Automotive Stamping Production Cycle Time: Cold vs Hot Benchmarks

TL;DR

Automotive stamping production cycle times are primarily dictated by the forming method: Cold Stamping is the industry standard for high-volume speed, typically achieving 20–60 Strokes Per Minute (SPM), or approximately 1–3 seconds per part. In contrast, Hot Stamping (Press Hardening) is significantly slower due to the required in-die quenching time, averaging 10–30 seconds per cycle but delivering superior tensile strength for safety components.

For manufacturers, the benchmark for efficiency is often measured against leaders like Toyota, where individual stamping steps are completed in as little as 3 seconds. While cold stamping offers rapid throughput for body panels and structural parts, hot stamping remains essential for critical pillars and reinforcements despite the time penalty. Optimizing these cycles requires advanced servo press technology and automated transfer systems to minimize non-value-added handling time.

Cold Stamping Cycle Times: The High-Volume Standard

Cold stamping remains the backbone of automotive mass production, prized for its ability to produce parts at room temperature with exceptional speed. In this process, coils of steel or aluminum are fed into mechanical or servo presses where they are cut, shaped, and pierced in rapid succession. Because there is no thermal bottleneck (waiting for materials to heat or cool), the cycle time is limited only by the mechanics of the press and the material feeding speed.

The industry benchmark for cold stamping efficiency is often cited from Toyota's production lines. In their standard four-step stamping process (drawing, trimming, bending, and piercing), each step takes approximately 3 seconds to complete. Modern high-speed tandem lines and transfer presses can push this even further. For example, the press shop at Toyota Motor Manufacturing France runs its lines at roughly 25 strokes per minute (SPM) for single parts, translating to a cycle time of just 2.4 seconds per stroke. When running dual parts (two parts per stroke), the output effectively doubles, demonstrating the massive throughput capability of cold forming.

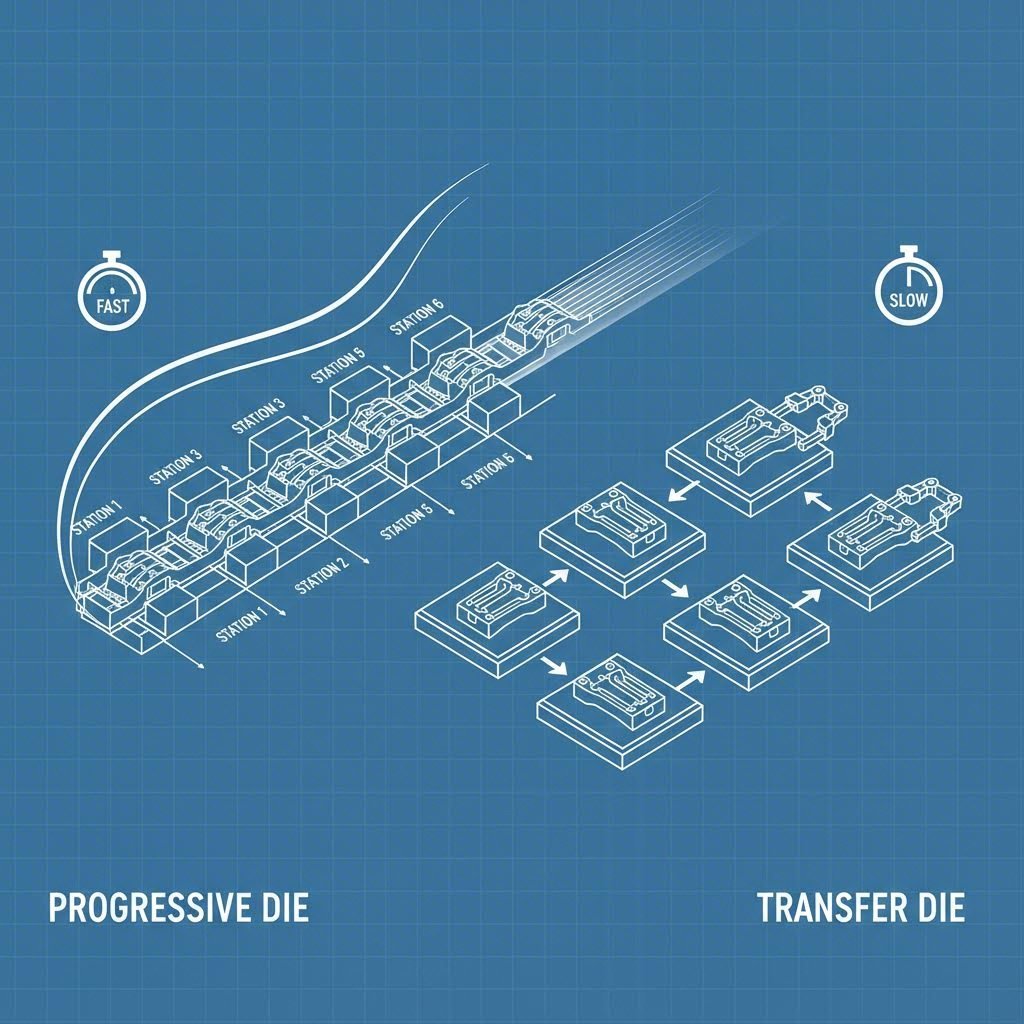

Progressive Die vs. Transfer Die Speeds

Within cold stamping, the tooling strategy significantly impacts cycle time:

- Progressive Die Stamping: This is the fastest method, ideal for smaller, complex parts like brackets and fasteners. The metal strip feeds continuously through a single die with multiple stations. Speeds can easily exceed 60–80 SPM because the part remains attached to the carrier strip, allowing for rapid, precise movement without complex transfer arms.

- Transfer Die Stamping: Used for larger body panels and structural components that must be free from the strip to be formed. Mechanical transfer fingers move the part between stations. While slower than progressive stamping, modern servo-driven transfers have improved speeds to the 15–30 SPM range, balancing size capability with production velocity.

The table below outlines the typical performance metrics for cold stamping technologies:

| Parameter | Progressive Die | Transfer Die | Tandem Line |

|---|---|---|---|

| Typical Speed | 40–80+ SPM | 15–30 SPM | 10–18 SPM |

| Cycle Time / Part | 0.75–1.5 seconds | 2–4 seconds | 3–6 seconds |

| Primary Application | Brackets, Connectors, Small Rails | Cross Members, Pillars, Structures | Large Skin Panels (Hoods, Doors) |

| Key Advantage | Maximum Speed | Geometry Flexibility | Surface Quality Control |

Hot Stamping Cycle Times: The High-Strength Trade-off

Hot stamping, or press hardening, operates on a fundamentally different timeline. This process involves heating boron steel blanks to approximately 900°C (1,650°F) in a furnace before transferring them to a cooled die. The defining characteristic of this cycle is not the forming speed, but the dwell time required for quenching. The part must be held in the closed die under pressure while it cools rapidly to transform the microstructure into martensite, achieving tensile strengths up to 1,500 MPa.

This quenching phase creates a significant bottleneck. A typical hot stamping cycle runs between 10 and 30 seconds, which is 5 to 10 times slower than cold stamping. The breakdown of a standard hot stamping cycle typically looks like this:

- Transfer (Furnace to Press): < 3 seconds (Critical to prevent premature cooling)

- Forming: 1–2 seconds

- Quenching (Dwell): 5–15 seconds (The primary time cost)

- Part Ejection & Removal: 2–4 seconds

To mitigate this slowness, manufacturers often employ multi-cavity dies (stamping 2, 4, or even 8 parts at once) to increase the effective parts per minute, even if the cycle time per stroke remains long. Recent advancements in cooling channel design and tool steels with high thermal conductivity are slowly pushing these times down, with some advanced lines claiming cycles approaching 8–10 seconds, though this is not yet the widespread standard.

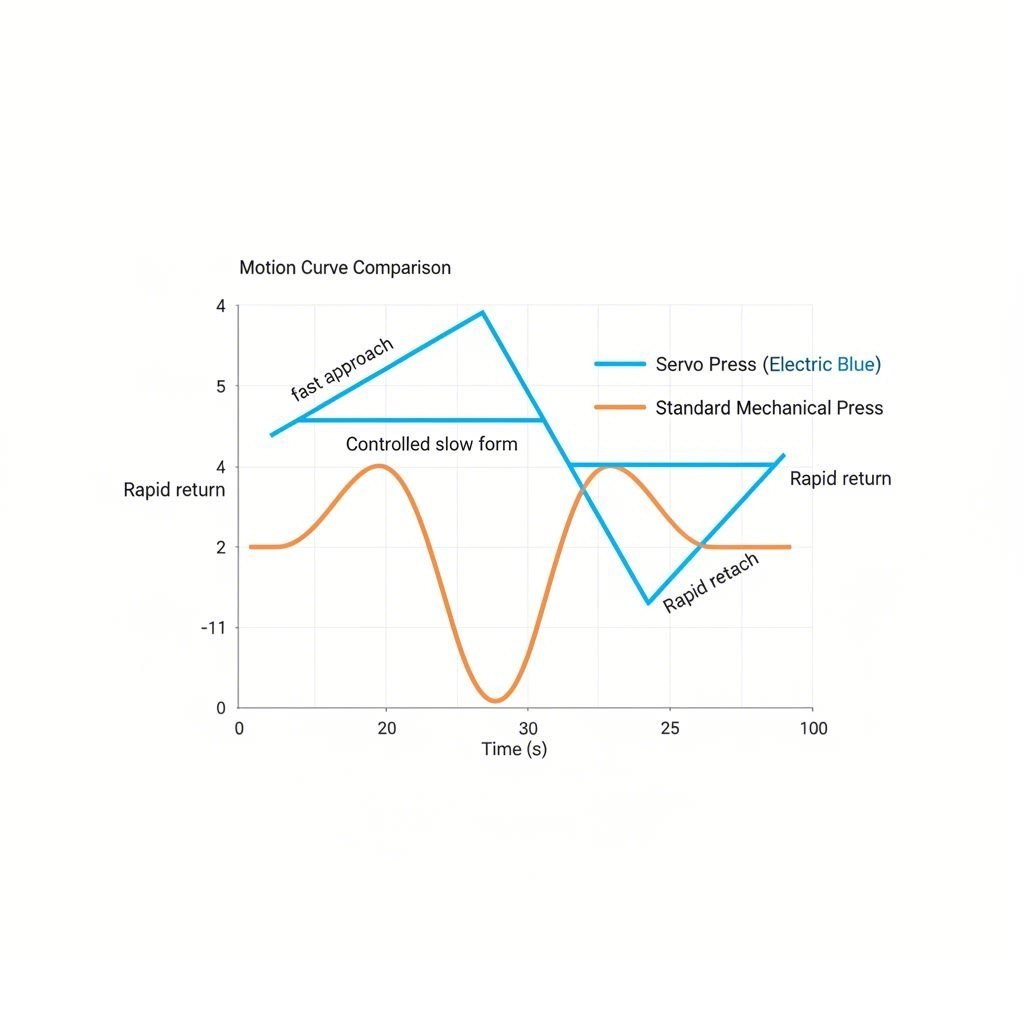

Critical Factors Influencing Production Speed

Beyond the fundamental physics of hot vs. cold forming, several technological factors play a pivotal role in shaving seconds off the production clock. The shift from mechanical to servo press technology has been a game-changer. Unlike a mechanical flywheel that runs at a constant velocity, a servo press features a programmable slide motion. Engineers can program the press to slow down only during the critical forming moment and accelerate rapidly during the non-working portion of the stroke (approach and return). This optimization can reduce cycle time by 30–60% compared to traditional mechanical presses.

Automation and Changeover Efficiency are equally critical. In high-mix production environments, the "cycle time" isn't just about stroke speed; it's about availability. Modern stamping lines, such as those used for the Toyota Yaris, utilize automated die change systems and servo-driven grippers that can switch production from one part to another in under 180 seconds. This Single Minute Exchange of Die (SMED) capability ensures that the press spends more time making parts and less time sitting idle.

However, achieving these optimized cycle times requires a partner who understands the entire manufacturing spectrum. Shaoyi Metal Technology specializes in bridging the gap between rapid prototyping and mass production. By leveraging press capabilities up to 600 tons and IATF 16949-certified precision, they help automotive clients validate designs quickly with prototypes before scaling to high-volume manufacturing. This integrated approach allows engineers to identify cycle-time bottlenecks early in the design phase, ensuring that components like control arms and subframes are optimized for speed and quality before full-scale production begins.

Cycle Time vs. Lead Time vs. Takt Time

In the context of automotive manufacturing, "time" can mean different things to different stakeholders. Confusion between these terms often leads to misaligned expectations between engineering and procurement teams. It is essential to distinguish Cycle Time from other temporal metrics.

- Cycle Time (The Machine Pace): This is the time it takes to complete one operation on one unit. In stamping, if a press runs at 20 SPM, the cycle time is 3 seconds. This metric is the primary concern of plant managers and process engineers focused on immediate line efficiency.

- Lead Time (The Customer Wait): This represents the total time from order placement to delivery. For a new stamping project, lead time includes tooling design, die fabrication, and testing, which typically spans 8–14 weeks for progressive dies. Even for existing parts, lead time includes raw material scheduling and logistics, measured in days or weeks, not seconds.

- Takt Time (The Demand Pulse): Takt time is calculated by dividing available production time by customer demand. If a customer needs 1,000 parts per day and the plant operates for 1,000 minutes, the takt time is 1 minute. Cycle time must always be faster than takt time to avoid shortages.

- Vehicle Throughput Time: This is the total time to assemble a complete car. For context, while stamping a door panel takes only seconds, the total production time for a vehicle like the Toyota Yaris is approximately 15 hours, with painting often accounting for half of that duration.

Conclusion

Understanding automotive stamping production cycle time requires looking beyond the stopwatch and analyzing the process requirements. While cold stamping offers the blistering speed of 20–60 SPM necessary for high-volume outer panels, hot stamping accepts a slower 10–30 second cycle to deliver the life-saving strength required for safety cages. The choice is rarely about speed alone, but about the balance of material properties, geometry, and volume.

For automotive engineers, the path to optimization lies in leveraging technologies like servo presses and automated transfer systems to minimize non-value-added time. By clearly defining the distinctions between cycle time and lead time, and selecting the appropriate stamping method for the application, manufacturers can achieve the synchronized efficiency that defines modern automotive production.

Frequently Asked Questions

1. How long does the entire stamping process take for a car body?

While individual parts are stamped in seconds (typically 1–3 seconds per step), a complete car body consists of hundreds of stamped parts. A modern press shop produces these parts in batches. The actual time a specific sheet of metal spends in the press line is very short—often less than 15 seconds for a complete 4-step tandem line process—but the logistical coordination to stamp all necessary parts for a vehicle usually spans several shifts or days of inventory buildup.

2. What are the typical steps in an automotive stamping cycle?

A standard automotive stamping line typically involves four distinct steps: Drawing (forming the initial 3D shape), Trimming (cutting away excess metal), Bending/Flanging (creating precise edges and stiffness), and Piercing/Restriking (punching holes and refining final geometry). In a tandem line, these happen in separate presses; in a transfer or progressive die, they occur sequentially within a single press system.

3. Why is hot stamping so much slower than cold stamping?

Hot stamping requires the metal to be heated to ~900°C and then cooled (quenched) while held inside the die to lock in the martensitic steel structure. This cooling phase, or "dwell time," typically lasts 5–15 seconds, during which the press cannot open. Cold stamping does not require this thermal waiting period, allowing the press to cycle continuously as fast as the mechanism allows.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —