Automotive Thermal Control With Extruded Aluminum Heat Sinks

TL;DR

Extruded aluminum heat sinks are essential thermal management components for modern automotive applications, created by forcing a heated aluminum alloy through a die to form a complex, finned profile. They are critical for dissipating heat from sensitive electronics like Engine Control Units (ECUs), power inverters, and LED lighting systems. Their widespread use is due to an excellent combination of high thermal conductivity, low weight, cost-effectiveness, and significant design flexibility, ensuring reliability and longevity of vehicular systems.

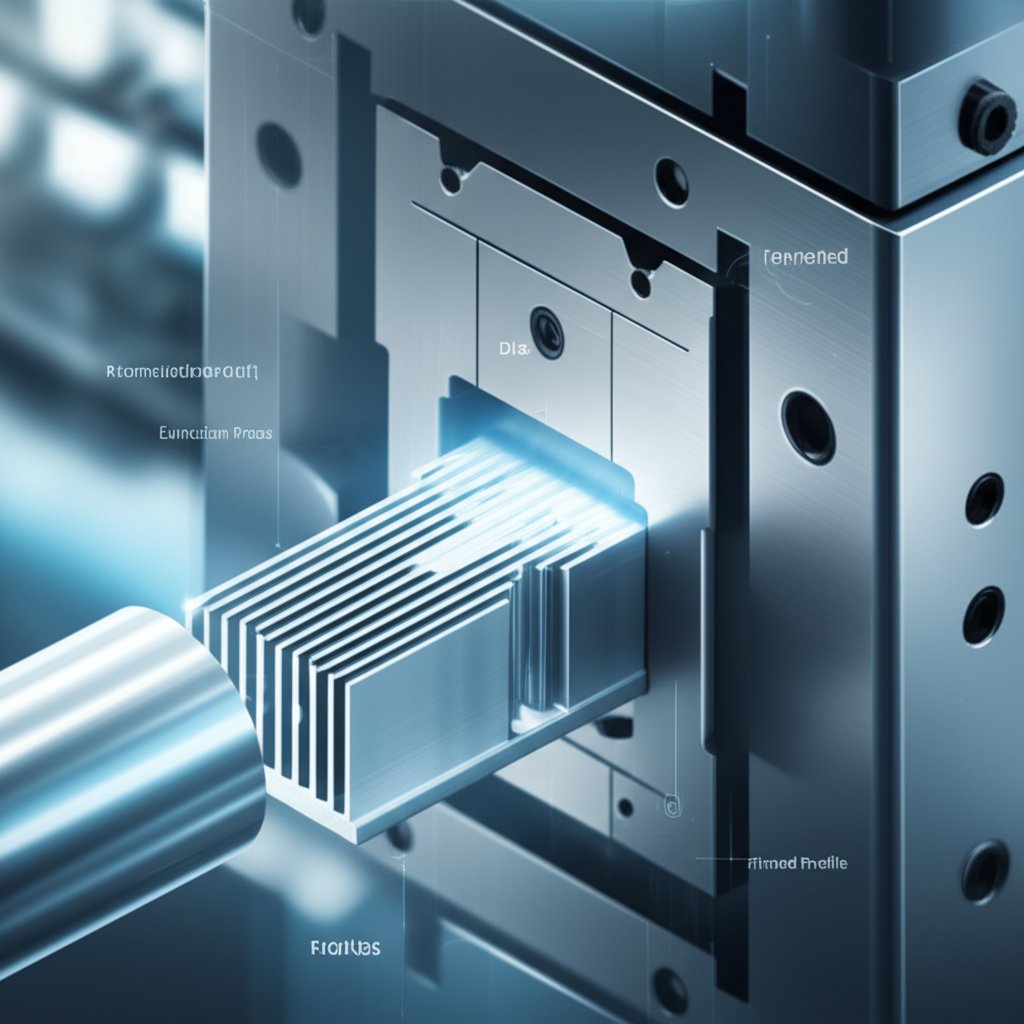

The Fundamentals of Extruded Aluminum Heat Sinks

An extruded heat sink is a cooling device specifically engineered to increase the surface area available for heat dissipation from an electronic component to a surrounding fluid, typically air. The term 'extruded' refers to its manufacturing process, which is fundamental to its performance and cost-effectiveness. In this process, a cylindrical billet of aluminum alloy is heated to a malleable state and then forced through a shaped steel die with a high-pressure ram. This action forms a continuous profile with the exact cross-sectional shape of the die, which is then cut to the required length. This method allows for the creation of intricate fin geometries that maximize the surface area for efficient heat transfer, a core principle of thermal management as detailed in resources from Zetwerk.

Aluminum is the material of choice for these applications, primarily due to its superior thermal properties and manufacturing advantages. Alloys such as 6063 and 6061 are commonly specified for their excellent thermal conductivity, good mechanical strength, and high corrosion resistance. While copper offers significantly higher thermal conductivity, aluminum provides a more practical solution for automotive use. It is significantly lighter—approximately one-third the density of copper—and more cost-effective, both in raw material price and tooling costs. As highlighted by Hydro, aluminum's ability to be easily shaped into complex profiles makes it far more versatile than copper for creating optimized, application-specific heat sinks.

The combination of an efficient manufacturing process and an ideal material makes extruded aluminum heat sinks a cornerstone of thermal engineering. The process allows for consistent quality over high-volume production runs, ensuring that each part meets precise thermal and mechanical specifications. The inherent properties of aluminum ensure that these components perform reliably under the demanding conditions found within automotive environments, providing a lightweight yet robust solution for heat dissipation.

Critical Automotive Applications and Thermal Challenges

The increasing electrification and complexity of modern vehicles have made effective thermal management more critical than ever. Extruded aluminum heat sinks are integral to ensuring the reliability and performance of numerous electronic systems that generate significant heat. Their application spans across several key areas within a vehicle, each with unique thermal challenges.

Engine Control Units (ECUs)

The ECU is the brain of a modern vehicle, managing everything from engine performance and fuel efficiency to emissions. These powerful microprocessors generate substantial heat during operation. If not properly dissipated, this heat can lead to performance degradation or complete failure, compromising vehicle safety and functionality. Extruded aluminum heat sinks are designed to mount directly to the ECU housing, providing a large surface area to efficiently transfer heat away from the sensitive electronics through natural or forced convection. Their customized profiles can be designed to fit into the tight, vibration-prone spaces of the engine bay.

Power Electronics (Inverters and Converters)

In electric vehicles (EVs), hybrids (HEVs), and even traditional internal combustion engines, power electronics like inverters and DC-DC converters manage the flow of high-voltage electricity. These components are essential for controlling the electric motor and charging the battery. The process of converting and regulating high currents generates intense, concentrated heat. Aluminum heat sinks, often with complex fin structures, are essential for cooling these power modules. As noted by sources like BRT Extrusions, these heat sinks ensure that components like power transistors and integrated circuits operate within their safe temperature limits, preventing thermal runaway and ensuring the longevity of the vehicle's powertrain.

Advanced Lighting Systems (LEDs)

Modern automotive lighting has largely shifted to Light-Emitting Diodes (LEDs) for headlights, taillights, and interior illumination due to their efficiency and long lifespan. However, an LED's performance and longevity are highly sensitive to temperature. Excessive heat can cause a drop in light output and color shifts. Extruded aluminum heat sinks are widely used to cool LED modules, often forming the structural housing of the light fixture itself. The design flexibility of extrusion allows for compact, aesthetically integrated cooling solutions that effectively manage heat, ensuring consistent and reliable lighting performance over the vehicle's lifetime.

Key Design and Manufacturing Considerations

The effectiveness of an extruded aluminum heat sink is not accidental; it is the result of careful engineering that balances thermal performance, material properties, and manufacturing constraints. Both the design of the profile and the intricacies of the manufacturing process are critical to producing a component that meets the stringent demands of automotive applications.

Design Principles for Optimal Performance

The thermal performance of a heat sink is dictated by its geometry. Engineers must consider several key parameters to maximize heat dissipation while adhering to spatial and cost limitations. These factors include:

- Fin Profile: The height, thickness, and spacing of the fins determine the total surface area available for heat transfer. Taller, thinner, and more densely packed fins generally increase surface area but can also impede airflow, a trade-off that must be optimized for the specific cooling environment (natural vs. forced convection).

- Base Thickness: The base of the heat sink spreads heat from the source component to the fins. A thicker base promotes more uniform heat distribution but adds weight and cost. The thickness must be sufficient to prevent heat concentration directly under the component.

- Aspect Ratio: This is the ratio of fin height to the spacing between fins. A high aspect ratio is generally desirable for maximizing surface area but can be challenging to extrude and may increase air pressure drop, which is a key consideration in forced-air cooling systems.

- Material Alloy Selection: The choice of aluminum alloy impacts thermal conductivity, strength, and finishing options. Different alloys offer distinct advantages, making selection a critical part of the design process.

| Alloy | Key Characteristics | Primary Automotive Use Case |

|---|---|---|

| 6063 | Excellent thermal conductivity (~200-218 W/mK), superior surface finish, and ideal for complex cross-sections. | The most common choice for custom heat sinks in ECUs, LED lighting, and power supplies where intricate shapes are needed. |

| 6061 | Good thermal conductivity (~167 W/mK), higher mechanical strength, and excellent for machining and welding. | Used in applications requiring higher structural integrity or where significant post-extrusion machining is necessary. |

The Manufacturing Process and Customization

The journey from raw material to a finished heat sink involves several precise steps. It begins with the creation of a hardened steel die, which is the mold for the heat sink's profile. An aluminum billet is then heated and pushed through this die to create the long, continuous extrusion. After extrusion, the profile is cooled, stretched to relieve internal stresses, and cut to length. Secondary operations such as CNC machining for mounting holes, surface treatments like anodizing for corrosion resistance and improved thermal emissivity, and assembly may follow. For automotive projects demanding precision-engineered components, consider custom aluminum extrusions from a trusted partner. For example, some suppliers offer a comprehensive one-stop service, from rapid prototyping to full-scale production under a strict IATF 16949 certified quality system. Advanced capabilities from specialized providers like Shaoyi Metal Technology can streamline manufacturing and support highly customized part development.

Advantages of Extruded Aluminum for Thermal Management

Extruded aluminum has become the industry standard for heat sinks in automotive and other high-performance electronics for a compelling set of reasons. These components offer a superior balance of thermal, mechanical, and economic benefits that are difficult to achieve with other materials or manufacturing methods.

High Thermal Conductivity

Aluminum alloys used for heat sinks, particularly those in the 6000 series, possess excellent thermal conductivity. This property is fundamental to a heat sink's function, as it allows heat to be drawn away from the critical component and spread efficiently across the fins for dissipation. This rapid heat transfer is crucial for maintaining stable operating temperatures in high-power automotive electronics.

Lightweight Construction

In the automotive industry, every gram matters. Vehicle weight directly impacts fuel efficiency, performance, and handling. Aluminum is approximately one-third the density of copper, offering a significant weight reduction without a major compromise in thermal performance. This makes extruded aluminum heat sinks the ideal choice for applications where minimizing mass is a primary design goal, from electric vehicle battery systems to advanced driver-assistance systems (ADAS).

Cost-Effectiveness

Both the raw material and the manufacturing process contribute to the cost-effectiveness of extruded aluminum heat sinks. Aluminum is more abundant and less expensive than copper. Furthermore, the extrusion process is highly efficient for producing complex profiles in high volumes, with relatively low tooling costs and minimal material waste. This economic advantage allows for the widespread use of effective thermal management solutions across a range of vehicle models and price points.

Exceptional Design Flexibility and Customization

The extrusion process offers unparalleled freedom to create complex, customized cross-sectional profiles. As detailed by manufacturers like Cofan Thermal, this allows engineers to design heat sinks with optimized fin geometries tailored to specific airflow conditions, space constraints, and thermal loads. Features like screw ports, mounting channels, and other hardware can be integrated directly into the extrusion profile, simplifying assembly and reducing the number of individual parts required. This ability to create a one-piece, highly functional component is a key advantage in modern vehicle design.

Durability and Corrosion Resistance

Aluminum naturally forms a passive, protective oxide layer on its surface, which provides inherent resistance to corrosion. This durability can be further enhanced through surface treatments like anodizing, which creates a harder, more robust surface that also improves thermal emissivity. This ensures that the heat sink will perform reliably over the vehicle's lifespan, even when exposed to the harsh conditions of the automotive environment, including moisture, salt, and temperature fluctuations.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —