Fine Blanking Automotive Applications: The Engineer’s Guide

TL;DR

Fine blanking is a specialized high-precision metal forming process that utilizes a triple-action press (stinger, punch, and counter-punch) to produce components with 100% fully sheared edges, superior flatness, and dimensional tolerances as tight as ±0.001 inches. Unlike conventional stamping, which leaves rough fracture zones, fine blanking produces ready-to-assemble parts in a single stroke, eliminating secondary operations like grinding, milling, or reaming.

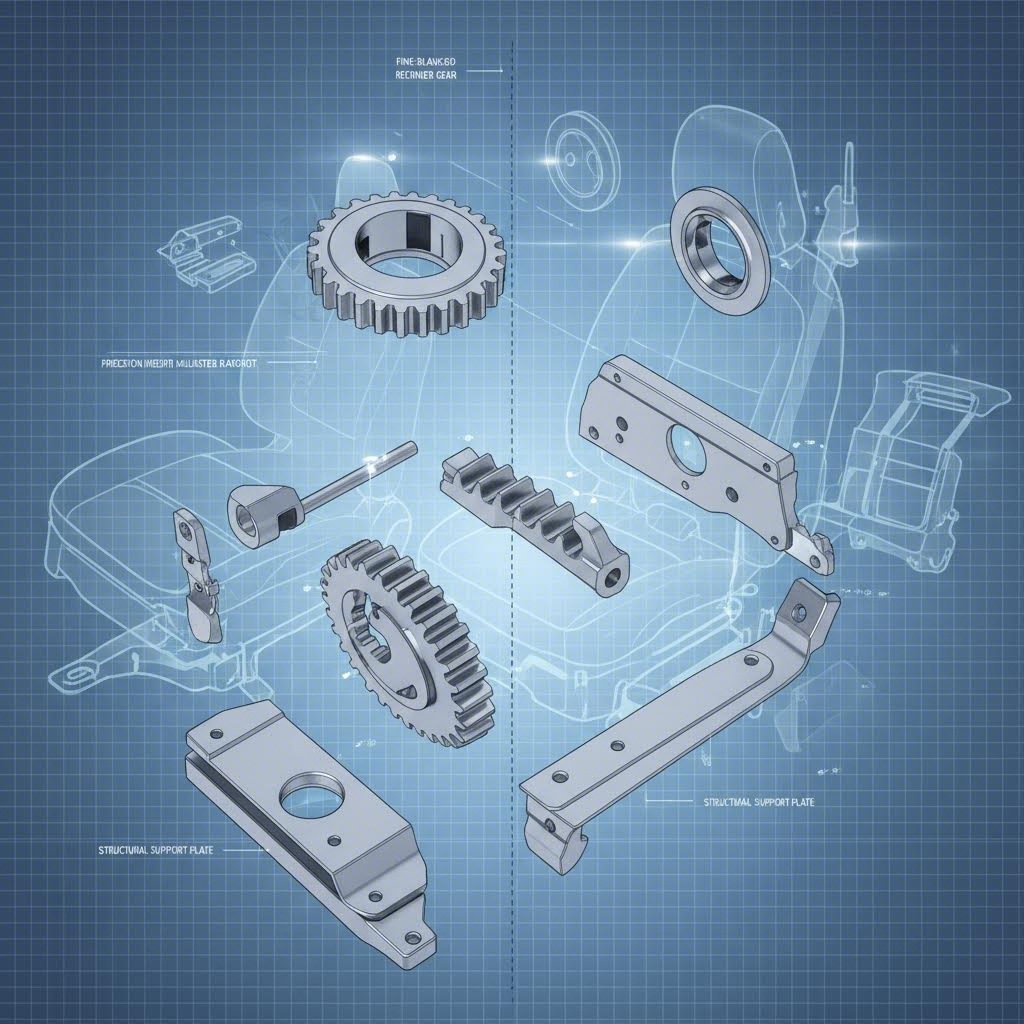

For automotive engineers and procurement managers, fine blanking is the standard for safety-critical systems. Key applications include seat recliners, transmission parking pawls, seatbelt buckles, and brake system components. While tooling costs are higher, the elimination of post-processing steps significantly lowers the total cost per part for high-volume production runs (typically 10,000+ units).

Critical Automotive Applications by System

Fine blanking accounts for approximately 60% of all fine-blanked parts globally, with the automotive sector being the dominant consumer. The process is reserved for components where failure is not an option and geometric precision is paramount. Below are the primary vehicle systems that rely on this technology.

Seating Mechanisms and Hardware

Automotive seating is perhaps the most ubiquitous application of fine blanking. Modern seat structures require complex mechanisms to handle crash loads while operating smoothly for the user. Fine blanking is used to manufacture seat recliners, height adjusters, and track latches. These parts often feature intricate gear teeth that must mesh perfectly to prevent slippage during a collision.

Case studies from manufacturers like Feintool highlight that seat recliners produced via fine blanking can withstand millions of adjustment cycles without significant wear. The process achieves the necessary tooth profile accuracy and surface finish (often Ra 0.6 µm or better) directly from the press, ensuring safety compliance without expensive secondary gear cutting.

Powertrain and Drivetrain Components

In internal combustion and hybrid powertrains, fine blanking is essential for parts that require high flatness and wear resistance. Common applications include:

- Transmission Parking Pawls: These locking mechanisms require a perfectly sheared edge to engage the parking gear securely. Fine blanking ensures the load-bearing surfaces are 100% solid metal, avoiding the brittle fracture zones of conventional stamping.

- Clutch Plates and Hubs: The flatness achieved by the counter-punch pressure (clamping the part during ejection) is critical for clutch performance, preventing drag and ensuring smooth engagement.

- Planetary Carrier Plates: Used in automatic transmissions, these heavy-gauge parts require precise hole locations for gear shafts, which fine blanking delivers with positional tolerances that rival machining.

Safety and Chassis Systems

Safety-critical components such as seatbelt tongues (buckles), airbag initiators, and ABS brake sensor rings are almost exclusively produced via fine blanking. The “stinger” or V-ring element of the tooling prevents material tearing, ensuring that the steel retains its structural integrity even at the edges. For brake systems, the process is used to create backing plates for brake pads, where flatness is essential for uniform braking pressure and noise reduction.

The Triple-Action Advantage: How It Works

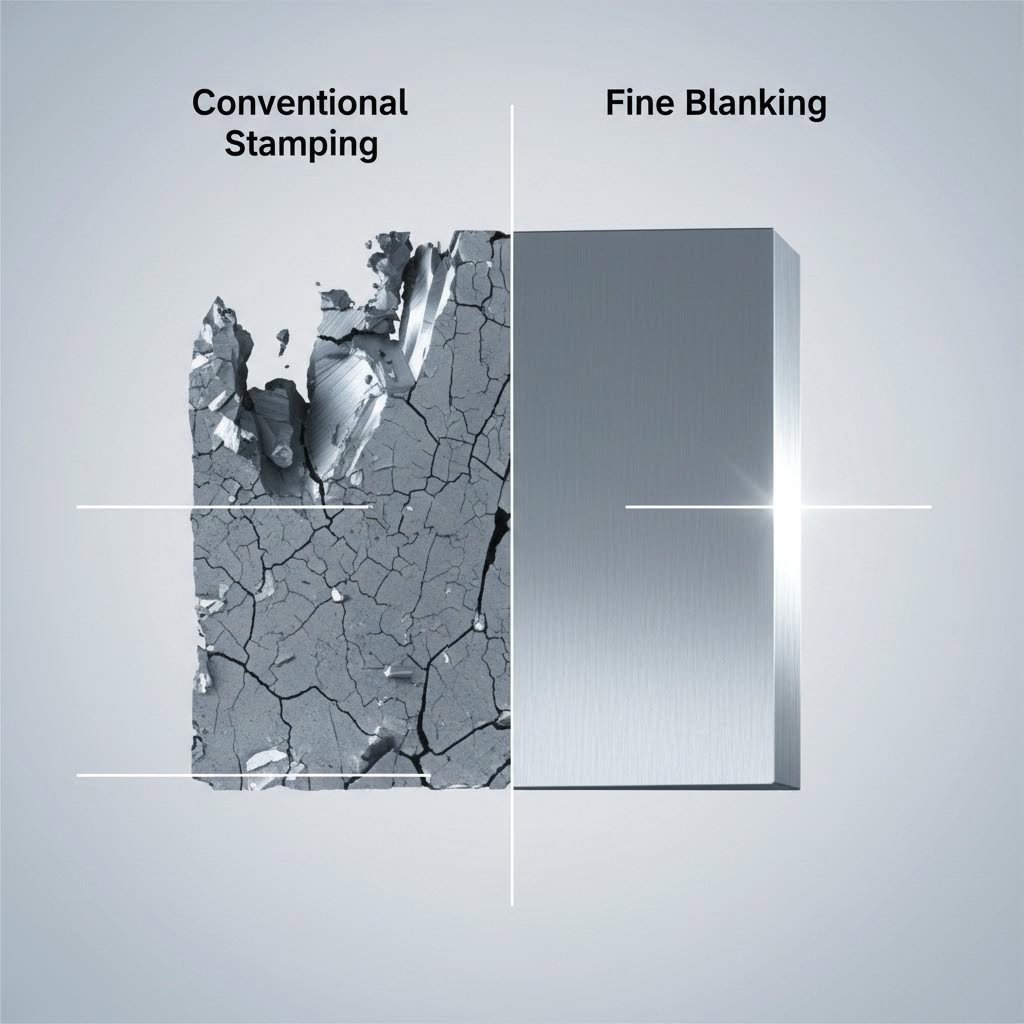

The distinction between fine blanking and conventional stamping lies in the control of material flow. Conventional stamping uses a simple punch and die, often resulting in a part with only 30% sheared edge and 70% rough fracture (die break). Fine blanking employs a triple-action press that applies three distinct forces:

- V-Ring (Stinger) Pressure: Before the cut begins, a V-shaped ring embedded in the stripper plate impinges on the material, locking it in place and preventing lateral movement. This puts the material under hydrostatic pressure.

- Blanking Force: The punch advances to cut the material. Because the material is compressed by the V-ring, it flows plastically rather than fracturing.

- Counter-Punch Pressure: A counter-punch supports the part from the bottom throughout the entire stroke, ensuring the part remains perfectly flat and pushing it back into the strip after the cut.

This configuration allows for die clearances of roughly 0.5% of material thickness, compared to the 10% typical in conventional stamping. The result is a “fully sheared” edge that is vertical, smooth, and free of cracks.

Comparison: Fine Blanking vs. Conventional Stamping

For engineers deciding between processes, the choice often comes down to the trade-off between upfront tooling investment and downstream processing costs.

| Feature | Fine Blanking | Conventional Stamping |

|---|---|---|

| Edge Quality | 100% Sheared, Smooth, Vertical | 30% Sheared, 70% Fracture/Break |

| Tolerances | ±0.001" (±0.025 mm) | ±0.010" (±0.25 mm) |

| Flatness | Excellent (supported by counter-punch) | Variable (often requires flattening) |

| Secondary Ops | None (Ready for Assembly) | Deburring, Grinding, Reaming often required |

| Hole Size | Can punch holes < 50% of thickness | Holes typically must be ≥ material thickness |

| Tooling Cost | High (Complex compound dies) | Low to Medium |

Material Selection and Design Guidelines

Fine blanking relies on the material's ability to flow under pressure (cold extrusion). Therefore, material selection is critical. Spheroidize-annealed steels are the gold standard because their globular carbide structure allows for maximum deformability without cracking.

- High-Strength Low-Alloy (HSLA) Steels: Widely used for seat mechanisms where strength-to-weight ratio is critical.

- Stainless Steel (300/400 Series): Common in exhaust and emissions components.

- Aluminum Alloys: Increasingly used for EV lightweighting, though grade selection is vital to prevent galling.

Design Constraints: While fine blanking offers freedom, engineers should adhere to specific rules. Corner radii should generally be at least 10-15% of the material thickness to prevent punch chipping. Web widths (distance between holes or edges) can be surprisingly thin—often as low as 60% of material thickness—allowing for tightly packed designs that save weight.

Cost Analysis and Strategic Sourcing

The economic case for fine blanking is built on volume and complexity. If a part requires grinding to achieve flatness, reaming to size holes, or hobbing to cut gear teeth, fine blanking is often cheaper per unit despite higher tooling costs. The crossover point where fine blanking becomes more economical than stamping + machining is typically around 10,000 to 20,000 parts per year.

For automotive programs ramping up to mass production, selecting the right manufacturing partner is critical. Suppliers must be evaluated not just on their fine blanking presses, but on their ability to bridge the gap from initial design to full-scale output. Companies like Shaoyi Metal Technology support this lifecycle by offering comprehensive stamping solutions, from rapid prototyping to high-volume manufacturing with press capabilities up to 600 tons. Their IATF 16949 certification ensures that whether you are validating a design with 50 prototypes or committing to millions of mass-produced parts, the transition meets global OEM standards.

As the industry shifts toward Electric Vehicles (EVs), fine blanking is finding new applications in copper busbars and battery structural components, where the clean edge quality prevents electrical arcing and short circuits.

Engineering Precision for the Road Ahead

Fine blanking remains the premier choice for automotive components where safety, precision, and high-volume consistency intersect. By leveraging the triple-action press technology, engineers can design complex, multi-functional parts that are stronger, flatter, and more reliable than those produced by conventional methods. While the initial investment in tooling is significant, the elimination of secondary operations and the guarantee of zero-defect functionality make it an indispensable process for modern vehicle manufacturing.

Frequently Asked Questions

1. What is the maximum material thickness for fine blanking?

Modern fine blanking presses can handle materials significantly thicker than conventional stamping. While standard applications range from 1mm to 12mm, specialized heavy-duty presses (up to 1,500 tons) can blank steel parts up to 19mm (0.75 inches) thick, depending on the material's yield strength and the part geometry.

2. Can fine blanking replace CNC machining?

Yes, for many 2D profiles. Fine blanking is often called “stamping at machining tolerances.” If a part is primarily flat with complex contours, holes, or gear teeth, fine blanking can produce it in a single stroke with tolerances comparable to CNC machining, but at a fraction of the time and cost for high volumes.

3. Why is spheroidize-annealing important for fine blanking materials?

Spheroidize-annealing is a heat treatment that changes the microstructure of steel, making the carbides spherical (globular) rather than laminar (plate-like). This significantly increases the steel's ductility and reduces the risk of tearing or cracking during the intense cold-flow deformation of the fine blanking process, ensuring a smooth, fully sheared edge.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —