Galvanized Steel Stamping Issues: Troubleshooting Zinc Pickup

TL;DR

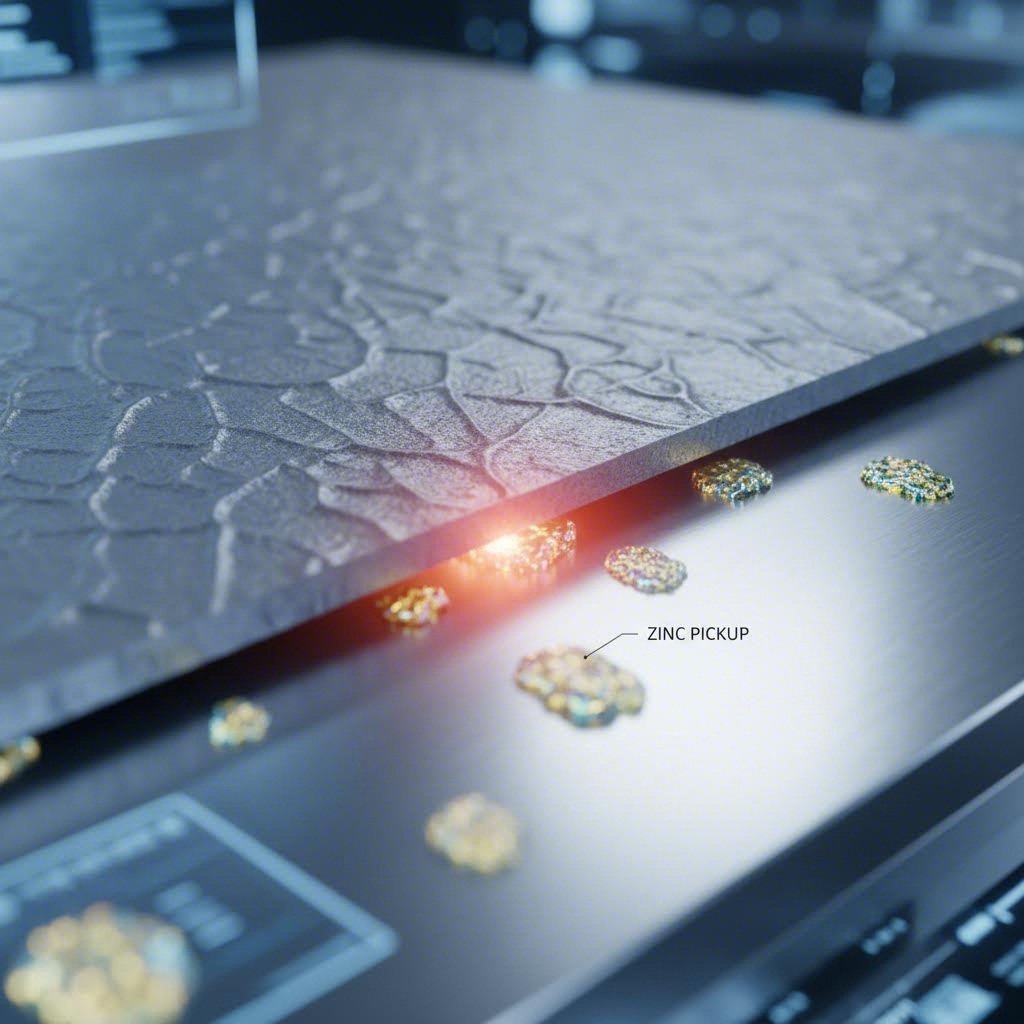

Stamping galvanized steel introduces a unique tribological challenge: the soft, reactive zinc coating creates distinct friction behaviors compared to bare steel. The primary issue is "zinc pickup" or galling, where the coating transfers to the die surface, leading to a "stick-slip" phenomenon often described by operators as a screeching sound similar to chalk on a blackboard. This friction instability causes part splitting, coating flaking, and rapid tool wear.

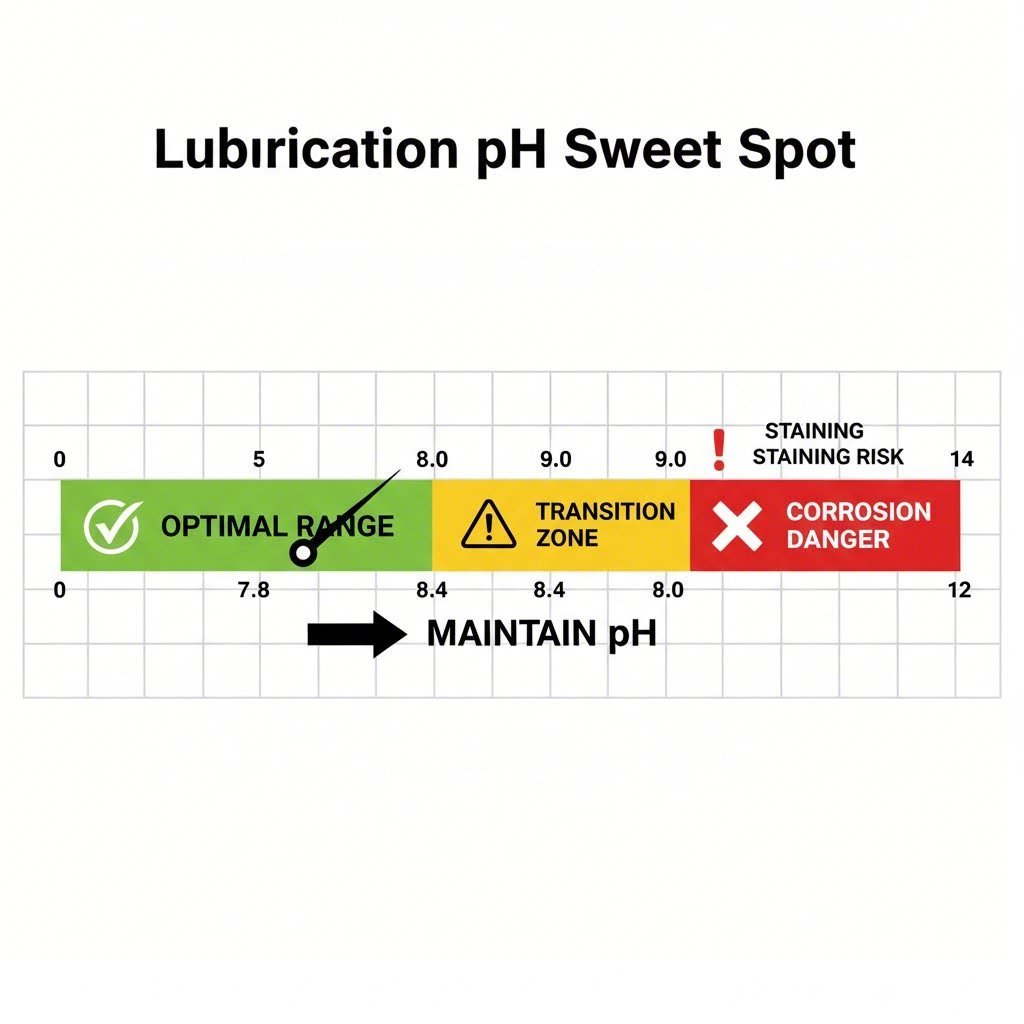

To solve these galvanized steel stamping issues, manufacturers must manage the entire tribological system. This involves maintaining lubricant pH between 7.8 and 8.4 to prevent staining, using PVD-coated tooling (like TiAlN) to reduce adhesion, and widening die clearances to accommodate the coating thickness. Success lies in preventing the initial zinc transfer that triggers catastrophic tool failure.

The Friction & Galling Crisis: Zinc Pickup and Die Maintenance

The most pervasive failure mode in galvanized stamping is galling, commonly referred to as "zinc pickup." Unlike the abrasive wear seen with high-strength steels, zinc pickup is an adhesive failure mechanism. The soft zinc coating, under the immense heat and pressure of the draw, literally fuses to the die surface. Once this transfer begins, it alters the die's geometry and surface finish, creating a rough, high-friction area that scores and ruins subsequent parts.

Research using draw-bead simulators has revealed a characteristic "stick-slip" behavior in electrogalvanized steels. During testing, this manifests as an initial load spike—a sudden jump in friction force as the zinc adheres to the tool steel. On the shop floor, this unstable friction creates an audible screeching or chattering noise. This instability is not just a nuisance; it leads to inconsistent material flow, causing the steel to lock up in binder areas or buckle where it should flow freely.

To combat this, die maintenance strategies must evolve. Traditional polishing techniques used for bare steel can be detrimental if they are too aggressive. Instead, the focus should be on maintaining a mirror finish that prevents the initial adhesion. Advanced PVD (Physical Vapor Deposition) coatings, such as Titanium Aluminum Nitride (TiAlN) or Diamond-Like Carbon (DLC), are essential for modern dies. These hard, smooth coatings provide a chemical barrier that zinc cannot easily bond to, significantly extending the intervals between maintenance stops.

Coating Failure Modes: Flaking vs. Powdering

Understanding the difference between flaking and powdering is critical for diagnosing the root cause of a failure. These two defects look similar to the untrained eye but result from completely different metallurgical failure modes. Misdiagnosing them often leads to expensive, ineffective countermeasures.

Flaking is an adhesive failure at the interface between the steel substrate and the zinc coating. It typically appears as large, distinct chips of zinc peeling away, often caused by excessively thick coatings (typically over 8–10 mils) that generate high internal stresses during deformation. It is frequently observed in Hot-Dipped Galvanized (GI) products where the brittle intermetallic layer at the interface fractures under shear stress.

Powdering, in contrast, is a cohesive failure within the coating itself. It manifests as a fine dust or accumulation of debris in the die. This is particularly common in Galvannealed (GA) steel, where the coating is an iron-zinc alloy. While Galvanneal is harder and more weldable, its coating is inherently more brittle. The degree of powdering is often linked to the Skin Pass Mill (SPM) elongation during steel production; higher elongation can improve resistance to powdering but may negatively impact flaking resistance, creating a delicate trade-off for material suppliers.

Surface Defects: Blackening, Staining, and White Rust

Beyond structural failures, aesthetic defects are a major source of scrap, particularly for exposed automotive panels. "Blackening" is a common phenomenon caused by friction-induced oxidation. When the stamping process generates excessive heat, the aluminum or zinc in the coating oxidizes rapidly, leaving dark streaks on the part. This is often a signal that the lubrication barrier has broken down.

"White rust" (wet storage stain) is another pervasive issue, though it typically originates in storage rather than the press. It occurs when zinc reacts with moisture in an oxygen-deprived environment, such as between tightly nested parts. To prevent this, parts must be dried thoroughly—often using air knives—before stacking. Stacking patterns should allow for airflow to prevent moisture entrapment.

Environmental factors in the plant also play a role. High levels of sulfur or sulfates in the process water can react with the zinc to create black stains. Operators must monitor the water quality used to dilute lubricants, as even minor changes in municipal water chemistry can trigger a sudden outbreak of surface defects.

Lubrication & Tooling Strategy: The Preventative Fix

The choice of lubricant is the single most controllable variable in preventing galvanized steel stamping issues. The chemistry of the lubricant must be compatible with the reactive nature of zinc. A critical parameter is pH control. Lubricants with a pH above 8.5 or 9.0 can trigger "saponification," a reaction where the alkali lubricant attacks the zinc to form a soap-like residue. This not only stains the part but can gum up the die.

The Golden Rule of Lubrication: Maintain a pH between 7.8 and 8.4. This range is the "sweet spot" that provides sufficient corrosion protection without attacking the coating. Furthermore, the industry is shifting away from heavy mineral oils, which leave a residue that complicates welding and cleaning, toward synthetic lubricants. Synthetics (like polymer-based fluids) offer excellent film strength to separate the die from the workpiece without the cleaning headaches associated with oil.

For high-volume production where precision is paramount, partnering with capable suppliers is essential. Shaoyi Metal Technology’s comprehensive stamping solutions bridge the gap between prototyping and mass production, leveraging IATF 16949-certified processes to manage these complex variables. Their expertise in handling coated steels allows for tight control over the entire forming process, ensuring that lubrication and tooling strategies are optimized for zero-defect manufacturing.

Downstream Implications: Welding and Finishing

The consequences of stamping decisions often manifest downstream in the assembly line. A major safety and quality concern is the generation of zinc fumes during welding. If the stamping lubricant is not properly removed or if it reacts with the zinc, it can exacerbate the porosity in welds and increase the volume of toxic zinc oxide fumes, leading to "Metal Fume Fever" among operators. Cleanability of the stamped part is therefore a safety feature.

Paint adhesion is another victim of poor stamping process control. If alkyd-based paints are used on parts with residual zinc soaps (from high-pH lubricants), the paint will peel—a failure mechanism known as saponification. To ensure proper paint adhesion, stamped parts typically require a phosphate conversion coating pre-treatment. This chemical process converts the surface into a non-reactive layer that promotes strong paint bonding, neutralizing the risks created during the stamping phase.

Conclusion

Mastering galvanized steel stamping requires a shift from reactive troubleshooting to proactive process engineering. It is not enough to simply apply more oil when parts split; the entire tribological system—coating type, die material, lubricant pH, and surface topography—must be balanced. By understanding the distinct mechanisms of zinc pickup, flaking, and chemical staining, manufacturers can turn a notorious production headache into a reliable, high-quality process.

The difference between 10% scrap and near-zero defects often lies in the invisible details: the pH of a lubricant, the coating on a die, or the microscopic roughness of the sheet surface. Attention to these variables is the hallmark of a world-class press shop.

Frequently Asked Questions

1. What causes black marks on galvanized steel parts?

Black marks are typically caused by friction oxidation or "friction polymers." When the stamping process generates excessive heat due to poor lubrication or tight clearances, the zinc or aluminum in the coating oxidizes, creating dark streaks. High sulfur content in the process water can also react with the zinc to form black stains.

2. Why does paint peel off galvanized steel?

Paint peeling is often due to saponification. If an alkyd-based paint is applied directly to a galvanized surface, the zinc reacts with the resins to form a soap layer at the interface, causing the paint to delaminate. Proper cleaning and the use of a phosphate conversion coating or a wash primer are required to prevent this.

3. How do I prevent white rust on stamped parts?

White rust forms when galvanized parts are exposed to moisture without adequate airflow, common in tightly nested stacks. To prevent it, ensure parts are completely dry before stacking, use air knives to remove residual coolant, and store parts in a climate-controlled environment with low humidity.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —