Chromate Coating for Zinc Die Casts: A Technical Guide

TL;DR

Chromate conversion coating is a chemical treatment applied to zinc die casts to form a protective, corrosion-resistant surface layer. This process is highly effective at preventing "white corrosion," a common form of oxidation on zinc. The coating also serves as an excellent primer for paint and other finishes, significantly improving adhesion. Different colors, such as yellow, olive drab, or black, typically indicate varying levels of corrosion protection.

Understanding Chromate Conversion Coating for Zinc Die Casts

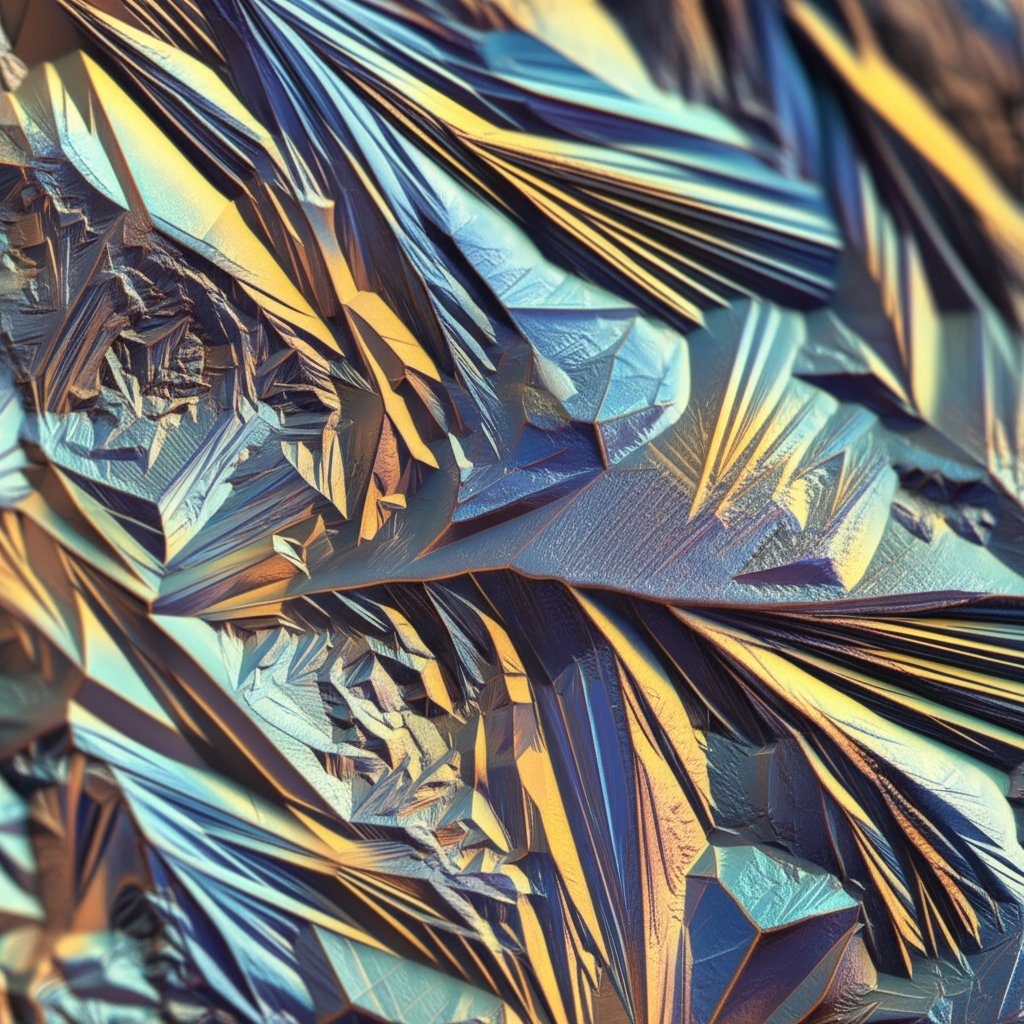

Chromate conversion coating is a chemical film applied to zinc die casts to inhibit corrosion and enhance the material's durability. The process, known as passivation, involves a chemical reaction between a chromate solution and the zinc surface. This reaction transforms the outermost layer of the metal into a non-porous, protective film that is integral to the part itself, rather than just an additive layer like paint.

At a molecular level, the chromate solution reacts with the zinc, consuming a microscopic layer of the surface and replacing it with a new, stable compound layer composed primarily of chromium oxides. According to an explanation by Valence Surface Technologies, this passivation layer effectively seals the metal from environmental factors like humidity and oxygen, which are the primary drivers of corrosion. This is crucial for zinc die casts, which are susceptible to a specific type of degradation known as white rust or white corrosion.

Unlike painting or powder coating, which add a distinct layer on top of the substrate, a chromate conversion coating chemically alters the existing surface. This results in minimal dimensional changes, a critical factor for precision-engineered components with tight tolerances. The coating also maintains the electrical conductivity of the zinc, making it a suitable treatment for electronic housings and connectors where grounding is essential.

The Chromate Conversion Process: A Step-by-Step Overview

The application of a chromate conversion coating is a precise, multi-stage process that relies on careful control of chemical concentrations, temperature, and immersion times to achieve a uniform and effective finish. While specific steps can vary, the fundamental process for treating zinc die casts involves thorough preparation and controlled chemical immersion. The goal is to create a pristine surface that can react uniformly with the chromate solution.

A typical application follows a sequence designed for maximum adhesion and protection. Based on industry best practices, the process can be broken down into the following key stages:

- Thorough Cleaning and Degreasing: The zinc die cast part must be completely free of oils, grease, dirt, and other surface contaminants. This is typically achieved using alkaline cleaners or solvents. An immaculate surface is non-negotiable, as any residue will prevent the chromate solution from reacting properly with the zinc, leading to an uneven or ineffective coating.

- Rinsing: After cleaning, the part is thoroughly rinsed with water to remove any residual cleaning agents. This step is critical to prevent contamination of the subsequent chemical baths.

- Acid Etching or Deoxidizing (Optional): Depending on the condition of the zinc surface, a mild acid bath may be used to remove any existing oxides or to lightly etch the surface. This creates a more active surface area for the conversion reaction to occur. This is followed by another rinse.

- Immersion in Chromate Solution: The clean part is immersed in a chemical bath containing the chromate solution. The duration of immersion, the solution's temperature, and its chemical makeup are precisely controlled. These factors determine the thickness, color, and protective properties of the final coating.

- Final Rinsing and Drying: After immersion, the part is rinsed again to remove excess chromate solution. It is then carefully dried, often with warm air. The coating is typically soft and gelatinous immediately after processing and requires time to fully cure and harden, which can take up to 24 hours.

Types of Chromate Coatings: Hexavalent vs. Trivalent and Color Indicators

Chromate conversion coatings are broadly categorized into two main types based on the valence state of the chromium used: traditional hexavalent chromium (Cr6+) and the more modern, environmentally safer trivalent chromium (Cr3+). This distinction is critical for regulatory compliance, safety, and application selection. As SKS Die Casting points out, the use of hexavalent chromium is now heavily restricted by directives like RoHS (Restriction of Hazardous Substances) due to its toxicity and carcinogenic properties.

Hexavalent chromium has been the industry standard for decades, prized for its exceptional corrosion resistance and self-healing properties, where the coating can re-passivate minor scratches. However, its significant health and environmental risks have driven the industry toward safer alternatives. Trivalent chromium is the leading replacement, offering good corrosion protection without the high toxicity of its predecessor. As noted by National Plating Company, trivalent processes are RoHS and REACH compliant, making them the standard for new products, especially in the automotive and electronics industries.

The choice between these types involves a trade-off between performance, safety, and compliance. Below is a comparison of their key characteristics:

| Feature | Hexavalent Chromium (Cr6+) | Trivalent Chromium (Cr3+) |

|---|---|---|

| Corrosion Resistance | Excellent, often considered superior with self-healing properties. | Good to excellent, often comparable or superior to hexavalent when used with a top coat or sealer. |

| Toxicity | High; known carcinogen. | Significantly lower toxicity. |

| Environmental Compliance | Not RoHS or REACH compliant. Heavily regulated. | RoHS and REACH compliant. The environmentally preferred option. |

| Appearance | Typically produces distinct yellow/gold or olive drab colors. | Often clear or blue-bright, but can be dyed to achieve yellow, black, and other colors. |

The color of the final coating is often a functional indicator of its thickness and level of corrosion resistance. This is particularly true for hexavalent coatings, where a clear or blue finish offers basic protection, yellow or gold provides better resistance, and olive drab or black offers the highest level of protection. While trivalent coatings are often clear, they can be dyed to mimic these colors for identification or aesthetic purposes.

Key Benefits and Industrial Applications

The adoption of chromate conversion coating on zinc die casts is driven by a range of functional benefits that directly translate to improved component performance and longevity. These advantages make it an essential finishing process across numerous industries where reliability is paramount. The primary benefits are directly linked to protection, surface preparation, and maintaining the inherent properties of the base metal.

The most significant advantages of applying this coating include:

- Enhanced Corrosion Resistance: The primary function is to protect the zinc substrate from environmental factors that cause white corrosion. This dramatically extends the service life of components, especially in humid or moderately corrosive atmospheres.

- Improved Paint and Finish Adhesion: The coating creates a chemically inert and stable surface that serves as an excellent primer. Paints, powder coatings, and adhesives bond more strongly to a chromated surface than to bare zinc, reducing the risk of chipping, flaking, or delamination.

- Maintained Electrical Conductivity: Unlike many thicker coatings like paint or anodizing, the thin chromate film allows electrical current to pass through. This makes it ideal for electronic enclosures, connectors, and chassis components that require grounding or EMI shielding.

- Minimal Dimensional Change: Because the coating is exceptionally thin—often less than a micron—it does not significantly alter the dimensions of the part. This is critical for high-precision components with tight tolerances that must fit perfectly within an assembly.

These benefits make chromate conversion coating indispensable in various sectors. In the automotive industry, it is used on fasteners, brackets, and fuel system components to prevent corrosion. The electronics sector relies on it for housings, heat sinks, and connectors. It is also found in industrial machinery, hardware, and aerospace applications where durable and reliable metal components are essential. For instance, manufacturers of robust die cast components rely on such high-performance coatings to meet the stringent quality and durability standards of the automotive sector.

Frequently Asked Questions

1. Is chromate conversion coating RoHS compliant?

It depends on the type. Coatings using hexavalent chromium (Cr6+) are not RoHS compliant due to the toxicity of the substance. However, modern trivalent chromium (Cr3+) conversion coatings are fully RoHS and REACH compliant and are the standard for new products in regulated industries.

2. How thick is a chromate conversion coating?

Chromate conversion coatings are extremely thin, typically ranging from 0.25 to 1.0 microns (0.00001 to 0.00004 inches). This minimal thickness is a key advantage, as it protects the part without affecting its dimensional tolerances.

3. Can you paint over a chromate conversion coating?

Yes, one of the primary benefits of a chromate conversion coating is that it serves as an excellent primer for paint, powder coats, and other organic finishes. It significantly improves the adhesion of the subsequent layer, leading to a more durable and long-lasting finish.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —