Billet Vs Forged Crankshaft Strength: Which Survives Your Power Goals

The Critical Strength Decision Every Engine Builder Faces

When you're chasing serious horsepower, one question keeps every performance engine builder up at night: which crankshaft manufacturing method will actually survive your power goals? Whether you're building a weekend warrior or a dedicated drag machine, understanding the difference between billet and forged crankshafts isn't just technical knowledge—it's engine insurance.

Here's the brutal reality. Crankshaft failure doesn't just mean a broken part. It means catastrophic engine destruction. We're talking about a rotating assembly spinning at thousands of RPM suddenly letting go, sending shrapnel through your block, heads, and everything else you've invested in. A complete engine build can easily exceed $20,000 to $50,000 for serious performance applications, and one crankshaft failure can destroy it all in milliseconds.

Why Crankshaft Strength Determines Engine Survival

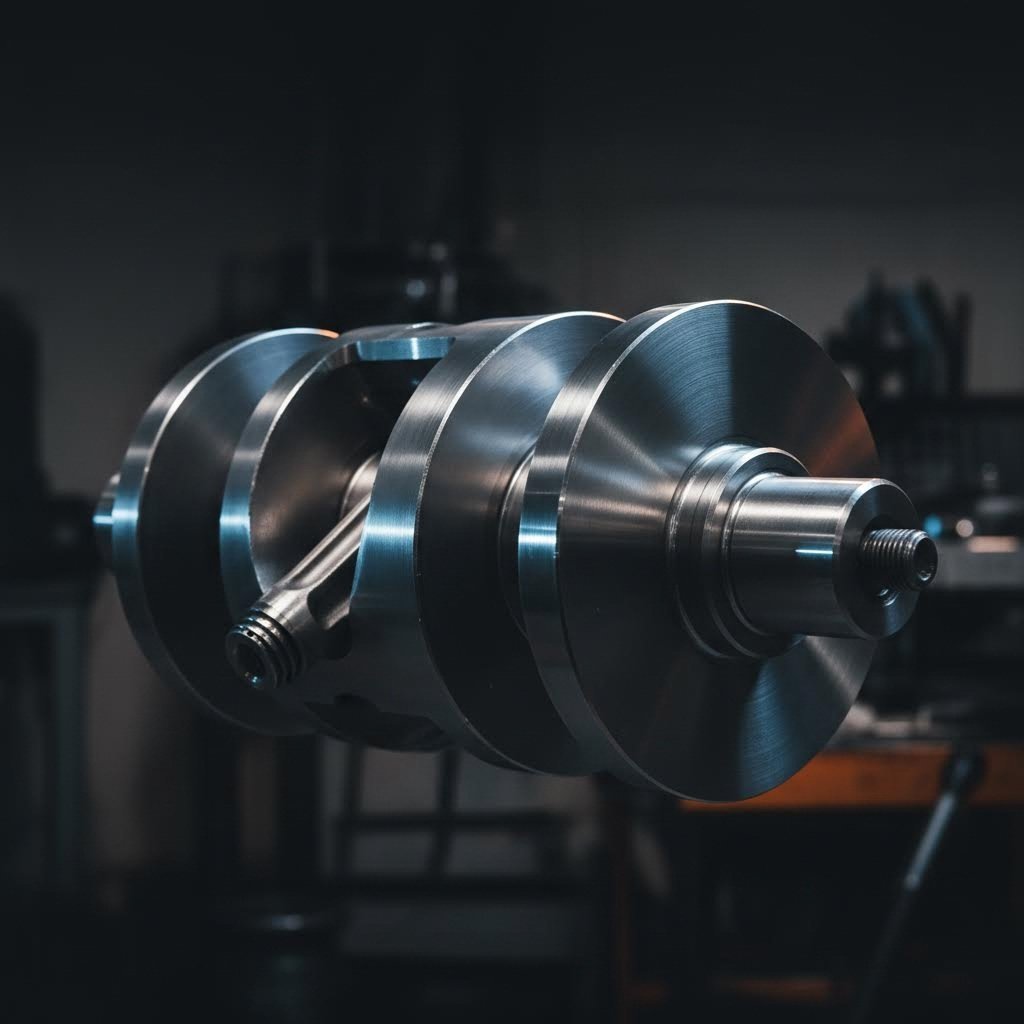

The crankshaft sits at the heart of your engine, converting the violent linear motion of your pistons into usable rotational power. According to Engine Labs, savvy builders recognize that selecting the right crankshaft involves analyzing factors far beyond just expected horsepower output. Every combustion event sends tremendous force through this single component, and it must withstand constant flexing, torsional stress, and heat cycles—all while maintaining perfect balance.

Think about what happens in a high-performance engine. You might be running a boss nine v8 crate engine pushing extreme power levels, or a boosted street car seeing 20+ PSI of boost. In either scenario, your crankshaft endures punishment that would destroy lesser components. The difference between a forged crankshaft and a billet crankshaft often determines whether your engine survives that punishment or becomes an expensive pile of scrap metal.

The Real Stakes of Choosing Wrong

Making the wrong choice isn't just about losing a crankshaft. As noted by industry experts at SoFi, crankshaft replacement alone can cost upwards of $3,000 including parts and labor—and that's for a standard vehicle. For a performance engine, multiply that figure significantly. But the real cost comes from collateral damage: destroyed pistons, bent connecting rods, cracked blocks, and ruined cylinder heads.

This guide cuts through the marketing hype to give you an objective, data-driven comparison of crankshaft manufacturing methods. You'll learn:

- How forged and billet construction methods create fundamentally different strength characteristics

- The specific power thresholds where each crankshaft type becomes necessary

- Common misconceptions that lead builders to overspend—or worse, under-build

- Clear recommendations based on your actual power goals and intended use

Both forged billet and traditionally forged crankshafts have legitimate applications in performance engines. A quality forged crankshaft handles most high-horsepower street and strip builds beautifully. A billet crankshaft becomes the logical choice when you're chasing extreme boost, custom specifications, or sustained high-RPM stability. The key is matching the right manufacturing method to your specific build requirements—because strength requirements vary dramatically based on power levels, intended use, and how often you plan to push those limits.

How We Evaluated Crankshaft Strength and Durability

Sounds complex? Understanding how we compare forged strength against billet performance doesn't require a metallurgy degree. But it does require looking beyond manufacturer claims and marketing buzzwords. Our evaluation methodology focuses on measurable characteristics that directly impact whether your crankshaft survives your power goals—or becomes the weak link in your rotating assembly.

When comparing forging crankshafts to billet machining processes, we prioritize real-world durability under extreme stress rather than theoretical maximums that only matter in laboratory conditions. A forged crank that handles 1,200 horsepower reliably for 500 passes is more valuable than a billet design rated for 2,000 horsepower that fails unpredictably at 1,500.

Strength Metrics That Actually Matter

Before diving into manufacturing methods, you need to understand what "strength" actually means for a crankshaft. Four primary metrics determine whether your rotating assembly survives your power ambitions:

Tensile Strength measures the maximum stress a material can withstand before breaking when pulled apart. For crankshafts, this matters most during high-RPM operation when centrifugal forces try to tear the counterweights away from the main journals.

Yield Strength indicates the stress level where permanent deformation begins. A crankshaft that bends—even slightly—under load is finished. This metric tells you how much punishment your crank absorbs before it takes a permanent set.

Fatigue Resistance represents the crankshaft's ability to withstand repeated stress cycles without developing cracks. According to High Performance Academy, the fillet radius where journals meet the throws is one of the most highly stressed parts of the crankshaft—this is generally where cracking begins, signaling the end of your crankshaft's useful life.

Torsional Rigidity describes resistance to twisting forces. Every combustion event creates torsional loads that try to wind up your crankshaft like a spring. Insufficient rigidity leads to harmonic vibrations that accelerate fatigue failure and can destroy bearings.

How Manufacturing Methods Affect Grain Structure

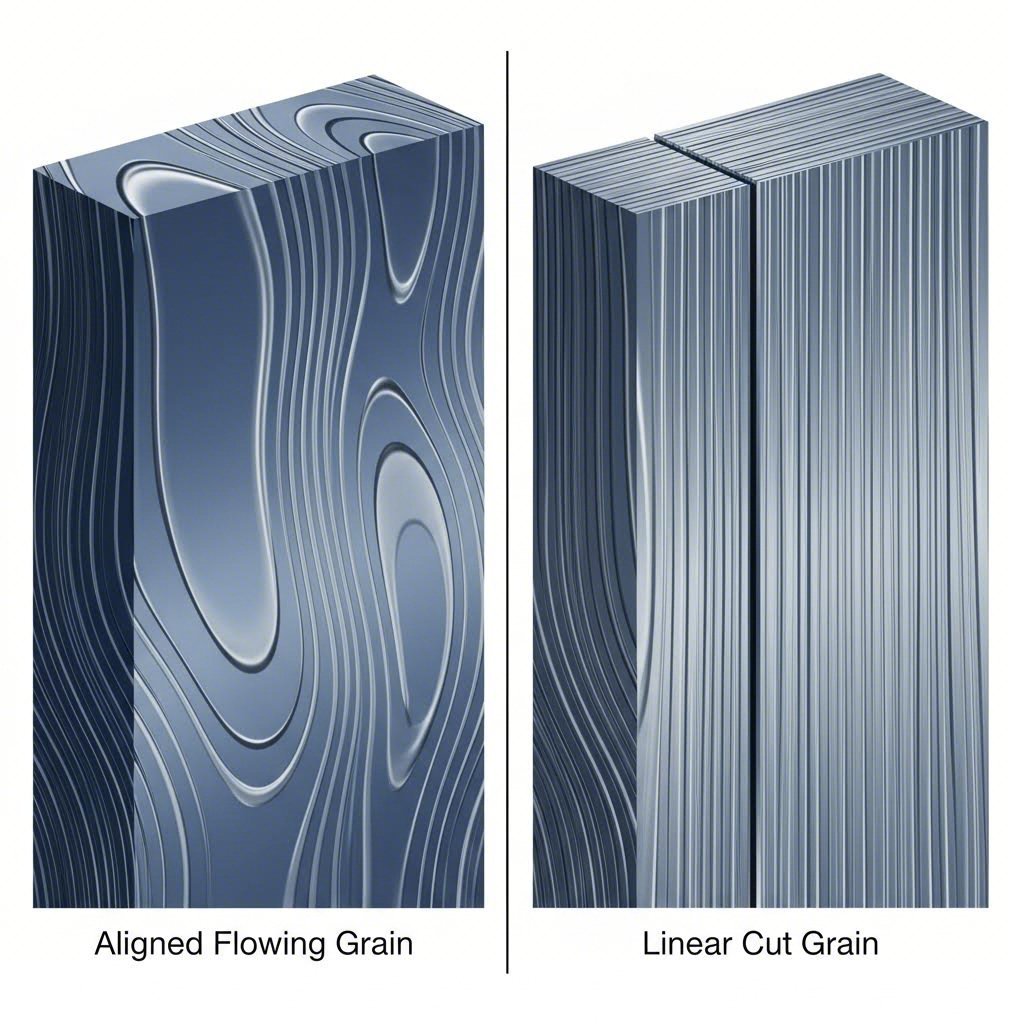

Here's where the real difference between billet and forged crankshafts becomes critical. When you machine a billet crank from a solid steel bar, you're cutting through the material's existing grain structure. When forging crankshafts using heat and pressure, the grain flows continuously along the component's contours.

Imagine cutting a piece of wood. Slicing across the grain creates a weak point where splitting occurs easily. But following the grain produces maximum strength. The same principle applies to steel—though the effects are more subtle.

As noted by metal forming experts at MetalTek, the forging process alters the grain structure and can "aim" or "point" it in a particular direction, creating a directionally strong component. Forged parts are anisotropic—containing different strength values in different directions—while machined billet components are more isotropic with uniform properties throughout.

This grain structure difference creates a fascinating paradox. All things being equal, a properly forged crankshaft maintains superior grain flow compared to machined billet. However, billet manufacturers compensate by using superior materials and precision machining that eliminates forging-related defects. The result? Both methods can produce exceptional crankshafts when executed properly—but they excel in different applications.

When pairing your crankshaft with complementary rotating assembly components like quality lunati camshafts or performance bullet cams, understanding these material differences helps you build a cohesive package. The h beam vs i beam connecting rod debate follows similar metallurgical principles—matching the right construction method to your specific power and RPM requirements.

Material Matters: Steel Alloys Compared

Beyond manufacturing method, the base material dramatically affects final crankshaft performance. Here's what you'll encounter in the aftermarket:

4340 Steel: The industry standard for performance crankshafts. This nickel-chromium-molybdenum alloy offers excellent tensile strength (typically 180,000-200,000 PSI when properly heat treated) combined with good toughness and fatigue resistance. Most quality forged and billet crankshafts use 4340.

5140 Steel: A chromium steel found in many factory forged crankshafts. Lower alloy content means reduced cost but also lower ultimate strength compared to 4340. Adequate for moderate performance builds but not ideal for extreme applications.

4130 Steel: Common in aerospace applications and some lightweight crankshaft designs. Good strength-to-weight ratio but lower fatigue resistance than 4340 in crankshaft applications.

EN40B Steel: When 4340 isn't enough, serious builders turn to this higher-specification material. According to High Performance Academy's research with Nitto Performance Engineering, engines producing 2,500+ wheel horsepower found that 4340 material lacked sufficient rigidity. The crankshaft would flex under extreme cylinder pressures and high RPM, causing metal-to-metal contact between journals and bearings—a recipe for catastrophic failure. EN40B addresses this limitation for the most extreme applications.

Our Five-Point Evaluation Criteria

Throughout this comparison, we rank crankshaft options using these specific criteria:

- Fatigue Life Under Repeated Stress: How many power cycles before cracks initiate, tested at realistic power levels

- Torsional Stability at Target RPM: Resistance to twisting and harmonic vibration at your intended operating range

- Material Consistency and Defect Rate: Quality control measures that ensure every crankshaft meets specifications

- Heat Treatment Effectiveness: Proper hardening that maximizes material properties without inducing brittleness

- Value Relative to Power Level: Cost-effectiveness for your specific horsepower goals—because overspending on crankshaft strength you'll never need wastes resources better spent elsewhere

These criteria prioritize what actually matters when your engine is making power: survival under real-world conditions. With this framework established, we can now examine specific crankshaft options and determine which manufacturing method best serves different power levels and applications.

Premium Billet Crankshafts for Maximum Power Applications

When your engine build demands absolute maximum strength with zero compromises, a billet crankshaft becomes the ultimate solution. Imagine starting with a solid bar of premium steel—inspected, verified, and guaranteed free from internal defects—then machining it into exactly the crankshaft your build requires. That's the billet advantage in its purest form.

A billet crank represents the pinnacle of rotating assembly engineering. Unlike forged components shaped by dies, a crankshaft billet starts as homogeneous bar stock, typically 4340 or EN40B steel, then undergoes precision CNC machining to create the finished component. According to experts at Engine Builder Magazine, "Billet means you're starting from scratch. It's a blank slate. You're not limited by pre-existing die shapes or forging constraints."

When Absolute Maximum Strength Is Non-Negotiable

Here's where billet construction truly shines: applications where forged crankshaft fatigue limits simply cannot keep up with the punishment. We're talking about engines producing over 2,000 horsepower, nitrous oxide systems delivering massive instantaneous torque spikes, or twin-turbo drag cars launching at full boost with a lencodrive transmission handling the abuse.

The Howards Cams Billet Reaper LS crankshaft exemplifies this extreme capability. As reported by Dragzine, this crankshaft is "capable of handling over 2,000 horsepower" while using E4230 billet material for exceptional strength and extended main bearing life. It's CNC machined to exact tolerances with computer-designed counterweights that reduce bearing loads and improve balancing precision.

What makes billet construction uniquely suited for these extreme applications? Three critical advantages:

Pre-Machining Material Inspection: Before any cutting begins, manufacturers can verify the bar stock meets exact specifications. There are no hidden inclusions, porosity, or grain irregularities lurking inside—problems that can occur during forging and remain undetected until failure.

Complete Design Freedom: Need a custom stroke for your SBC billet crankshaft? Non-standard bore spacing for a big block Chevy? Unusual counterweight positioning? Billet delivers. As Steve Arent of Scat Crankshafts explains, "Billet cranks can be fully custom designed for stroke, counterweight configuration, journal sizing, oiling, or special applications."

Superior Material Consistency: The grain structure in billet steel is linear and uniform throughout, providing predictable fatigue resistance across the entire component. This consistency becomes critical when torsional loads reach levels that would exceed forged crankshaft fatigue limits.

Ideal Applications for Billet Construction

So when does spending the extra money on billet actually make sense? The applications fall into specific categories where forged alternatives simply cannot deliver the required performance:

Dedicated Drag Racing Above 1,800-2,000 HP: When your supercharged or turbocharged combination is making serious power, billet provides the strength headroom you need. Many racers shopping for a lenco cs1 4 speed transmission for sale are building the kind of engine that demands billet-level crankshaft strength.

Nitrous Oxide Applications: The instantaneous torque spikes from nitrous create unique stress patterns that punish crankshafts differently than boosted applications. Billet's consistent material properties handle these sudden loads more predictably.

Custom Stroke Requirements: Building an engine with non-standard stroke dimensions? Billet is often the only practical option. Brook Piper of Callies Performance Products notes, "Just in the big block Chevy world alone, we've had everything from 4.840", 4.900", 5.000", 5.250", to 5.300" bore spacing over the years. You can't justify a dedicated forging for each of those combinations—billet is the only practical solution."

Tractor Pulling and High-Stress Endurance: Applications requiring sustained maximum effort benefit from billet's durability. According to industry data, some tractor pulling builds require 25-32 hours of machine time invested in a single billet crank to achieve the required specifications.

Pros of Billet Crankshafts

- Ultimate Strength Potential: Verified material quality before machining ensures maximum possible strength from your chosen alloy

- Complete Custom Stroke Options: Any stroke, any bore spacing, any counterweight configuration—billet delivers exactly what your build requires

- Material Consistency: Linear, uniform grain structure throughout provides predictable fatigue resistance

- Optimized High-Stress Zones: Engineers can reinforce rod journals, main throws, and fillets precisely as needed

- Precision Tolerances: CNC machining delivers tighter concentricity, balance, and journal sizing than forging dies allow

- Exceptional Longevity: Properly maintained billet cranks routinely survive 20+ years in demanding applications

Cons of Billet Crankshafts

- Highest Cost: Billet cranks typically cost $1,000-$1,200 more than forged equivalents from manufacturers like Callies, with highly customized versions from Scat ranging $2,000-$8,000 above forged options

- Longer Lead Times: The complete manufacturing process takes several days to a couple of weeks depending on complexity and shop load

- Potential for Machining-Induced Stress Risers: Improperly manufactured billet cranks can develop stress concentrations at machined surfaces—quality control matters enormously

- Not Inherently Stronger Than Forged: As Callies' Brook Piper states, "If you have two cranks made from the exact same material—one forged, one billet—the forging will be stronger every time" due to grain compression

- Requires Proper Stress Relief: Metal has memory, requiring careful stress relieving during machining to prevent dimensional instability

The critical takeaway? Billet crankshafts become necessary when power levels create torsional loads that exceed forged crankshaft fatigue limits. Below those thresholds, you're paying premium prices for capability you'll never use. As Piper candidly admits, "Nine times out of 10, our forging will do the job. That's why we go through it with our customers."

A quality billet rod paired with your crankshaft completes the rotating assembly equation, but the crankshaft choice remains paramount. Understanding when billet's advantages justify the investment—versus when a premium forged alternative delivers equal real-world performance—separates informed builders from those simply chasing specifications they'll never need.

Forged 4340 Steel Crankshafts for Proven Performance

Here's a reality check that might surprise you: for the vast majority of performance builds, a high-quality forged 4340 crankshaft delivers everything you need—without the premium price tag of billet. When you understand why forging creates inherently strong crankshafts, you'll see why manufacturers like Callies cranks have built their reputation on this proven technology.

The forged crank represents the optimal balance point where strength, reliability, and value intersect. According to Callies Performance Products, "Nine times out of 10, our forging will do the job." That's not marketing speak—it's decades of racing experience distilled into practical guidance for serious builders.

The Sweet Spot for Serious Performance Builds

What makes a quality Callies crank or similar premium forged crankshaft such a compelling choice? It starts with the manufacturing process itself. Unlike casting, which pours molten metal into molds, or billet machining, which cuts material away from solid bar stock, forging shapes heated steel under tremendous pressure. This process fundamentally alters the metal's internal structure in beneficial ways.

When steel is heated and compressed in forging dies on a multi-ton press, the grain structure flows continuously along the crankshaft's contours. As Brook Piper of Callies explains, "If you have two cranks made from the exact same material—one forged, one billet—the forging will be stronger every time." That's because forging compresses and aligns the grain, creating directional strength precisely where you need it most.

The numbers tell the story. Quality forged 4340 crankshafts from reputable manufacturers reliably handle 1,200 to 1,800 horsepower in properly designed applications. For street/strip builds in the 800-1,200 horsepower range—which covers the vast majority of serious performance engines—forged cranks deliver exceptional value. According to Spool Imports, their forged LS cranks in 3.622" and 4.000" strokes handle these power levels beautifully when balanced with quality H-beam or Drag Pro forged con rods.

Why Grain Flow Matters for Fatigue Resistance

Imagine a bundle of steel cables twisted together, then bent to follow a specific path. Each cable maintains its integrity while the bundle gains collective strength from the unified direction. That's essentially what happens to steel's grain structure during forging—the crystalline structure aligns and flows with the component's shape.

This aligned grain flow creates superior fatigue resistance compared to machined billet in many applications. Here's why that matters:

Work Hardening: The forging process itself work-hardens the steel. As metal is compressed and shaped, its crystalline structure becomes denser and more resistant to deformation. This inherent strengthening happens throughout the forging process—you're not just shaping metal, you're making it stronger.

Continuous Grain Boundaries: In a forged crankshaft, the grain boundaries flow continuously from main journal to rod throw to counterweight. There are no abrupt transitions where stress can concentrate. Compare this to billet machining, which cuts through existing grain structure regardless of the crankshaft's final shape.

Fatigue Crack Resistance: Fatigue failures typically start at grain boundaries where stress concentrations exist. With aligned grain flow following the crankshaft's contours, forged cranks distribute stress more evenly and resist crack initiation better than components with interrupted grain structure.

Quality also depends heavily on material sourcing and processing. As Callies' Brook Piper notes, "What qualifies as 4340 steel is a broad term. Many parts of the world struggle with material cleanliness, but it still reaches the parameters as a 4340 material." This is why choosing forged crankshafts from manufacturers who control their material supply chain matters enormously.

Callies, for example, sources raw materials globally to create what they consider the purest SAE 4340 billet that goes into their Magnum crankshaft line. Their Compstar line offers a more affordable option—forged overseas in Callies-owned dies, rough machined to pre-finish dimensions, then completed in Ohio. This approach delivers cost-effective value for racing applications up to approximately 1,000 horsepower.

Forged Crankshaft Quality Tiers

Not all forged crankshafts are created equal. Understanding the quality tiers helps you match your investment to your power goals:

Premium Domestic Forged (Callies Magnum, similar): American-made with domestic 4340 material offering maximum nickel content and optimal heat treatment. Reliable to 1,500-1,800 horsepower in properly designed applications. Higher surface hardness from advanced nitriding processes.

Mid-Range Forged (Callies Compstar, similar): Forged overseas in quality-controlled dies, finished domestically. Brook Piper suggests these are perfect for "an enthusiast wants a big-block crank for 800 horsepower. Our Compstar will do that all day long." Cost-effective for builds under 1,000 horsepower.

Economy Forged: Import forgings with less stringent material standards. Suitable for mild performance builds but not recommended for serious power applications where fatigue life matters.

When pairing your forged crankshaft with quality Carrillo rods or similar forged con rods, you're building a rotating assembly with matched strength characteristics. This synergy between components maximizes reliability while keeping costs reasonable.

Pros of Forged 4340 Crankshafts

- Excellent Fatigue Life: Aligned grain structure provides superior resistance to crack initiation and propagation under repeated stress cycles

- Proven Reliability: Decades of racing success demonstrate forged crankshafts handle serious power when properly specified

- Better Value Than Billet: Premium forged cranks cost $1,000-$1,200 less than equivalent billet options while serving 90% of performance applications

- Wide Availability: Multiple manufacturers offer forged options for popular engine platforms with reasonable lead times

- Work-Hardened Strength: The forging process itself creates inherent strength advantages beyond the base material properties

- Established Power Thresholds: Clear, proven guidelines exist for when forged cranks are appropriate versus when to upgrade

Cons of Forged 4340 Crankshafts

- Limited Custom Stroke Options: Forging requires expensive dies, making non-standard strokes impractical for small production runs

- Potential for Forging Defects: If quality control is inadequate, internal defects can escape detection until failure—always choose reputable manufacturers

- Material Source Variability: Offshore forgings may use 4340 that technically meets specifications but with lower nickel content or less optimal cleanliness

- Finite Power Ceiling: Above 1,800 horsepower, even premium forged cranks approach their fatigue limits under sustained use

The bottom line? For 90% of performance builds producing under 1,500 horsepower, a quality forged 4340 crankshaft represents the intelligent choice. You're investing in proven technology with documented reliability, leaving budget available for other rotating assembly components where it makes a real difference.

As Callies' Brook Piper puts it, "Let's say an enthusiast wants a big-block crank for 800 horsepower. Our Compstar will do that all day long. If they want American-made with a longer life, they will be spending 3,000 dollars for a billet crank, but that's what we do. We sit down and try to cater to a customer's needs." That honest approach—matching crankshaft selection to actual requirements rather than maximum specifications—is what separates informed builders from those simply chasing bragging rights.

Precision Hot-Forged Crankshafts with Certified Quality

What separates a good forged crankshaft from a great one? It's not just the steel alloy or the basic forging process—it's the precision, consistency, and quality assurance behind every component that rolls off the production line. For professional engine builders and racing teams who can't afford variability, precision hot-forged crankshafts manufactured under IATF 16949 certification represent the professional-grade solution that bridges the gap between standard forged options and premium billet construction.

When you're comparing cast crankshaft vs forged options, the differences are obvious. But within the forged category itself, manufacturing quality varies dramatically. A precision hot-forged crankshaft produced with advanced process controls and certified quality management delivers consistency that standard forgings simply cannot match—and at a price point that makes sense for serious builds.

Certified Quality Control for Critical Components

You've probably encountered IATF 16949 certification without fully understanding what it means for crankshaft quality. This internationally recognized quality management standard specifically addresses automotive production requirements, demanding rigorous process controls, documented procedures, and continuous improvement protocols. When a manufacturer holds this certification, you're getting more than just a crankshaft—you're getting a guarantee of manufacturing consistency.

Why does this matter for your rotating assembly? Consider what happens during crank casting or basic forging operations without stringent controls:

- Temperature variations during heating create inconsistent grain structure

- Die wear produces dimensional variations between production runs

- Inadequate inspection allows defective components to ship

- Material substitution or contamination goes undetected

Certified precision forging eliminates these variables. According to Queen City Forging, the forging process promotes a more uniform material structure, reducing the presence of inclusions or segregations that can act as stress concentrators and lead to failure. When combined with IATF 16949 quality protocols, every crankshaft meets documented specifications—not just most of them.

The certification also ensures traceability. Should a problem ever arise, certified manufacturers can trace materials, processes, and inspections back through the entire production chain. For racing teams running multiple engines or engine builders with professional reputations to protect, this documentation provides invaluable peace of mind.

How Precision Forging Maximizes Grain Structure Benefits

Advanced hot forging processes take the inherent advantages of forged construction and amplify them through engineering optimization. When steel is heated to precise temperatures and formed in carefully designed dies under controlled conditions, the grain structure benefits we discussed earlier—aligned flow, work hardening, and directional strength—reach their maximum potential.

Here's what precision forging delivers that standard processes don't:

Optimized Die Design: In-house engineering teams use computer modeling to design forging dies that maximize grain flow through critical stress areas. The fillet radii, journal transitions, and counterweight roots all receive intentional grain orientation rather than whatever pattern the basic forging process produces.

Controlled Deformation Rates: The speed and pressure applied during forging affect final properties. As noted in forging research, the extent of work hardening can be controlled by adjusting the degree of deformation and temperature during forging, allowing for optimization of the material's mechanical properties. Precision forging facilities control these variables precisely.

Consistent Heat Treatment: Post-forging heat treatment processes like quenching, tempering, and annealing further enhance mechanical properties. Certified facilities document and control these processes to ensure every crankshaft receives identical treatment—eliminating the batch-to-batch variations that plague less rigorous operations.

Surface Quality Optimization: The forging process can produce components with excellent surface quality, which is important for fatigue strength. A smooth, defect-free surface reduces the risk of crack initiation, contributing to overall strength and longevity. Precision forging delivers this surface quality consistently.

For professional engine builders sourcing components from manufacturers like those found through callies com or seeking Carrilo rods equivalents, finding a forging partner with these capabilities solves the consistency challenge that plagues volume production.

Rapid Prototyping to Production

Racing teams and professional engine builders often face tight development timelines. You need prototype components quickly to validate designs, then seamless transition to production quantities when specifications are finalized. Precision hot forging facilities with in-house engineering capabilities deliver this workflow efficiently.

For example, Shaoyi (Ningbo) Metal Technology offers rapid prototyping in as little as 10 days, backed by IATF 16949 certification and the engineering expertise to optimize designs for both strength and manufacturability. Their location near Ningbo Port enables fast global shipping for international racing programs or engine builders sourcing components worldwide.

This prototyping capability matters because crankshaft design involves tradeoffs. Counterweight positioning affects balance and windage. Journal sizing impacts oil film thickness and bearing load capacity. Stroke dimensions determine rod angles and piston speeds. Having engineering support during the design phase—rather than simply receiving whatever the forging dies produce—results in optimized components that maximize strength-to-weight ratios for your specific application.

Pros of Precision Hot-Forged Crankshafts

- Certified Quality Assurance: IATF 16949 certification guarantees consistent manufacturing processes and documented traceability

- Optimized Grain Structure: Advanced die design and controlled forging parameters maximize the inherent strength advantages of forged construction

- Competitive Pricing for Volume: Professional engine builders and racing teams benefit from economies of scale without sacrificing quality

- Fast Turnaround from Prototyping to Production: In-house engineering and rapid prototyping capabilities compress development timelines

- Elimination of Forging Defects: Rigorous quality control catches the inclusions, porosity, and grain irregularities that compromise strength in standard forgings

- Global Compliance: Certified manufacturing meets international quality standards for racing organizations and OEM programs

Cons of Precision Hot-Forged Crankshafts

- May Require Minimum Order Quantities: Custom specifications typically require MOQs to justify die development and setup costs

- Not Ideal for One-Off Builds: Individual hobbyists with single-crankshaft needs may find off-the-shelf options more practical

- Lead Time for Custom Tooling: While prototyping is fast, new die development for unique designs requires additional planning

The Professional Builder's Choice

Precision hot-forged crankshafts with certified quality control occupy a unique position in the billet vs forged crankshaft strength debate. They deliver the grain structure advantages inherent to forging—work hardening, aligned grain flow, and elimination of internal voids—while adding the manufacturing consistency that professional applications demand.

For racing teams running multiple cars, engine builders with production volume requirements, or anyone who cannot tolerate component variability, this category offers the optimal combination of strength, consistency, and value. You're not paying billet prices for capability you may never need, but you're also not gambling on economy forgings with uncertain quality control.

The key is partnering with manufacturers who combine forging expertise with certified quality systems and engineering support. When your reputation—or your racing season—depends on crankshaft reliability, precision hot forging from a certified facility delivers the confidence that every component meets exact specifications.

Cast Steel Crankshafts and Their Performance Limits

Before you invest in a premium forged or billet crankshaft, you need to understand what you're replacing—and why. Cast steel crankshafts represent the entry-level option that comes standard in most production vehicles. While they serve their intended purpose admirably in stock applications, understanding their limitations helps you make smarter decisions when building beyond factory power levels.

Think about it this way: every engine that rolled off an assembly line—whether it's a small block Chevy, a 283 crankshaft application, or even a 300 ford straight six—likely contains a cast crankshaft. Manufacturers choose casting because it's economical for mass production, not because it offers superior strength. When your power goals exceed what the factory engineers anticipated, that casting becomes the weak link in your rotating assembly.

Understanding Cast Crankshaft Limitations

What makes cast crankshafts fundamentally different from their forged or billet counterparts? It comes down to how the metal is formed and the resulting internal structure.

As noted by Street Muscle Magazine, cast cranks are created by pouring molten material—typically cast iron—into a mold to create a raw casting. The benefits of this process include lower cost, inexpensive tooling, and minimal machining required to produce a finished product. That's why the vast majority of OEM cranks are created using this process.

Here's where the problem starts for performance builders. When metal solidifies from a liquid state in a mold, the grain structure forms randomly. There's no aligned flow following the crankshaft's contours like you get with forging, and no verified material consistency like billet provides. This random grain orientation creates several critical weaknesses:

Lower Fatigue Resistance: Random grain boundaries act as stress concentration points where cracks can initiate. Under repeated loading cycles—exactly what a crankshaft experiences during normal operation—these weak points accumulate damage faster than aligned grain structures.

Reduced Tensile Strength: According to the same source, cast cranks start near 60,000 PSI tensile strength, while forgings can more than double this rating to as high as 125,000 PSI. That's a significant difference when your engine is making serious power.

Brittleness Under Stress: The elongation rating—essentially how much the material can flex before breaking—tells the real story. Factory cast cranks have an elongation rating around 3 percent, meaning they're relatively brittle. Even nodular iron castings only improve this to about 6 percent, compared to the 20+ percent rating offered by high-end forged cranks.

For big block applications or any build where you're chasing significant power increases, these limitations become failure risks rather than theoretical concerns.

When Factory Cast Cranks Are Sufficient

Despite their limitations, cast crankshafts have legitimate applications. Not every engine build requires premium components, and understanding where cast cranks remain adequate prevents overspending on capability you'll never need.

According to Summit Racing's technical experts, cast or nodular iron crankshafts are usually good for 300 to 400 horsepower reliably and can withstand some occasional weekend track usage. Carl Pritts from Summit's technical department notes that cast crankshafts are ideal for stock or mildly modified street applications.

The common industry guidance suggests that cast cranks become replacement candidates when building beyond 450-500 horsepower. This threshold isn't arbitrary—it represents the point where stress levels begin approaching the fatigue limits of cast construction under repeated use.

Here's practical guidance for cast crankshaft applications:

- Stock Rebuilds: If you're refreshing an engine to factory specifications, the original cast crank is perfectly adequate

- Mild Street Performance: Bolt-on modifications like intake, headers, and cam upgrades that keep power under 400-450 horsepower work fine with cast cranks

- Low-Stress Daily Drivers: Engines that rarely see redline and never experience sustained high-load operation can run cast cranks indefinitely

- Budget-Conscious Builds: When funds are limited, a factory cast crank allows you to allocate budget toward heads, cam, or forced induction

As Street Muscle Magazine's Mike McLaughlin from Lunati explains, crank strength is much more than a function of what it will survive on a single hero run. Factory cranks were designed by the OEMs to last 100,000 miles or more—literally millions of cycles—and that life span is a function of more than just tensile strength. It's possible for even the wimpiest of cast cranks to survive indefinitely if run at lower engine speeds and power levels.

The key distinction? Time spent at high load and RPM determines the need for a forged crank every bit as much as peak power level. A 400-horsepower small block in a daily driven street car might work well with a cast crank, but the same motor powering a pleasure boat—running at sustained high load for hours—would require forged components.

Pros of Cast Steel Crankshafts

- Lowest Cost: Cast cranks cost significantly less than forged or billet alternatives, making them budget-friendly for mild builds

- Readily Available for Stock Applications: OEM replacement cast cranks are widely stocked for most popular engine platforms

- Sufficient for Mild Builds: Power levels under 400-450 horsepower in street applications work reliably with cast construction

- No Special Heat Treatment Required: Cast iron journals become work-hardened during machining, eliminating the heat treatment step required for forged cranks

- Easy Sourcing: Junkyards, parts stores, and online suppliers maintain extensive cast crank inventory

Cons of Cast Steel Crankshafts

- Lowest Strength: Tensile strength around 60,000-80,000 PSI limits power handling capability significantly compared to forged options

- Unpredictable Failure Modes: Random grain structure means cracks can initiate at various locations, making failures difficult to anticipate

- Not Suitable for Serious Performance: Any build targeting 500+ horsepower or sustained high-RPM operation requires upgrading beyond cast construction

- Brittleness: Low elongation ratings mean cast cranks tend to break suddenly rather than bending or warning before failure

- Limited Fatigue Life Under Stress: Repeated high-load cycles accumulate damage faster than in forged alternatives

How to Identify Cast Versus Forged Crankshafts

Before you start building, you need to know what you're working with. Identifying whether your crankshaft is cast or forged involves a few straightforward inspection techniques:

Look for Casting Lines: Cast crankshafts typically show a visible parting line where the two halves of the mold met. This line runs along the counterweights and is often visible without cleaning. Forged cranks may have a parting line too, but it's usually narrower and cleaner.

Check the Surface Finish: Cast cranks often have a slightly rougher, more porous surface texture on non-machined areas. Forged cranks tend to show smoother, denser surfaces even before final machining.

Research Part Numbers: Factory part numbers typically indicate whether a crank is cast or forged. For Chevrolet engines, casting numbers on the crank can be cross-referenced against known cast and forged applications. Many 4340 bar stock forgings will be clearly marked by aftermarket manufacturers.

Weight Comparison: Forged steel cranks are often slightly heavier than cast iron equivalents of the same stroke due to denser material. If you have access to specifications, comparing actual weight against known values can confirm construction type.

Magnet Test: While not definitive, cast iron cranks respond slightly differently to magnets than forged steel. This method requires experience to interpret correctly but can provide additional confirmation.

When you're building a serious performance engine—whether it's a 300 ford straight six stroker or a big block monster—knowing your starting point helps you plan the appropriate upgrades. A cast crank in an engine destined for 600+ horsepower needs replacement regardless of its current condition. That same cast crank in a mild street build might serve perfectly for years to come.

The intelligent approach matches crankshaft construction to actual power goals and intended use. Cast cranks have their place in the performance spectrum—just make sure that place aligns with your build's requirements before assuming the factory component will survive your ambitions.

Complete Strength Comparison Table and Power Thresholds

Now that we've examined each crankshaft manufacturing method individually, let's put everything side by side. When you're calculating displacement using a cubic inch calculator or figuring out how to calculate cubic inches for your stroker build, the crankshaft you select must match your power goals—not just today's numbers, but where you're heading.

This comprehensive comparison consolidates everything we've covered into actionable guidelines. Whether you're building a mild street cruiser or a dedicated drag car, you'll find clear thresholds for matching crankshaft construction to your specific requirements.

Strength Rankings by Manufacturing Method

The following table ranks crankshaft options from optimal balance of strength and value down to entry-level options with significant limitations. Use this as your starting point, then consider the specific factors discussed for each category:

| Manufacturing Method | Typical Material | Tensile Strength (PSI) | Fatigue Resistance | Recommended Power Range | Typical Cost Range |

|---|---|---|---|---|---|

| Precision Hot-Forged (IATF Certified) | 4340 Steel | 180,000-200,000 | Excellent | 600-1,800 HP | $1,200-$2,500 |

| Premium Billet | 4340/EN40B Steel | 180,000-220,000 | Excellent | 1,500-3,000+ HP | $2,500-$8,000+ |

| Standard Forged 4340 | 4340 Steel | 125,000-180,000 | Very Good | 500-1,500 HP | $800-$1,800 |

| Economy Forged | 5140/4130 Steel | 95,000-125,000 | Good | 400-800 HP | $400-$900 |

| Cast Steel/Iron | Nodular Iron | 60,000-80,000 | Fair | Under 500 HP | $150-$400 |

Notice that precision hot-forged crankshafts occupy the top position—not premium billet. This ranking reflects real-world performance where certified quality control and optimized grain structure deliver exceptional reliability across the widest power range. Billet excels at the extreme top end, but for most serious performance builds, precision forging offers the optimal balance.

Power Thresholds for Each Crankshaft Type

These specific horsepower thresholds represent industry consensus based on decades of racing experience and documented failures. Use them as guidelines, but remember that application type matters as much as peak power numbers:

Under 500 Horsepower: Cast crankshafts remain acceptable for street-driven applications with occasional track use. The factory engineers designed these components for reliability within this power envelope. However, if you're planning future upgrades, investing in forged construction now prevents expensive teardowns later.

500-1,200 Horsepower: Forged crankshafts become the minimum recommendation. According to Engine Labs, aftermarket suppliers typically recommend their cast cranks for use up to 500 horsepower—that threshold exists for good reason. Quality forged 4340 construction handles this power range reliably in street/strip applications.

1,200-1,800 Horsepower: Premium forged crankshafts with certified quality control become necessary. As noted by Callies Performance Products, their premium forged options reliably handle this power range when combined with appropriate rotating assembly components. Economy forgings lack the material quality and process control required for sustained operation at these levels.

Over 1,800 Horsepower: Billet crankshafts become the recommended choice, particularly for applications involving nitrous oxide, aggressive supercharger systems, or sustained high-RPM operation. The ability to verify material quality before machining and achieve custom stroke specifications justifies the premium investment at these power levels.

How Heat Treatment Affects Final Strength

Regardless of manufacturing method, heat treatment processes dramatically influence final crankshaft properties. As industry experts explain, "The key to a cast crank is the heat treating. Castings require a different type of heat treating than a forging." This principle applies across all construction types.

Heat treatment involves three critical steps:

- Quenching: Rapid cooling from high temperature hardens the steel's crystalline structure

- Tempering: Controlled reheating reduces brittleness while maintaining hardness

- Stress Relieving: Final treatment eliminates internal stresses from machining or forging

Some manufacturers add cryogenic treatment—cooling to approximately -300°F immediately after initial heat treatment. This step helps complete the quenching process and increases material density. Quality aftermarket crankshaft companies either maintain in-house heat treatment facilities or partner with nearby specialists where quality control measures can be directly observed.

Tom Lieb of Scat Crankshafts notes that "When we do our own heat treating, we're effectively testing the crankshafts. Because if something is wrong with the metal, the cranks will come back cracked, misshaped or swollen." This built-in quality verification explains why heat treatment should never be outsourced to unknown facilities.

The Billet vs Forged Misconception

Here's a truth that contradicts what many enthusiasts believe: billet is not automatically stronger than forged. This misconception has cost builders money and, in some cases, led to engine failures when they assumed expensive billet construction guaranteed superior results.

As Brook Piper of Callies Performance Products states clearly, "If you have two cranks made from the exact same material—one forged, one billet—the forging will be stronger every time." The forging process compresses and aligns grain structure, creating directional strength that machined billet simply cannot replicate.

Where does billet gain its advantage? Three specific areas:

- Material Selection: Billet manufacturers can use higher-specification alloys like EN40B that aren't practical for forging dies

- Pre-Machining Inspection: Bar stock can be verified for defects before any machining begins

- Design Freedom: Custom strokes and counterweight configurations are possible without expensive die development

However, a poorly machined billet crankshaft with inadequate stress relief can actually exhibit worse fatigue resistance than a properly forged alternative. The machining process itself can create stress risers if not executed correctly, and cutting through grain structure eliminates the directional strength benefits that forging provides.

The practical takeaway? Don't assume billet superiority based on price alone. A precision hot-forged crankshaft from a certified manufacturer often outperforms a budget billet crank from a less rigorous source. Match your selection to actual power requirements, and invest in quality manufacturing regardless of construction method.

Application-Specific Considerations

Peak horsepower numbers tell only part of the story. How you use that power matters equally when selecting crankshaft construction:

Sustained High-RPM Operation: NASCAR engines running 500-mile races at 9,000+ RPM require billet construction not because of peak power, but because of accumulated fatigue cycles. A 900-horsepower NASCAR engine runs billet cranks while a 1,500-horsepower drag engine might use forged—the difference is duration under load.

Instantaneous Torque Spikes: Nitrous oxide and aggressive boost applications create shock loads that differ from naturally aspirated power curves. These sudden forces can exceed material yield strength even when average power levels suggest forged construction would suffice.

Street/Strip Dual Purpose: Engines that see both daily driving and occasional track use benefit from forged construction's fatigue resistance. The repeated thermal cycles and varied loading conditions favor aligned grain structure over machined billet.

Dedicated Competition: Single-purpose race engines can optimize crankshaft selection for specific conditions. A bracket racing small block running consistent 10-second passes has different requirements than a heads-up car making full-power pulls with minimal cooldown between rounds.

Understanding these nuances helps you avoid both overspending on capability you'll never use and under-building components that will fail when pushed to their limits. The strength comparison table provides starting points, but thoughtful application of these principles ensures your crankshaft selection truly matches your build goals.

Understanding Crankshaft Failure Modes and Prevention

Knowing which crankshaft construction method suits your power goals is only half the equation. Understanding how these components actually fail—and recognizing the warning signs before catastrophic destruction—can save your entire engine investment. Whether you're running a forged or billet crankshaft, failure modes differ significantly based on construction method, and catching problems early is your best defense.

Here's the uncomfortable truth: even the strongest crankshaft will eventually fail if subjected to conditions beyond its design limits. According to automotive experts, the extra strain you put on the engine when you constantly floor it from a standstill forces the crankshaft to absorb violent torque spikes it can't sustain forever. Eventually, temperatures rise too high and the bearing load becomes too great. Understanding these failure mechanisms helps you prevent them.

How Crankshafts Fail Under Extreme Loads

Forged and billet crankshafts fail through distinctly different mechanisms—knowledge that can help you identify problems before they become disasters.

Forged Crankshaft Failure Patterns: Forged cranks typically fail through fatigue cracks that originate at stress concentration points. The most common failure initiation sites include:

- Oil Hole Intersections: Where oil passages meet journal surfaces, stress concentrates at the transition. Repeated loading cycles can initiate microscopic cracks that propagate over time.

- Fillet Radii: The curved transitions between journals and throws experience the highest stress concentrations during operation. Inadequate fillet radius or poor surface finish in these areas accelerates crack formation.

- Counterweight Roots: The junction between counterweights and the main body sees significant bending stress, particularly in high-RPM applications.

Because forged cranks have aligned grain structure, cracks typically propagate along predictable paths. This actually provides a slight advantage—fatigue cracks often grow slowly enough to produce warning signs before complete failure. A forged crankshaft might run for dozens of passes or thousands of miles with a developing crack, giving you opportunities to detect the problem.

Billet Crankshaft Failure Patterns: Billet cranks can fail more suddenly and unpredictably when problems exist. Two primary failure modes dominate:

Machining-Induced Stress Risers: When CNC machining cuts through the material's grain structure, any tool marks, sharp internal corners, or surface defects become potential crack initiation points. Unlike forging, where grain flows continuously through stress areas, machined surfaces interrupt grain structure at every cut. If machining quality is poor, these interruptions become failure points under load.

Undetected Material Defects: While billet construction allows pre-machining material inspection, internal defects can still escape detection. Inclusions, voids, or segregated alloy concentrations deep within the bar stock may only reveal themselves when the crankshaft experiences maximum stress—often resulting in sudden, catastrophic failure without warning.

The failure mode also depends heavily on whether your engine experiences sustained high-RPM operation versus instantaneous torque spikes. A 351w firing order engine running consistent RPM in circle track racing accumulates fatigue damage gradually. The 351 windsor firing order creates predictable firing pulses that stress the crankshaft in consistent patterns, allowing fatigue cracks to develop progressively.

In contrast, a nitrous-equipped drag engine experiences massive instantaneous torque spikes that can exceed material yield strength suddenly. The windsor 351 firing order or any firing order for a 351 windsor matters less than the sudden shock loads that can cause immediate failure if the crankshaft was already compromised.

Warning Signs Before Catastrophic Failure

Catching a failing crankshaft before it destroys your engine requires vigilance. These warning signs indicate developing problems that demand immediate attention:

- Unusual Vibrations: New vibrations that weren't present before, particularly at specific RPM ranges, can indicate developing cracks or bearing issues. Pay attention to harmonic frequencies that change character over time.

- Bearing Wear Patterns: During teardowns, inspect main and rod bearings carefully. Uneven wear, scoring, or copper showing through bearing material suggests alignment problems or journal damage that stresses the crankshaft unevenly.

- Oil Analysis Indicators: Regular oil analysis can detect elevated iron, chromium, or bearing material particles before visible damage occurs. Trending these values over time reveals developing problems.

- Unusual Noises: Knocking, rumbling, or rhythmic sounds that correspond to engine speed often indicate bearing clearance issues or journal damage affecting crankshaft loading.

- Harmonic Damper Issues: A failing or improperly matched harmonic damper allows torsional vibrations to damage the crankshaft. Inspect dampers regularly for rubber deterioration or fluid leaks.

- Oil Pressure Fluctuations: Inconsistent oil pressure, particularly at idle or during deceleration, can indicate bearing clearance changes from journal wear or crankshaft flex.

As noted by industry experts, cheap bearings, off-brand bolts, and poorly machined components won't hold tolerances as well, which increases the risk of misalignment, poor oil clearances, and uneven loading on the crank journals. A crankshaft is only as good as the parts supporting it.

Prevention Through Proper Setup

The best crankshaft failure is the one that never happens. Several factors dramatically extend crankshaft life regardless of manufacturing method:

Proper Balancing: A precisely balanced rotating assembly eliminates the vibration-induced stress that accelerates fatigue failure. Professional balancing accounts for pistons, pins, rings, rods, and all rotating mass to achieve the tightest possible balance.

Harmonic Damper Selection: The harmonic damper controls torsional vibrations that would otherwise wind up the crankshaft like a spring with each firing pulse. Matching damper characteristics to your engine's specific harmonic frequencies is critical—the wrong damper can actually amplify harmful vibrations.

Heat Treatment and Surface Finishing: Proper heat treatment maximizes material properties while appropriate surface finishing eliminates stress risers. Fillet rolling—a process that work-hardens the critical fillet radius areas—dramatically improves fatigue life in both forged and billet crankshafts.

Supporting Component Quality: Your crankshaft relies on main bearings, rod bearings, and proper lubrication to survive. Using OEM or highest-quality aftermarket components built to exact specifications ensures your crankshaft rotates smoothly on a true axis, fully supported by its oil film.

When building serious power combinations—whether you're running a holley blue fuel pump to support aggressive fuel demands or researching c6 forum aux fuel pump boost a pump options for your boosted application—remember that fuel system capability means nothing if your rotating assembly fails. The crankshaft must survive the power your fuel system enables.

The advice from experienced builders remains consistent: avoid harsh acceleration, abrupt braking, and unnecessary high RPMs during break-in. These small habits accumulate over time, helping the crankshaft, bearings, and entire bottom end last far longer. Once your engine is properly broken in, match your driving style to your crankshaft's capability—and never assume any component is indestructible.

Final Recommendations for Every Power Level

After examining metallurgy, manufacturing processes, failure modes, and real-world performance data, it's time to cut through the noise and give you definitive guidance. Whether you're building a weekend cruiser with a ford 460 engine or a dedicated drag car pushing four-digit horsepower, matching your crankshaft selection to your actual power goals prevents both overspending and catastrophic failure.

The billet vs forged crankshaft strength debate ultimately comes down to this: what does your specific build actually require? Not what sounds impressive at the car show, but what survives your power goals reliably over time. Let's break it down by application.

Matching Crankshaft Type to Your Build Goals

Your crankshaft selection should follow a logical decision tree based on power level, intended use, and budget priorities. Here are the definitive recommendations ranked by application:

- Builds Under 600 Horsepower: Quality forged 4340 crankshafts provide excellent value and reliability for this power range. Whether you're building a 460 ford engine for street duty or a small block for weekend bracket racing, premium forged construction handles these power levels with significant safety margin. You'll spend $800-$1,800 for a crankshaft that reliably survives your power goals while leaving budget for other rotating assembly components. The grain structure benefits of forging—work hardening and aligned grain flow—deliver fatigue resistance that exceeds what most street/strip builds will ever demand.

- 600-1,500 Horsepower Street/Strip Builds: Premium forged crankshafts with certified quality control become the optimal choice. This is where manufacturing consistency matters enormously—you need verified material quality, proper heat treatment, and documented process controls. Whether you're running a supercharged ford 460 motor combination or a turbocharged import platform, certified forged cranks from reputable manufacturers deliver the strength you need without billet pricing. According to Engine Labs, manufacturers like Callies have demonstrated forged cranks reliably handle 1,200-1,800 horsepower in properly designed applications.

- Dedicated Drag Racing Over 1,500 Horsepower: Consider billet crankshafts when custom stroke requirements, extreme boost pressures, or nitrous applications push beyond forged fatigue limits. If you're shopping for a ford 460 crate engine to build into a serious competition piece or developing a custom stroker combination, billet's design freedom and verified material quality justify the $2,500-$8,000+ investment. The ability to specify exact stroke dimensions, counterweight positioning, and journal sizing becomes practical necessity rather than luxury at these power levels.

- Professional Racing Teams and Volume Builders: Precision hot-forged components with IATF 16949 certification offer the best combination of strength, consistency, and value. When you're building multiple engines or your racing season depends on component reliability, certified manufacturing processes eliminate the variability that plagues standard forgings. Partners like Shaoyi (Ningbo) Metal Technology deliver rapid prototyping in as little as 10 days combined with high-volume production capability—exactly what professional programs require for development and competition.

The Bottom Line on Strength Selection

Here's what experienced engine builders understand that casual enthusiasts often miss: the strength advantage of billet only becomes meaningful above certain power thresholds. As Brook Piper of Callies Performance Products states, "Nine times out of 10, our forging will do the job." That's not underselling billet—it's honest recognition that most builds never approach the limits where billet construction provides tangible benefits.

Consider the math. A premium forged crankshaft costs $1,000-$1,200 less than an equivalent billet option. If your build produces 1,200 horsepower and you're running forged cranks rated to 1,800 horsepower, where does the extra billet investment provide value? It doesn't. That $1,200 buys better connecting rods, higher-quality pistons, or a precision harmonic damper—components that genuinely improve your combination's reliability and performance.

The exception proves the rule. When you're chasing 460 big block power levels that push into the 2,000+ horsepower range, or building engines where the ford 460 firing order rhythm delivers brutal cylinder pressure spikes through forced induction, billet construction becomes the intelligent choice. The verified material quality and design freedom justify the investment because you're actually using that capability.

Most builders are better served by investing in quality forged cranks and supporting components rather than chasing billet specifications they'll never need.

Complete Rotating Assembly Strategy

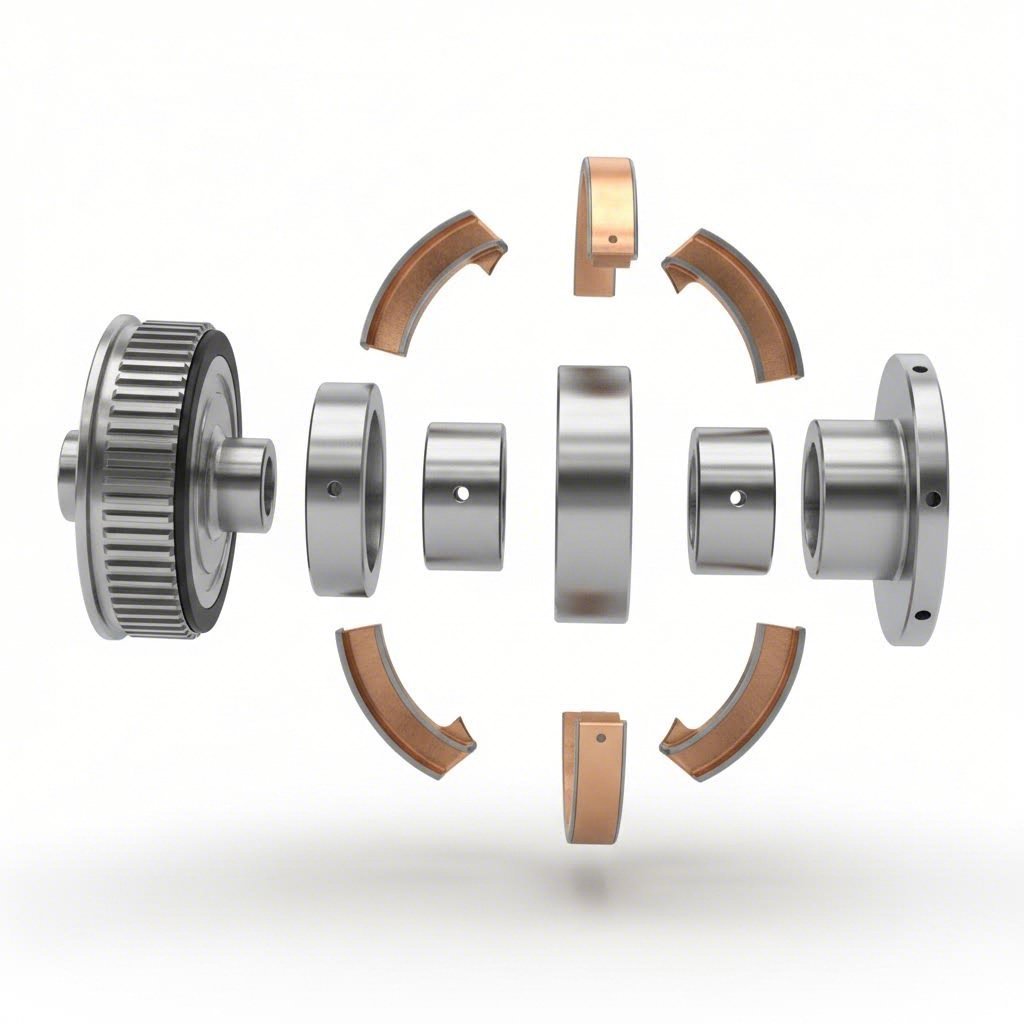

Your crankshaft selection should never happen in isolation. The rotating assembly operates as a system—crankshaft, connecting rods, pistons, bearings, and harmonic damper must work together to survive your power goals. Mismatched components create weak links that defeat the purpose of premium crankshaft investment.

Here's how to think about it strategically:

- Match Rod Strength to Crankshaft Capability: Running a premium forged crankshaft with economy connecting rods creates an unnecessary failure point. Budget for H-beam or quality forged rods that complement your crankshaft choice.

- Piston Selection Affects Crankshaft Loading: Heavier pistons increase reciprocating mass and crankshaft stress. Lighter forged pistons reduce loading but require careful ring package selection. Balance these tradeoffs against your RPM targets.

- Bearing Quality Matters Enormously: Your crankshaft rides on an oil film supported by main and rod bearings. According to Tomorrow's Technician, debris is the number one cause for bearing and crankshaft failures. Premium tri-metal or coated bearings provide the protection serious builds demand.

- Harmonic Damper Selection: The wrong damper can actually amplify harmful vibrations rather than controlling them. Match damper characteristics to your engine's specific harmonic frequencies—especially critical as power levels increase.

For professional engine builders sourcing components for multiple builds or racing teams requiring consistent quality across their programs, partnering with IATF 16949-certified manufacturers streamlines procurement while guaranteeing specifications. In-house engineering support during the design phase optimizes strength-to-weight ratios for your specific application rather than accepting whatever generic forging dies produce.

Your Decision Framework

When you're ready to make your crankshaft selection, work through these questions:

- What is your realistic peak horsepower target—not the number you tell your friends, but the actual power your combination will produce?

- How will the engine be used? Daily driver, weekend warrior, dedicated competition, or professional racing?

- What's your complete rotating assembly budget? Can you afford premium forged with quality supporting components, or would billet pricing force compromises elsewhere?

- Do you need custom stroke specifications, or do standard forging options cover your requirements?

- How important is manufacturing consistency? Single builds tolerate more variability than professional programs requiring identical components across multiple engines.

Answer these honestly, and your crankshaft choice becomes obvious. The billet vs forged crankshaft strength debate resolves itself when you match construction method to actual requirements rather than chasing specifications that sound impressive but provide no real-world benefit.

Whether you're building a mild street engine or a monster drag car, the goal remains the same: assemble a rotating assembly that survives your power goals reliably over time. Choose wisely, invest in quality manufacturing, and your crankshaft will be the last thing you worry about when you mash the throttle.

Frequently Asked Questions About Crankshaft Strength

1. What is the strongest crankshaft?

The strongest crankshaft depends on your application. Premium billet crankshafts machined from EN40B or 4340 steel offer the highest potential strength for extreme applications exceeding 2,000 horsepower. However, quality forged 4340 crankshafts from manufacturers like Callies provide superior fatigue resistance due to aligned grain flow and work-hardened material. For most performance builds under 1,500 horsepower, precision hot-forged crankshafts with IATF 16949 certification deliver optimal strength and reliability. IATF-certified manufacturers like Shaoyi Metal Technology ensure consistent quality through rigorous process controls and verified material specifications.

2. Is billet inherently stronger than forged?

No, billet is not inherently stronger than forged. According to industry experts, if two crankshafts are made from identical material—one forged, one billet—the forging will be stronger due to compressed, aligned grain structure that follows the component's contours. Billet's advantages come from design freedom, pre-machining material inspection, and the ability to use higher-specification alloys. The forging process creates work-hardened steel with directional strength, while machining billet cuts through existing grain structure. Both methods produce exceptional crankshafts when executed properly, but they excel in different power ranges and applications.

3. At what horsepower should I upgrade from a cast to forged crankshaft?

Industry consensus recommends upgrading from cast to forged crankshafts when building beyond 450-500 horsepower. Cast crankshafts have tensile strength around 60,000-80,000 PSI compared to forged at 125,000-200,000 PSI. For power levels between 500-1,200 horsepower, quality forged 4340 steel becomes the minimum recommendation. Above 1,200 horsepower, premium forged with certified quality control is required. Applications exceeding 1,800 horsepower typically warrant billet construction for maximum strength and custom specifications.

4. What causes crankshaft failure in high-performance engines?

Crankshaft failures typically originate from fatigue cracks at stress concentration points including oil hole intersections, fillet radii, and counterweight roots. Forged crankshafts usually fail through progressive fatigue cracking that provides warning signs, while billet cranks can fail suddenly from machining-induced stress risers or undetected material defects. Contributing factors include improper heat treatment, poor bearing quality, mismatched harmonic dampers, and exceeding the crankshaft's rated power capacity. Regular oil analysis, bearing inspections, and attention to unusual vibrations help detect problems before catastrophic failure.

5. How does grain structure affect crankshaft durability?

Grain structure significantly impacts crankshaft fatigue resistance and durability. Forging aligns the metal's crystalline grain flow along the crankshaft's contours, creating directional strength where stress concentrations are highest. This aligned structure resists crack initiation and propagation better than random or interrupted grain patterns. Billet machining cuts through existing linear grain structure, potentially creating stress concentration points at machined surfaces. Cast crankshafts have random grain orientation with unpredictable weak points. Proper heat treatment further enhances grain structure benefits regardless of manufacturing method.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —