Custom Forged Wheel Engraving Options: Laser Vs CNC Vs Hand-Etched

The Rise of Custom Forged Wheel Engraving

Imagine pulling up to a car meet and watching heads turn - not just because of your ride's stance or paint, but because of the intricate details etched into your wheels. That's the power of custom forged wheel engraving, and it's rapidly becoming the ultimate expression of automotive individuality.

Here's the problem: while the demand for bespoke wheels and personalized touches continues to surge, finding comprehensive information about engraving options remains frustratingly difficult. Most resources barely scratch the surface, leaving enthusiasts to navigate this premium customization choice without proper guidance.

This guide changes that. Consider it your complete educational resource - not a sales pitch, but an honest breakdown of everything you need to know before committing to wheel engraving.

Why Wheel Engraving Has Become the Ultimate Personalization Statement

The automotive aftermarket is experiencing a personalization revolution. According to recent market analysis, the high-performance wheels market is projected to reach USD 19.5 billion in 2025, with aftermarket personalization identified as a key growth driver across North America, Europe, and Asia-Pacific.

So why has engraving specifically captured enthusiast attention? Custom forged wheels already represent the pinnacle of wheel craftsmanship - constructed from aerospace-grade aluminum under immense pressure to achieve unmatched strength-to-weight ratios. Adding engraved rims takes this exclusivity further, transforming functional components into rolling works of art.

Whether it's your initials subtly etched into the wheel lip, a family crest on the center cap area, or performance specs commemorating a build - engraving creates something genuinely one-of-a-kind. Unlike vinyl decals or painted graphics that fade and peel, properly executed engravings become permanent features of the wheel itself.

What This Guide Covers That Others Miss

You'll notice most online resources mention wheel engraving exists - then leave you hanging. They fail to address the questions that actually matter when you're ready to invest.

This comprehensive guide delivers what competitors overlook:

- Technique deep-dives: Laser engraving, CNC milling, hand-etching, and chemical etching - each explained with real-world pros, cons, and ideal applications

- Placement mapping: Every possible engraving location on your wheels, from visible spoke faces to hidden barrel areas

- Pricing transparency: The cost factors nobody discusses, including factory versus aftermarket pricing differences

- Durability testing: How each technique holds up against brake dust, road debris, cleaning chemicals, and daily abuse

- Warranty implications: What custom engraving means for your manufacturer coverage

By the end, you'll understand exactly which engraving method suits your driving style, budget, and aesthetic goals - whether you're building a weekend show car or a daily-driven track weapon.

How We Evaluated Custom Engraving Options

With multiple engraving techniques available for wheel customization, how do you determine which one actually delivers? Simply put, you need a framework - a consistent set of criteria that cuts through marketing claims and reveals real-world performance.

That's exactly what we built. Rather than relying on manufacturer promises or surface-level reviews, we developed a comprehensive evaluation methodology designed specifically for enthusiasts researching the best forged wheels with engraving capabilities.

Five Critical Factors for Evaluating Engraving Services

When you're investing in engraving wheels, you need to assess more than just how the finished product looks. Here are the five factors we weighted equally in our analysis:

- Technique Quality: How precise and consistent is the engraving execution? This includes edge definition, depth uniformity, and the ability to reproduce intricate details without distortion.

- Placement Versatility: Can the technique work effectively on all wheel locations - spokes, lips, barrels, and center cap areas - or is it limited to specific surfaces?

- Design Flexibility: What are the realistic limitations on font sizes, character counts, logo complexity, and custom artwork? Understanding these constraints upfront prevents disappointment later.

- Durability Under Road Conditions: How well does the engraving withstand brake dust accumulation, rock chips, aggressive cleaning chemicals, and UV exposure over time?

- Pricing Transparency and Turnaround Time: Are costs clearly communicated with itemized breakdowns? What's the realistic timeline from design approval to delivery?

How We Assessed Each Option

Our evaluation process mirrors the actual buyer journey you'll experience. We started by examining what questions matter at each stage - from initial research through final delivery.

When you first consider wheel customization, you're likely asking: "What techniques exist, and which one fits my needs?" As you move deeper, questions shift toward specifics: "Can this provider execute my design on a 2-piece forged wheel lip? What happens if I'm not satisfied with the proof?"

Here's what we recommend asking any engraving provider before committing:

- What file formats do you accept for custom designs, and do you offer design assistance?

- Can I see examples of similar work on the same wheel construction type?

- What's included in the quoted price - design revisions, proofing, protective coatings?

- How do you handle errors or quality issues after completion?

- Does the engraving process affect any existing wheel warranties?

Armed with this evaluation framework, you're now prepared to dive into the specific techniques. Let's start with the most popular modern method - laser engraving - and examine exactly how it achieves microscopic precision on forged aluminum.

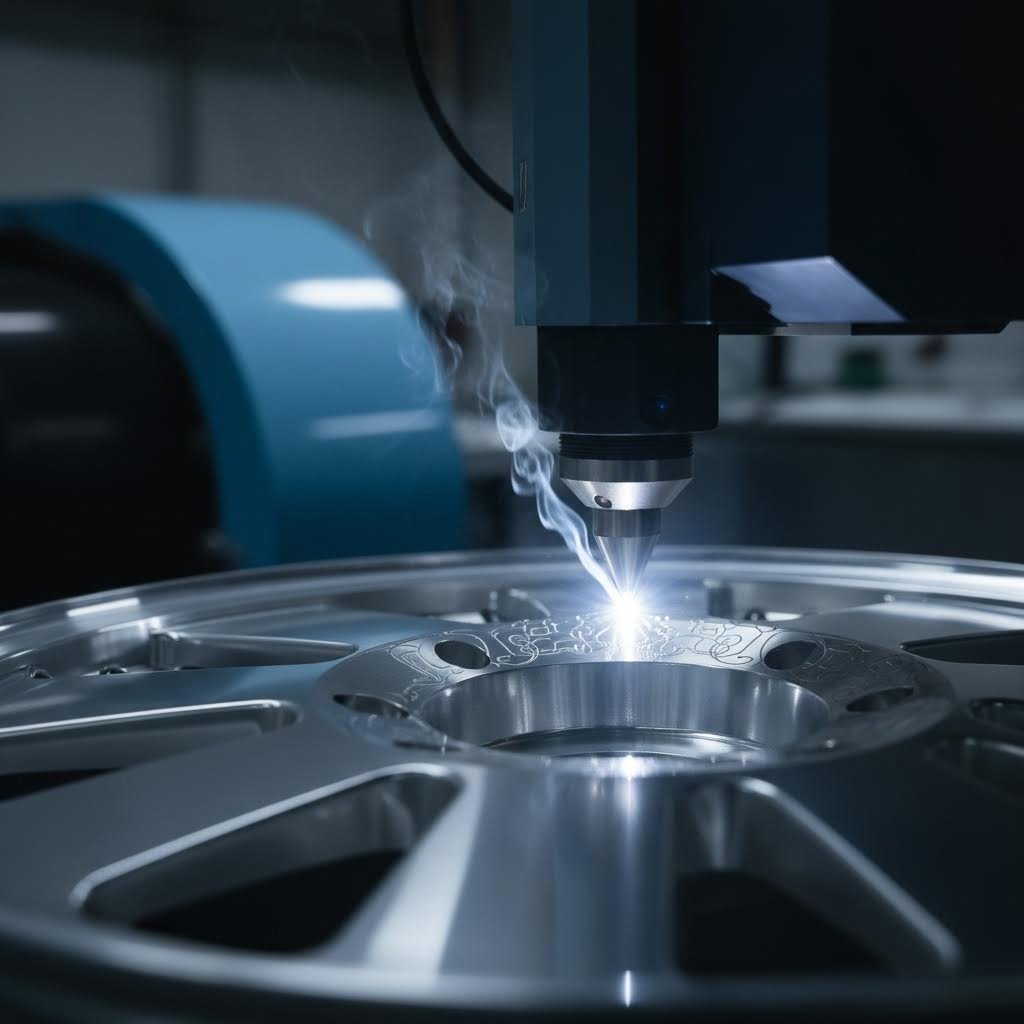

Laser Engraving for Ultra-Precise Detailing

When it comes to engraving rims with intricate logos, fine text, or complex designs, laser engraving stands as the dominant choice among automotive enthusiasts. But what makes this technique so effective on forged aluminum wheels? The answer lies in the fascinating science of controlled material vaporization - and understanding this process helps you determine if laser engraving matches your customization goals.

Fiber lasers, the preferred type for metal wheel engraving, operate at a 1064nm wavelength that achieves approximately 4-10% absorption rate on aluminum surfaces. When the focused beam contacts the wheel surface, temperatures in the irradiated area can reach aluminum's boiling point of 2470°C, causing surface particles to vaporize and create permanent, precise markings.

How Laser Engraving Achieves Microscopic Precision

Sounds complex? Here's the practical breakdown. Unlike mechanical methods that physically cut into material, laser engraving uses concentrated light energy to alter the wheel's surface at a microscopic level. This non-contact approach offers several distinct advantages for 2 piece forged wheels and multi-piece constructions.

The precision capabilities are remarkable. Laser systems can achieve extremely fine lines reaching the micron level, ensuring detailed and intricate pattern designs appear clearly and precisely. For context, a human hair measures approximately 70 microns in diameter - quality laser engravers can produce lines finer than that.

This level of detail makes laser engraving ideal for:

- Manufacturer logos with fine gradients or small text elements

- Serial numbers and VIN information for authentication

- Detailed artwork featuring thin lines and precise curves

- Small text including build specifications, dates, or dedications

Because the process is computer-controlled, consistency across all four wheels remains exceptional. Whether you're engraving 2-piece forged wheels or any premium forged set, each wheel receives identical marking depth and clarity.

Best Applications for Laser-Engraved Wheels

The surface finish of your forged wheels significantly impacts laser engraving results. Here's what you need to know about different wheel finishes:

Anodized aluminum wheels produce the highest contrast engravings. The laser alters only the anodized layer (typically 5-60 μm thick) while the engraving depth reaches just 0.2-1 μm. Uncolored anodized surfaces produce dark gray markings, while colored anodized finishes typically yield black markings - both with excellent visibility.

Bare or brushed aluminum creates more subtle contrast. The laser melts the surface to create patterns that, while permanent, appear less pronounced. This suits enthusiasts wanting understated personalization that reveals itself upon close inspection.

Powder-coated wheels offer colorful design possibilities. The laser ablates through the coating to expose the underlying aluminum, creating contrast between the coating color and raw metal. However, the coating's wear resistance may affect long-term appearance.

Design Limitations to Consider

Before submitting your custom design, understand these practical constraints:

- Minimum font size: Most providers recommend 4-point font or larger for guaranteed legibility

- Character count: Wheel lip circumference limits total characters - expect 30-60 characters depending on wheel diameter

- Line thickness: Extremely thin lines may appear inconsistent; lines under 0.3mm can be problematic

- Gradient effects: True gradients aren't possible - designs must use solid lines and shapes

- File formats: Vector files (AI, EPS, SVG) produce superior results compared to raster images

Durability Against Real-World Conditions

Here's what separates laser engraving from surface treatments like vinyl or paint: the marking becomes part of the material itself. According to durability testing, properly executed laser engraving on metals can last the entire lifespan of the product - even in harsh environments.

What does this mean for your daily driver or show car? Laser-engraved marks won't wash away with aggressive wheel cleaners. Brake dust accumulation can be cleaned without affecting the engraving. Even acidic cleaning compounds used for heavy contamination won't fade properly executed laser work.

The key phrase here is "properly executed." Deep engravings that actually remove material create grooves that won't disappear. Compare this to surface printing where abrasion simply removes the top layer - it's the difference between carving and painting.

Pros and Cons of Laser Engraving

Pros

- Exceptional precision for intricate designs and small text

- Permanent markings that resist cleaning chemicals and brake dust

- Non-contact process eliminates risk of wheel deformation

- Highly consistent results across multiple wheels

- Computer-controlled accuracy ensures design fidelity

- Relatively fast turnaround compared to hand methods

- Eco-friendly process requiring no inks, solvents, or consumables

Cons

- Limited depth compared to CNC milling - less tactile presence

- Contrast varies significantly based on wheel finish type

- Cannot produce color variations - monochromatic results only

- Extremely fine details may appear inconsistent on textured surfaces

- Initial setup costs make small character counts less cost-effective

Laser engraving excels for show car builds, finspeed wheels, and enthusiasts prioritizing crisp visual detail over tactile depth. If your goal is razor-sharp logos visible from several feet away or commemorative text that documents your build, laser technology delivers exceptional results.

However, if you need engravings you can feel with your fingertips or markings that withstand extreme track abuse, CNC milling offers advantages worth considering - which brings us to examining this deeper, more tactile engraving method.

CNC Milling for Deep and Durable Engravings

Ever run your fingers across a wheel and feel the engraving beneath your touch? That tactile dimension separates CNC milling from surface-level marking techniques. For enthusiasts who demand engravings that survive aggressive track sessions, harsh weather, and years of daily driving, CNC milling represents the gold standard in wheel customization durability.

Unlike laser engraving's heat-based surface alteration, CNC milling physically removes material using precision cutting tools. This fundamental difference creates engravings you can see and feel - permanent grooves carved directly into your fully forged wheels that won't fade, wash away, or deteriorate under extreme conditions.

Why CNC Milling Creates the Most Durable Engravings

Here's what makes CNC engraving exceptional for wheel applications: the process uses a sharp, pointed cutting tool that's dragged across the part surface to physically remove material. Connected to computer-aided manufacturing software, the engraver follows precise tool paths programmed specifically for your design.

The result? Engravings with genuine depth - typically ranging from 0.5mm to several millimeters depending on the application. Compare this to laser engraving depths measured in microns, and you understand why CNC work creates such striking visual and tactile impact.

According to industry testing, CNC engraved markings typically last the lifetime of the part since they're physically cut into the material. This makes them ideal for parts that undergo frequent handling or exposure to chemicals and cleaning processes - exactly the conditions your wheels face every time you drive.

Consider the abuse your wheels endure:

- Brake dust accumulation: Hot metallic particles constantly bombarding the surface

- Road debris impact: Stones, sand, and gravel striking at highway speeds

- Chemical exposure: Wheel cleaners, tire dressings, and road salt

- Thermal cycling: Extreme temperature swings from braking heat and ambient conditions

- Pressure washing: High-pressure water jets during cleaning

CNC-engraved details withstand all of this because the marking exists within the material itself - not on top of it. Even aggressive sand blasting, as demonstrated in durability testing at 80 PSI, showed that deep etching outlasted all other marking methods.

Ideal Wheel Placements for CNC Work

CNC milling truly shines on specific wheel areas where its deeper cut creates maximum visual impact. Understanding optimal placement helps you leverage this technique's strengths while avoiding its limitations.

Wheel lip engraving represents the premier application for CNC work. The lip's flat, accessible surface allows cutting tools to operate at optimal angles, producing clean edges and consistent depth. Wheels with lip designs - particularly multi-piece constructions - offer generous real estate for brand names, build specifications, or commemorative text that wraps the circumference.

Barrel areas on 2-piece and 3-piece forged wheels provide additional CNC opportunities. The inner barrel sections visible through spoke gaps create dramatic reveals - imagine seeing your custom text or logo flash past as the wheel rotates. This placement also offers natural protection from direct road debris impact.

Spoke backs and mounting surfaces suit CNC engraving for subtle personalization. These hidden areas allow you to add personal touches - initials, dates, or messages - that only you and mechanics will see. The deeper CNC cuts ensure these details remain legible even after repeated tire changes.

However, CNC milling faces challenges on highly contoured surfaces. Unlike laser's non-contact operation, the physical cutting tool requires relatively flat surfaces for optimal results. Heavily sculpted spoke faces or complex 3D designs may limit CNC placement options.

Material Considerations for Forged Aluminum

Not all forged aluminum behaves identically under CNC engraving. Understanding your wheel's material grade helps predict results and durability.

6061-T6 aluminum - the aerospace-grade alloy used by manufacturers like Vossen for their forged line - machines exceptionally well. This heat-treated alloy offers the ideal balance of hardness for clean cuts while remaining soft enough to prevent excessive tool wear. The T6 temper specifically provides consistent material properties that translate to uniform engraving depth.

7075 aluminum wheels, while stronger, present different characteristics. The increased zinc content creates a harder surface that may require adjusted cutting parameters. Engravings on 7075 typically produce slightly sharper edges but require more careful tool selection.

The forging process itself matters significantly. Fully forged wheels undergo tremendous pressure that aligns the aluminum's grain structure, creating more consistent material properties throughout. This uniformity means CNC tools encounter predictable resistance, producing cleaner, more consistent engravings compared to cast alternatives.

CNC Engraving: Practical Considerations

Before choosing CNC milling for your wheel customization, understand its operational realities. Unlike laser systems that can process multiple wheels simultaneously, CNC engraving usually works on one part at a time. Each wheel must be secured in a vice attached to the engraving table while the cutting tool moves around to mark the surface.

This individual attention affects both turnaround time and pricing. Expect CNC engraving to cost more than laser alternatives - you're paying for physical material removal, individual wheel handling, and typically longer machine time per piece.

Design complexity also impacts CNC feasibility differently than laser work:

- Simple text and numbers: Ideal for CNC - clean, bold, easily readable

- Basic logos and shapes: Excellent results with proper tool selection

- Intricate detailed artwork: Limited by minimum tool diameter - typically 1-2mm

- QR codes or barcodes: Not recommended - laser excels here

- Very small text: Practical minimum around 8-10 point for legibility

Pros

- Maximum durability - engravings last the lifetime of the wheel

- Tactile depth creates visual and physical dimension

- Excellent visibility on highly polished surfaces where laser contrast suffers

- Resistant to chemicals, abrasion, and pressure washing

- Clean, precise edges on properly prepared surfaces

- Works exceptionally well on wheel lip and barrel sections

- No heat-affected zone that could alter material properties

Cons

- Higher cost due to individual wheel processing and longer cycle times

- Limited to relatively flat surfaces - struggles with complex contours

- Minimum detail size larger than laser capabilities

- Not suitable for extremely intricate designs or very small text

- Requires secure fixturing that may not accommodate all wheel designs

- Longer turnaround time compared to batch laser processing

CNC milling represents the definitive choice for daily drivers and track vehicles where engraving durability matters most. When your wheels face constant exposure to harsh conditions - whether that's daily commuting through salted winter roads or repeated hot laps at the track - the physical depth of CNC engravings ensures your customization remains visible and legible for years.

But what if you're seeking something truly unique - artisanal craftsmanship that machines simply cannot replicate? Hand engraving and chemical etching offer artisanal alternatives that bring human creativity directly into the customization process.

Artisanal Hand Engraving and Chemical Etching

Imagine owning wheels where every line, every curve, every detail was carved by human hands using techniques passed down through centuries. That's the realm of artisanal wheel customization - where machines step aside and master craftspeople take over. For enthusiasts seeking truly one-of-a-kind forged customs, hand engraving and chemical etching offer something no automated process can replicate: the unmistakable touch of human artistry.

These techniques demand premium investment, but they deliver results that transform premium forged wheels into genuine works of automotive art. Understanding when these methods justify their cost - and what makes them special - helps you decide if artisanal customization aligns with your vision.

The Art of Hand-Engraved Wheel Customization

Hand engraving represents the apex of wheel personalization - a centuries-old craft applied to modern automotive components. The technique involves skilled artisans using specialized chisels and hammers to carve intricate designs directly into metal surfaces, one precise strike at a time.

Consider the craftsmanship involved: according to Toyota Times' profile of master engraver Masashi Miyazawa, becoming a full-fledged hand engraver requires approximately ten years of dedicated practice. This isn't exaggeration - the technique demands developing an intuitive feel for how much force is needed and at what angle the chisel should be applied, such that it becomes second nature.

The Edo chokin (metal engraving) tradition Miyazawa practices dates back to Japan's Edo period (1603-1868). Originally used for decorating sword guards, furniture handles, and ornamental hairpins, this technique now adorns premium automotive emblems and - for the most discerning collectors - custom wheel surfaces.

What Makes Hand Engraving Worth the Premium

Why would anyone pay significantly more for hand-carved details when lasers and CNC machines offer precision and consistency? The answer lies in what machines cannot provide:

- Living artistry: Each engraving reflects the individual craftsperson's interpretation - subtle variations that create organic, breathing designs

- Microscopic detail: Master engravers working under 20x magnification can carve details measuring one-tenth of a millimeter - approximately half the width of a human hair

- Adaptive creativity: Artisans adjust their approach in real-time, enhancing designs as they work rather than following rigid programming

- Heritage connection: Owning hand-engraved wheels connects you to centuries of metalworking tradition

- True exclusivity: No two hand-engraved pieces are identical, even when following the same design template

A master engraver like Miyazawa uses approximately 30 different chisels for a single emblem project, selected from an arsenal of 200-300 custom-made tools. Each chisel is crafted by the artisan themselves to suit specific metals and design requirements - a level of specialization that produces results simply unattainable through automation.

Hand engraving suits legacy forged wheels destined for prestigious concours events, museum-quality restorations, or collectors who value provenance and craftsmanship above all else. If your wheels will primarily be admired at close range by appreciative audiences, the investment in human artistry delivers irreplaceable value.

Pros of Hand Engraving

- Unmatched artistic expression and organic character

- Microscopic precision achievable under magnification

- Each piece genuinely unique - not mass-produced

- Direct connection to centuries-old metalworking traditions

- Exceptional depth and dimensionality in complex designs

- Artisan can adapt and enhance designs during execution

Cons of Hand Engraving

- Significantly higher cost than automated methods

- Extended turnaround times - weeks to months depending on complexity

- Limited availability of qualified master craftspeople

- Subtle variations between wheels in a set (feature or flaw depending on perspective)

- Not practical for large-scale production runs

Chemical Etching for Unique Surface Effects

While hand engraving removes material through physical cutting, chemical etching takes an entirely different approach - using controlled chemical reactions to dissolve targeted areas of metal. This technique unlocks textures and patterns that neither laser, CNC, nor hand methods can achieve.

According to Neway Die Cast's technical documentation, chemical etching (also called chemical milling or photochemical machining) is a subtractive process that selectively removes metal from a surface by applying an acid or alkaline etchant. A photoresist mask defines the areas to be etched, allowing intricate designs or uniform textures to be created without mechanical force.

The process delivers impressive precision - tolerances typically within ±0.025 mm and surface roughness ranging from Ra 0.4-1.6 μm depending on alloy and depth. This makes chemical etching ideal for creating functional surface textures alongside decorative elements.

Unique Capabilities of Chemical Etching

What can chemical etching accomplish that other methods cannot? Consider these distinctive applications:

- Uniform matte textures: Reproducible satin or functional roughness across large areas - impossible with point-based methods

- Grip enhancement: Micro-patterns that increase surface friction for functional applications

- Anti-reflective finishes: Light-diffusing patterns that reduce glare on polished surfaces

- Pre-coating preparation: Textured surfaces that dramatically improve adhesion for painting, powder coating, or anodizing

- Complex geometric patterns: Intricate repeating designs over large surface areas with perfect consistency

The technique creates no mechanical stress - no tool pressure or thermal distortion affects the wheel. This makes chemical etching suitable for thin-wall areas or delicate features where other methods might compromise structural integrity.

Material Quality: The Foundation for Premium Engraving

Here's what many enthusiasts overlook: the quality of your forged wheel blanks fundamentally determines the success of any engraving technique - especially artisanal methods. Inconsistent material properties create unpredictable results, whether you're working with chisels, chemicals, or cutting tools.

Chemical etching particularly depends on consistent alloy composition. Aluminum alloys with high silicon content require carefully controlled etching solutions to avoid uneven pitting. When your forged wheel blanks come from certified manufacturers using precision hot forging processes, the uniform grain structure and consistent material properties ensure predictable, beautiful etching results.

This is where starting with quality components from IATF 16949 certified manufacturers like Shaoyi creates measurable advantages. Their precision hot forging processes ensure consistent material quality throughout each component - eliminating the porosity, grain structure variations, and alloy inconsistencies that plague lower-quality blanks. For enthusiasts planning premium engraving work, beginning with certified forged components protects your investment in artisanal customization.

Pros of Chemical Etching

- Creates textures and patterns impossible with mechanical methods

- No mechanical stress or thermal distortion to the wheel

- Highly uniform results across large surface areas

- Compatible with curved, irregular, or flat surfaces

- Excellent precision - tolerances within ±0.025 mm

- Enhances adhesion for subsequent coatings or finishes

- Can simulate bead blasting, brushing, or sand texture without physical abrasion

Cons of Chemical Etching

- Requires specialized equipment and chemical handling expertise

- Results vary significantly based on aluminum alloy composition

- High-silicon alloys (common in some castings) may etch unevenly

- Environmental considerations for chemical waste disposal

- Limited to surface texture effects - not suitable for deep engraving

- Requires thorough surface preparation for consistent results

Chemical etching excels when you want surface effects that complement other engraving techniques. Imagine a wheel featuring laser-engraved logos on a chemically-etched matte background - the combination creates visual depth and tactile interest that single-technique approaches cannot match.

Now that you understand all available engraving techniques, the next critical question emerges: where exactly on your wheels should these engravings go? The placement decision affects visibility, durability, and overall aesthetic impact more than most enthusiasts realize.

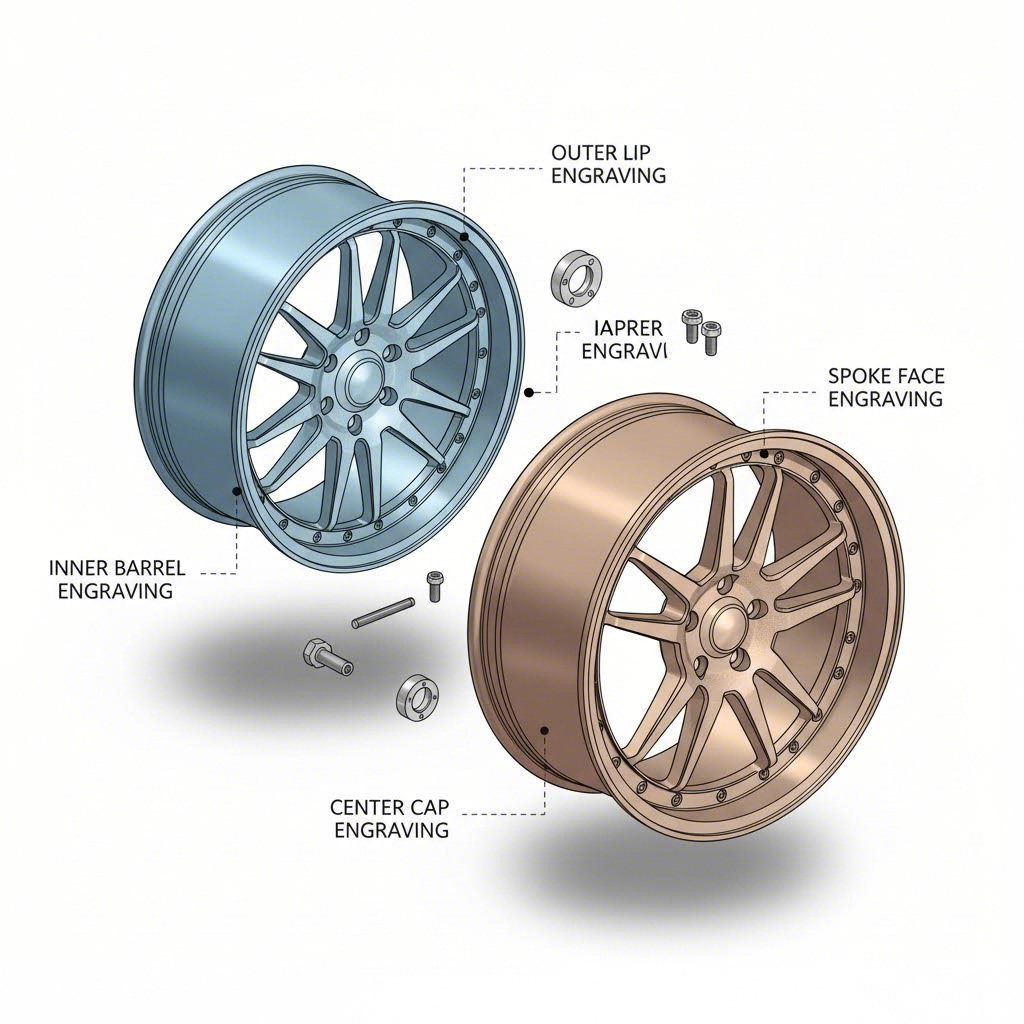

Engraving Placement Options and Visibility Guide

You've selected your engraving technique - but where exactly should those custom details go? This question stumps many enthusiasts, yet placement decisions fundamentally shape how your personalization reads, lasts, and integrates with your wheel's design. Surprisingly, most resources completely ignore this critical topic.

Your forged wheels offer far more engraving real estate than you might realize. From the constantly visible spoke faces to hidden barrel areas that reveal themselves only in motion, each location presents distinct advantages and trade-offs. Understanding these options transforms good customization into exceptional personalization.

Mapping Every Possible Engraving Location on Your Wheels

Think of your wheel as divided into distinct zones, each with unique characteristics for engraving. Let's explore every available surface:

Wheel Lip (Outer Rim Edge)

The wheels lip represents premium engraving territory - especially on rims with lips that feature deep dish or stepped designs. This flat, continuous surface wraps the entire wheel circumference, providing substantial space for text, repeated patterns, or brand messaging. On forged 2 piece wheels, the lip section often consists of a separate forged component, offering even more customization flexibility.

Visibility here depends heavily on wheel design and vehicle stance. Deep concave designs expose the lip prominently, while flush-mounted wheels partially obscure this area behind tire sidewalls.

Barrel (Inner Cylinder)

The barrel - that cylindrical section connecting the lip to the center - offers intriguing placement possibilities. While not directly visible when stationary, barrel engravings create dramatic flash effects during wheel rotation. Through spoke gaps, viewers catch glimpses of your customization in motion.

Multi-piece construction dramatically expands barrel opportunities. Forged 2 piece wheels separate the center from the outer barrel, allowing distinct engravings on each component. Some enthusiasts engrave specifications on the inner barrel - visible only during tire changes - while reserving outer areas for design elements.

Spoke Face (Front-Facing Surfaces)

Spoke faces deliver maximum visibility - these surfaces point directly toward viewers and remain constantly exposed. However, space constraints limit options here. Individual spokes may accommodate only short text, small logos, or minimal design elements.

Consider spoke geometry carefully. Flat-faced spokes accept engravings readily, while heavily contoured or sculpted designs may limit technique options. CNC milling struggles with extreme curves, whereas laser engraving adapts more flexibly to varied surface angles.

Center Cap Area

The center cap zone - whether featuring a removable cap or integrated hub cover - serves as the wheel's focal point. This central position draws the eye naturally, making it ideal for primary branding, crests, or signature designs.

Removable center caps offer practical advantages: they can be engraved separately, replaced if preferences change, and even swapped between different designs for various occasions. Integrated hub areas require permanent commitment but create seamless, cohesive aesthetics.

Lug Nut Surrounds

Often overlooked, the areas surrounding lug nut holes provide subtle personalization opportunities. Small numbers, dots, or micro-text around each lug position create understated details that reward close inspection. This placement works particularly well for build dates, sequence numbers, or subtle pattern elements.

How Placement Affects Visibility and Durability

Your placement choice directly impacts two critical factors: how often people see your engraving and how long it survives daily abuse. These considerations often conflict - the most visible locations typically face the harshest conditions.

Visibility Considerations

Ask yourself: who should see this customization, and when? Show car builds benefit from spoke face and center cap placements that photograph well and display prominently at static events. Daily drivers might prefer wheel lip engravings that reveal themselves dynamically during cornering or through wheel gaps while parked.

Vehicle ride height and wheel offset also matter. Lowered vehicles with aggressive offsets expose wheel lips prominently. Trucks and SUVs with recessed wheels may hide lip areas entirely, making spoke face placement more practical.

Durability by Location

Different wheel zones experience vastly different abuse levels:

- Spoke faces: Direct exposure to road debris, brake dust, and cleaning chemicals - requires maximum durability techniques

- Wheel lip outer edge: Vulnerable to curb contact, parking damage, and tire mounting abrasion

- Wheel lip inner face: Protected from curbs but exposed to brake heat and dust accumulation

- Barrel areas: Relatively protected, experiencing less direct impact but significant heat cycling

- Center cap: Moderate exposure with occasional cleaning chemical contact

- Lug surrounds: Periodic contact during wheel installation - vulnerable to socket scratches

Complete Placement Comparison

The following table synthesizes placement options to help you match locations with your specific goals:

| Location | Visibility Level | Durability Rating | Best Technique | Ideal Content Type |

|---|---|---|---|---|

| Wheel Lip (Outer) | Medium-High (varies with design) | Medium (curb risk) | CNC Milling, Laser | Brand names, build specs, repeated text |

| Wheel Lip (Inner Face) | Medium (visible through spokes) | High | CNC Milling | Technical specifications, serial numbers |

| Barrel | Low-Medium (motion reveals) | High | Laser, CNC Milling | Hidden messages, patterns, specs |

| Spoke Face | Very High | Medium (debris exposure) | Laser Engraving | Small logos, initials, minimal text |

| Center Cap Area | Very High | Medium-High | All techniques viable | Primary logos, crests, signature designs |

| Lug Nut Surrounds | Low (close inspection only) | Low (tool contact risk) | Laser Engraving | Numbers, dots, micro-patterns |

Multi-Piece Wheel Advantages

If maximum engraving flexibility matters to you, forged 2 piece wheels and three-piece constructions offer compelling advantages. The separate lip component - typically available in various widths - provides dedicated engraving surface independent of center design. According to manufacturers like FLEXIFORGED, custom center caps with engraved logos and optional engraved branding for private label projects represent popular customization options for their 2-piece forged wheels.

This modularity means you could theoretically engrave different content on each component: technical specifications on the barrel, brand messaging on the lip, and personal touches on the center cap. The assembly hardware itself - those visible bolts circling multi-piece wheels - creates additional personalization opportunities through custom finishes or engraved fastener heads.

With placement strategy established, one crucial question remains unanswered: what will all this actually cost? Understanding pricing factors - including the significant difference between factory and aftermarket engraving - helps you budget realistically for your customization project.

Pricing Factors and Warranty Considerations

Here's what nobody tells you upfront: custom wheel engraving costs vary dramatically based on factors most providers never clearly explain. You might receive quotes ranging from a few hundred dollars to several thousand for seemingly similar work - and without understanding the underlying cost drivers, comparing options becomes nearly impossible.

Whether you're considering bonspeed wheels with factory personalization or adding aftermarket engraving to your existing forged 20 inch rims, understanding these pricing dynamics protects your investment and sets realistic expectations. Let's break down exactly what influences your final cost - and what that American Force wheels sticker price actually buys you.

Understanding the True Cost of Quality Wheel Engraving

Wheel engraving pricing isn't arbitrary - it reflects measurable factors that directly impact labor time, equipment requirements, and skill level needed. Recognizing these variables helps you evaluate quotes intelligently rather than simply choosing the cheapest option.

Primary Cost Factors

The following elements combine to determine your engraving investment:

| Cost Factor | Impact Level | How It Affects Price |

|---|---|---|

| Technique Selected | High | Hand engraving costs 3-5x more than laser; CNC falls between |

| Placement Location | Medium-High | Complex surfaces and hard-to-reach areas increase labor time |

| Design Complexity | Medium-High | Intricate logos require more passes, programming, or hand work |

| Character/Element Count | Medium | More content equals more machine time or labor hours |

| Wheel Construction Type | Medium | Multi-piece wheels may require disassembly and reassembly |

| Finish Type | Low-Medium | Some finishes require additional preparation or post-treatment |

| Quantity | Medium | Per-wheel costs decrease with full sets due to setup efficiency |

Technique complexity represents the largest cost variable. Laser engraving operates quickly with minimal operator intervention once programmed - making it the most economical automated option. CNC milling requires individual wheel fixturing, longer cycle times, and more expensive cutting tools that wear during use. Hand engraving demands hours of skilled artisan labor for even simple designs.

Placement difficulty matters more than many realize. Engraving a flat wheel lip takes significantly less time than working on curved spoke faces or recessed barrel areas. Providers may charge premiums for placements requiring special fixturing or awkward tool angles.

Design intricacy directly correlates with execution time. A simple text string might require 15 minutes of laser time, while a detailed crest with fine lines and multiple elements could need an hour or more. Vector artwork ready for production costs less than designs requiring provider refinement.

Hidden Costs to Anticipate

Beyond the quoted engraving price, factor in these commonly overlooked expenses:

- Design services: If you lack print-ready vector files, expect fees for artwork creation or conversion

- Proofing rounds: Some providers include one proof; additional revisions may incur charges

- Wheel preparation: Dirty or damaged wheels may require cleaning or refinishing before engraving

- Protective coatings: Clear coat or sealant application over engravings often costs extra

- Shipping and handling: Wheels are heavy - shipping four forged wheels both directions adds up quickly

- Disassembly fees: Multi-piece wheels requiring separation before engraving may incur labor charges

Factory vs Aftermarket Engraving Price Differences

When you order custom forged wheels, you face a fundamental choice: specify engraving through the wheel manufacturer during production, or add personalization afterward through aftermarket services. Each path offers distinct advantages - and significantly different cost structures.

Factory Engraving Advantages

Ordering engraving directly from wheel manufacturers during the build process typically offers:

- Streamlined pricing: Engraving costs bundle into the wheel package rather than requiring separate transactions

- Process optimization: Manufacturers engrave before final finishing, eliminating concerns about damaging completed surfaces

- Guaranteed compatibility: Factory teams understand their wheel geometry intimately, ensuring optimal placement

- Warranty integration: Engraving performed during manufacturing typically remains covered under the original wheel warranty

- No shipping delays: Your personalized wheels arrive ready to install without additional service turnaround

Factory options, however, come with limitations. Design choices may be restricted to manufacturer-approved fonts, sizes, and placements. Truly custom artwork might not be available, or may require significant upcharges for special programming.

Aftermarket Engraving Considerations

Adding engraving to existing wheels through independent services provides maximum flexibility but introduces additional variables:

- Complete design freedom: Independent providers often accommodate custom artwork, unusual placements, and mixed techniques

- Technique selection: You choose the specific method rather than accepting manufacturer defaults

- Existing wheel personalization: Perfect for adding engraving to wheels already in your possession

- Competitive pricing: Shopping multiple providers may yield better rates than manufacturer premiums

The trade-offs include shipping costs and risks, turnaround time while your vehicle sits on jack stands, and the warranty considerations discussed below.

Warranty Implications You Need to Understand

Will custom engraving void your wheel warranty? This question concerns many enthusiasts - and the answer depends entirely on who performs the work and how it's executed.

Factory Engraving and Warranty Coverage

When manufacturers perform engraving during production, warranty coverage typically remains intact. The personalization becomes part of the original product, manufactured under the same quality controls as the wheel itself. This represents the safest path for enthusiasts prioritizing warranty protection.

Aftermarket Engraving Risks

Third-party modifications create more complex warranty situations. Most wheel manufacturers include language allowing warranty denial for products altered after sale. However, practical enforcement varies:

- Surface-only engraving: Laser work that doesn't significantly remove material rarely affects structural integrity - manufacturers may overlook such modifications

- Deep CNC engraving: Material removal in structural areas could legitimately void coverage if failure occurs near the engraved zone

- Placement matters: Engraving on decorative center caps differs dramatically from work on load-bearing spoke sections

- Documentation helps: Retaining proof that engraving was performed by qualified professionals using appropriate techniques may support warranty claims

Before proceeding with aftermarket engraving, contact your wheel manufacturer directly. Request written clarification about how specific modifications affect warranty coverage. Some manufacturers explicitly permit certain customizations while prohibiting others.

Protecting Your Investment

Regardless of warranty considerations, these practices minimize risk:

- Choose reputable engraving providers with wheel-specific experience

- Avoid engraving structural areas like spoke centers or mounting surfaces

- Request documentation of the engraving process and specifications

- Consider limiting deep engraving to replaceable components like center caps on multi-piece wheels

- Photograph wheels thoroughly before and after engraving for documentation

Understanding these pricing factors and warranty implications positions you to make informed decisions. But how do all these engraving options actually compare when evaluated side-by-side? The next section synthesizes everything we've covered into a comprehensive comparison framework.

Complete Engraving Options Comparison

You've explored laser precision, CNC depth, hand-carved artistry, and chemical surface effects. Now comes the practical question: which wheel engraving technique actually fits your situation? Rather than forcing you to flip between sections, this comparison consolidates everything into actionable guidance - complete with the common mistakes that derail customization projects and best practices that ensure success.

Think of this as your decision-making toolkit. Whether you're finalizing a show car build or personalizing your daily driver, the following comparisons cut through complexity and point you toward the right choice.

Side-by-Side Comparison of All Engraving Methods

The table below synthesizes the critical characteristics of each engraving technique we've examined. Use it as a quick reference when evaluating providers or discussing options with engraving services:

| Technique | Best For | Durability Rating | Cost Level | Turnaround Time | Design Flexibility |

|---|---|---|---|---|---|

| Laser Engraving | Intricate logos, fine text, detailed artwork, serial numbers | High - permanent surface alteration | Low-Medium | Fast (1-3 days typical) | Excellent for fine details; limited to flat/2D designs |

| CNC Milling | Daily drivers, track wheels, bold text, tactile depth | Very High - physically carved grooves | Medium-High | Moderate (3-7 days typical) | Good for bold designs; limited on complex contours |

| Hand Engraving | Show cars, concours entries, collector pieces, heritage builds | Very High - deep artistic carving | Very High | Slow (weeks to months) | Exceptional - 3D relief and organic designs possible |

| Chemical Etching | Surface textures, matte finishes, grip patterns, coating prep | Medium-High - surface treatment depth | Medium | Moderate (3-5 days typical) | Unique textures; not suitable for deep engraving |

Notice how each technique occupies a distinct niche. Laser engraving dominates when you need microscopic precision at reasonable cost. CNC milling wins when durability trumps everything else. Hand engraving exists for those rare projects where artistry and exclusivity justify premium investment. Chemical etching complements other methods by adding surface character impossible to achieve mechanically.

Quick Decision Framework

Still uncertain? Answer these three questions:

- What matters most - detail precision or tactile depth? Precision points toward laser; depth points toward CNC or hand engraving.

- How will these wheels be used? Track days and daily driving demand CNC durability; show-only applications allow any technique.

- What's your realistic budget and timeline? Laser fits tight budgets and schedules; hand engraving requires significant investment in both.

Matching Techniques to Your Use Case

Beyond the comparison table, understanding how techniques perform in real-world scenarios helps refine your choice. Here's how each method serves specific enthusiast profiles:

Show Car Builders

Your wheels will be photographed, judged, and scrutinized at close range. Laser engraving delivers the crisp, camera-ready details that photograph beautifully - manufacturer logos with perfect edges, commemorative text without visual artifacts. For truly exceptional builds, hand engraving creates talking-point personalization that judges and spectators genuinely appreciate.

Daily Drivers

Your engraved wheels face brake dust, road salt, aggressive cleaning, and occasional curb encounters. CNC milling's physical depth survives conditions that would fade lesser techniques. Those carved grooves remain visible and legible after years of real-world abuse - exactly what you want when your customization investment faces daily punishment.

Track Enthusiasts

Extreme heat cycling, brake dust bombardment, and potential debris impact define your wheel environment. CNC engraving handles this abuse without question. Avoid surface-only techniques on high-heat areas near brake rotors - thermal stress can affect shallow markings over time.

Brand Loyalists

Displaying manufacturer heritage or team affiliations? Laser engraving reproduces complex logos with perfect fidelity. The technique's computer-controlled precision ensures your brand representation matches official artwork exactly - no interpretation or variation that might misrepresent the identity you're celebrating.

Common Engraving Mistakes to Avoid

Even the best technique choice can't overcome execution errors. According to industry documentation on common engraving pitfalls, these mistakes derail projects most frequently:

Design Submission Errors

The most preventable mistakes happen before engraving even begins:

- Wrong file format: Raster images (JPG, PNG) produce inferior results compared to vector files (AI, EPS, SVG). Always provide or request vector artwork for clean, scalable engravings.

- Misspelled names or incorrect dates: According to Haitech Lasers, misspellings rank among the most common engraving errors. Always get text in writing and triple-check before approving production.

- Low-resolution logos: Scaling up small images creates fuzzy, unprofessional results. Source the highest resolution version available - ideally the original vector file.

- Assuming the provider will fix issues: Don't expect engraving services to catch your errors. Review proofs carefully and confirm every detail matches your intent.

Font Selection Issues

Your font choice dramatically impacts engraving success:

- Fonts too thin: Hairline fonts disappear at small sizes or engrave inconsistently. Choose medium-weight fonts for reliability.

- Decorative scripts: Ornate scripts with extreme thick-thin variation challenge all techniques. Simpler typefaces engrave more predictably.

- Font licensing: Some providers cannot use fonts you don't own licenses for. Confirm font availability or convert text to outlines before submission.

- Size minimums: Each technique has practical minimum sizes. Laser handles 4-point text; CNC may require 8-10 point for legibility. Confirm limits before finalizing designs.

Placement Miscalculations

Where you engrave matters as much as what you engrave:

- Ignoring wheel geometry: Curved spoke faces distort text and logos. Request mockups showing how designs wrap around actual wheel surfaces.

- Forgetting tire coverage: Wheel lip engravings may be partially hidden by tire sidewalls. Measure actual visible area before specifying content length.

- Overlooking rotation effects: Text engraved on spinning wheels becomes unreadable. Consider how content appears both stationary and in motion.

- Structural area engraving: Placing deep engravings on load-bearing sections like spoke centers risks warranty voiding and potential safety concerns.

Best Practices for Working with Engraving Services

Successful custom wheel engraving projects share common preparation and communication patterns. Follow these practices to ensure optimal results:

Before You Contact Providers

- Document your wheels completely: Photograph all surfaces you're considering for engraving. Include measurements of flat areas and note any existing finishes.

- Prepare your design files: Convert logos to vectors, finalize text content, and determine placement preferences before requesting quotes.

- Define your priorities: Know whether durability, detail, cost, or timeline matters most. This guides technique recommendations.

- Research provider portfolios: Look for examples matching your wheel type and desired technique. Wheel-specific experience matters.

During the Quoting Process

- Request itemized quotes: Understand what's included - design work, proofing rounds, protective coatings, shipping. Hidden fees frustrate everyone.

- Ask about material handling: How will your wheels be protected during shipping and processing? Quality providers have established protocols.

- Confirm revision policies: How many proof revisions are included? What happens if you're unsatisfied with results?

- Discuss warranty implications: Reputable providers explain how their work affects manufacturer coverage and may document their processes for your records.

During Production

- Review proofs meticulously: Check spelling, sizing, placement, and orientation. Approve only when completely satisfied.

- Request sample testing: According to industry best practices, testing on sample material or inconspicuous areas confirms settings produce desired results before committing to visible surfaces.

- Document approved settings: If the provider offers future work, having recorded settings ensures consistency across additional wheels or replacement pieces.

- Stay accessible: Quick responses to provider questions prevent delays and miscommunication.

After Receiving Your Wheels

- Inspect immediately: Check engraving quality before mounting. Document any concerns with photographs.

- Follow care instructions: Some techniques require specific cleaning approaches or protective coating maintenance.

- Provide feedback: Quality providers appreciate knowing what worked well - and need to know if anything fell short.

Armed with this comprehensive comparison and practical guidance, you're ready to make confident decisions about your wheel customization project. The final section translates all this information into specific recommendations based on how you actually use your vehicle - ensuring your engraving investment delivers lasting satisfaction.

Final Recommendations for Every Enthusiast

You've absorbed the techniques, understood the placements, evaluated the costs, and learned from common mistakes. Now comes the moment of decision: which custom forged wheel engraving option actually makes sense for your specific situation? Rather than leaving you with abstract comparisons, this section delivers concrete recommendations tailored to how you actually drive and what you genuinely value.

The best custom forged wheels deserve personalization that matches their purpose. A show car sitting under museum lighting faces entirely different demands than track wheels enduring 1,200-degree brake temperatures. Your engraving choice should reflect these realities - not just aesthetic preferences, but practical considerations that determine long-term satisfaction.

Your Ideal Engraving Choice Based on How You Drive

Think about your wheels' actual life. Where do they spend most of their time? What conditions do they face? Your honest answers point directly toward the right premium wheel engraving options for your situation.

Show Car Owners and Concours Competitors

Your wheels exist to be admired, photographed, and judged at close range. Every detail matters because judges and spectators examine your build with critical eyes - and cameras capture imperfections mercilessly.

- Primary recommendation: Laser engraving for logos, specifications, and commemorative text. The microscopic precision delivers camera-ready details with perfect edge definition.

- Premium upgrade: Hand engraving for truly exceptional builds. When your project competes at concours level, artisan-carved details create conversation pieces that distinguish your entry from machine-produced alternatives.

- Placement priority: Center cap areas and spoke faces where visibility is maximum. Consider barrel engravings as hidden details that reward close inspection.

- Budget consideration: Allocate 15-25% of wheel cost for quality engraving on show builds - this investment directly impacts presentation scores and perceived build quality.

Daily Drivers and Street Enthusiasts

Your personalized wheels face reality every day: parking lots, weather extremes, road debris, and countless cleaning cycles. Durability isn't optional - it's essential for protecting your investment over years of actual use.

- Primary recommendation: CNC milling for maximum longevity. Those physically carved grooves survive conditions that fade surface-only techniques. Your engraving remains legible after years of brake dust accumulation and aggressive cleaning.

- Secondary option: Laser engraving on protected areas like inner barrel sections or wheel lip inner faces. These placements reduce direct exposure while maintaining personalization.

- Placement priority: Wheel lip sections offer visibility with reasonable protection. Avoid spoke faces for deep engraving - they face the harshest direct exposure.

- Budget consideration: CNC costs more upfront but eliminates the frustration of watching cheaper engraving fade over time. Consider it durability insurance.

Track Day Warriors and Performance Drivers

Extreme heat cycling, intense brake dust bombardment, and potential debris impact define your wheel environment. Your engraving technique must survive conditions that destroy lesser customization methods.

- Primary recommendation: CNC milling exclusively. No other technique matches CNC durability under sustained high-temperature operation. The physical depth ensures visibility even when brake dust accumulation is severe.

- Technique to avoid: Surface-only laser engraving on high-heat areas near brake rotors. Thermal stress can affect shallow markings over extended track sessions.

- Placement priority: Inner barrel areas and wheel lip inner faces - protected locations that still allow personalization without compromising performance or safety.

- Budget consideration: Factor engraving into your overall wheel budget from the start. Track wheels represent serious investment - protect that investment with equally serious engraving durability.

Brand Loyalists and Team Representatives

Displaying manufacturer heritage, racing team affiliations, or sponsor recognition requires perfect brand representation. Your engraving must match official artwork exactly - no interpretation or variation that might misrepresent the identity you're celebrating.

- Primary recommendation: Laser engraving for complex logos with fine details, gradients, or small text elements. Computer-controlled precision ensures your brand representation matches source artwork perfectly.

- Design preparation: Always source original vector files from brand owners. Recreated logos risk inaccuracy and potential trademark concerns.

- Placement priority: Center cap areas for primary logos; wheel lip for secondary branding, sponsor lists, or team information.

- Budget consideration: Brand representation justifies premium investment. Poorly executed logos reflect negatively on both you and the brands you're representing.

Final Recommendations for Every Budget

Your available budget shouldn't prevent wheel personalization - it should guide technique and scope decisions. Here's how to maximize impact at every investment level:

Entry Level: Maximum Impact, Minimum Investment

- Focus on single-location laser engraving - center cap or wheel lip

- Choose simple text designs over complex logos to reduce programming costs

- Consider engraving removable center caps only - allows future changes without affecting wheels

- Request quotes from multiple providers; pricing varies significantly for identical work

Mid-Range: Balanced Customization

- CNC milling becomes accessible at this level - prioritize durability over complexity

- Combine techniques: laser logos with CNC text for visual and tactile interest

- Engrave multiple locations for cohesive personalization across the wheel

- Factor in protective clear coating to extend engraving life

Premium: No-Compromise Personalization

- Hand engraving becomes viable for special elements - consider artisan work on center caps

- Chemical etching combined with other techniques creates unique surface character

- Multi-piece wheel construction offers maximum placement flexibility

- Factory engraving during wheel production ensures warranty coverage and optimal integration

The Foundation Matters: Starting with Quality Components

Here's what experienced builders understand: the best engraving technique applied to inferior materials produces disappointing results. Porosity, grain structure inconsistencies, and alloy variations in lower-quality wheel blanks create unpredictable engraving outcomes - regardless of which technique you select.

According to industry insights from XZ Forged Wheels, the forging process compresses metal grains to create denser, more uniform structures. This density isn't just about strength - it directly impacts how consistently materials accept engraving. A denser material with aligned grain structure produces cleaner cuts, more uniform laser absorption, and predictable chemical etching results.

This is precisely why starting with quality forged components from certified manufacturers like Shaoyi creates measurable advantages for engraving projects. Their IATF 16949 certification ensures consistent material quality throughout each component - eliminating the porosity and grain variations that plague lower-quality blanks. For enthusiasts planning premium engraving work, beginning with certified forged components protects your customization investment.

Additionally, Shaoyi's rapid prototyping capabilities - with turnaround as quick as 10 days - support custom wheel projects where unique specifications matter. When your project requires specific forged wheel blanks engineered for particular engraving applications, their in-house engineering and globally compliant manufacturing ensure your foundation meets the same quality standards as your finishing touches.

Your Forged Wheel Customization Guide: Key Takeaways

After exploring every aspect of custom forged wheel engraving options, these principles should guide your decisions:

- Match technique to use case: Show cars favor laser precision; daily drivers and track wheels demand CNC durability; collector pieces justify hand engraving artistry.

- Placement affects everything: Visibility and durability trade off against each other. Choose locations that balance how often your engraving is seen against how much abuse it faces.

- Budget realistically: Quality engraving represents 10-25% of premium wheel investment. Cutting corners here undermines the entire customization effort.

- Prepare thoroughly: Vector files, finalized text, and clear placement specifications prevent costly errors and delays.

- Start with quality materials: The best engraving technique cannot overcome inconsistent material properties. Certified forged components ensure predictable, beautiful results.

- Protect your warranty: Factory engraving preserves coverage; aftermarket work requires careful provider selection and documentation.

Custom forged wheel engraving transforms functional components into personal statements - rolling expressions of your automotive passion that distinguish your build from every other vehicle on the road. Armed with this forged wheel customization guide, you now possess the knowledge to make confident decisions that deliver lasting satisfaction.

Whether you choose laser precision, CNC durability, or artisanal hand-carved exclusivity, the personalization you add becomes part of your vehicle's identity. Choose wisely, prepare thoroughly, and work with providers who share your commitment to quality. Your wheels deserve nothing less.

Frequently Asked Questions About Custom Forged Wheel Engraving

1. What are the different custom forged wheel engraving options available?

The main custom forged wheel engraving options include laser engraving for ultra-precise detailing and intricate logos, CNC milling for deep and durable engravings ideal for daily drivers and track wheels, hand engraving for artisanal craftsmanship on show cars, and chemical etching for unique surface textures. Each technique offers distinct advantages: laser provides microscopic precision at moderate cost, CNC delivers maximum durability with tactile depth, hand engraving creates one-of-a-kind artistry, and chemical etching produces patterns impossible with mechanical methods.

2. Where can I engrave my forged wheels for best visibility and durability?

Forged wheels offer multiple engraving locations including the wheel lip (outer rim edge) for brand names and specifications, barrel sections for hidden reveals during rotation, spoke faces for maximum visibility, center cap areas as focal points for primary logos, and lug nut surrounds for subtle personalization. Multi-piece forged wheels provide additional flexibility with separate components. Wheel lips offer medium-high visibility with CNC or laser techniques, while spoke faces deliver very high visibility but face more debris exposure. Balance your placement choice between how often the engraving is seen versus the abuse it will face.

3. How much does custom wheel engraving cost?

Custom wheel engraving costs vary based on technique complexity, placement difficulty, design intricacy, and wheel construction type. Laser engraving represents the most economical option due to quick processing. CNC milling costs more due to individual wheel handling and longer cycle times. Hand engraving commands premium pricing at 3-5x laser costs due to skilled artisan labor. Additional expenses include design services, proofing rounds, protective coatings, and shipping. Factory engraving ordered with new wheels typically bundles into the package price and preserves warranty coverage, while aftermarket services offer more design flexibility but require separate transactions.

4. Does custom engraving void my wheel warranty?

Factory engraving performed during production typically maintains warranty coverage since personalization becomes part of the original product. Aftermarket modifications create more complex situations. Most manufacturers include language allowing warranty denial for altered products, though enforcement varies. Surface-only laser work rarely affects structural integrity, while deep CNC engraving in structural areas could legitimately void coverage. Contact your wheel manufacturer directly before proceeding with aftermarket engraving and request written clarification. Choosing reputable providers, avoiding structural areas, and documenting the engraving process helps protect your investment.

5. Which engraving technique is most durable for daily driving?

CNC milling creates the most durable engravings for daily drivers and track vehicles. Unlike laser engraving's heat-based surface alteration, CNC physically removes material using precision cutting tools, creating engravings with genuine depth ranging from 0.5mm to several millimeters. These carved grooves remain visible and legible after years of brake dust accumulation, road salt exposure, aggressive cleaning, and thermal cycling. Industry testing confirms CNC engraved markings typically last the lifetime of the wheel since they're physically cut into the material. Starting with quality forged components from IATF 16949 certified manufacturers like Shaoyi ensures consistent material properties for optimal engraving results.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —