Why Forging is Essential for Automotive Chassis Parts

Why Forging is Essential for Automotive Chassis Parts

TL;DR

Automotive chassis parts forging is a manufacturing process that shapes metal under extreme pressure to create exceptionally strong and reliable components. This method is vital for producing critical parts like control arms, axles, and steering knuckles, ensuring superior vehicle safety, durability, and performance compared to other manufacturing techniques like casting or machining.

The Critical Role of Forging for Automotive Chassis Integrity

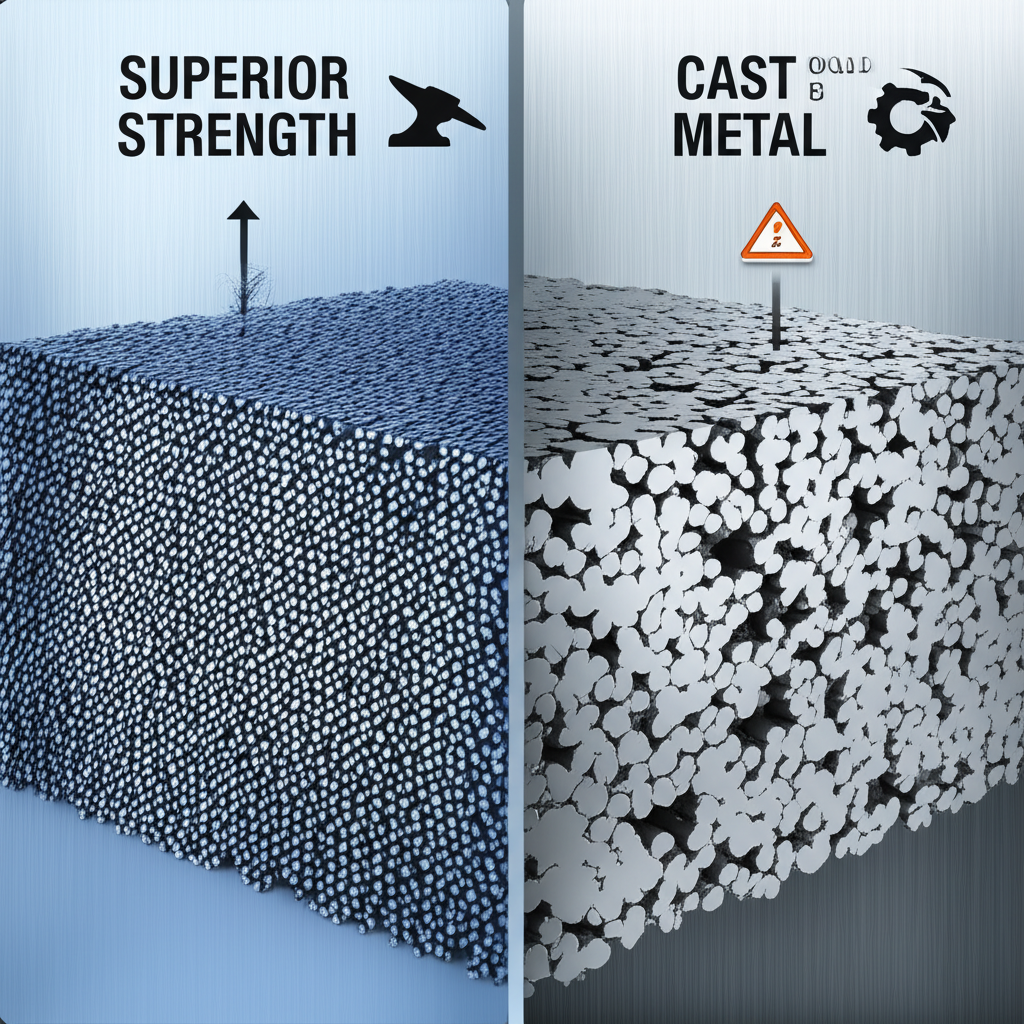

In automotive engineering, the choice of manufacturing process is paramount, especially for chassis components that are subjected to immense stress and vibration. Forging stands out as the superior method for these critical parts. Unlike casting, which involves pouring molten metal into a mold, forging mechanically works the metal, refining its grain structure and eliminating internal defects like porosity. This results in components with significantly enhanced strength, toughness, and fatigue resistance.

One of the primary advantages of forging is the creation of a continuous grain flow that follows the contour of the part. This alignment makes the component exceptionally strong and resilient, capable of withstanding the demanding conditions of daily vehicle operation. Forged chassis parts, such as control arms and tie rods, provide the structural integrity necessary for vehicle stability and handling, directly contributing to driver safety. The denser material structure achieved through forging ensures these parts are less likely to crack or fail under pressure.

Furthermore, forging offers a superior strength-to-weight ratio. As manufacturers strive to improve fuel efficiency and vehicle performance, reducing weight without compromising strength is a key objective. High-precision drop forging allows for the design of lightweight yet robust components. This optimization is crucial for parts like suspension systems and wheel hubs, where reduced unsprung mass can significantly improve handling and ride quality.

Ultimately, the reliability and longevity of a vehicle depend heavily on the quality of its foundational components. Forged chassis parts offer improved durability and wear resistance over their cast or machined counterparts. This means a longer service life, fewer maintenance issues, and a safer vehicle over its entire lifespan. The precision and consistency inherent in the forging process also ensure that every part meets exact specifications, which is critical for the seamless assembly and proper functioning of the entire vehicle system.

Key Materials and Forging Processes for Chassis Parts

The performance of a forged automotive component is determined by both the material selected and the specific forging process used. Manufacturers choose these based on the part's required strength, weight, corrosion resistance, and cost-effectiveness.

Common Forging Materials

Several metals are prevalent in automotive forging, each offering distinct advantages. Steel and its alloys are the most common choice due to their exceptional strength, high tensile strength, and widespread availability. Carbon and alloy steels are used for over 250 different forged parts in vehicles, including high-stress components like crankshafts and gears. For applications requiring corrosion resistance, stainless steel is often employed. In recent years, aluminum has gained significant popularity as manufacturers prioritize lightweighting to enhance fuel efficiency. Aluminum is not only lighter but also offers excellent strength, design flexibility, and natural corrosion resistance.

Primary Forging Processes

The automotive industry utilizes several forging techniques to produce a wide array of chassis parts. The main types include:

- Impression Die Forging (Closed-Die Forging): This is one of the most common methods for automotive parts. The workpiece is placed between two dies that contain a precise impression of the final shape. As the dies press together, the metal is forced to fill the cavity, creating a strong, near-net-shape part with excellent dimensional accuracy. This process is ideal for complex geometries and high-volume production of parts like connecting rods and steering components.

- Open-Die Forging: In this process, the metal is shaped between two flat or simple dies that do not fully enclose the workpiece. It relies on the skill of the operator to manipulate the workpiece to achieve the desired shape. While less precise than closed-die forging, it is highly flexible and suitable for larger components or smaller production runs.

- Roll Forging: This process uses opposing rollers to shape a heated metal bar or billet. The rollers have grooves that progressively shape the metal as it passes through. Roll forging is an efficient way to reduce the cross-section of a workpiece and pre-form it for subsequent forging operations, often used for parts like axles and shafts.

- Cold Forging: Performed at or near room temperature, cold forging improves the metal's strength through work hardening. This process offers excellent dimensional accuracy and surface finish, often eliminating the need for secondary machining. It is typically used for smaller, simpler parts that require high precision.

Essential Forged Components in a Modern Vehicle Chassis

A vehicle's chassis and powertrain rely on numerous forged components to ensure safety, performance, and durability under extreme conditions. The superior strength and reliability of forging make it the ideal manufacturing method for the following critical parts:

- Connecting Rods and Crankshafts: As core engine components, connecting rods and crankshafts are subjected to immense mechanical stress, high pressure, and heat. Forging ensures they can withstand these forces without failure, which is essential for engine performance and longevity.

- Axles and Shafts: Part of the drivetrain, axles must transmit torque from the engine to the wheels. Forging provides the necessary torsional strength and fatigue resistance to handle the constant stress of acceleration and deceleration.

- Control Arms and Steering Knuckles: These are vital suspension and steering components that connect the wheel assembly to the vehicle's frame. Forged control arms and knuckles offer the high strength needed to manage road impacts and maintain vehicle stability and precise handling.

- Tie Rod Ends and Ball Joints: Critical for steering accuracy and suspension movement, these parts must be incredibly durable. Forging provides the wear resistance and strength required to ensure reliable operation and prevent premature failure, which could lead to a loss of vehicle control.

- Gears and Transmission Parts: Transmission components must endure constant friction and high loads. The forging process creates dense, tough gears and shafts that can withstand these conditions, ensuring smooth and reliable power transfer.

- Wheel Hubs and Spindles: These parts support the vehicle's weight and are critical for wheel assembly. Forging provides the strength and impact resistance necessary to handle heavy loads and harsh road conditions safely.

How to Select a High-Precision Automotive Forging Partner

Choosing the right forging supplier is a critical decision for any automotive manufacturer. A reliable partner not only delivers high-quality components but also contributes to the efficiency of your supply chain. When evaluating potential suppliers, consider the following key factors to ensure you select a partner capable of meeting the stringent demands of the automotive industry.

- Industry Certifications: The most important credential to look for is the IATF 16949 certification. This is the international quality management standard specifically for the automotive sector. A certified supplier, like the one mentioned by Carbo Forge, demonstrates a commitment to quality, process control, and continuous improvement. This certification ensures that the supplier's processes are designed to meet the rigorous safety and quality requirements of the industry.

- Material and Process Expertise: A capable partner should have deep expertise in working with a variety of materials, including different grades of carbon, alloy, and stainless steel, as well as aluminum. They should also be able to recommend the most suitable material and forging process (e.g., closed-die, roll forging) for your specific application to optimize for strength, weight, and cost.

- In-House Capabilities: Look for a supplier with comprehensive in-house capabilities, including tool and die manufacturing, secondary machining, and quality testing. A vertically integrated partner can better control the entire production process, leading to faster lead times, consistent quality, and greater efficiency.

- Quality Control and Testing: Rigorous quality assurance is non-negotiable. Ensure the supplier has robust inspection protocols at every stage of production, from raw material certification to final dimensional and mechanical property testing. This guarantees that every component meets your precise specifications and industry standards.

- Customization and Prototyping: The ability to provide custom solutions is crucial. A good partner will work closely with your engineering team to design and produce components tailored to your exact needs. For instance, suppliers like Shaoyi Metal Technology specialize in IATF 16949 certified hot forging and offer comprehensive services from rapid prototyping for small batches to full-scale mass production, demonstrating the kind of end-to-end capability that is valuable in a partner.

Frequently Asked Questions

1. What are the 4 types of forging processes?

The four primary types of forging processes are impression die forging (also known as closed-die forging), open-die forging, roll forging, and cold forging. Each method is suited for different types of components, production volumes, and precision requirements in the automotive industry.

2. What metal is used to make car chassis?

Car chassis and their components are primarily made from high-strength steel and its alloys due to their excellent durability, fatigue resistance, and cost-effectiveness. Aluminum alloys are also increasingly used for chassis parts where weight reduction is a key priority for improving fuel efficiency and vehicle performance.

3. What engine parts should be forged?

Engine parts that endure the highest levels of stress, pressure, and temperature should be forged. This includes critical components like crankshafts, connecting rods, and pistons. Forging provides these parts with the superior strength and durability needed to withstand the demanding environment inside a high-performance engine.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —