Choosing Die Materials for AHSS Stamping: PM Steels & Coatings Guide

TL;DR

Choosing the right die materials for AHSS stamping requires a fundamental shift from conventional tooling strategies. For Advanced High-Strength Steels (AHSS) exceeding 590 MPa, standard D2 tool steel often fails due to insufficient toughness and microstructural inconsistencies like carbide stringers. The industry consensus is to upgrade to Powder Metallurgy (PM) tool steels (such as Vanadis 4E or CPM 3V), which offer a uniform grain structure capable of withstanding high impact shocks without chipping.

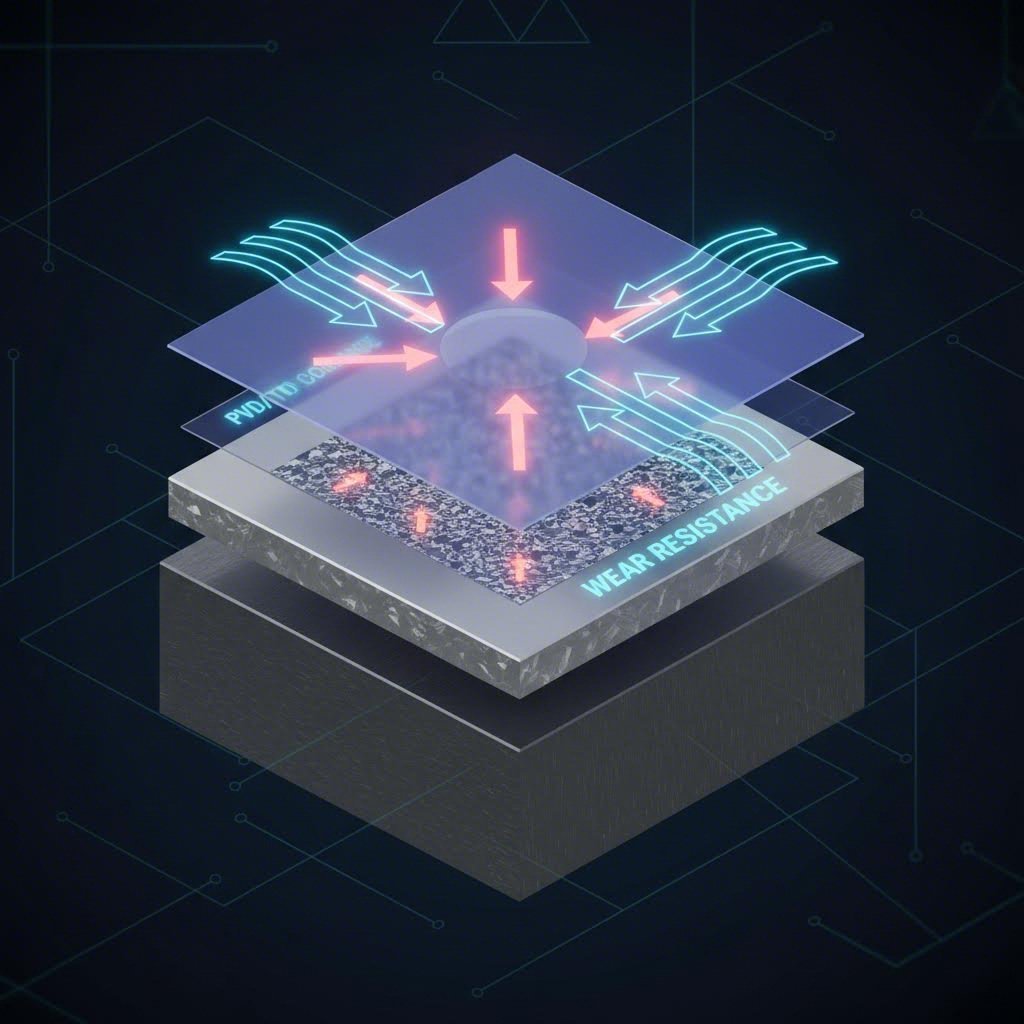

However, the substrate material is only half the battle. To combat the extreme abrasive wear and galling typical of AHSS, you must pair the correct PM substrate with an advanced surface coating—typically PVD (Physical Vapor Deposition) for precision maintenance or TD (Thermal Diffusion) for maximum surface hardness. A successful selection strategy correlates the sheet metal's tensile strength directly to the die material's toughness and the coating's wear resistance.

The AHSS Challenge: Why Conventional Tool Steels Fail

Stamping Advanced High-Strength Steel (AHSS) introduces forces that are exponentially higher than those found in mild steel forming. While mild steel might require relatively low contact pressure, AHSS grades—particularly Dual Phase (DP) and Martensitic (MS) steels—exert tremendous compressive stress on the die surface. This leads to rapid work hardening of the sheet material during formation, creating a scenario where the stamped part becomes nearly as hard as the tool itself.

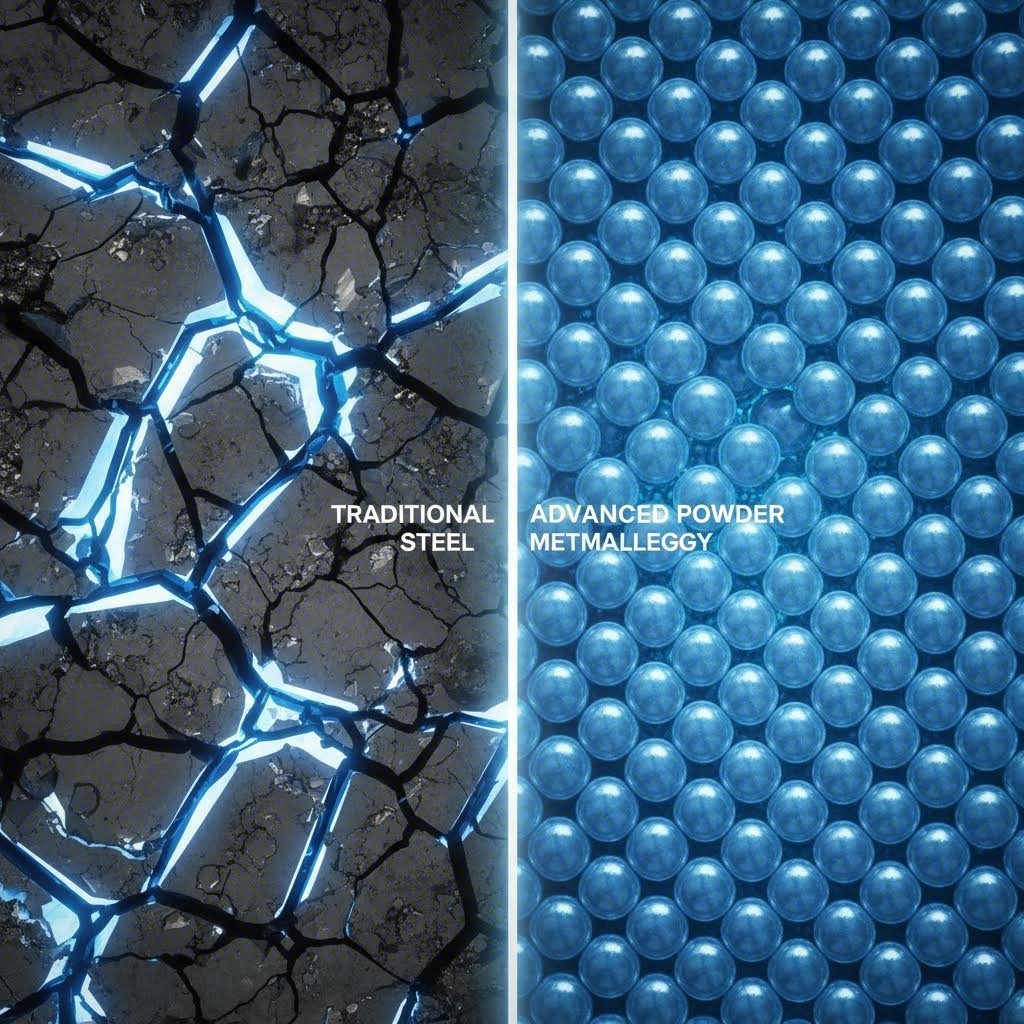

The primary failure point for conventional cold work tool steels like AISI D2 is their microstructure. In traditional ingot-cast steels, carbides form large, irregular networks known as "stringers." When subjected to the high impact shock of snapping through 980 MPa or 1180 MPa steel, these stringers act as stress risers, leading to catastrophic chipping or cracking. Unlike mild steel stamping, where wear is gradual, AHSS failure is often sudden and structural.

Furthermore, the high contact pressure generates significant heat, which degrades standard lubricants and leads to galling (adhesive wear). This is where the sheet metal literally welds itself to the tool surface, tearing away microscopic chunks of the die. AHSS Insights notes that for grades with tensile strengths above 980 MPa, the failure mode shifts from simple abrasive wear to complex fatigue failures, rendering standard D2 obsolete for high-volume runs.

Core Material Classes: D2 vs. PM vs. Carbide

Selecting the die material is a trade-off between cost, toughness (resistance to chipping), and wear resistance. For AHSS applications, the hierarchy is distinct.

Conventional Tool Steels (D2, A2)

D2 remains the baseline for stamping mild steels due to its low cost and decent wear resistance. However, its coarse carbide structure limits its toughness. For AHSS applications, D2 is generally restricted to prototyping or low-volume runs of lower-grade AHSS (under 590 MPa). If used for higher grades, it requires frequent maintenance and often suffers from early fatigue failure.

Powder Metallurgy (PM) Steels

This is the standard for modern AHSS production. PM steels are produced by atomizing molten metal into a fine powder, then bonding it under high heat and pressure (Hot Isostatic Pressing). This process creates a uniform microstructure with fine, evenly distributed carbides. Grades like Vanadis 4E, CPM 3V, or K340 provide the high impact toughness needed to prevent chipping while maintaining excellent compressive strength. A study cited by The Fabricator demonstrated that while D2 dies might fail after 5,000 cycles on a control arm part, PM steel dies continued performing well beyond 40,000 cycles.

Cemented Carbide

For the most extreme applications, or for specific inserts like punches and die buttons, cemented carbide offers superior wear resistance. However, it is extremely brittle. While it resists abrasive wear better than any steel, it is prone to shattering under the shock loads typical of AHSS snap-through. It is best reserved for high-wear areas where shock is managed or for forming lower-tensile but abrasive materials.

The Critical Role of Coatings: PVD, CVD, and TD

Because AHSS is so abrasive, even the best PM steel will eventually wear down. Coatings are essential to provide a hard, low-friction barrier that prevents galling.

| Coating Type | Process Temp | Primary Benefit | Key Limitation |

|---|---|---|---|

| PVD (Physical Vapor Deposition) | Low (~500°C) | Maintains substrate hardness; excellent dimensional precision. | Lower bond strength than TD/CVD; thinner layer. |

| TD (Thermal Diffusion) | High (~1000°C) | Extreme surface hardness (Vanadium Carbide); metallurgical bond. | Requires re-hardening of the tool; high risk of dimensional distortion. |

| CVD (Chemical Vapor Deposition) | High (~1000°C) | Thick, durable coating; good for complex geometries. | High heat can distort the tool; requires vacuum hardening. |

Physical Vapor Deposition (PVD) is often preferred for precision dies because it is applied at lower temperatures, preserving the substrate's heat treatment and dimensional accuracy. It is ideal for cutting edges where maintaining sharp geometry is critical.

Thermal Diffusion (TD) creates a vanadium carbide layer that is incredibly hard (3000+ HV), making it the gold standard for resisting galling in heavy forming operations. However, because the process takes place at austenitizing temperatures, the tool steel acts as the carbon source and must be re-hardened. This can lead to dimensional movement, making TD risky for tight-tolerance components unless managed carefully.

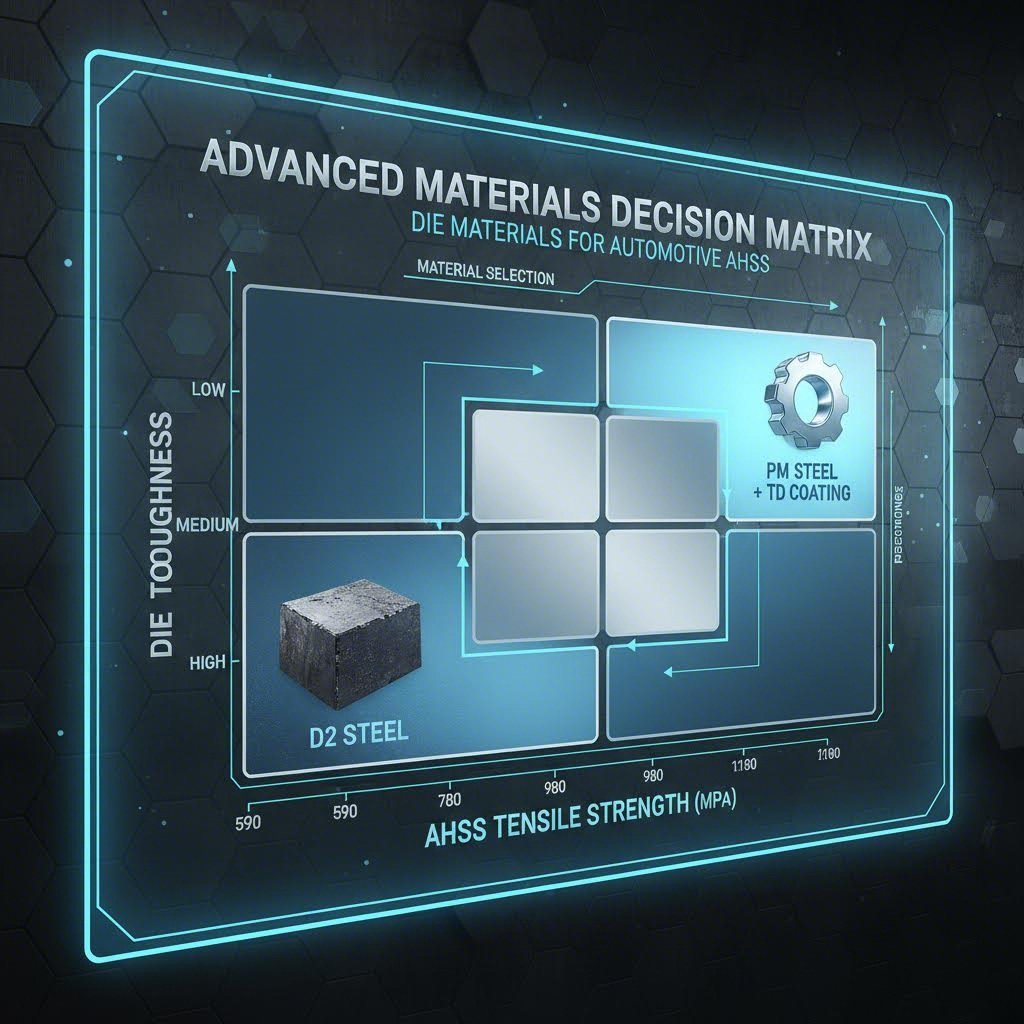

Selection Framework: Matching Material to AHSS Grade

The decision of which material to use should be driven by the specific tensile strength of the sheet metal. As the material grade increases, the demand on the tooling shifts from simple wear resistance to impact toughness.

- 590 MPa - 780 MPa: Conventional D2 can be used for lower volumes, but a modified cold-work steel (like 8% Cr) or a basic PM grade is safer for long runs. A PVD coating (such as TiAlN or CrN) is recommended to reduce friction.

- 980 MPa - 1180 MPa: This is the tipping point. D2 is largely unsafe. You must use a tough PM steel (e.g., Vanadis 4 Extra or equivalent). For forming sections prone to galling, a TD coating is highly effective. For trimming edges, a PVD coating on a PM substrate helps retain the edge while resisting chipping.

- Above 1180 MPa (Martensitic/Hot Stamped): Only the highest toughness PM grades or specialized matrix high-speed steels should be used. Surface preparation is critical, and duplex coatings (nitriding followed by PVD) are often employed to support the extreme surface loads.

It is also crucial to recognize that material selection is just one part of the production ecosystem. For manufacturers scaling from prototype to mass production, partnering with a stamper that has the equipment to handle these materials is vital. Companies like Shaoyi Metal Technology utilize high-tonnage presses (up to 600 tons) and IATF 16949-certified processes to bridge the gap between material specification and successful part fabrication, ensuring that the chosen die materials perform as intended under production conditions.

Best Practices for Heat Treatment and Surface Prep

Even the most expensive PM steel with a premium coating will fail if the substrate is not prepared correctly. A common failure mode is the "egg-shell effect," where a hard coating is applied to a soft substrate. Under pressure, the substrate yields, causing the brittle coating to crack and spall off.

To prevent this, the substrate must be heat-treated to a sufficient hardness (typically 58-62 HRC for PM steels) to support the coating. Triple tempering is often required to convert retained austenite and ensure dimensional stability. Furthermore, the surface finish before coating is non-negotiable. The tool surface must be polished to a roughness average (Ra) of roughly 0.2 µm or better. Any grinding marks or scratches left on the tool become stress risers that can initiate cracks or compromise coating adhesion.

Finally, maintenance strategies must be adapted. You cannot simply grind a coated tool to sharpen it without removing the coating. For PVD-coated tools, the coating must often be stripped chemically, the tool sharpened and polished, and then re-coated to restore full performance. This lifecycle cost must be factored into the initial die material selection.

Optimizing for Long-Term Production

The transition to AHSS requires a holistic approach to tooling. It is no longer sufficient to rely on the "safe" choices of the past. Engineers must treat the die as a composite system where the substrate provides the structural integrity and the coating provides the tribological performance. By matching the toughness of PM steels with the wear resistance of modern coatings, manufacturers can turn the challenge of stamping high-strength materials into a consistent, profitable operation. The upfront cost of premium materials is almost always recovered through reduced downtime and lower scrap rates.

Frequently Asked Questions

1. What is the best die material for stamping AHSS?

For most AHSS applications above 590 MPa, Powder Metallurgy (PM) tool steels like Vanadis 4E, CPM 3V, or similar grades are considered the best choice. Unlike conventional D2, PM steels have a fine, uniform microstructure that provides the necessary toughness to resist chipping while maintaining high compressive strength.

2. Why does D2 tool steel fail with AHSS?

D2 fails primarily due to its microstructure, which contains large "carbide stringers." When subjected to the high shock and contact pressures of AHSS stamping, these stringers act as stress concentration points, leading to cracking and chipping. D2 also lacks the necessary toughness to handle the snap-through forces generated by high-strength materials.

3. What is the difference between PVD and CVD coatings for stamping dies?

The main difference is the application temperature. PVD (Physical Vapor Deposition) is applied at lower temperatures (~500°C), which prevents the tool steel from softening or distorting. CVD (Chemical Vapor Deposition) and TD (Thermal Diffusion) are applied at much higher temperatures (~1000°C), which creates a stronger metallurgical bond and thicker coating but requires the tool to be re-hardened, posing a risk of dimensional distortion.

4. When should I use Powder Metallurgy (PM) steel for stamping?

You should switch to PM steel whenever you are stamping sheet metal with a tensile strength above 590 MPa, or for long-run production of lower-strength materials where maintenance costs are a concern. PM steel is also essential for any application involving complex die geometries where the risk of cracking is high.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —