Dual Phase Steel Stamping Properties: Engineering Guide

TL;DR

Dual Phase (DP) steels are advanced high-strength steels (AHSS) characterized by a microstructure of hard martensite islands dispersed in a soft ferrite matrix. This unique combination delivers a low yield-to-tensile strength ratio (~0.6) and a high initial work hardening rate (n-value), making them ideal for complex automotive stampings that require both formability and crashworthiness. However, successful stamping requires managing significant springback and edge cracking risks. Engineers must typically increase punch clearances to 12–14% and utilize stiffer tooling with advanced coatings like TiC or CrN to handle the elevated tonnage and wear rates.

Microstructure and Mechanical Properties

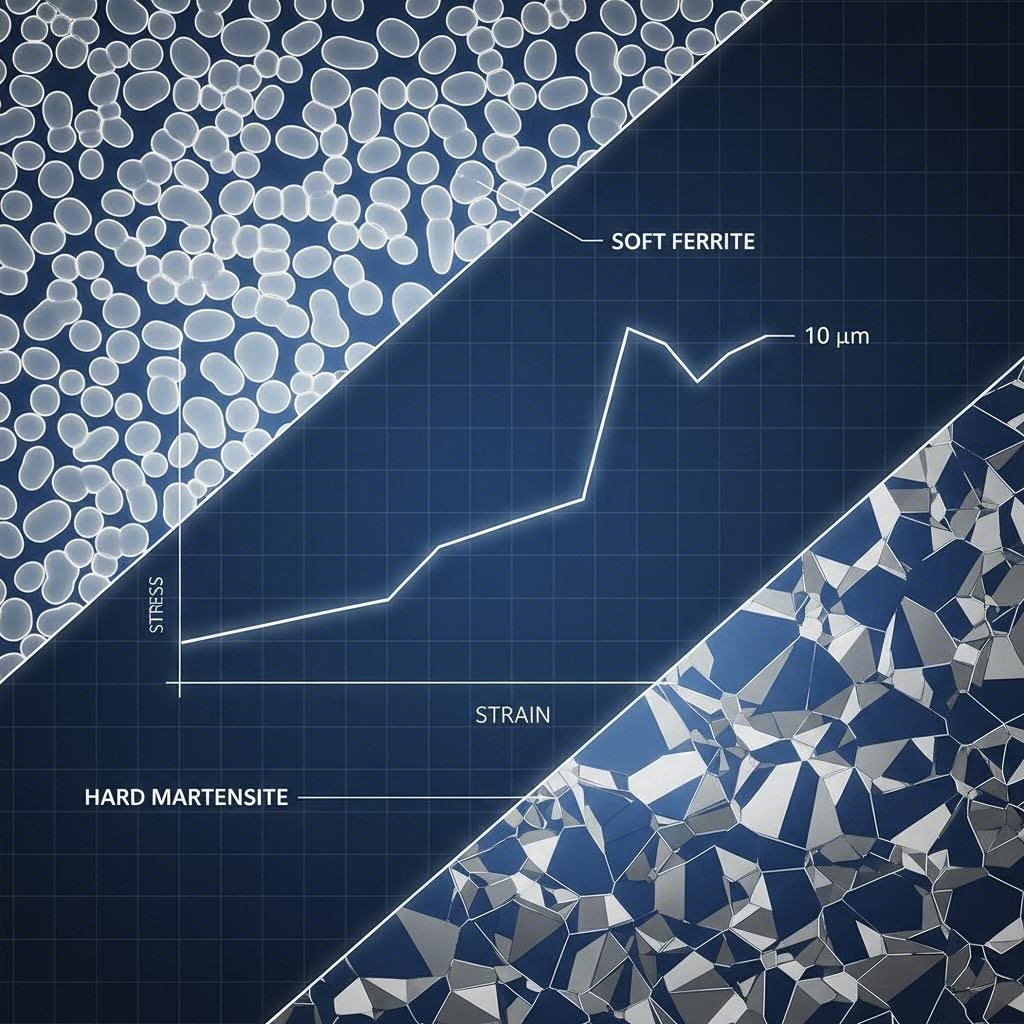

The engineering value of Dual Phase steel lies in its distinct two-phase microstructure. Unlike High-Strength Low-Alloy (HSLA) steels, which rely on precipitation hardening, DP steels derive their properties from a composite structure: a continuous soft ferrite matrix that provides ductility, and dispersed hard martensitic islands that provide strength. When deformed, strain concentrates in the softer ferrite phase surrounding the martensite, resulting in a high initial work hardening rate (n-value).

This microstructure creates a mechanical behavior profile specifically optimized for cold forming. While HSLA grades typically exhibit a yield strength-to-tensile strength (YS/TS) ratio of around 0.8, DP steels maintain a much lower ratio of approximately 0.6. This lower yield point allows for plastic deformation to begin earlier, facilitating complex shape formation before the material reaches its ultimate tensile limit. The Fabricator notes that this high n-value is particularly pronounced at lower strain ranges (4–6%), which helps distribute strain uniformly across the part and prevents localized necking early in the press stroke.

Common commercial grades—such as DP590, DP780, and DP980—are defined by their minimum tensile strengths (in MPa). As the volume fraction of martensite increases, tensile strength rises, but ductility naturally decreases. Engineers must balance these factors, often selecting lower martensite fractions for deep-drawn parts and higher fractions for structural rails where anti-intrusion performance is paramount.

Stamping Challenges: Springback and Edge Cracking

The very characteristic that makes DP steel desirable—its high work hardening rate—introduces its primary manufacturing defect: springback. Because the material hardens rapidly during deformation, the elastic recovery stress stored in the part is significantly higher than in mild steels. This manifests as side wall curl and angular change after the part is removed from the die, complicating dimensional accuracy for assembly.

To mitigate springback, process engineers employ several die design strategies. Over-crowning the die surfaces allows the material to relax into the correct geometry. Additionally, designing wall beads or stiffeners can lock the geometry in place. A more advanced technique involves imparting high strain at the end of the press stroke to reduce residual compressive stresses, effectively "setting" the shape.

Edge cracking is another critical failure mode, particularly during stretch flanging operations. The hardness disparity between the soft ferrite and hard martensite creates stress concentrations at sheared edges, leading to micro-voids that can coalesce into cracks. SSAB suggests using specialized "Dual Phase High Formability" (DH) grades for geometries requiring deep drawing or stretched edges. These 3rd Generation AHSS grades use TRIP-assisted microstructures (with retained austenite) to maintain formability at higher strain levels, offering superior resistance to edge cracking compared to standard DP grades.

Tooling and Die Design Guidelines

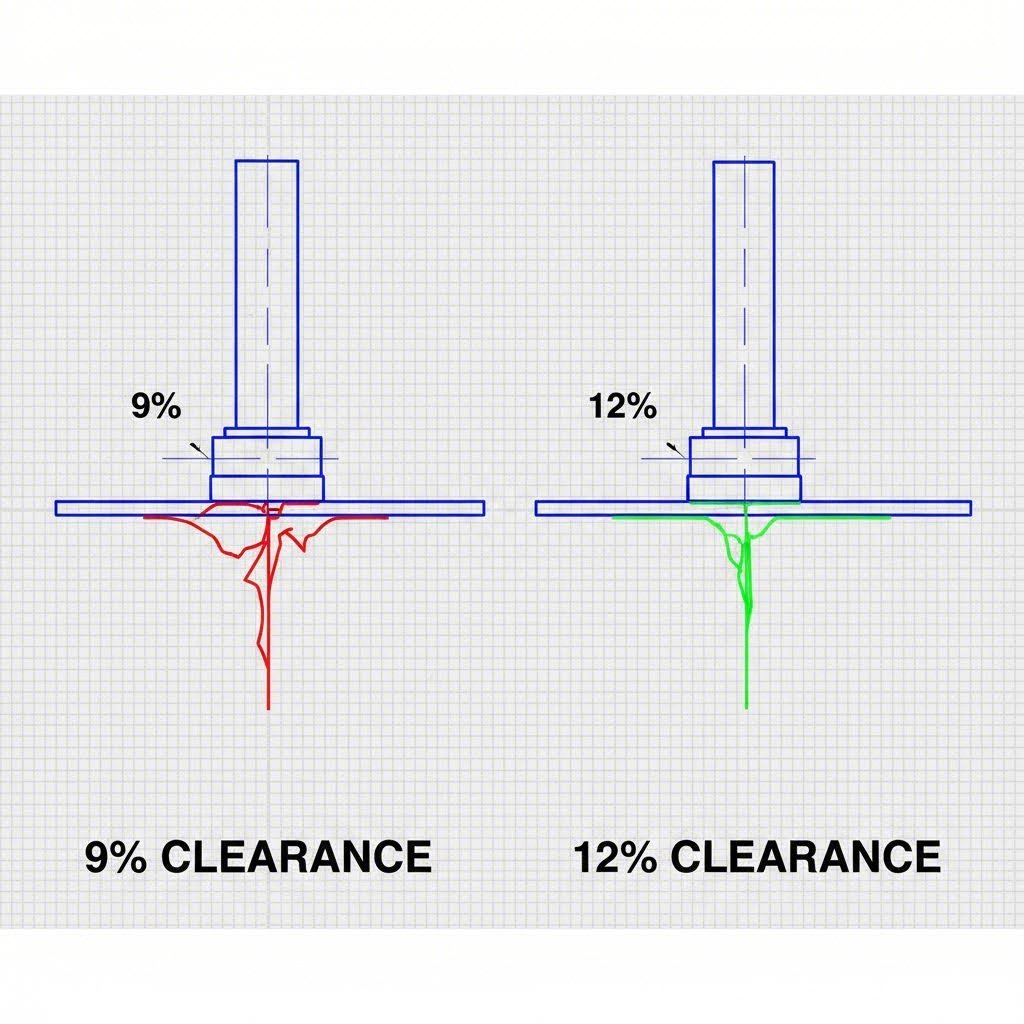

Stamping Dual Phase steel requires a fundamental rethink of standard tooling parameters used for mild steel or HSLA. The most critical adjustment is punch clearance. Standard clearances of roughly 9% of metal thickness often lead to severe edge splitting in DP steels due to the material's high shear strength.

Data from Tata Steel demonstrates that increasing punch clearance to 12–14% significantly improves edge quality. In one case study, increasing clearance from 9% to 12% reduced part splitting rates from 22% to near zero. This larger gap changes the stress state at the cutting edge, reducing the tendency for micro-cracks to propagate into the flange.

Tool wear is also accelerated. The high contact pressures required to form DP steel—often exceeding 600 tons for structural components—can cause galling and rapid die degradation. Tool steels must be coated with hard, low-friction surface treatments such as Titanium Carbide (TiC) or Chromium Nitride (CrN) to extend service intervals. Furthermore, the press itself must have sufficient rigidity to prevent deflection under these high loads, which would otherwise compromise part tolerances.

For manufacturers facing these elevated equipment demands, partnering with a specialized fabrication provider is often the most efficient path. Shaoyi Metal Technology offers comprehensive stamping solutions that bridge the gap from prototyping to mass production. With press capabilities up to 600 tons and IATF 16949 certification, they are equipped to handle the rigorous tonnage and precision requirements of advanced high-strength steels like DP and DH grades for critical components such as control arms and subframes.

Bake Hardening and Final Performance

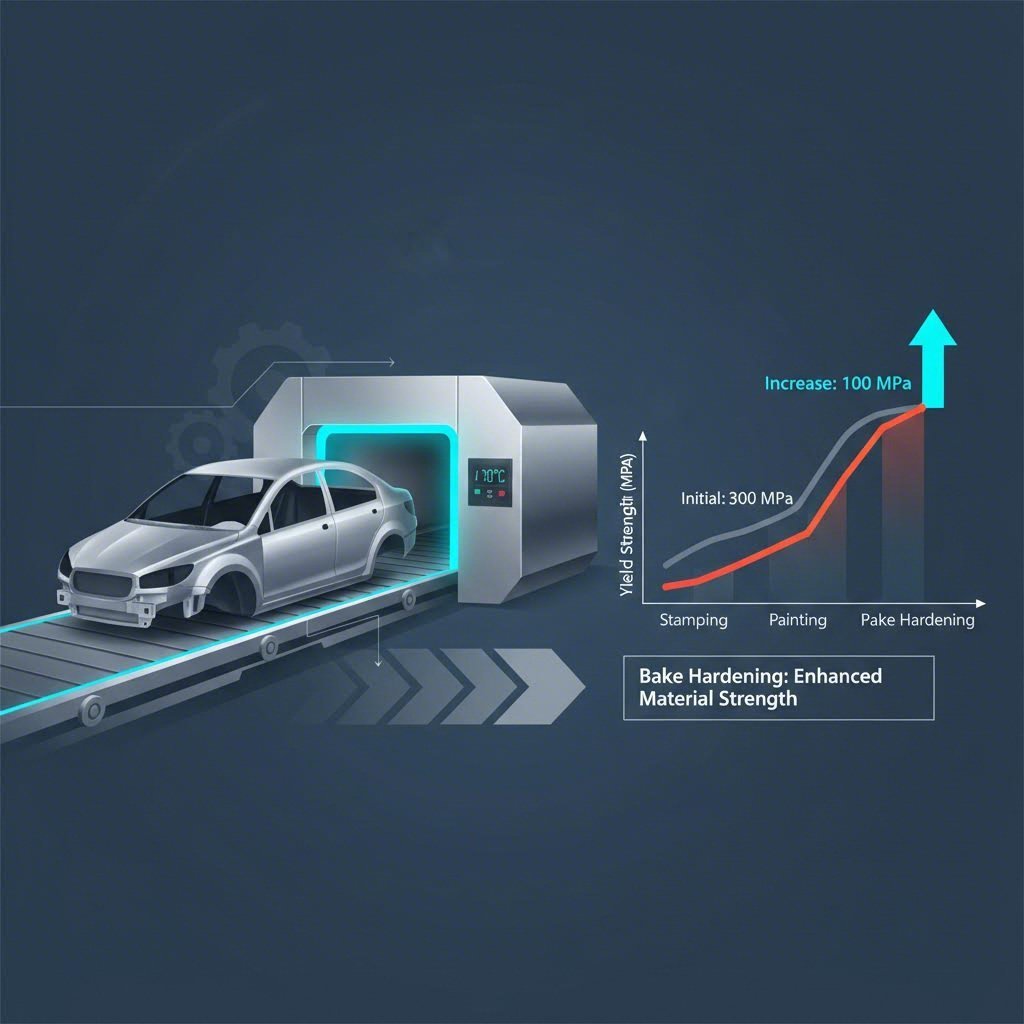

One of the hidden advantages of Dual Phase steel is its "Bake Hardening" (BH) effect. This phenomenon occurs during the automotive paint curing cycle, typically around 170°C for 20 minutes. During this thermal process, free carbon atoms in the steel microstructure diffuse and pin the dislocations generated during stamping.

This mechanism results in a substantial boost in yield strength—typically increasing by 50 to 100 MPa—without affecting the part's dimensions. This static strength gain allows automotive engineers to "downgauge" (use thinner material) to reduce vehicle weight while ensuring the final part meets crash safety targets. The combination of work hardening from the press shop and bake hardening from the paint shop gives the final component exceptional energy absorption capacity, making DP steel the standard choice for safety cage components like B-pillars, roof rails, and cross members.

Conclusion: Optimizing for AHSS Production

Dual Phase steel represents a critical balance point in modern automotive engineering, offering the strength necessary for safety compliance and the ductility required for manufacturing feasibility. While the material presents distinct challenges—specifically regarding springback management and tool wear—these can be effectively overcome through data-driven die design and appropriate press selection. By respecting the unique physics of the ferrite-martensite microstructure and adjusting parameters like punch clearance to the recommended 12–14% range, manufacturers can fully leverage the weight-saving and performance potential of this versatile material.

Frequently Asked Questions

1. How does Dual Phase steel differ from HSLA steel?

While High-Strength Low-Alloy (HSLA) steels rely on micro-alloying elements for precipitation hardening, Dual Phase (DP) steels rely on a two-phase microstructure of ferrite and martensite. This gives DP steels a lower yield-to-tensile ratio (~0.6 vs 0.8 for HSLA) and a higher initial work hardening rate, allowing for better formability at equivalent tensile strengths.

2. What is the recommended punch clearance for stamping DP steel?

Standard punch clearances used for mild steel (around 9%) are typically too tight for DP steel and can cause edge splitting. Industry best practices suggest increasing the punch clearance to 12–14% of the material thickness to improve edge quality and tool life.

3. What causes springback in Dual Phase steel?

Springback is caused by the high elastic recovery of the material after forming. DP steel's high work hardening rate means it stores significant elastic energy during deformation. When the die opens, this energy is released, causing the part to spring back or curl. This must be compensated for via over-crowning or restriking in the die design.

4. Can Dual Phase steel be welded?

Yes, DP steels generally have good weldability, but the specific carbon equivalent must be considered. While lower strength grades (DP590) are easily spot welded, higher strength grades (DP980 and above) may require adjustments to welding parameters, such as increased electrode force or specific pulse schedules, to prevent brittle fractures in the weld heat-affected zone.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —