How High-Performance Die Casting Drives Automotive Innovation

TL;DR

High-performance automotive die casting is a manufacturing process where molten metal, such as aluminum or zinc, is injected into a mold under extreme pressure. This method produces strong, lightweight, and highly precise components essential for modern vehicles. The technology is critical for improving fuel efficiency, enhancing overall performance, and enabling the advanced designs required for both internal combustion engine (ICE) and electric vehicles (EVs).

Understanding High-Performance Automotive Die Casting

Automotive die casting is a foundational manufacturing process that creates complex and dimensionally accurate metal parts by forcing molten metal into a reusable steel mold, known as a die. In high-performance applications, this process is refined to produce components that meet stringent requirements for strength, weight, and precision. The use of high pressure ensures the molten metal fills every intricacy of the mold, resulting in a net-shape part that requires minimal secondary machining.

This technology is central to the production of numerous critical vehicle components. Automakers rely on die casting for parts that are both lightweight and durable, directly contributing to vehicle safety and efficiency. As described by experts at Autocast Inc., the process is vital for producing everything from engine blocks and transmission cases to structural chassis components. For example, die-cast aluminum engine blocks reduce overall engine weight, which improves acceleration and fuel economy, while their precise design aids in efficient heat dissipation.

The applications extend throughout the vehicle. Key examples of die-cast parts highlighted by industry analyses from Transvalor include:

- Engine Components: Cylinder heads and engine blocks that are lightweight and robust.

- Transmission Cases: Rigid and dimensionally stable housings for efficient power transmission.

- Chassis and Structural Parts: Suspension brackets and steering knuckles with high strength-to-weight ratios.

- Electronic Housings: Protective covers for sensors, gearboxes, and motors.

- Brake Components: Brake calipers that require high strength and precision for safety.

The adoption of high-performance die casting offers a suite of benefits that directly translate to better vehicles. By creating lightweight parts, it reduces a vehicle's curb weight, which is a primary factor in improving fuel efficiency and reducing emissions. Furthermore, the precision of die-cast components leads to smoother engine operation, more responsive handling, and increased overall durability. The process is also highly efficient, enabling rapid production cycles and cost-effective manufacturing for high-volume parts.

Core Processes and Manufacturing Considerations

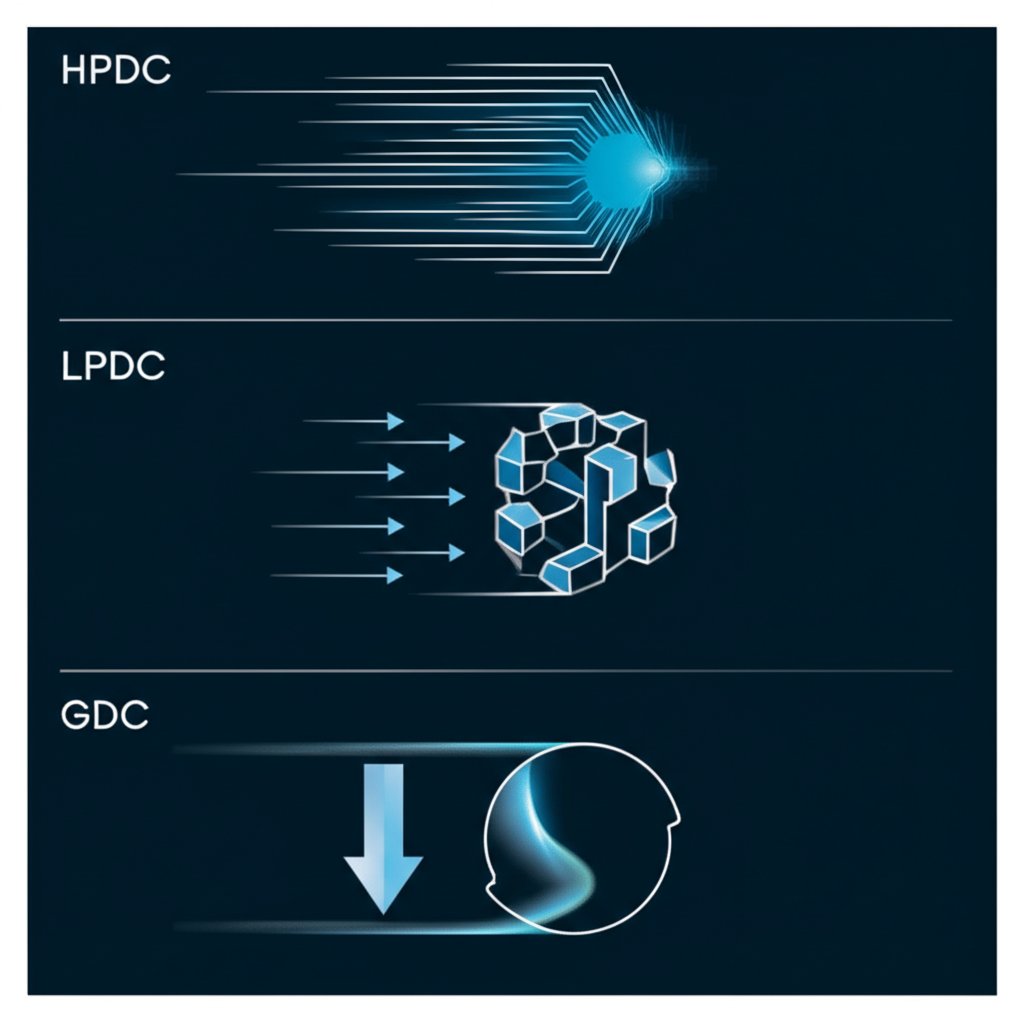

The world of die casting is not monolithic; several distinct processes exist, each tailored to different materials and component requirements. The three primary methods are High-Pressure Die Casting (HPDC), Low-Pressure Die Casting (LPDC), and Gravity Die Casting (GDC). Understanding their differences is key to appreciating why HPDC is so prevalent in high-performance automotive applications.

HPDC, as the name implies, injects molten metal at extremely high speeds and pressures. According to DyCast Specialties Corporation, this method is ideal for producing large volumes of complex, thin-walled parts with excellent dimensional accuracy and smooth surface finishes. HPDC itself is divided into two main categories: the hot-chamber process, used for low-melting-point alloys like zinc, and the cold-chamber process, used for high-melting-point alloys like aluminum. The cold-chamber method is dominant in automotive for producing large structural parts like engine blocks and transmission housings.

While die casting excels for complex, net-shape parts, other high-performance manufacturing processes like forging are critical for components requiring maximum strength and fatigue resistance. For instance, companies like Shaoyi (Ningbo) Metal Technology specialize in automotive forging, offering another pathway to creating robust vehicle parts through a process that shapes metal using compressive forces.

However, HPDC is not without its challenges. A primary disadvantage is the potential for porosity, where tiny voids or holes form within the cast part due to trapped gases. This can compromise the mechanical properties of the component. To combat this, advanced techniques like the Transition Flow Filling Method (TFFM) are used to minimize trapped gas, as noted by AdvanTech International. Below is a comparison of the main casting processes:

| Process | Key Characteristics | Best For | Common Automotive Applications |

|---|---|---|---|

| High-Pressure Die Casting (HPDC) | Very high speed, high precision, smooth finish, potential for porosity. | High-volume, complex, and thin-walled parts. | Engine blocks, transmission cases, electronic housings, structural components. |

| Low-Pressure Die Casting (LPDC) | Slower fill speed, good structural integrity, less turbulence. | Large, symmetrical, and structurally sound components requiring high integrity. | Wheels, suspension parts, and other safety-critical components. |

| Gravity Die Casting (GDC) | Uses gravity to fill the mold, simple process, results in dense parts. | Producing strong, high-integrity parts with minimal porosity. | Brake calipers, pistons, and other parts needing high strength. |

Key Materials in High-Performance Die Casting

The choice of material is as critical as the casting process itself. In automotive die casting, engineers primarily select from a range of non-ferrous alloys, with aluminum, zinc, and magnesium being the most prominent. Each material offers a unique profile of properties that makes it suitable for specific applications, directly impacting vehicle performance, weight, and durability.

Aluminum is the workhorse of the automotive die casting industry. Its combination of light weight, high strength, excellent corrosion resistance, and good thermal conductivity makes it an ideal choice for a wide array of components. As detailed by manufacturing experts at Dynacast, thin-walled aluminum castings can withstand the highest operating temperatures of all die-cast alloys, making them perfect for engine blocks, transmission housings, and heat sinks. The push for lightweighting to improve fuel efficiency has made aluminum an indispensable material.

Zinc alloys are another popular choice, particularly for parts requiring intricate detail and a high-quality surface finish. Zinc's fluidity allows it to fill thin-walled, complex sections of a die with exceptional precision, often eliminating the need for secondary operations. It is commonly used for smaller, detailed components like electronic housings, interior cosmetic parts, and complex sensor bodies. Furthermore, dies used for zinc casting last significantly longer than those for aluminum, making it a cost-effective option for high-volume production runs.

Magnesium stands out as the lightest of all structural metals. Its primary advantage is its exceptional strength-to-weight ratio, making it a premium choice for applications where weight reduction is the absolute priority. Magnesium components are often found in high-end vehicles in parts like interior frames, steering wheel cores, and instrument panels. The use of advanced processes like Thixomolding can further enhance the quality and application range of magnesium parts.

| Material | Key Properties | Cost | Common Automotive Use Cases |

|---|---|---|---|

| Aluminum | Lightweight, high strength, excellent heat dissipation, corrosion resistant. | Moderate | Engine blocks, transmission cases, chassis components, heat sinks, EV motor housings. |

| Zinc | High fluidity for complex shapes, excellent surface finish, high durability. | Lower (factoring in tool life) | Electronic housings, sensors, interior components, connectors, gears. |

| Magnesium | Extremely lightweight, excellent strength-to-weight ratio, good stiffness. | Higher | Instrument panels, steering wheel frames, seat frames, sub-frames. |

The Future of Automotive Die Casting: Innovations for EVs and Electronics

The automotive industry is undergoing a seismic shift toward electrification and autonomous driving, and die casting technology is evolving rapidly to meet these new challenges. The future of high-performance die casting is intrinsically linked to the demands of Electric Vehicles (EVs) and the proliferation of advanced electronics. This evolution is not just about making existing parts better; it's about enabling entirely new vehicle architectures.

For EVs, lightweighting is even more critical than for traditional vehicles, as it directly impacts range and performance. Die casting is playing a pivotal role in producing large, single-piece structural components—a trend often referred to as 'gigacasting'. This involves casting massive parts like an entire vehicle underbody or a battery tray as a single unit. This approach consolidates hundreds of smaller stamped and welded parts into one, dramatically simplifying assembly, reducing weight, and lowering costs. These large aluminum castings are essential for housing and protecting heavy battery packs while contributing to the vehicle's structural rigidity.

Simultaneously, the rise of advanced driver-assistance systems (ADAS) and in-car connectivity has led to an explosion in the number of sensors, cameras, and electronic control units (ECUs) in a vehicle. Each of these components requires precisely manufactured, electromagnetically shielded housings. Die casting, particularly with zinc and aluminum alloys, is the ideal process for creating these complex, thin-walled enclosures. The net-shape capability of die casting allows intricate features like heat sinks and mounting points to be integrated directly into the part, saving space and improving thermal management for sensitive electronics.

Technological advancements in the casting process itself are also pushing the boundaries of what's possible. Innovations such as vacuum-assisted casting and advanced mold flow simulation software allow for the production of parts with lower porosity, higher strength, and even weldable properties. These advancements are critical for creating safety-critical structural components and leak-proof battery enclosures for EVs. As the industry moves forward, die casting will continue to be a key enabler of safer, more efficient, and more sustainable vehicles.

Frequently Asked Questions

1. What are the disadvantages of HPDC?

The primary disadvantage of High-Pressure Die Casting (HPDC) is the risk of porosity. Because the molten metal is injected at high speed, gases can become trapped within the die, forming tiny voids in the finished part. This porosity can weaken the component and may make it unsuitable for applications requiring heat treatment or welding. However, modern techniques like vacuum assistance and advanced mold design help to mitigate this issue.

2. What is the difference between HPDC, LPDC, and GDC?

As detailed in the main body of the article, the key difference lies in the pressure and speed used to fill the mold. HPDC uses very high pressure for rapid, high-volume production of complex parts. LPDC uses lower pressure for a slower, more controlled fill, ideal for structurally sound components like wheels. GDC relies solely on gravity, resulting in dense, strong parts but with a much slower production cycle.

3. What is the filling ratio for HPDC?

The filling ratio in HPDC refers to the volume of molten metal poured into the injection sleeve compared to the sleeve's total volume. Research suggests that a filling ratio of 60-70% is often recommended. This helps minimize the amount of air that gets pushed into the mold cavity along with the metal, thereby reducing gas entrapment and porosity in the final component.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —