Al 6061 Density To Weight: Fast Formulas For Plates, Bars, Tube

Understanding the Basics of Al 6061 Density for Accurate Weight Calculations

What is al 6061 density?

When you start a new design project or need to estimate the weight of a component, understanding the density of 6061 aluminum is key. But what does "al 6061 density" actually mean? In simple terms, it’s the mass per unit volume of the alloy—how much a given block of 6061 weighs for its size. This value is fundamental to everything from early-stage sizing to final cost rollups. The density of 6061 aluminum is not just a number pulled from thin air; it’s a carefully measured physical property, often reported by trusted organizations like the Aluminum Association, ASM International, and MatWeb.

For example, the ASM/MatWeb datasheet for 6061-T6 aluminum lists its density as exactly 2.70 g/cm³ or 0.0975 lb/in³. These values are widely accepted as the nominal benchmarks for the alloy and are used in everything from bill of materials (BOM) calculations to strength-to-weight assessments and supplier quotes. Quoting these numbers verbatim, rather than rounding or estimating, ensures accuracy and consistency across your engineering documentation.

Nominal versus measured values

Sounds simple, right? But in practice, you’ll notice that real-world parts might not match the nominal density exactly. Why? The actual "mass density of aluminum" in a finished 6061 part can shift slightly due to manufacturing variations, trace alloying elements, and even tiny air pockets (porosity) inside the metal. That’s why standards organizations specify a nominal value: it’s a reliable baseline for calculations, but not an ironclad guarantee for every batch or supplier.

Key takeaway: The published nominal density of al 6061 is a dependable starting point for design and estimation, but real-world values can vary due to alloying tolerances and internal porosity.

Units engineers actually use

Ever wondered why datasheets show density in so many units? It’s all about context. In the U.S., you’ll often see "density of aluminium in lb in3" or "lb/ft³"—these are convenient for quick weight calculations in imperial units. Elsewhere, metric units like "g/cm³" or "kg/m³" are standard. No matter the unit, the underlying physical meaning is the same. For reference, the most common units you’ll encounter for aluminum density are:

- g/cm³ (grams per cubic centimeter)

- kg/m³ (kilograms per cubic meter)

- lb/ft³ (pounds per cubic foot)

- lb/in³ (pounds per cubic inch)

This unit flexibility is why experienced engineers always double-check which system is being used, especially when comparing international supplier quotes or plugging numbers into finite element analysis (FEA) tools.

Glossary: Key terms at a glance

- Density: The mass per unit volume of a material.

- Specific gravity of aluminium: The ratio of aluminum’s density to that of water at a reference temperature. It’s a dimensionless way to compare materials.

- Mass vs weight: Mass measures the amount of material; weight is mass under gravity. In engineering, we often use "weight" for convenience, but calculations start with mass.

How do designers use al 6061 density?

- Estimate part weight in early-stage sizing and layout

- Calculate material cost for BOM and quoting

- Assess strength-to-weight ratios for structural components

- Input baseline values for FEA pre-checks and simulations

- Communicate expectations with suppliers and QA teams

Whenever you cite a "density of aluminum" value, best practice is to cross-verify with at least two trusted sources—such as ASM/MatWeb and the Aluminum Association—to ensure you’re using the correct nominal figure for your specific alloy and temper.

Curious about "what is density of aluminium" or how the "mass density of aluminum" impacts your application? Getting these basics right is the first step to accurate, reliable weight and cost calculations throughout your project.

Measurement Methods and Real World Variability for 6061 Aluminum Density

How density is measured in practice

When you’re tasked with determining the actual density of a 6061 aluminum part, you’ll find there’s more to it than just plugging in a number from a datasheet. So, how do labs and engineers measure the density of al 6061-t6 and similar alloys? The most common methods are designed to be precise but can yield slightly different results depending on the process and sample condition.

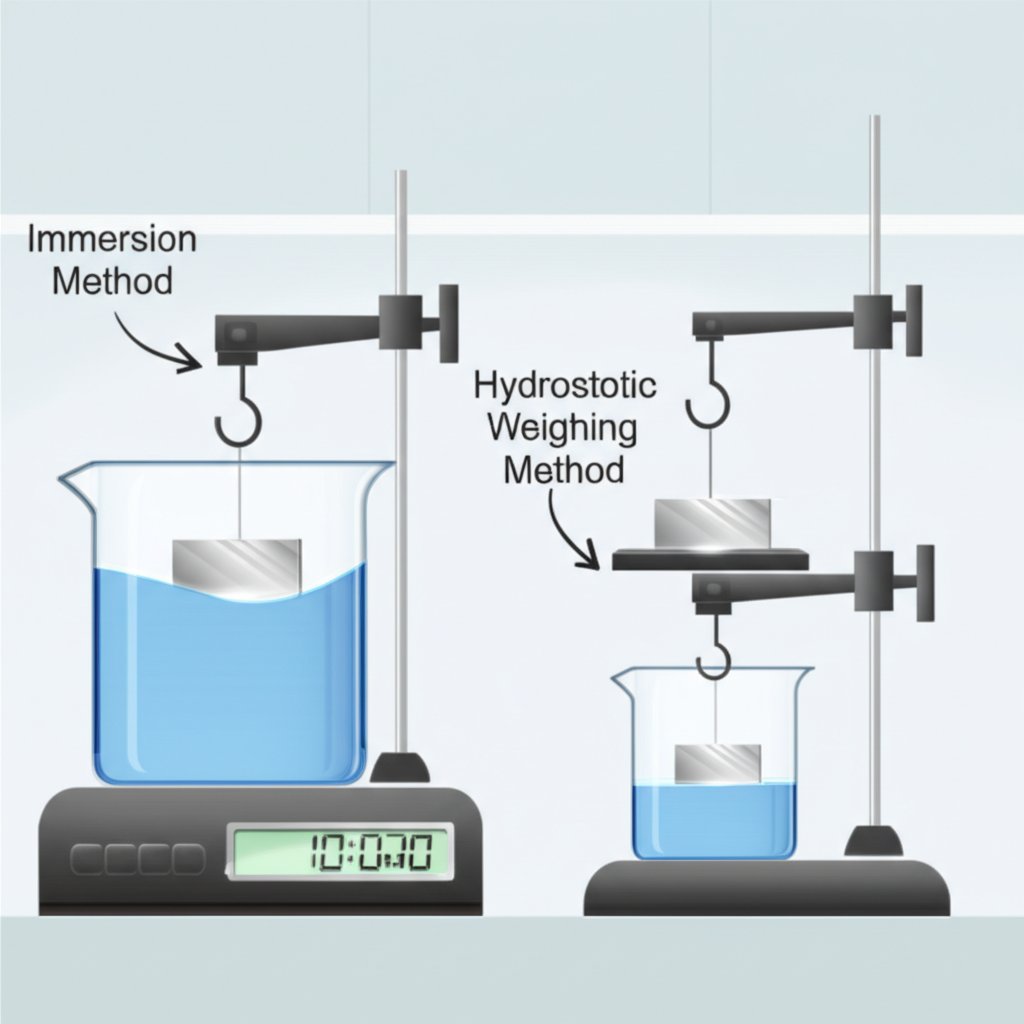

- Archimedes’ Immersion: Submerge the aluminum sample in water and measure the displaced volume. Divide the mass of the sample by the displaced water volume to get density. This classic method is widely used for solid shapes and is straightforward for most engineering labs.

- Hydrostatic Weighing: Weigh the sample in air, then weigh it while fully submerged in water. The difference between these weights gives the buoyant force, which corresponds to the volume of the sample. Dividing the mass by this volume yields the density, which is especially useful for irregular shapes.

- Helium or Nitrogen Pycnometry: For powders or very precise requirements, a pycnometer is used. The mass is measured, and the volume is determined by gas displacement. This high-precision method is favored in industries where the smallest deviations matter.

- X-ray Crystallography: Used in research, this method analyzes atomic structure and calculates density based on unit cell volume. While accurate, it’s more common in academic or advanced R&D settings.

For all these methods, accuracy depends on careful measurement and sample preparation. Even a small error in weighing or volume estimation can shift your results, so repeated trials and calibration against standards are best practice.

Sources of variability you should expect

Sounds complex? It can be, especially when you realize that the density of 6061 aluminum isn’t always exactly what’s published. Here’s why:

- Manufacturing route: Extruded, rolled, or cast forms can have different microstructures, introducing tiny density variations.

- Heat treatment: Tempers like T6 (as in "6061-t6 density") involve solution heat treating and artificial aging, which can change the distribution of alloying elements and cause slight shifts in density.

- Porosity and inclusions: Small air pockets or non-metallic inclusions reduce the real density compared to the nominal value.

- Alloying tolerances: The exact mix of magnesium, silicon, and other elements allowed by standards can nudge density up or down by a fraction of a percent.

- Measurement temperature: Density changes with temperature due to thermal expansion, so readings at different temperatures may not match.

For example, the density of 6061-t6 aluminum is typically cited as 2.70 g/cm³, but slight deviations are normal and expected at the mill or batch level. You’ll also see values reported as "density of 6061 aluminum lb/in3" on imperial datasheets—again, these are subject to minor real-world variation.

Documentation and tolerances

When it comes to engineering documentation, you can’t just jot down a single number and call it a day. For traceability and quality assurance, it’s important to record not only the measured density, but also the conditions and methods used. Here’s a practical checklist for your materials dossier:

| What to Log |

|---|

| Alloy designation (e.g., 6061-T6) |

| Temper or heat treatment (e.g., T6, T651) |

| Source mill or supplier |

| Product form (plate, bar, extrusion, etc.) |

| Measurement method (Archimedes, hydrostatic, pycnometry) |

| Measurement temperature |

| Calibration reference or standard used |

Industry standards, such as ASTM B209 for aluminum alloys, may specify acceptable density tolerances. For critical applications—think aerospace or precise mass-balance calculations—it’s best to use supplier-certified density values, not just nominal figures from datasheets.

For routine cost or weight rollups, using the nominal density of 6061 is fine. But for critical mass-balance or aerospace applications, always rely on supplier-certified density and document your methods.

Next, we’ll look at how to convert between different units of density, and why careful conversion matters for your engineering calculations.

Unit Conversions Made Simple for Engineers

Quick conversions engineers rely on

Ever found yourself staring at a datasheet and wondering how to go from “g/cm³” to “lb/in³” or “kg/m³”? You’re not alone. When specifying aluminum 6061 for a project, you’ll almost always need to convert between metric and imperial units. This isn’t just a paperwork exercise—using the right density value in the right unit can make or break your weight calculations.

The nominal density of 6061 aluminum is most often cited as 2.70 g/cm³ or 0.0975 lb/in³. But what if your supplier quotes “aluminum density in lb/in³,” and your CAD software expects “kg/m³”? That’s where fast, reliable conversions come in. Let’s break down the most common conversions for aluminum density:

| From | To | Conversion Factor | Example (Al 6061) |

|---|---|---|---|

| g/cm³ | kg/m³ | × 1,000 | 2.70 g/cm³ → 2,700 kg/m³ |

| g/cm³ | lb/in³ | × 0.036127 | 2.70 g/cm³ → 0.0975 lb/in³ |

| lb/in³ | g/cm³ | × 27.68 | 0.0975 lb/in³ → 2.70 g/cm³ |

| lb/in³ | lb/ft³ | × 1,728 | 0.0975 lb/in³ → 168.48 lb/ft³ |

| kg/m³ | g/cm³ | ÷ 1,000 | 2,700 kg/m³ → 2.70 g/cm³ |

| lb/ft³ | kg/m³ | × 16.0185 | 168.48 lb/ft³ → 2699.2 kg/m³ |

These factors are sourced from NIST and industry datasheets, ensuring you’re working with authoritative numbers every time.

Worked example using a published value

Let’s walk through a real-world scenario. Imagine you need to confirm the density of aluminum 6061 in multiple units for a global project team:

- Select a published value: The ASM/MatWeb entry for 6061-T6 aluminum gives 2.70 g/cm³ and 0.0975 lb/in³ as the standard values.

-

Convert to lb/ft³: Multiply by 1,728 (since 1 ft³ = 1,728 in³):

0.0975 lb/in³ × 1,728 = 168.48 lb/ft³ (rounded to two decimal places). -

Convert to kg/m³: Multiply by 1,000:

2.70 g/cm³ × 1,000 = 2,700 kg/m³. - Check against reference: Cross-reference your results with industry sources. Both ASM/MatWeb and conversion guides agree on these values.

This workflow ensures you’re using the right figure—whether your supplier provides “aluminium density lb in3,” your simulation calls for “density of aluminum kg/m3,” or your documentation needs “density of aluminum lb/ft3.”

Avoiding rounding errors

Sounds easy, but here’s the catch: small rounding errors can creep in with every step, especially when converting back and forth between unit systems. If you’re calculating the weight of a complex part, even a tiny error in the density value can lead to significant discrepancies in final mass or cost estimates.

For critical calculations, always use double-precision in your spreadsheets or CAD software—and reference the original published density to minimize cumulative rounding errors.

Many engineering teams create a shared calculator or spreadsheet using these exact conversion factors. If you want to streamline your process, consider setting one up for your team—or look for downloadable calculators from trusted industry sources.

Mastering these conversions means you’ll never be caught off guard by a unit mismatch again. Next, we’ll explore how density knowledge translates into practical design guidance for estimating weight, machining allowances, and supplier communication.

Practical Design Guidance Using Density

Early stage weight estimation rules

When you’re in the early phases of a new design—maybe sketching out a frame, enclosure, or bracket—how do you quickly estimate the weight of aluminum components? The answer starts with the nominal aluminum 6061 density value. For most engineering purposes, this is 2.70 g/cm³ (or 0.0975 lb/in³), which lets you convert volume to mass in seconds.

- Use nominal density for first-pass weight rollups: Multiply the calculated volume of each part by the standard density. This gives you a fast estimate for the total weight of aluminum per cubic inch or per foot, perfect for bill of materials (BOM) cost projections and early structural checks.

- Factor in machining allowances: If your part will be milled, drilled, or turned, remember that material will be removed. Add a machining allowance—typically a percentage based on experience or past jobs—to account for chips and swarf. This helps avoid underestimating actual aluminum weights in finished assemblies.

- Update as you refine: As the design matures, replace assumptions with measured weights from prototypes or supplier data. This is especially important for parts with complex geometry or tight tolerances.

Machining, coatings, and finish impacts

Sounds straightforward, but what about the real-world impacts of machining, anodizing, or other finishes? Each process can subtly affect both the weight and the dimensions of your aluminum parts.

- Machining: Material removal through milling or turning reduces weight. The actual amount depends on the design and machining strategy. To avoid surprises, use CAD/CAM simulation or supplier input to estimate the final weight of aluminum after machining.

- Coatings and anodize: Surface treatments like anodizing add a thin oxide layer, which can slightly increase weight and change dimensions. However, unless a standard or supplier provides a quantified value, the added mass is usually minimal compared to the base aluminum. For critical applications, consult the Aluminum Association or ASTM finishing standards for authoritative guidance.

- Finishing operations: Deburring, polishing, or coating may remove or add tiny amounts of material. Always check with your supplier or reference standards if you need to account for these effects in high-precision work.

Imagine you’re designing a lightweight enclosure and want to keep shipping costs low. Factoring in machining and finish allowances ensures your initial estimate matches reality, especially when calculating aluminum weight per cubic foot for logistics or cost analysis.

Documentation for suppliers and QA

Accurate documentation is your bridge between design intent and final product quality. Here’s how to make sure your weight estimates and density assumptions hold up through procurement and quality assurance:

- Specify the density source: Clearly state the reference value and source (e.g., ASM/MatWeb, Aluminum Association) in your drawings and BOMs.

- Log machining and finish allowances: Document any extra material or expected removal for each part family.

- Track and update tolerances: After first-article inspection, refine your weight models with measured data. This helps suppliers quote accurately and QA teams verify compliance.

- Communicate with suppliers: Share your density and weight calculations up front, and request confirmation or adjustments based on their process knowledge or test results. This is especially wise when tracking aluminum alloy 6061 price per pound for cost control.

Refine your weight estimates from nominal to measured as the design matures—early accuracy pays off in cost, performance, and quality.

By applying these practical rules, you’ll minimize surprises and keep your project on track. Next, we’ll show you how to use these density values to calculate the weight of common 6061 shapes—from sheet and plate to bar and tube—so you can move from theory to hands-on engineering with confidence.

Weight Calculations for Common 6061 Shapes

Formulas for Sheet, Plate, Bar, and Tube

When you’re ready to turn density numbers into actionable weight estimates, the right formula makes all the difference. Sounds complex? It’s actually straightforward—especially when you break it down by shape and use the published density of aluminum 6061. For most engineering work, the nominal value is 2.70 g/cm³ or 2,700 kg/m³, which is consistent with ASM/MatWeb and industry standards.

- Sheet/Plate: Weight (kg) = Length × Width × Thickness × Density

- Bar (Rectangular): Weight (kg) = Length × Width × Height × Density

- Bar (Round): Weight (kg) = π × (Diameter/2)2 × Length × Density

- Tube: Weight (kg) = π × (Outer Radius2 – Inner Radius2) × Length × Density

For all these shapes, ensure your units match the density (e.g., use centimeters with g/cm³, meters with kg/m³), and convert as needed. This approach applies equally to a 6061 aluminum sheet or a thick-walled tube.

| Shape | Required Dimensions | Cross-sectional Area | Volume per Length/Area | Mass per Length/Area |

|---|---|---|---|---|

| Sheet/Plate | Length, Width, Thickness | Width × Thickness | Area × Length | Volume × Density |

| Rectangular Bar | Length, Width, Height | Width × Height | Area × Length | Volume × Density |

| Round Bar | Length, Diameter | π × (D/2)2 | Area × Length | Volume × Density |

| Tube | Length, Outer Diameter, Wall Thickness | π × [(OD/2)2 – (ID/2)2] | Area × Length | Volume × Density |

Extrusions and Complex Profiles

Imagine you’re working with a custom shape, like a heat sink or frame rail. For extrusions, the process starts with the cross-sectional area—often calculated in CAD. The formula is simple:

- Mass per meter (kg/m) = Cross-sectional Area (mm²) × Density (kg/cm³)

For example, if your 6061 extrusion has a cross-sectional area of 1,200 mm², and you use a density of 0.0027 kg/cm³ (which equals 2.70 g/cm³), you’ll get the theoretical weight per meter. Not sure about the area? Most CAD software will calculate it for you, or your supplier can provide it. For more on manufacturability and sourcing, Shaoyi Metal Parts Supplier is a leading integrated precision auto metal parts solutions provider in China. Their team can review your design for optimal weight, manufacturability, and quality. For expert support on custom extrusions, visit aluminum extrusion parts.

Complex profiles—think intricate automotive rails or enclosures—benefit from supplier DFM (Design for Manufacturability) feedback and verified density figures from mill certificates. This ensures your "density of aluminum 6061" calculations match real-world performance, not just theory.

Worked Examples with Cited Density

- Choose a published density: Use 2.70 g/cm³ for 6061-T6, as cited by Aluminium-Alloys.com.

- Calculate cross-sectional area: For a tube, subtract the inner area from the outer area: π × (OD/2)2 – π × (ID/2)2.

- Compute volume: Multiply the area by length (in cm or m, matching your density units).

- Find mass: Mass = Volume × Density. For a 1-meter tube, simply multiply the cross-sectional area (in cm²) by 100 (for cm length), then by 2.70 g/cm³ to get grams—or convert to kg.

- Scale by quantity: Multiply mass per unit by the number of pieces for a total weight estimate.

Let’s say you have a 6061 aluminum sheet that’s 1,250 mm × 2,500 mm × 4 mm. Convert to cm: 125 × 250 × 0.4. Multiply to get volume (12,500 cm³), then multiply by 2.70 g/cm³ to get 33,750 g (or 33.75 kg). This matches the theoretical approach outlined by Aluminium-Alloys.com.

Key takeaway: Use the published density of 6061 aluminum—2.70 g/cm³ or 2,700 kg/m³—for fast, reliable weight calculations, but always confirm with actual measurements or supplier data for critical parts.

By following these formulas and workflows, you’ll ensure your weight estimates for aluminum alloy 6061 density are both accurate and actionable—whether you’re specifying a 6061 aluminum sheet, a round bar, or a complex extrusion. Next, we’ll see how 6061 compares to other alloys and steel for even deeper design insights.

How 6061 Aluminum Density Compares to 6063, 7075, and Steel

6061 versus 6063 and 7075: Density and Performance

When you’re deciding between aluminum 6061, 6063, and 7075 for your next project, it’s natural to wonder: does density really make a difference? Or are other properties more important? Let’s break down how these popular alloys stack up—so you can make an informed choice for strength, weight, and manufacturability.

| Alloy | Density (g/cm³) | Density (lb/ft³) | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Corrosion Behavior | Machinability | Common Applications |

|---|---|---|---|---|---|---|---|

| 6061 | 2.70 | 168.48 | 270 | 310 | Excellent (natural oxide layer) | Good | Aerospace, automotive, furniture, device molds, ships |

| 6063 | 2.70 | 168.48 | 214 (T6 temper) | 241 (T6 temper) | Excellent | Very Good (extrusion-friendly) | Architectural profiles, windows, curtain walls, transportation |

| 7075 | 2.81 | 175.42 | 503 | 572 | Very good (marine and aircraft use) | Fair | Aircraft, marine plates, high-strength parts |

You’ll notice that the aluminum density 6061 and 6063 are identical at 2.70 g/cm³ (168.48 lb/ft³), making them nearly interchangeable in terms of weight. However, 7075 aluminum density is slightly higher at 2.81 g/cm³ (175.42 lb/ft³)—but this comes with a significant boost in strength. For reference, the density of aluminium 7075 and al 7075 density are key factors in aerospace and high-performance applications where strength-to-weight is critical.

In practical terms:

- 6061 is the go-to for balanced strength, weldability, and machinability. It’s widely used in structural and automotive parts.

- 6063 is preferred for architectural and decorative extrusions due to its superior surface finish and ease of forming.

- 7075 is chosen for maximum strength, especially in aerospace, despite its slightly higher weight and more challenging machinability.

6061 Compared to Steel by Density

Now, imagine you’re weighing aluminum 6061 against a common structural steel like ASTM A36. Here’s where the difference really stands out. The density of steel lb/in3 is about 0.284 lb/in³ (or roughly 7.85 g/cm³), while 6061 sits at 0.0975 lb/in³ (2.70 g/cm³) [MakeItFrom]. That means steel is nearly three times heavier for the same volume!

| Material | Density (g/cm³) | Density (lb/ft³) | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Corrosion Behavior | Machinability | Common Applications |

|---|---|---|---|---|---|---|---|

| 6061 Aluminum | 2.70 | 168.48 | 270 | 310 | Excellent | Good | Aerospace, automotive, general engineering |

| ASTM A36 Steel | 7.85 | 490 | 290 | 480 | Moderate (requires coatings for corrosion protection) | Good | Structural beams, plates, frames |

What does this mean for your design? If you swap steel for 6061, you can achieve massive weight savings—crucial for transportation, aerospace, and anywhere density of aluminum lb ft3 matters. However, steel still wins in raw strength and is often more cost-effective for heavy-duty, non-weight-sensitive structures.

Strength-to-Weight: Why Density Isn’t the Only Story

Strength-to-weight ratio is where aluminum alloys shine. For example, 7075 boasts much higher yield and ultimate strength than 6061 or 6063, while only being marginally denser. This makes 7075 ideal for high-performance parts where every ounce counts. Conversely, 6063 trades a bit of strength for superior extrusion quality and surface finish—making it the top choice for architectural frames and profiles.

Key insight: Choosing between 6061 and 6063 often hinges on extrusion quality and finish requirements—not just density. Always match the alloy and temper to your application’s demands.

Before making your final selection, remember to verify the specific alloy-temper (e.g., T6, T651) and consult the most current datasheets for your supplier. This ensures you’re working with accurate mechanical and density data, tailored to your real-world needs.

Ready to see how temperature can further affect density and weight calculations? Next, we’ll explore the impact of thermal expansion—and how to adjust your numbers for precise engineering.

Temperature Effects on Density and Calculations

Thermal Expansion and Volumetric Change

Ever wondered why your density calculations for 6061 aluminum don’t always match up, especially when temperatures change? Imagine a scenario where your part heats up during service or manufacturing—does its weight change? Not quite, but its volume does. As temperature rises, the atoms in aluminum vibrate more, causing the material to expand. This means the density of al decreases, even though the mass stays the same. This relationship is governed by the material’s coefficient of thermal expansion, commonly referred to as cte aluminium.

For 6061-T6 aluminum, the linear coefficient of thermal expansion (α) is typically reported as 23.6 × 10-6 /°C (from 20°C to 100°C) according to ASM/MatWeb. For isotropic solids like aluminum, the volumetric coefficient (β) can be approximated as three times the linear value: β ≈ 3α. This means that for every degree Celsius increase, the volume of your 6061 aluminum part expands by about 0.00708% (3 × 23.6 × 10-6). As a result, the al density drops slightly with each temperature rise.

The general formula for adjusting density with temperature is:

- Adjusted Density = Nominal Density / [1 + β × ΔT]

Where ΔT is the change in temperature from the reference point (usually 20°C or 68°F).

Formula-driven insight: As temperature increases, the volume of 6061 aluminum expands and its density decreases, but the mass remains unchanged. Always use the published coefficient of thermal expansion from sources like ASM or NIST to correct density for temperature shifts.

When Temperature Corrections Matter

Sounds like a minor detail? In many cases, you can use the nominal density of 6061-t6 aluminum lb/ft3 (168.48 lb/ft³) or 2.70 g/cm³ without adjustment. But there are situations where temperature corrections become critical. For example, if you’re designing parts for high-temperature environments (think aerospace, automotive engines, or industrial ovens), or if your weight calculations need to be extremely precise for mass-balance or metrology purposes, even small errors in density for aluminum can add up.

| Checklist: When to Apply Temperature Corrections |

|---|

| High-temperature service (above 100°C/212°F) |

| Precision mass-balance or metrology work |

| Comparing supplier data at different reference temperatures |

| Designs with tight tolerances on weight or volume |

If your supplier provides a density value at a temperature different from your design conditions, use the formula above to adjust. Always report the reference temperature of the published density you’re using, and cite your source for the cte aluminium value. This ensures your documentation is clear and your calculations are traceable.

For example, the ASM/MatWeb datasheet lists the density of 6061-T6 at 2.70 g/cm³, typically measured at 20°C. If you’re analyzing performance at elevated temperatures, apply the correction to maintain accuracy.

- Check the reference temperature of any published density value

- Apply the volumetric expansion formula for significant ΔT

- Document the CTE and calculation method in your engineering notes

By understanding how temperature influences the density of al, you can make more accurate predictions about part performance and ensure your engineering calculations stand up to scrutiny—no matter the application. Next, we’ll wrap up with actionable takeaways and trusted resources for sourcing and design refinement.

Actionable Wrap Up with Trusted Resources for Al 6061 Density

Key takeaways for engineers

When you’re wrapping up a project or preparing your documentation, it’s easy to wonder: what is the density for aluminum, and how do I make sure my numbers are truly reliable? Here’s how to keep your calculations and sourcing strategies on point, whether you’re estimating weight for a prototype or specifying production-ready extrusions.

- Always cite density from authoritative sources: Rely on published values from the Aluminum Association or ASM/MatWeb for al6061 density. This ensures consistency and traceability across your team and supply chain.

- Convert units using NIST constants: Don’t risk errors with guesswork—use National Institute of Standards and Technology (NIST) conversion factors for all unit changes. This is especially important when answering questions like “what is the density of aluminum” in both metric and imperial units.

- Refine nominal estimates with measured values as the design matures: Start with the standard published density, but update your models with actual measurements or mill certificates for critical applications. This step helps bridge the gap between theoretical calculations and real-world performance.

Trusted references and sourcing

To get the most accurate and up-to-date information, always double-check your data with these trusted industry references:

- Aluminum Association – The gold standard for alloy specifications, including what is aluminium density and related properties.

- ASM/MatWeb – Detailed datasheets for 6061 and other alloys, with physical and mechanical property tables.

- ASTM International – Authoritative material standards for aluminum alloys and testing methods.

- NIST – Official conversion factors for all common density units, helping you answer “what is the density of al” in any system.

When it comes to sourcing and manufacturability feedback for complex extrusions, don’t go it alone. For automotive, transportation, or industrial applications, early supplier engagement is critical. Shaoyi Metal Parts Supplier is a leading integrated precision auto metal parts solutions provider in China, specializing in project-based support from design through production. For direct access to design-for-manufacturability expertise and a rapid path to validated, production-ready aluminum extrusion parts, consider reaching out during the early design phase.

- Share your density assumptions and cross-sectional calculations with your extrusion supplier up front.

- Request DFM feedback to optimize for achievable tolerances, surface finish, and cost.

- Ask for mill-certified density data to ensure your mass rollups match real-world deliveries.

By following these best practices, you’ll ensure that your documentation, weight estimates, and sourcing decisions are grounded in authoritative data—so you can confidently answer questions like “what is aluminum's density” for every project stage.

Frequently Asked Questions About Al 6061 Density

1. What is the nominal density of 6061 aluminum?

The nominal density of 6061 aluminum is 2.70 g/cm³ or 0.0975 lb/in³, as published by sources like ASM/MatWeb. This value is widely used for engineering calculations, BOM estimates, and supplier communications.

2. Why does the measured density of 6061 aluminum sometimes differ from the nominal value?

Measured density can vary due to manufacturing processes, heat treatment, alloying tolerances, and internal porosity. While the nominal value is a reliable baseline, real-world parts may show slight deviations, especially in critical applications.

3. How do you convert the density of aluminum 6061 to different units?

To convert 6061 aluminum density, use trusted conversion factors: 2.70 g/cm³ equals 2,700 kg/m³, 0.0975 lb/in³, or 168.48 lb/ft³. Always use NIST constants to ensure accuracy and avoid rounding errors in your calculations.

4. How does temperature affect the density of 6061 aluminum?

As temperature increases, 6061 aluminum expands, causing its density to decrease. The mass remains constant, but the volume increases. For high-precision work or high-temperature applications, use the coefficient of thermal expansion to adjust density values.

5. Where can I source high-quality 6061 aluminum extrusions with reliable density data?

For precise 6061 aluminum extrusion parts, consider Shaoyi Metal Parts Supplier. They offer DFM expertise, rapid prototyping, and mill-certified density data, ensuring your project meets strict quality and performance standards. Learn more about their automotive aluminum extrusions at https://www.shao-yi.com/automotive-aluminum-extrusions.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —