Enhancing Creep Resistance in Magnesium Die Cast Alloys

TL;DR

Creep resistance in magnesium die-cast alloys is the material's crucial ability to resist slow deformation under sustained mechanical stress at high temperatures. This property is a primary limiting factor for their use in demanding environments like automotive powertrains. It is significantly enhanced through two primary strategies: the strategic addition of specific alloying elements—such as Gadolinium (Gd), Strontium (Sr), and other rare earths—and the precise control of the alloy's microstructure to form thermally stable, interconnected compounds, particularly at the grain boundaries.

Fundamentals of Creep in Die-Cast Magnesium Alloys

Creep is a time-dependent deformation of a solid material under a constant load or stress, occurring at temperatures above approximately half of the material's melting point. For magnesium (Mg) alloys, which are prized for their low density, this phenomenon represents a significant engineering challenge. Poor creep resistance limits their application in components that must maintain dimensional stability under thermal and mechanical loads, such as engine blocks, transmission cases, and other powertrain parts where operating temperatures can exceed 150°C.

The mechanisms driving creep in metals are complex, involving the movement of dislocations within the crystal structure and the sliding of grain boundaries. As temperature increases, these atomic-level movements become more pronounced, leading to gradual elongation, distortion, and eventual failure of the component. The inherent crystal structure of magnesium makes it particularly susceptible to creep, especially when compared to aluminum or steel at similar homologous temperatures. This inadequacy in high-temperature performance is a well-recognized disadvantage that researchers continuously work to overcome.

Understanding the distinction between tensile and compressive creep behavior is also vital for component design. Depending on the nature of the stress, the alloy may respond differently, impacting its service life and failure mode. Consequently, developing alloys with high creep resistance is not merely an academic exercise; it is essential for expanding the use of lightweight magnesium in industries striving for greater fuel efficiency and reduced emissions without compromising on safety or durability.

The Role of Alloying Elements in Enhancing Creep Resistance

The most effective method for improving the creep resistance of magnesium die-cast alloys is through metallurgical design, specifically the introduction of carefully selected alloying elements. These additions alter the alloy's fundamental properties by forming new phases and strengthening the microstructure against deformation at elevated temperatures. Different elements achieve this through various mechanisms, making the choice of alloy composition critical for specific applications.

Rare Earth (RE) elements, particularly Gadolinium (Gd), have demonstrated an exceptional ability to improve creep performance. They contribute to the formation of thermally stable precipitate phases within the magnesium matrix and along grain boundaries. These precipitates act as strong obstacles to dislocation motion, effectively pinning the microstructure in place. For instance, a die-cast Mg-RE-Gd-Mn-Al alloy was shown to achieve a super-low steady-state creep rate, highlighting the potent effect of this combination.

Other elements also play crucial roles. Strontium (Sr) has been found to offer significant improvements in creep resistance, particularly in Mg-Al systems, making them competitive with or superior to established Mg-Al-RE alloys at temperatures like 150°C and 175°C. Minor additions of Zinc (Zn) to Mg-Gd based alloys can further enhance performance by creating new, complex Zn-containing precipitate phases that add another layer of microstructural stability. Conversely, while Aluminum (Al) is a common alloying element in magnesium, many high-performance, creep-resistant gravity-cast alloys are deliberately aluminum-free, instead relying on elements like zirconium for grain refinement and strengthening.

To summarize the influence of these key elements, the following table outlines their general effects:

| Alloying Element | Primary Mechanism for Improving Creep Resistance | Typical Effect |

|---|---|---|

| Gadolinium (Gd) & Rare Earths (RE) | Formation of highly stable precipitate phases at grain boundaries and within the matrix. | Exceptional increase in creep life and strength at high temperatures. |

| Strontium (Sr) | Modifies the Mg-Al system to create more stable intermetallic compounds. | Improves creep performance and bolt-load retention, especially in Mg-Al alloys. |

| Zinc (Zn) | Contributes to the formation of new, complex precipitate phases in conjunction with other elements like Gd. | Provides an additional strengthening effect, further increasing creep life. |

| Aluminum (Al) | Forms precipitates, but can have a complex and sometimes detrimental effect on high-temperature creep compared to RE-based systems. | Commonly used, but often omitted from the most advanced creep-resistant alloys. |

Microstructure's Impact on Creep Performance

While alloy composition lays the foundation, the final microstructure of the material governs its real-world creep performance. The size, shape, and distribution of grains, along with the nature of the phases at their boundaries, are critical factors. For superior creep resistance, the goal is to create a microstructure that is inherently stable and resistant to change under thermal and mechanical stress. An ideal structure effectively hinders dislocation movement and grain boundary sliding, the primary mechanisms of creep deformation.

Research consistently shows that the formation of thermally stable and interconnected compounds at the grain boundaries (GBs) is a key strategy. These compounds act like a reinforcing network throughout the material, locking the grains in place and preventing them from sliding past one another at high temperatures. The relationship between microstructure and creep resistance is particularly evident in die-cast magnesium-rare earth alloys, where the specific arrangement of phases dictates the material's strength.

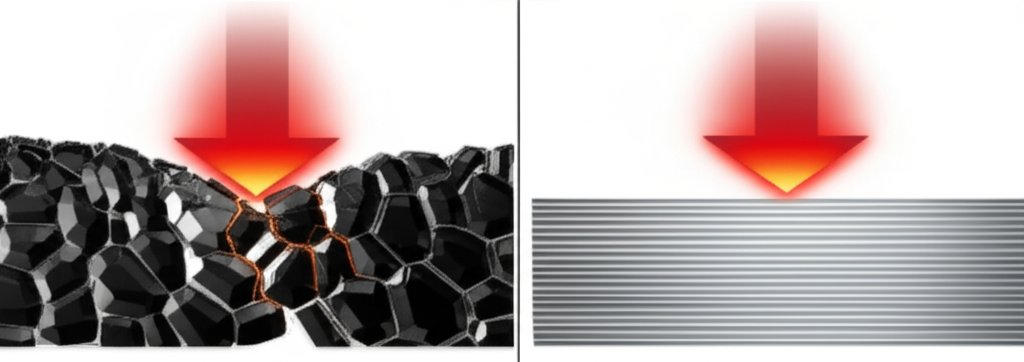

However, the rapid cooling inherent in the die-casting process often results in a non-uniform as-cast microstructure, which can be detrimental to predictable creep performance. This heterogeneity creates localized weak points where creep can initiate. One microstructural configuration known for its excellent creep resistance is a fully lamellar structure, characterized by alternating layers of different phases. While this arrangement is highly effective at impeding creep, it often comes with a trade-off: reduced ductility and toughness at room temperature due to its large, coarse grains.

Design Perspectives and Future Development

The ongoing development of creep-resistant magnesium alloys is a dynamic field, driven by the persistent demand for lightweight materials in high-performance sectors. Current progress focuses on both novel alloy compositions and advanced processing techniques to optimize microstructure and properties. Researchers are moving beyond trial-and-error, employing modern tools to accelerate the design cycle and achieve targeted performance characteristics.

One of the most promising frontiers is the use of computational thermodynamics and modeling. These tools allow scientists to predict how different alloying elements will interact and what microstructures will form under specific conditions, significantly reducing the time and cost associated with experimental work. This design-led approach is crucial for overcoming the challenges posed by the complex, non-uniform structures often found in die-cast components.

The primary application driving this research remains the automotive industry, especially for powertrain components. As vehicle manufacturers continue to pursue aggressive lightweighting strategies to improve efficiency and reduce emissions, the need for magnesium alloys that can reliably operate at elevated temperatures becomes ever more critical. The successful development of these advanced materials relies on a complete supply chain, from alloy design to final component manufacturing. For instance, companies like Shaoyi (Ningbo) Metal Technology, which specialize in precision-engineered automotive forging parts, represent the final step in this process, transforming advanced alloys into robust, reliable components through processes like hot forging, ensuring the material's engineered properties translate into real-world performance.

The future outlook involves balancing the perpetual trade-off between creep resistance, strength, ductility, and—critically—cost. As new alloy systems are perfected, their widespread adoption will depend on creating scalable and cost-effective manufacturing processes that can deliver the exceptional performance demonstrated in the laboratory to mass-produced industrial components.

Frequently Asked Questions

1. What is the disadvantage of magnesium alloy?

While magnesium alloys are highly valued for their low weight and high strength-to-weight ratio, they have several disadvantages that can limit their use. These include relatively low absolute strength and poor ductility compared to other metals, insufficient resistance to corrosion and combustion, and, most critically for certain applications, inadequate performance at high temperatures, including poor creep resistance.

2. What are the properties of cast magnesium alloy?

Cast magnesium alloys typically exhibit a proof stress between 75 and 200 MPa and a tensile strength ranging from 135 to 285 MPa. Their elongation is generally between 2% and 10%. A key property is their low density, around 1.8 g/cm³, and they have a Young's modulus of approximately 42 GPa, which is lower than that of aluminum or steel.

3. Which microstructure of the material has the highest creep resistance?

In general, a fully lamellar microstructure, which consists of alternating, plate-like layers of different phases, is considered to have very high creep resistance. This structure is effective at impeding the movement of dislocations. However, this benefit comes with a significant trade-off: fully lamellar structures often exhibit low ductility at room temperature due to their large grain size.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —