smaller stamped parts to create a vehicle's underbody, a massive die casting machine injects molten aluminum into a mold to form a large section of the car in a single piece. This approach dramatically simplifies the production line. For instance, one notable application replaced 79 individual stamped parts with just one or two large die-cast components. As detailed in a report by the International Society of Automation (ISA), this consolidation reduced the number of robotic weld points from approximately 800 down to just 50.

This shift has profound implications for efficiency and speed. The traditional process of stamping and welding a car's body-in-white could take one to two hours. With integrated die casting, the same structural component can be produced in as little as three to five minutes. This massive reduction in cycle time not only accelerates vehicle output but also significantly shrinks the factory footprint required for production, as a single large die casting machine can replace an entire line of welding robots.

Furthermore, this innovation is a critical enabler for the advancement of electric vehicles (EVs). A primary challenge for EVs is "range anxiety," which manufacturers address by adding more battery modules. However, this adds significant weight, which in turn reduces range. Integrated die casting allows for the creation of lighter, yet stronger, vehicle bodies, a process known as lightweighting. By reducing the overall vehicle weight, manufacturers can improve battery efficiency and extend driving range without sacrificing structural integrity, making automation a key driver of next-generation automotive design.

The Core Benefits and Opportunities of Automation in Die Casting

The adoption of automated die casting offers a compelling business case built on significant improvements in safety, efficiency, quality, and cost-effectiveness. These advantages address some of the most persistent challenges in high-volume manufacturing and provide a clear pathway to a leaner, more competitive operation. By automating dangerous and repetitive tasks, manufacturers can unlock new levels of productivity and precision.

One of the most immediate and critical benefits is enhanced worker safety. Die casting environments involve extreme heat, molten metal, and high-pressure injection systems, all of which pose significant risks to human operators. As highlighted by Convergix Automation, robots are designed to tolerate these harsh conditions. They can handle tasks like ladling molten aluminum, lubricating hot dies, and extracting newly formed castings without exposure to danger, creating a safer and more comfortable work environment for employees.

Automation also delivers major gains in efficiency and speed. Unlike human workers, robotic systems can operate continuously without breaks or fatigue, leading to higher throughput and reduced cycle times. This capability is essential for meeting the high-volume demands of the automotive industry. A prime example of this impact comes from a case study involving automotive supplier Pentaflex, which implemented a semi-automated assembly system. This collaboration with JR Automation resulted in a remarkable 70% reduction in labor requirements and faster production cycles, allowing the company to upskill its team for more value-added roles.

Beyond speed, automation ensures superior quality and consistency. Manual processes, such as lubricating a die, can vary from one operator to another, potentially leading to casting defects. Automated systems perform these tasks with machinelike precision every single time, ensuring consistent application of lubricants and uniform part quality. This repeatability minimizes defects, reduces scrap rates, and leads to a more reliable final product with tighter tolerances.

Ultimately, these benefits translate into substantial cost reduction. The ISA report on integrated die casting noted that the technology can lower manufacturing costs by as much as 40%. These savings are achieved through multiple avenues: reduced labor requirements, lower material waste, fewer production steps, and decreased scrap rates. By optimizing the entire process, automation provides a powerful financial incentive for manufacturers to invest in modernizing their die casting operations.

Key Automation Technologies in the Die Casting Process

The successful automation of die casting relies on a suite of integrated technologies that work in concert to manage the process from raw material to finished part. These systems replace manual intervention at critical stages, ensuring precision, safety, and efficiency. The core technologies involved include advanced robotics, machine vision, and intelligent control systems that oversee each step of the manufacturing workflow.

The process begins with Material Handling and Ladling. Automated guided vehicles (AGVs) can transport molten aluminum from the furnace to the die casting machine, while robotic arms perform the dangerous task of ladling the precise amount of metal required for each shot. This eliminates human exposure to extreme heat and ensures a consistent volume of material for every cycle, which is crucial for part quality. After casting, robots are also used to extract the hot part from the die and place it on cooling conveyors or in trimming presses.

Next is Machine Tending and Die Preparation. Before each cycle, the die must be sprayed with a lubricant to prevent the casting from sticking and to manage the die's temperature. Robots equipped with specialized spray heads can apply this lubricant with perfect consistency, covering all surfaces evenly. This automated lubrication is far more precise than manual spraying and is critical for extending the life of the die and preventing casting defects. The robot also signals the machine to close the die and initiate the injection cycle, seamlessly tending the machine.

Quality Control and Inspection represent one of the most significant areas of advancement. Automated Optical Inspection (AOI) systems use high-resolution cameras and sophisticated software to scan each part for surface defects like cracks, porosity, or dimensional inaccuracies. As explained by Die-Matic, these systems can detect imperfections that might be missed by the human eye, ensuring that only high-quality parts move forward. For even greater precision, Coordinate Measuring Machines (CMMs) can be used to verify that the part's dimensions meet strict design specifications.

Finally, Post-Processing tasks are also prime candidates for automation. After the part is cast, it often has excess material, known as flash or burrs, that must be removed. Robotic arms can be fitted with tools to perform deburring, trimming, drilling, or grinding with high precision and repeatability. This not only speeds up the finishing process but also improves the consistency of the final product. For manufacturers seeking to implement such advanced systems, specialized providers offer expertise in creating the custom die casting dies and components that form the foundation of these automated production lines.

The Future Trajectory: Automation and the Evolution of Automotive Manufacturing

Automation in die casting is not just an optimization of current processes; it is a foundational technology shaping the future of the automotive industry. As manufacturers face pressures from the shift to electric vehicles, supply chain disruptions, and evolving consumer demands, advanced automation provides the flexibility and intelligence needed to build a more resilient and innovative production ecosystem. The trajectory is moving toward smarter, more connected, and highly adaptable factories.

A key driver of this evolution is the transition to Electric and Hybrid Vehicles. These vehicles require complex and highly integrated components, such as battery trays and powertrain housings, that are ideally suited for die casting. Automation enables the precision and scale needed to produce these parts efficiently. Techniques like giga casting are becoming central to EV manufacturing strategies, as they allow for lighter, more rigid vehicle platforms that improve safety and range. As battery technology evolves, automated systems will be critical for adapting production lines to new designs and chemistries.

The concept of the Smart Supply Chain is another major trend. Automation extends beyond the factory floor to create more intelligent logistics and inventory management. By integrating AI-driven analytics, manufacturers can predict material shortages, optimize inventory levels, and track components with enhanced traceability using technologies like RFID and IoT. This data-driven approach minimizes downtime and allows for a more agile response to global disruptions, making the entire supply chain more robust.

Furthermore, digital tools like Digital Twins and Simulation are revolutionizing how production lines are designed and managed. A digital twin is a virtual replica of a physical system, allowing engineers to simulate the entire die casting process, test different configurations, and identify potential bottlenecks before a single piece of equipment is installed. This virtual commissioning saves time and resources, ensuring that new automated systems are optimized for peak performance from day one. This technology is a cornerstone of Industry 4.0, enabling continuous improvement and predictive maintenance.

Looking ahead, these trends point toward a future of modular, flexible production where automation allows manufacturers to quickly adapt to market shifts. Investing in these advanced systems is no longer just about efficiency gains; it has become a strategic necessity for any automaker looking to maintain a competitive edge in a rapidly transforming industry.

The Strategic Imperative of Automated Die Casting

The integration of automation into automotive die manufacturing represents more than an incremental improvement; it is a paradigm shift that redefines the boundaries of production efficiency, vehicle design, and industry competitiveness. By consolidating complex, multi-stage processes into a single, streamlined operation, this technology offers a powerful solution to the modern challenges of lightweighting, cost reduction, and speed to market. From enhancing worker safety to ensuring flawless part quality, the benefits are comprehensive and compelling.

As the automotive world accelerates toward an electric and digitally connected future, the role of advanced manufacturing will only grow. Technologies like giga casting and AI-driven quality control are no longer futuristic concepts but practical tools being deployed today to build the next generation of vehicles. For OEMs and suppliers, embracing automation is not merely an option but a strategic imperative for survival and growth. The ability to produce stronger, lighter, and more complex components at scale will be the defining characteristic of industry leaders in the years to come.

Frequently Asked Questions

1. Can die casting be automated?

Yes, die casting is highly suitable for automation. Robots and automated systems can efficiently manage nearly every step of the process, including pouring molten metal, lubricating dies, extracting finished parts, and performing quality inspections. This automation increases speed, improves safety by removing humans from hazardous conditions, and ensures consistent product quality.

2. How is automation used in car manufacturing?

In car manufacturing, automation is used extensively across the production line. Robotics are integral to tasks like welding, painting, assembly, and material handling. In the context of die casting, automation is used to create large structural components, handle molten metals, inspect parts for defects using machine vision, and perform post-processing tasks like trimming and deburring, all of which increase capacity and protect workers.

3. What are the 4 types of industrial automation?

The four main types of industrial automation are fixed automation, programmable automation, flexible automation, and integrated automation. Fixed automation is used for high-volume, repetitive tasks with dedicated equipment. Programmable automation allows for changes in the sequence of operations to accommodate different product configurations. Flexible automation is an extension of programmable automation that allows for quicker changeovers between different products. Integrated automation connects all of these systems under a central control system for a fully unified production process.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —