Choosing Your Mold Release Agent for Aluminum Die Casting

TL;DR

Mold release agents for aluminum die casting are essential chemical coatings applied to the mold surface before injecting molten metal. These agents, typically water-based lubricants, form a critical barrier that prevents the hot aluminum from sticking to the steel die. This ensures a smooth ejection of the cast part, protects the expensive mold from wear and soldering, and significantly improves the final product's surface finish, ultimately boosting production efficiency and reducing scrap rates.

Understanding Mold Release Agents: Function and Importance

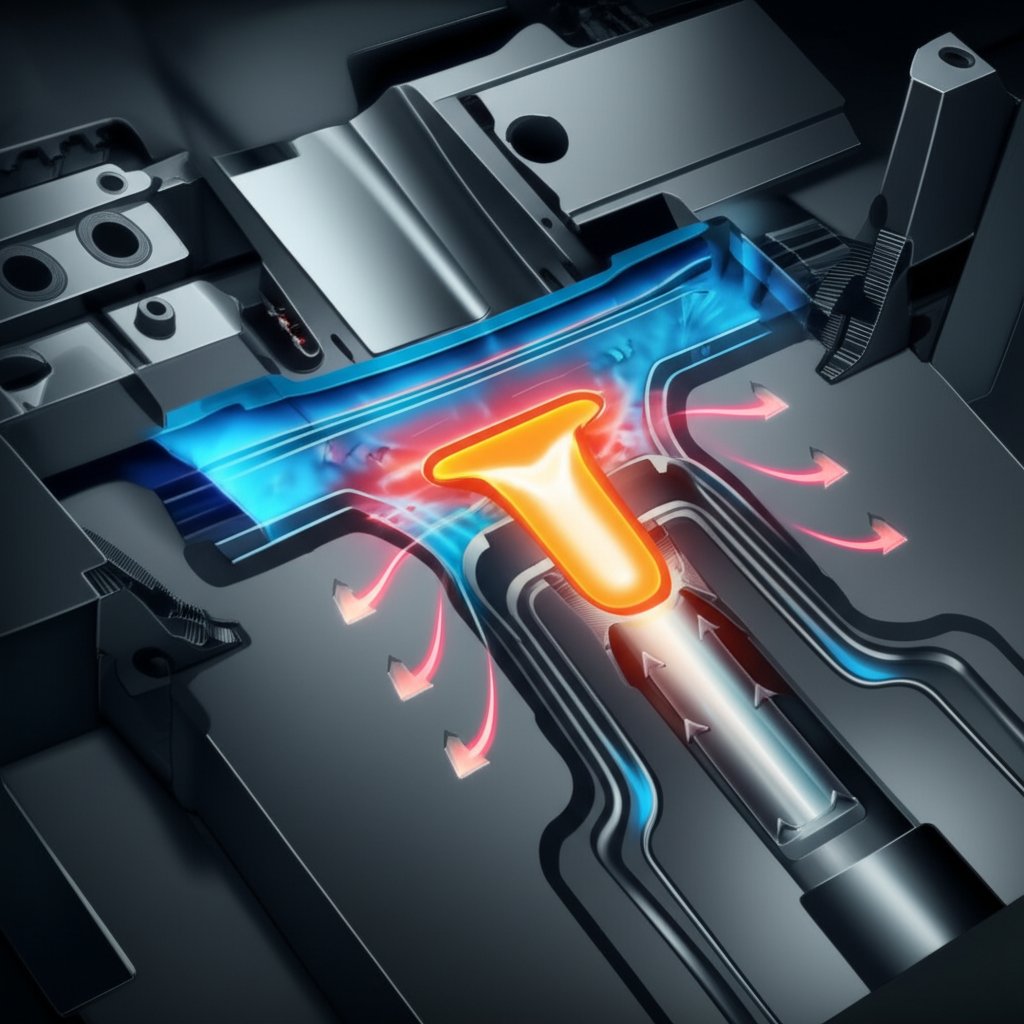

In the high-pressure, high-temperature environment of aluminum die casting, the interaction between the molten metal and the steel mold is a critical point of failure or success. A mold release agent, also known as a die lubricant, is a specialized compound sprayed onto the mold cavity before each casting cycle. Its primary purpose is to create a stable, thin interfacial film that acts as a physical barrier between the mold and the molten aluminum. This prevents the two materials from adhering, a common issue known as soldering, which can damage both the casting and the mold. Without an effective release agent, part ejection becomes difficult, leading to production stoppages, increased wear on the mold, and a higher rate of defective parts.

The mechanism of a release agent is sophisticated. When the typically water-based liquid is sprayed onto the hot mold surface (often operating between 150°C and 350°C), the water evaporates almost instantly. This process leaves behind a uniform, micro-thin layer of active ingredients—such as waxes, polymers, silicones, or other proprietary components. This durable film must withstand the intense heat and pressure of the injected aluminum, providing lubrication to facilitate metal flow into complex cavities while ensuring the finished part can be cleanly removed from the mold after solidification. The quality of this film directly influences cycle times, part quality, and the overall economic efficiency of the casting operation.

The importance of using a high-quality, correctly applied release agent cannot be overstated. It serves several vital functions that are integral to a modern die casting process. As detailed by industry resources like the Giesserei Lexikon, the right agent contributes to uniform product quality and extends the service life of expensive dies. The consequences of using an inadequate agent include soldering, difficult demolding, surface defects on the casting, and accelerated mold fatigue due to thermal shock. The key functions of a mold release agent include:

- Release Performance: Preventing the cast aluminum part from sticking to the mold, ensuring easy and clean ejection.

- Lubrication: Aiding the flow of molten metal into intricate sections of the die, reducing porosity and ensuring complete mold filling.

- Mold Protection: Creating a barrier that minimizes soldering and erosion of the mold surface, thus extending its operational life.

- Cooling Effect: For water-based agents, the evaporation provides a controlled cooling effect on the die surface, helping to manage the thermal balance of the mold.

- Surface Finish Improvement: Promoting a smoother, brighter surface on the cast part, which can reduce the need for secondary finishing operations.

Key Types of Release Agents for Aluminum Casting

The selection of a mold release agent is a critical decision, with different formulations designed to meet specific production needs for aluminum alloys. The most common agents fall into distinct categories, each with unique properties, advantages, and limitations. Understanding these types is the first step toward optimizing the die casting process for performance and quality.

Water-Based Agents are the most prevalent choice for aluminum die casting due to their excellent cooling properties, environmental safety, and cost-effectiveness. These are emulsions or dispersions where the active lubricating components (like waxes, silicones, or polymers) are mixed in water. Upon application to the hot mold, the water evaporates, leaving a lubricating film. Products like the Nekote series from Pyrotek contain fine graphite particles to enhance lubrication. Advanced water-based formulations, such as the ReleaSys™ HTX-D from Miller-Stephenson, are engineered for high-integrity casting, offering superior release with minimal buildup, which is crucial for parts requiring post-molding processing.

Silicone-Based and Silicon-Free Agents represent another important distinction. Silicone emulsions provide excellent release properties and can produce parts with a bright, appealing surface finish. They are effective at high temperatures and offer great lubrication. However, the presence of silicone can interfere with secondary operations like painting, powder coating, or adhesive bonding. For applications where post-casting finishing is critical, Silicon-Free Agents are the preferred solution. As highlighted by manufacturers like Meiya Chemical, these agents are formulated to provide effective release without leaving silicone residues, ensuring that subsequent surface treatments adhere properly. This makes them essential for many automotive and consumer electronics components.

The choice between these primary types involves a trade-off between performance, cost, and final part requirements. Below is a comparison to help guide the decision-making process.

| Agent Type | Pros | Cons | Best For |

|---|---|---|---|

| Water-Based | Excellent cooling, environmentally friendly (low VOCs), non-flammable, cost-effective. | Can cause thermal shock to molds if applied improperly, requires careful dilution control. | General-purpose aluminum die casting, high-volume production. |

| Silicone-Based | Excellent release and lubrication, provides a bright surface finish, high thermal stability. | Can interfere with post-casting painting, coating, or welding; may cause buildup. | Complex parts where a high-quality finish is desired and no secondary surface treatment is needed. |

| Silicon-Free | Allows for excellent adhesion in secondary operations (painting, plating, bonding), clean release. | May offer slightly less lubrication than silicone-based agents; can be more expensive. | Parts requiring any form of post-casting surface finishing, such as automotive or consumer appliance components. |

How to Select the Best Mold Release Agent for Your Application

Choosing the optimal mold release agent is not a one-size-fits-all decision. The "best" agent is one that is perfectly matched to the specific parameters of your die casting operation. A systematic approach to selection ensures higher productivity, lower scrap rates, and longer mold life. Factors such as the alloy being cast, the complexity of the part, and the desired surface finish must all be carefully considered to achieve the desired outcome. As noted in a guide from OEForm, different metals and operating conditions demand specific formulations.

Making an informed decision requires evaluating several key operational factors. For instance, a large, intricate automotive component will have different release requirements than a small, simple housing. High-performance components, such as those found in modern vehicles, often demand flawless surface integrity for subsequent processing. For those in related high-performance industries, it's worth noting that suppliers like Shaoyi (Ningbo) Metal Technology specialize in precision-engineered automotive parts, where the quality of every production step, including lubrication and release, is paramount. This highlights the importance of matching materials and processes to achieve superior end-products.

To navigate this complex choice, consider the following criteria:

- Alloy Composition: While the focus is on aluminum, different aluminum alloys (e.g., A380, A356) can have varying levels of adhesion and flow characteristics, influencing the type of release agent needed.

- Casting Complexity and Geometry: Parts with deep draws, thin walls, or complex geometries require agents with excellent lubrication and metal flow properties to ensure the mold fills completely without defects.

- Mold Temperature: The release agent must be effective at the operating temperature of your die. High-temperature agents are formulated to form a stable release film on surfaces that can reach up to 280°C.

- Desired Surface Finish: If the part requires a bright, cosmetic finish directly from the mold, a silicone-based agent might be suitable. If the part will be painted, plated, or welded, a silicon-free agent is essential to prevent adhesion problems.

- Cycle Times: High-speed operations require an agent that can be applied quickly and forms an effective film with minimal drying time. Semi-permanent agents can be beneficial here, as they may last for multiple cycles.

- Environmental and Safety Regulations: With increasing restrictions on Volatile Organic Compounds (VOCs), water-based agents are often the preferred choice for compliance and improved worker safety.

To further aid in the selection process, foundry managers should engage with potential suppliers armed with specific questions. This ensures the chosen product aligns perfectly with operational needs. Create a checklist before discussing your requirements:

- What is the optimal dilution ratio for our specific application?

- Is this agent compatible with our mold material and the aluminum alloy we use?

- Does this product leave any residue that could affect our post-casting finishing processes?

- What is the recommended application method (e.g., manual vs. automated spray)?

- Can you provide data on the agent's performance regarding mold buildup and maintenance intervals?

- What are the safety and disposal requirements for this product?

Frequently Asked Questions

1. What is the mold release for die casting?

A mold release for die casting, often called a die lubricant or die spray, is a chemical coating applied to the mold's interior surface. It forms a barrier between the hot mold and the molten metal. This film prevents the metal from sticking to the mold, lubricates metal flow, helps cool the die, and protects the mold from wear, ensuring easy part ejection and a quality surface finish.

2. Can you use vaseline as a release agent?

While petroleum jelly (Vaseline) can be used as a release agent for some low-temperature, low-pressure molding applications like certain plastics or resins, it is entirely unsuitable for high-pressure aluminum die casting. The extreme temperatures (over 600°C for molten aluminum) and pressures of die casting would cause petroleum jelly to instantly burn off, offering no release properties and likely creating significant carbon buildup and defects on the part.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —