Why Custom Forged Steering Knuckles Benefits Outperform Cast Parts

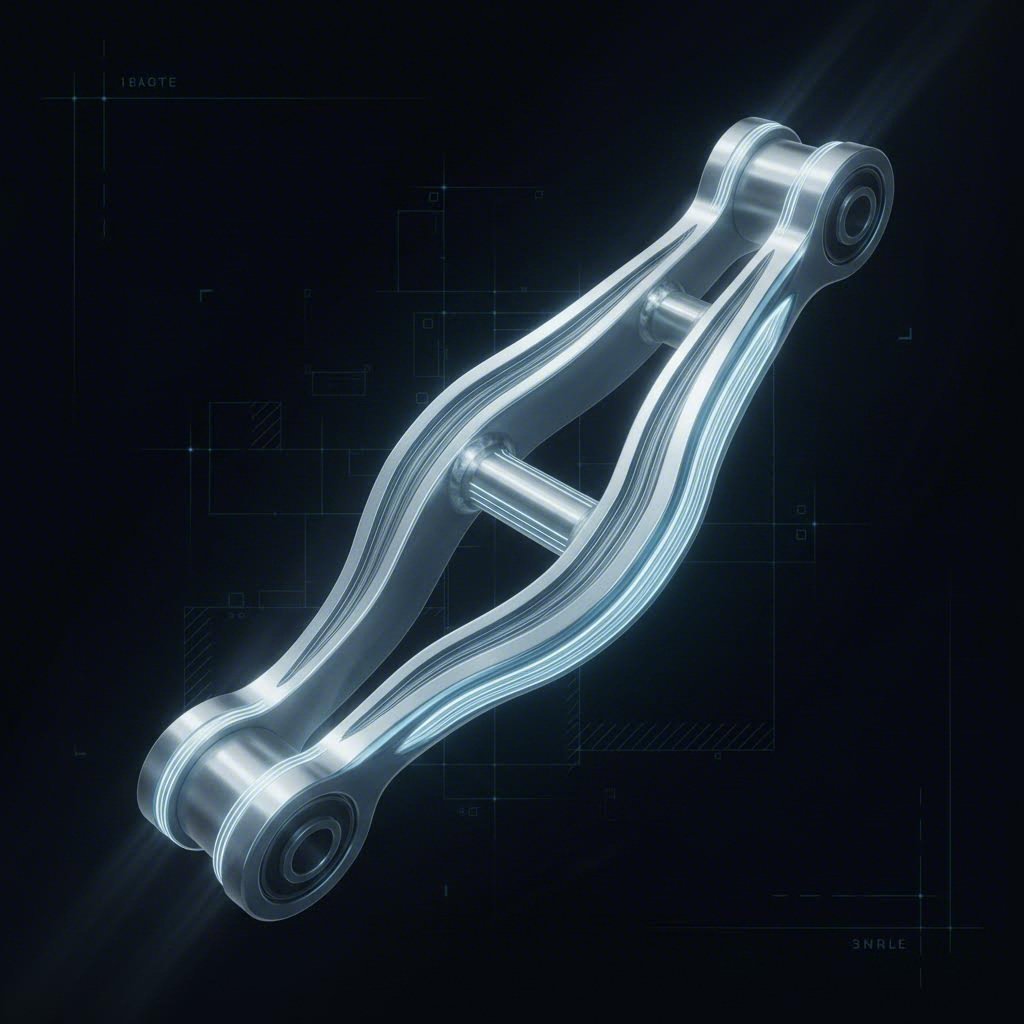

Understanding the Steering Knuckle and Its Role in Vehicle Performance

Ever wondered what makes your vehicle respond so precisely when you turn the steering wheel? The answer lies in a critical yet often overlooked component: the steering knuckle. Understanding what is a steering knuckle and how it functions is essential for anyone involved in automotive engineering, procurement, or vehicle performance optimization.

Simply put, a steering knuckle is the central hub that connects your wheel assembly to both the suspension and steering systems. According to Wikipedia, in automotive suspension, a steering knuckle or upright is the part that contains the wheel hub or spindle and attaches to the suspension and steering components. Think of it as the critical junction point where multiple vehicle systems meet and work together seamlessly.

The Steering Knuckle as Your Vehicle's Critical Connection Point

So, what is a knuckle on a car in practical terms? Imagine you're standing at a busy intersection where several roads converge. The steering knuckle serves a similar purpose in your vehicle's architecture. It acts as the meeting point where the wheel, suspension components, and steering mechanism all connect to ensure smooth, controlled operation.

The knuckle in car applications typically sits in the front suspension system, though rear steering knuckles are also common in modern vehicles. This component must withstand tremendous forces while maintaining precise alignment and allowing controlled movement. Every time you navigate a turn, hit a pothole, or brake hard, your steering knuckle absorbs and transfers these forces throughout the chassis.

How Steering Knuckles Enable Precise Wheel Control

What is a car knuckle designed to accomplish? Its primary function is guiding wheel movement when you turn the steering wheel while simultaneously supporting the vehicle's weight and managing suspension travel. This dual responsibility makes the steering knuckle one of the most stressed components in your vehicle's undercarriage.

Understanding what connects to the steering knuckle helps illustrate why this component is so critical. Here are the key suspension components that interface with this central hub:

- Wheel Hub or Spindle: The wheel and tire assembly attaches here, rotating while being held in a stable plane of motion by the knuckle and suspension assembly

- Upper and Lower Control Arms: These attach at the top and bottom of the knuckle, controlling vertical wheel movement during suspension travel

- Tie Rods: Connected to a protruding arm on the knuckle, these transfer steering input from the steering rack to turn the wheel assembly

- Brake Caliper Mounting Points: Integrated mounting surfaces allow secure attachment of the braking system

- Ball Joints: These pivoting connections enable the knuckle to rotate for steering while accommodating suspension movement

- Wheel Bearings: Housed within or mounted to the knuckle, these allow smooth wheel rotation under load

Each of these connection points must maintain precise alignment and structural integrity under demanding conditions. That's exactly why the manufacturing method used to produce steering knuckles matters so much. When you understand how many critical systems depend on this single component, the custom forged steering knuckles benefits become clear: superior strength, dimensional accuracy, and fatigue resistance directly translate to safer, better-performing vehicles.

Forged vs Cast vs Machined Steering Knuckles Compared

Now that you understand what connects to the steering knuckle and why it's so critical, you might be wondering: does it really matter how this component is manufactured? The short answer is absolutely. The manufacturing method you choose directly impacts how well a spindle knuckle performs under the extreme stresses of real-world driving. Let's break down the technical differences between forging, casting, and machining so you can make informed decisions for your specific application.

Grain Flow Patterns and Structural Integrity Differences

Imagine the internal structure of metal as tiny grains packed together. When you forge a car knuckle, something remarkable happens: those grains stretch and align with the component's shape. According to HTC Forge, this grain flow follows the curves and bends of the part, creating a smooth path through the metal that significantly increases strength and helps stop cracks from spreading.

Why does this matter for knuckle steering applications? Your steering knuckle experiences multiaxial stress, meaning forces come from multiple directions simultaneously. When you corner hard, the knuckle handles lateral loads. When you brake, longitudinal forces dominate. Hitting a pothole? That's a sudden impact load. The aligned grain structure in forged components creates natural pathways that distribute these varied stresses efficiently.

Cast parts tell a different story. During casting, molten metal cools unevenly, causing grains to grow in random directions and sizes. These grain ends meet at sharp angles, creating potential weak points where cracks can initiate under high stress. Machined parts present yet another challenge: the cutting process actually disrupts the existing grain structure, severing those beneficial continuous grain pathways that forging creates.

Why Manufacturing Method Determines Load-Bearing Capacity

The differences in grain structure translate directly to measurable performance advantages. Research from industry sources shows forged components deliver approximately 26% higher tensile strength, 37% higher fatigue strength, and 44% higher yield strength compared to cast or machined alternatives. For a spindle and knuckle assembly that must perform reliably over hundreds of thousands of miles, these aren't just numbers on paper. They represent the difference between a component that lasts and one that fails prematurely.

The forging process also eliminates internal defects that plague cast components. As Queen City Forging explains, forging compresses the material, closing any internal voids or cavities and promoting a more uniform material structure. Cast steering knuckles commonly contain porosity ranging from 2-5%, along with shrinkage defects and gas pockets. These hidden flaws act as stress concentrators that can trigger catastrophic failure under load.

When precision matters, forged knuckle car components excel. Precision forging achieves dimensional tolerances of ±0.05-0.1mm, meeting the tight specifications required for critical suspension system components. This accuracy ensures proper fit with mating parts like control arms, tie rods, and wheel bearings without extensive secondary machining operations.

| Criteria | Forged Steering Knuckles | Cast Steering Knuckles | Machined Steering Knuckles |

|---|---|---|---|

| Tensile Strength | Approximately 26% higher than cast/machined; handles greater pulling forces | Moderate; weakened by internal defects and porosity | Depends on starting material; no improvement from process |

| Fatigue Resistance | About 37% higher; up to 6x longer lifespan under repeated stress | Lower; defects initiate fatigue cracks more readily | Lower; cut grain boundaries create stress concentration points |

| Weight Characteristics | Optimized strength-to-weight ratio; lighter designs possible without sacrificing performance | Often heavier to compensate for lower material strength | Weight depends on design; material waste during production |

| Grain Structure Continuity | Continuous grain flow aligned with component contours | Random grain orientation; grains end at sharp angles | Grain structure cut through by machining operations |

| Tolerance Capabilities | ±0.05-0.1mm with precision forging; excellent dimensional accuracy | Lower dimensional accuracy; often requires secondary machining | Highest precision achievable; tight tolerances standard |

| Internal Defects | Eliminated or minimized; dense, homogeneous structure | Common porosity (2-5%), shrinkage, gas pockets | Defects from original material remain unchanged |

| Typical Applications | High-performance vehicles, motorsport, heavy-duty commercial, safety-critical applications | Standard passenger vehicles, cost-sensitive applications, complex geometries | Prototypes, low-volume custom parts, extremely tight tolerance requirements |

Looking at this comparison, you can see why custom forged steering knuckles benefits extend far beyond simple strength numbers. The combination of aligned grain structure, elimination of internal defects, and precise dimensional control creates components that perform reliably under the demanding conditions steering knuckles face daily. When failure isn't an option, especially in high-stress mounting points connecting suspension system components to wheels, the forging advantage becomes clear.

Understanding these manufacturing differences sets the foundation for appreciating the specific performance advantages that forged steering knuckles deliver in real-world applications.

Key Performance Advantages of Custom Forged Steering Knuckles

So you've seen the technical comparison between manufacturing methods. But what does this actually mean when your steering knuckles are handling real-world punishment? Let's explore how the custom forged steering knuckles benefits translate into tangible performance improvements that matter for automobile front suspension systems and beyond.

When you're evaluating suspension knuckles for demanding applications, understanding what is a wheel knuckle expected to endure helps clarify why forging delivers superior results. These components face a brutal combination of repeated stress cycles, sudden impacts, and constant load variations. That's exactly where forged steering knuckles excel.

Fatigue Resistance Under Repeated Stress Cycles

Imagine your front suspension parts experiencing thousands of stress cycles during a single drive. Every bump, turn, and braking event adds to that count. Over a vehicle's lifetime, a suspension knuckle may endure millions of these cycles. This is where fatigue resistance becomes critical.

Research from the International Journal of Novel Research and Development demonstrates that properly designed steering knuckles can achieve infinite fatigue life when stresses remain below the material's endurance limit. For forged components, this endurance limit is significantly higher thanks to the continuous grain structure that resists crack initiation and propagation.

According to Amfas International, forged parts better resist crack initiation and propagation, which is vital for components like crankshafts, axles, and suspension knuckles that experience cyclic loading. The aligned grain flow distributes stress evenly along natural pathways rather than concentrating at weak points. This means your steering knuckles maintain their structural integrity cycle after cycle, year after year.

Cast components, by contrast, contain internal voids and porosity that act as stress concentrators. These microscopic defects become the starting points for fatigue cracks. Under repeated loading, these cracks grow until catastrophic failure occurs, often with little warning. The forging process eliminates this vulnerability by compressing the material into a dense, homogeneous structure.

Weight Optimization Without Compromising Strength

Here's where things get interesting for performance-focused applications. The superior strength-to-weight ratio of forged components allows engineers to remove material from low-stress areas while maintaining structural integrity in critical zones.

A study documented by the International Journal of Novel Research and Development achieved an 18% weight reduction on a steering knuckle through finite element optimization, reducing weight from 4.8 kg to 4.0 kg while still meeting infinite fatigue life requirements. This wasn't possible with cast alternatives because they require additional material thickness to compensate for lower inherent strength and internal defects.

For automobile front suspension applications, every gram saved translates to improved handling dynamics, reduced unsprung mass, and better fuel efficiency. When you multiply this across all four corners of a vehicle, the performance gains become substantial. This is precisely why motorsport teams and performance vehicle manufacturers consistently choose forged front suspension parts despite higher upfront costs.

The key benefits of custom forged steering knuckles include:

- Improved Impact Resistance: Forged components absorb sudden shocks without fracturing, critical for vehicles encountering potholes, curbs, or off-road obstacles

- Consistent Material Density: High-pressure deformation creates uniform structure throughout the component, ensuring predictable performance under all loading conditions

- Elimination of Internal Voids and Porosity: Unlike castings where 2-5% porosity is common, forged parts achieve near-theoretical density with no hidden weak points

- Enhanced Surface Finish for Bearing Interfaces: Precision forging produces superior surface quality at critical mounting points where wheel bearings and other components interface

- Superior Corrosion Resistance: Dense, void-free material resists corrosive attack better than porous castings, extending service life in harsh environments

- Reduced Stress Concentration: Smooth grain flow patterns eliminate sharp internal boundaries where stresses accumulate and failures initiate

These benefits work together to deliver real-world performance improvements. Steering precision improves because the suspension knuckle maintains tighter dimensional tolerances under load. Vehicle handling stability increases because the component responds predictably to multiaxial stress conditions. And long-term reliability improves because fatigue-resistant materials don't degrade over time like porosity-prone castings.

The elimination of internal defects deserves special attention. Porosity-free construction means loads transfer efficiently through the material rather than concentrating around voids. This uniform microstructure prevents the stress concentrators that often lead to premature failures in cast parts. For safety-critical suspension system components, this difference can mean the distinction between reliable performance and unexpected failure.

Understanding these performance advantages naturally leads to an important question: which materials maximize these forging benefits for your specific application?

Material Selection and Alloy Specifications for Forged Knuckles

Choosing the right material for your forged steering knuckle isn't just a technical decision. It fundamentally shapes how your car suspension components perform under stress, resist corrosion, and respond to heat treatment. So what are knuckles on a car typically made from, and how do you pick the optimal alloy for your application?

The answer depends on balancing several factors: required strength, operating environment, weight constraints, and budget considerations. Let's explore the most common material grades used in vehicle suspension system components and when each makes sense.

Steel Alloy Selection for Heavy-Duty Applications

When maximum strength and durability are non-negotiable, steel alloys dominate. Three grades stand out for forged steering knuckle applications: 4140, 4340, and 1045. Each offers distinct advantages depending on your performance targets.

4140 Steel represents the workhorse of the chromium-molybdenum steel family. According to E Steel Sdn Bhd, 4140 delivers tensile strength of 950-1000 MPa in the quenched condition with excellent strength-to-cost ratios. This makes it ideal for parts of front suspension systems where reliability matters but extreme performance isn't the primary concern. It machines well and responds predictably to oil quenching and tempering at 400-600°C.

4340 Steel steps up the performance with one critical addition: nickel. That 1.65-2.00% nickel content transforms the alloy's behavior under stress. As industry data shows, 4340 achieves tensile strength of 1000-1170 MPa with impact toughness of 50-70 J even at -40°C. For car suspension parts facing extreme conditions like motorsport applications or heavy commercial vehicles, this superior low-temperature toughness and fatigue resistance justifies the higher cost.

1045 Steel offers a simpler, more economical alternative for less demanding applications. This medium carbon steel provides adequate strength for standard passenger vehicle components while remaining easy to machine and heat treat. When budget constraints exist and operating conditions are moderate, 1045 delivers solid performance without premium pricing.

Research documented in the Journal of Emerging Technologies and Innovative Research compared mild steel, stainless steel, and heat-treated steel for go-kart steering knuckles. The analysis revealed that heat-treated steel achieved yield strength of 329 MPa compared to 250 MPa for mild steel, demonstrating how heat treatment options dramatically influence final mechanical properties.

Aluminum Forging for Weight-Critical Performance Vehicles

When every gram counts, aluminum alloys become compelling options for car suspension components. Two grades dominate performance applications: 6061-T6 and 7075.

6061-T6 Aluminum offers an excellent balance of strength, workability, and corrosion resistance. According to Premium Alu, this alloy contains magnesium and silicon that provide good weldability and machinability while maintaining adequate strength. It responds well to anodizing thanks to its silicon content, creating a thick, protective oxide layer. For vehicle suspension system components where moderate strength meets weight savings, 6061-T6 delivers reliable performance.

7075 Aluminum pushes strength boundaries with tensile properties approaching some steel grades. Often called "aircraft grade," 7075's zinc-magnesium-copper composition achieves nearly double the tensile strength of 6061 in the T6 condition. This makes it ideal for motorsport applications where maximum strength-to-weight ratio matters most.

However, 7075 comes with trade-offs. Its higher hardness makes machining more challenging, requiring carbide tooling and slower cutting speeds. Welding 7075 presents significant crack risks, typically requiring post-weld heat treatment. For parts of front suspension designed as single forged components without welding requirements, these limitations matter less.

| Material Grade | Tensile Strength | Key Advantages | Best Applications |

|---|---|---|---|

| 4140 Steel | 950-1000 MPa | Excellent strength-to-cost ratio, good machinability | General automotive, hydraulic components |

| 4340 Steel | 1000-1170 MPa | Superior fatigue strength, low-temperature toughness | Aerospace, motorsport, heavy-duty commercial |

| 1045 Steel | 570-700 MPa | Economical, easy to machine and heat treat | Standard passenger vehicles, moderate stress applications |

| 6061-T6 Aluminum | 290-310 MPa | Excellent weldability, good corrosion resistance, weight savings | Performance vehicles, cycling, construction |

| 7075 Aluminum | 510-540 MPa | Highest strength aluminum, exceptional strength-to-weight | Racing applications, aerospace, military |

Titanium represents the ultimate material choice when budget permits. Ti-6Al-4V offers exceptional strength-to-weight ratios with outstanding corrosion resistance. However, titanium's high cost and difficult machinability limit its use to specialized applications like Formula 1 racing or military vehicles where performance trumps all other considerations.

The decision criteria for material selection ultimately come down to matching alloy properties with application requirements. Consider operating temperature range, expected load cycles, corrosion exposure, and weight targets. For what are knuckles on a car expected to handle in your specific use case, the right material choice ensures optimal performance throughout the component's service life.

With material selection understood, the next consideration becomes matching these alloy choices to specific vehicle categories and their unique demands.

Application-Specific Benefits Across Vehicle Categories

Now that you understand material options, here's the practical question: which specifications matter most for your specific vehicle type? The custom forged steering knuckles benefits you prioritize should align directly with your application's unique demands. A Formula racing team and a commercial fleet operator face completely different challenges, even though both need reliable knuckles on a car.

Let's break down what each vehicle category requires and how forged steering knuckles address those specific needs.

Motorsport Applications Where Every Gram Matters

In competitive racing, the difference between winning and losing often comes down to milliseconds. That's why motorsport teams obsess over unsprung mass reduction. When you reduce weight in rear suspension parts and front components alike, you improve acceleration, braking response, and cornering grip simultaneously.

Forged steering knuckles dominate this segment because they deliver maximum strength with minimum weight. According to Met3dp, topology-optimized designs can achieve weight reductions of 40% compared to conventional alternatives while maintaining structural integrity for demanding track conditions.

Key requirements for motorsport steering knuckles include:

- Maximum Strength-to-Weight Ratio: 7075 aluminum or titanium alloys preferred for ultimate performance

- Rapid Geometry Iterations: Ability to modify suspension pickup points for track-specific optimization

- Superior Fatigue Resistance: Components must endure high-frequency stress cycles during aggressive driving

- Tight Dimensional Tolerances: Precision mounting interfaces ensure predictable handling characteristics

- Heat Treatment Optimization: T6 temper or custom heat treatment for maximum mechanical properties

For racing applications, the investment in premium forged components pays dividends through improved lap times and reduced suspension failures during critical race situations.

Off-Road Vehicles: When Impact Resistance Defines Survival

Off-road environments present a fundamentally different challenge. Your rear suspension of a car might encounter rocks, logs, and sudden drops that would destroy lesser components. Here, the priority shifts from weight savings to pure durability and impact resistance.

Forged steel steering knuckles excel in these applications. As GDST Auto explains, forged steel offers exceptional strength and is ideal for vehicles subject to high loads and rough conditions, such as trucks and off-road vehicles.

Critical specifications for off-road steering knuckles include:

- High Impact Toughness: 4340 steel with Charpy impact values of 50-70 J even at low temperatures

- Generous Safety Margins: Thicker cross-sections at stress concentration points for unpredictable loads

- Corrosion Protection: Protective coatings or surface treatments to resist mud, water, and salt exposure

- Robust Mounting Features: Reinforced tie rod and control arm attachment points for extreme articulation

- Field Serviceability: Design considerations allowing repairs in remote locations if needed

Commercial Fleet Requirements for Extended Service Life

Commercial trucks operate on a different calculus entirely. When your trailer suspension parts and steering components accumulate hundreds of thousands of miles, long-term durability and maintenance costs become the primary concerns.

According to BFS Fleet Service, heavy-duty truck suspension systems must support vehicle weight, absorb impacts, and maintain stability under extreme conditions. Forged steering knuckles deliver the fatigue resistance needed for this demanding service life.

Fleet operators should prioritize these specifications:

- Exceptional Fatigue Life: Components rated for millions of stress cycles without degradation

- Consistent Quality: Tight process controls ensuring every knuckle performs identically across the fleet

- Predictable Maintenance Intervals: Reliable performance that integrates with scheduled service programs

- Total Cost of Ownership: Higher upfront cost justified by reduced replacement frequency and downtime

- Load Capacity Margins: Adequate strength for maximum payload plus safety factors for overload conditions

For commercial applications, the custom forged steering knuckles benefits manifest as reduced maintenance costs, fewer roadside failures, and improved fleet uptime over vehicle lifecycles.

Passenger Vehicles: Balancing Performance with Economics

Standard passenger vehicles represent the broadest market segment, and here the equation becomes more nuanced. You need reliable rear suspension components and front knuckles that perform safely for years, but extreme specifications may not justify their cost premium.

Interestingly, the electric vehicle segment is changing this calculation. As industry analysis notes, lightweighting is no longer just about performance in EVs. It's fundamental to the vehicle's viability for maximizing driving range.

Key considerations for passenger vehicle applications include:

- Cost-Effective Material Selection: 4140 steel or 6061-T6 aluminum providing adequate strength at reasonable cost

- Optimized Weight: Balance between mass reduction and structural requirements for the vehicle class

- Manufacturing Efficiency: Designs suitable for higher-volume production methods

- NVH Considerations: Surface finish and dimensional accuracy affecting ride quality and noise

- Warranty Period Coverage: Fatigue life exceeding typical warranty obligations with comfortable margins

When selecting knuckles on a car for your specific application, match the material grade and design specifications to your actual operating conditions rather than over-specifying based on theoretical worst cases.

Understanding these application-specific requirements helps you communicate effectively with suppliers about your actual needs. Rather than simply requesting a forged steering knuckle, you can specify the performance characteristics that matter for your use case, leading to better outcomes and optimized costs.

With application requirements defined, the next step is understanding which forging methods best achieve your specified performance targets.

Forging Methods and Process Selection for Optimal Results

You've identified your application requirements and selected the ideal material grade. Now comes a critical question: which forging method will transform that raw material into a high-performance steering knuckle? The process you choose directly impacts grain structure quality, dimensional accuracy, and ultimately how well your suspension system parts perform under real-world stress.

Understanding the differences between forging methods helps you specify the right approach when working with manufacturers. Not all forging is created equal, and the wrong process selection can undermine the custom forged steering knuckles benefits you're seeking.

Understanding the Three Primary Forging Approaches

Before diving into which method works best for steering knuckles, let's establish what each forging process actually involves.

Open-Die Forging compresses heated metal between flat or minimally contoured dies that don't fully enclose the workpiece. According to RPPL Industries, the dies do not enclose the materials, allowing them to flow freely according to the pressure applied. Skilled operators manipulate the workpiece through multiple compression cycles to achieve the desired shape. This method excels at producing large, relatively simple shapes with excellent grain refinement.

Closed-Die Forging (also called impression-die forging) takes a fundamentally different approach. Here, heated metal is compressed within specifically designed dies that create a cavity matching the desired component shape. The metal flows under high pressure to fill every contour of the die cavity, producing precise, complex geometries. As industry sources explain, this method is extensively used in the automotive industry for producing high-strength, long-lasting and precise components.

Precision Forging refines the closed-die approach further, achieving near-net-shape production with minimal material waste. This advanced technique produces components requiring little to no secondary machining, with tolerances as tight as ±0.05-0.1mm.

Closed-Die Forging for Complex Steering Knuckle Geometries

When you examine a knuckle on a car, you'll notice it's anything but simple. Multiple mounting interfaces, varying cross-sections, and precise alignment features make steering knuckles among the most geometrically complex suspension components. This complexity is exactly why closed-die forging dominates steering knuckle production.

According to Welong Casting, hot die forging produces components with superior strength-to-weight ratios, crucial for modern vehicle design where lightweight yet robust parts are essential. The process creates parts with continuous grain flow following the contours of the part, which enhances overall strength and reduces the likelihood of part failure under extreme conditions.

What makes closed-die forging ideal for auto suspension parts like steering knuckles?

- Complex Shape Capability: Die cavities can replicate intricate geometries including tie rod mounting ears, control arm attachment points, and wheel bearing bores

- Consistent Repeatability: Every part produced from the same die set matches dimensional specifications exactly, critical for high-volume automotive production

- Optimized Grain Flow: Metal flows into all sections of the die cavity, creating aligned grain structure throughout even complex shapes

- Near-Net-Shape Production: Parts emerge close to final dimensions, reducing machining requirements and material waste

- Superior Surface Quality: Die contact creates smooth surfaces at critical interfaces where bearings and other components mount

The precision achieved through closed-die forging is particularly valuable for arm knuckle assemblies where multiple components must interface perfectly. Ball joint bores, tie rod tapers, and caliper mounting surfaces all benefit from the dimensional accuracy this method provides.

How Precision Forging Minimizes Post-Processing Requirements

Traditional manufacturing often requires extensive secondary machining to achieve final specifications. Precision forging changes this equation dramatically, delivering car suspension system parts that need minimal finishing work.

According to hot die forging research, the near-net-shape capability means that components can be produced very close to their final dimensions, reducing the need for extensive machining operations. This saves material, reduces energy consumption, and shortens production time.

For steering knuckle applications, precision forging delivers several specific advantages:

- Reduced Machining Time: Critical surfaces emerge from forging within tight tolerances, requiring only finishing cuts rather than heavy material removal

- Preserved Grain Structure: Less machining means fewer interruptions to the beneficial grain flow patterns created during forging

- Lower Total Cost: Despite higher die costs, reduced secondary operations often result in lower overall part costs for production volumes

- Consistent Quality: Process control during forging ensures every part meets specifications, reducing inspection requirements and reject rates

Why Hot Forging Benefits Steering Knuckle Production

Temperature plays a crucial role in achieving optimal forging results. Hot die forging, where metal is heated to its recrystallization temperature before shaping, offers specific advantages for suspension system parts.

As industry research confirms, this process involves heating metal to its recrystallization temperature before applying pressure, resulting in a refined grain structure that dramatically improves the mechanical properties of the forged part.

Hot forging enables:

- Complex Geometries: Heated metal flows more readily, filling intricate die cavities completely

- Optimal Grain Refinement: Recrystallization during deformation creates fine, uniform grain structure throughout the component

- Reduced Forming Forces: Lower material resistance allows production of larger, more complex parts with available equipment

- Elimination of Work Hardening: Consistent material properties throughout the forged part without residual stresses from cold working

The combination of closed-die techniques with hot forging temperatures creates steering knuckles with the ideal balance of complex geometry, precise dimensions, and superior mechanical properties.

How Proper Forging Prevents Common Failure Modes

Understanding why non-forged steering knuckles fail helps illustrate why proper forging technique matters so much. Research from ScienceDirect analyzing cast aluminum knuckles reveals several failure mechanisms that forging inherently prevents.

Porosity-Induced Cracking: Cast components commonly contain internal voids ranging from microscopic pores to visible shrinkage cavities. According to the research findings, the presence of pores, shrinkage cavity, and uneven distribution of microstructure inside the material have a detrimental impact on service life. The forging process eliminates this vulnerability by compressing material under high pressure, closing any internal voids and creating dense, homogeneous structure.

Stress Concentration at Grain Boundaries: In cast parts, randomly oriented grains meet at sharp angles that concentrate stress under loading. Forging creates aligned grain flow that distributes stress along natural pathways rather than concentrating at weak boundary intersections.

Fatigue Failure at Mounting Points: The connection points where arm knuckle components attach to control arms, tie rods, and wheel bearings experience the highest stress concentrations. As research demonstrates, hot die forging produces parts with better fatigue resistance, which is vital for components subjected to repeated stress cycles. The continuous grain structure in forged mounting features resists crack initiation far more effectively than the disrupted grain patterns in castings.

Inhomogeneous Microstructure: The ScienceDirect study found that casting aluminum components produced by counter pressure casting shows a strong inhomogeneity of mechanical and fatigue properties across different positions. This variability means some areas of a cast knuckle may fail well before design life while other areas retain excess margin. Forged components achieve uniform properties throughout, ensuring predictable performance across the entire part.

| Failure Mode | Cause in Cast/Machined Parts | How Forging Prevents It |

|---|---|---|

| Porosity-Induced Cracking | Gas pockets and shrinkage voids from cooling | High-pressure compression eliminates internal voids |

| Grain Boundary Stress Concentration | Random grain orientation creates weak intersection points | Aligned grain flow distributes stress along natural pathways |

| Fatigue Failure at Mounting Points | Disrupted grain structure at high-stress interfaces | Continuous grain flow through mounting features resists crack initiation |

| Property Variation Across Part | Uneven cooling creates inconsistent microstructure | Controlled deformation produces uniform properties throughout |

By selecting the appropriate forging method and controlling process parameters, manufacturers can produce steering knuckles that resist all these common failure modes. The result is car suspension system parts that deliver reliable performance throughout their intended service life, even under the demanding multiaxial stress conditions these components face daily.

With forging methods understood, the next step is translating your requirements into specifications that ensure your custom forged steering knuckles meet your exact performance targets.

Design Considerations and Ordering Specifications

You've selected your forging method and identified the ideal material grade. Now comes the practical challenge: how do you communicate your exact requirements to a forging partner? The customization process for steering knuckles involves more than simply sending a drawing. It requires defining precise specifications that ensure your final component performs exactly as intended.

Whether you're an engineer designing a new suspension system or a procurement professional sourcing replacement parts, understanding what specifications to communicate upfront saves time, reduces revision cycles, and ultimately delivers better results. Let's walk through the critical elements you need to define before placing an order.

Critical Design Specifications to Define Before Ordering

Imagine ordering a custom component only to discover it doesn't interface correctly with your existing lower arm or control arm on car assemblies. This frustrating scenario happens when specifications aren't communicated clearly from the start. Here's what you need to define before engaging with a forging supplier:

- Load Requirements: Document the maximum forces your steering knuckle must withstand, including bump forces, cornering loads, braking torque, and steering input. According to research from the International Research Journal of Education and Technology, proper load analysis should consider weight transfer (based on gross vehicle mass), bump force calculations using kinetic energy formulas, and cornering forces derived from coefficient of friction and contact patch geometry.

- Mounting Interface Dimensions: Specify exact dimensions for every connection point, including kingpin mount, center bolt locations, steering tie rod attachment, brake caliper mounting holes, and wheel bearing bore. These interfaces must align precisely with your existing upper and lower control arms and other suspension components.

- Material Grade Preferences: Based on your application requirements, specify the alloy grade (such as 4140 steel, 4340 steel, 6061-T6 aluminum, or 7075 aluminum) that balances strength, weight, and cost for your use case.

- Surface Finish Requirements: Define surface roughness values for critical interfaces, particularly bearing bores and mounting surfaces where other components seat. Precision forging can achieve excellent surface quality, but specific Ra values should be documented.

- Heat Treatment Specifications: Specify the required heat treatment condition (such as T6 temper for aluminum or quench and temper parameters for steel) to achieve your target mechanical properties.

- Quality Certification Needs: Identify required certifications like IATF 16949 for automotive supply chains, along with testing requirements such as dimensional inspection, material verification, and non-destructive testing protocols.

The research paper on aluminum knuckle design demonstrates how thorough specification impacts results. Their steering knuckle achieved a factor of safety of 2.83 under combined loading conditions because engineers defined all force magnitudes and directions before design began. Without these specifications, the component might have been over-engineered (adding unnecessary weight) or under-engineered (risking failure).

Working with Engineers to Optimize Your Knuckle Design

Once you've defined initial specifications, the real value emerges through collaboration with engineering teams. What is control arm in a car applications connects directly to your knuckle design, meaning changes to one component often require adjustments to others. A good forging partner brings expertise that helps optimize your design beyond basic requirements.

According to Western of Texas Forge, the typical ordering process begins with an initial inquiry and consultation where you discuss requirements with engineering or sales teams. They may suggest adjustments or recommend optimal solutions based on your product details. This collaborative approach often reveals opportunities to improve performance, reduce weight, or lower costs.

The design optimization process typically follows these stages:

- Feasibility Assessment: Engineers evaluate whether your design is manufacturable through forging, considering material flow, die complexity, and achievable tolerances

- CAD Model Review: Submit detailed engineering drawings, CAD models, or sketches with dimensions and tolerances for technical evaluation

- FEA Analysis: For critical applications, finite element analysis validates that your design meets stress, strain, and factor of safety requirements under all loading conditions

- Prototype Development: Before committing to production tooling, prototypes verify form, fit, and function. As the research demonstrates, many iterations may be required during FEA analysis until desired values are reached, with modifications made to the CAD model according to stress, strain, and factor of safety requirements

- Production Planning: Once design is validated, the engineering team prepares detailed production drawings and plans, sources verified raw materials, and manufactures custom forging dies

Understanding what do control arms do and how they interface with your steering knuckle helps identify potential design conflicts early. Control arm with ball joint assemblies must articulate smoothly through suspension travel while maintaining precise wheel alignment. Your knuckle design must accommodate these mounting requirements while meeting strength targets.

When Custom Forged Steering Knuckles Justify the Investment

Custom forged components require tooling investment and higher per-unit costs compared to off-the-shelf alternatives. So when does this investment make sense, and when might OEM or cast alternatives suffice?

Custom forging justifies the investment when:

- Your application demands performance beyond what standard components deliver

- Existing parts have demonstrated fatigue failures or inadequate strength margins

- Weight reduction is critical for vehicle performance or efficiency

- Production volumes are sufficient to amortize tooling costs across multiple units

- Safety-critical applications where failure consequences are severe

- Unique mounting geometry doesn't match available aftermarket options

OEM or cast alternatives may suffice when:

- Standard passenger vehicle applications with moderate stress requirements

- Budget constraints outweigh performance optimization needs

- Low-volume requirements where tooling costs dominate total expense

- Replacement parts for existing designs where original specifications are adequate

As RPPL Industries notes, the choice between forging and casting depends on the budget, production scale, required strength and durability. Forging is cost-effective for high-strength, durable parts with lower long-term expenses, while casting may be budget-friendly for complex designs and small production runs but with higher maintenance and machining costs.

For procurement professionals, the total cost of ownership calculation should include not just initial part cost, but also expected service life, replacement frequency, and failure consequences. A custom forged steering knuckle that lasts the vehicle's lifetime often proves more economical than replacing cheaper cast alternatives multiple times.

With design specifications defined and customization decisions made, the final step is ensuring your supplier meets the quality standards your application demands.

Quality Assurance and Supplier Certification Standards

You've defined your design specifications and selected the optimal forging method. But here's a critical question many buyers overlook: how do you verify that your supplier can consistently deliver components meeting those exact requirements? When it comes to safety-critical parts like steering knuckles, quality assurance isn't optional. It's the foundation that determines whether your custom forged steering knuckles benefits actually materialize in production.

Think about what is the control arm of a car connected to, and you'll realize your steering knuckle interfaces with multiple critical systems. A single defective component can cascade into steering failure, suspension damage, or worse. That's why understanding quality certifications and testing protocols matters as much as material selection or design optimization.

Quality Certifications That Matter for Automotive Components

Not all quality certifications carry equal weight in the automotive industry. When sourcing control arms and bushings, steering knuckles, or other suspension components, one certification stands above the rest: IATF 16949.

According to industry analysis from Chase Corporation, IATF 16949 is specifically designed as a holistic review of a supplier's systems including supply chain diversification and risk, management response procedures, and continuous improvement and process reviews. Unlike basic ISO certifications that focus primarily on quality procedures, IATF 16949 addresses the unique supply chain risks that automotive manufacturers face.

Why does this matter for your steering knuckle procurement? The automotive task force that developed this standard understood something crucial: disruptions can travel up the supply chain without warning. As recent supply chain research confirms, procedures incorporated into IATF 16949 can minimize the risk of line-down and shutdown situations that have caused significant expense throughout the industry.

When evaluating whether a brand delivers reliable components, you might wonder is MOOG a good brand or how other aftermarket suppliers compare. The answer often comes down to certification status. SGS certification standards outline that IATF certification requires rigorous auditing schedules, with surveillance audits taking place within plus or minus three months of due dates. Suppliers who maintain this certification demonstrate ongoing commitment to quality, not just a one-time achievement.

Key certifications to verify when selecting suppliers for what is a control arm for a car or steering knuckle applications include:

- IATF 16949: The gold standard for automotive supply chain compliance, addressing quality systems plus supply chain risk management

- ISO 9001: Foundational quality management certification that IATF builds upon

- Material Certifications: Documentation verifying alloy composition meets specified grades like 4140, 4340, or 7075

- Process Certifications: Heat treatment, surface finishing, and machining process validations

- Customer-Specific Requirements: OEM-mandated specifications that may exceed standard certifications

Testing and Inspection Protocols for Forged Knuckles

Certification provides the framework, but specific testing protocols deliver the assurance that your components meet specifications. When you understand what is a control arm on a car expected to endure, you recognize why thorough inspection matters for every interfacing component.

According to quality assessment guidelines from Yudie International, comprehensive steering knuckle inspection encompasses visual examination, material verification, internal defect detection, fit accuracy checks, and performance testing.

Here's what thorough quality control processes should include:

| Inspection Category | Methods Used | What It Verifies |

|---|---|---|

| Visual Inspection | Surface examination under controlled lighting | Surface finish quality, absence of cracks, sand holes, pores, and color uniformity |

| Dimensional Verification | CMM measurement, gauging, precision instruments | Critical dimensions match specifications within tolerance (±0.05-0.1mm for precision forging) |

| Material Testing | Spectroscopy, hardness testing, tensile testing | Alloy composition and mechanical properties meet material grade requirements |

| Non-Destructive Testing | X-ray, ultrasonic, magnetic particle inspection | Absence of internal defects, cracks, inclusions without damaging the component |

| Fit Accuracy | Gauge testing, assembly verification | Proper clearances with mating components (kingpin clearance not exceeding 0.20mm per industry standards) |

As quality assessment experts note, non-destructive testing methods like X-ray and ultrasonic inspection can detect whether there are cracks, inclusions and other defects in the steering knuckle without destroying it, ensuring reliable quality verification for every production batch.

For what is a control arm on a car applications and steering knuckle assemblies, fit accuracy deserves special attention. The connection between your steering knuckle and other suspension components must be precise. Too much clearance causes steering play and accelerated wear. Too little creates binding and premature failure. Experienced suppliers understand these tolerances and verify them systematically.

Finding a Qualified Forging Partner

With certification requirements and testing protocols understood, how do you identify suppliers who actually deliver on these standards? Look for partners who combine IATF 16949 certification with demonstrated engineering capabilities and efficient logistics.

Shaoyi (Ningbo) Metal Technology exemplifies what qualified automotive forging suppliers should offer. Their IATF 16949 certification ensures supply chain compliance, while in-house engineering capabilities allow them to optimize designs for components meeting exact specifications. For procurement teams seeking rapid development cycles, their prototyping capability delivers results in as little as 10 days, accelerating validation timelines significantly.

Location matters for global supply chains. Suppliers positioned near major shipping hubs, like Shaoyi's proximity to Ningbo Port, streamline logistics and reduce delivery times for international customers. This geographic advantage, combined with globally compliant manufacturing processes, removes friction from procurement workflows.

When evaluating what is the control arm on a car applications require from your supplier, verify they can demonstrate:

- Current IATF 16949 Certification: Request certificate copies and verify status through certification body databases

- Documented Quality Processes: Review inspection protocols, testing equipment calibration records, and traceability systems

- Engineering Support: Assess their ability to collaborate on design optimization and provide technical recommendations

- Production Flexibility: Confirm capability to scale from prototype quantities to high-volume mass production

- Supply Chain Resilience: Evaluate raw material sourcing, inventory management, and contingency planning

Choosing suppliers with IATF certification ensures that beyond quality procedures, they maintain systems addressing supply chain diversification, management response protocols, and continuous improvement processes critical for automotive reliability.

The investment in proper supplier qualification pays dividends throughout your program. Components arrive meeting specifications consistently. Production schedules remain predictable. And most importantly, your steering knuckles deliver the custom forged steering knuckles benefits you specified rather than the compromises that inferior suppliers might hide behind acceptable-looking paperwork.

With quality assurance frameworks established, the final step is understanding how to evaluate and select the right forging partner for your specific needs and production volumes.

Selecting the Right Custom Forging Partner for Your Needs

You've defined your specifications, verified quality requirements, and understand what makes forged steering knuckles superior. Now comes the decision that brings everything together: choosing the right manufacturing partner. This choice impacts far more than just component quality. It determines whether your project meets deadlines, stays within budget, and delivers the custom forged steering knuckles benefits you've specified.

For procurement professionals managing complex automotive supply chains, supplier selection requires evaluating capabilities across the complete value chain. A partner who excels at forging but struggles with communication or logistics can derail your program just as easily as one with inadequate quality systems. Let's walk through how to evaluate potential suppliers systematically.

Evaluating Supplier Engineering and Prototyping Capabilities

Before a single part gets forged, engineering collaboration sets the foundation for success. According to United Steel and Fasteners, a reliable forging supplier should help optimize your part, not just produce it. This level of collaboration reduces cost, minimizes waste, and improves overall performance.

What does meaningful engineering support look like? When you're developing steering knucle designs or refining control arms on a car applications, your supplier should provide:

- Design for Manufacturability Analysis: Engineers review your CAD models and identify potential forging challenges before tooling begins, suggesting modifications that improve quality while reducing costs

- Material Selection Guidance: Expert recommendations on alloy grades based on your specific load requirements, operating environment, and budget constraints

- FEA and Simulation Support: Finite element analysis capabilities that validate designs meet stress, strain, and fatigue requirements before physical prototyping

- Process Optimization: Suggestions for die design, forging sequence, and heat treatment parameters that maximize the custom forged steering knuckles benefits for your application

Prototyping speed matters enormously when development timelines are tight. As industry guidance from Synergy Global Sourcing explains, a reliable custom forged parts supplier should be able to offer tool design, rapid prototyping, and flexible production schedules to meet your development needs.

Shaoyi (Ningbo) Metal Technology demonstrates what leading suppliers offer in this regard. Their in-house engineering team collaborates on robust components like suspension arms and drive shafts, ensuring designs are optimized for both performance and manufacturability. With prototyping capabilities delivering results in as little as 10 days, they compress development cycles significantly compared to suppliers requiring months for initial samples.

Supply Chain Considerations for Global Procurement

Engineering excellence means little if components don't arrive when needed. For global procurement teams, evaluating supply chain factors is equally critical as technical capabilities.

According to procurement best practices, you should analyze the supplier's historical performance in meeting delivery schedules, ask about lead times for tooling development, sampling, and bulk production, and verify they have efficient planning systems and dedicated logistics support.

Here are the essential criteria to evaluate when selecting your custom forging partner:

- Engineering Support Availability: Verify dedicated engineering resources are assigned to your project, not shared across dozens of customers. Ask about response times for technical questions and design revision turnaround

- Prototyping Lead Times: Request specific timelines from design submission to first article delivery. Top suppliers deliver prototypes in 10-15 days while others may require 8-12 weeks

- Production Capacity for Volume Scaling: Confirm the supplier can grow with your needs from prototype quantities to high-volume mass production without quality degradation or delivery delays

- Quality Certification Status: Verify current IATF 16949 certification for automotive applications. Request certificate copies and check expiration dates

- Geographic Location for Logistics Efficiency: Consider shipping distances, port access, and customs considerations. Suppliers near major shipping hubs reduce transit times and simplify logistics

- Communication Responsiveness: Test response times during the quotation process. Suppliers who take weeks to answer pre-order questions rarely improve after receiving your business

Geographic positioning deserves special attention for international procurement. Shaoyi's location near Ningbo Port provides significant logistics advantages for global customers. This proximity to one of the world's busiest container ports streamlines shipping and reduces delivery variability that can disrupt production schedules.

Red Flags That Signal Potential Problems

Knowing what to avoid is just as valuable as knowing what to seek. Industry experts identify several warning signs that should trigger caution:

- Vague or Inconsistent Answers: Suppliers who can't provide specific details about their processes, equipment, or certifications may be hiding capability gaps

- No Engineering Input or Suggestions: Partners who simply quote your drawing without offering optimization recommendations aren't invested in your success

- Unclear Pricing Structures: Hidden costs for tooling, inspection, or shipping that emerge after commitment signal poor transparency

- Reluctance to Provide References: Established suppliers proudly share customer testimonials and project examples

- Outdated Equipment or Facilities: Modern forging requires current technology for consistent quality and competitive lead times

Making Your Final Selection

With evaluation criteria defined, how do you synthesize this information into a confident decision? Consider creating a weighted scorecard that reflects your specific priorities. For safety-critical steering knucle applications, quality certification and engineering support might carry the highest weights. For cost-sensitive programs with established designs, pricing and delivery reliability might dominate.

As sourcing experts recommend, choose a supplier who treats your relationship as a strategic partnership. Look for flexibility in responding to urgent orders, willingness to co-develop solutions, and consistent technical support. A reliable forging vendor will invest in understanding your business and helping you grow.

For procurement teams ready to explore partnership options, Shaoyi (Ningbo) Metal Technology offers a compelling combination: IATF 16949 certified quality systems, scalable production from rapid prototyping to mass manufacturing, in-house engineering expertise, and globally compliant processes. Their strategic port location and responsive communication complete a package designed to streamline automotive component procurement.

The best forging suppliers act as extensions of your engineering team, offering value, support, and partnership that extends far beyond simple transaction processing.

Selecting the right partner transforms custom forged steering knuckles benefits from specification promises into delivered reality. Take time to evaluate thoroughly, ask the hard questions, and verify capabilities before commitment. The supplier relationship you establish today will determine your component quality, supply chain reliability, and ultimately your vehicle performance for years to come.

Frequently Asked Questions About Custom Forged Steering Knuckles

1. Does steering knuckle affect alignment?

Yes, the steering knuckle serves as the key reference point for wheel alignment. Even slight bending can offset camber, caster, or toe angles, causing repeated alignment issues. Custom forged steering knuckles maintain tighter dimensional tolerances under stress, ensuring consistent alignment throughout the component's service life. This precision is critical for predictable handling and even tire wear.

2. Are steering knuckles cast or forged?

Steering knuckles are manufactured using both methods. Traditional applications use ductile cast iron, while high-performance and heavy-duty applications prefer forged steel or aluminum. Forged knuckles offer approximately 26% higher tensile strength and 37% better fatigue resistance than cast alternatives, making them ideal for motorsport, commercial trucks, and safety-critical applications.

3. How often should I change my steering knuckle?

Quality forged steering knuckles typically last the vehicle's lifetime under normal conditions. Replacement becomes necessary only when excessive rust and corrosion occur, visible damage results from collisions, or wheel bearings become seized and cannot be removed. Custom forged components with superior fatigue resistance significantly extend service intervals compared to cast alternatives.

4. What materials are used for custom forged steering knuckles?

Common materials include steel alloys like 4140, 4340, and 1045 for heavy-duty applications, and aluminum alloys such as 6061-T6 and 7075 for weight-critical performance vehicles. Steel alloys offer tensile strengths up to 1170 MPa, while 7075 aluminum achieves strength-to-weight ratios approaching some steels. Material selection depends on load requirements, operating environment, and weight constraints.

5. What certifications should a forged steering knuckle supplier have?

IATF 16949 certification is the gold standard for automotive supply chain compliance, addressing both quality systems and supply chain risk management. Qualified suppliers like Shaoyi (Ningbo) Metal Technology combine this certification with in-house engineering capabilities, rapid prototyping in as little as 10 days, and globally compliant manufacturing processes for consistent quality delivery.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —