Stamped Steel Control Arms: Cost and Strength Benefits

TL;DR

Stamped steel control arms are the standard choice for many vehicles primarily due to their low manufacturing cost and excellent durability for everyday driving. While they are heavier and more susceptible to rust compared to aluminum or tubular alternatives, they provide a strong, reliable, and budget-friendly solution for most non-performance applications and routine vehicle repairs.

What Are Stamped Steel Control Arms?

A control arm is a critical component of your vehicle's suspension system. Also known as an A-arm, it acts as a hinged link between the vehicle's chassis and the wheel hub assembly. This connection allows your wheels to move up and down in response to road imperfections while keeping them securely aligned with the vehicle's body, ensuring stability and a smooth ride. Control arms are essential for reducing friction, absorbing vibrations, and allowing for controlled steering.

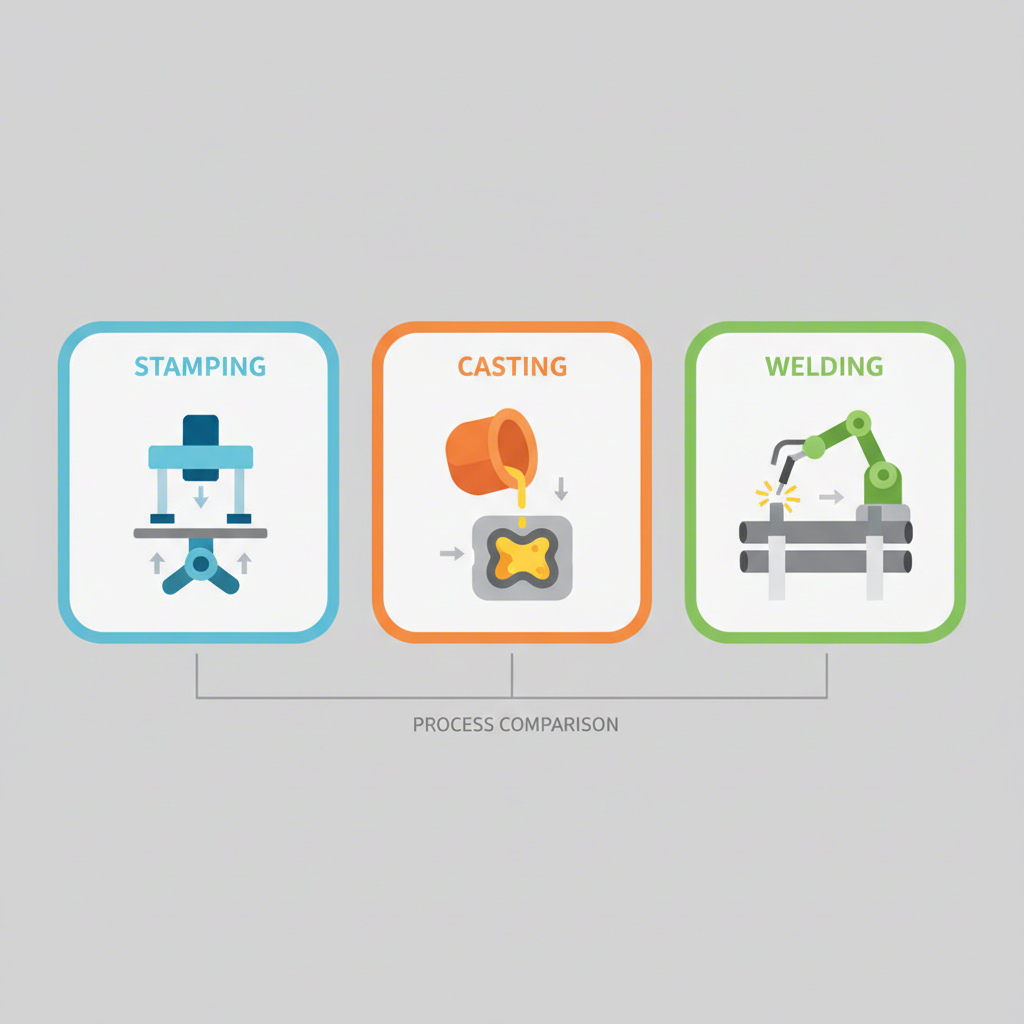

The term "stamped steel" refers to how these specific control arms are made. The process involves pressing or stamping sheets of steel into the desired shape using a powerful die. These shaped pieces are then typically welded together to form the final component. This manufacturing method is highly efficient and cost-effective, especially for mass production, which is why stamped steel arms are the go-to choice for Original Equipment Manufacturers (OEMs) on a vast range of modern, mass-market cars. Their affordability makes them a common sight in everything from family sedans to light-duty trucks.

The precision required in this process is immense, as even minor deviations can affect vehicle alignment and safety. For automotive manufacturers seeking high-quality components, specialized suppliers are key. For example, firms like Shaoyi (Ningbo) Metal Technology Co., Ltd. provide comprehensive metal stamping solutions, from prototyping to mass production, ensuring that critical parts like control arms meet stringent industry standards such as IATF 16949.

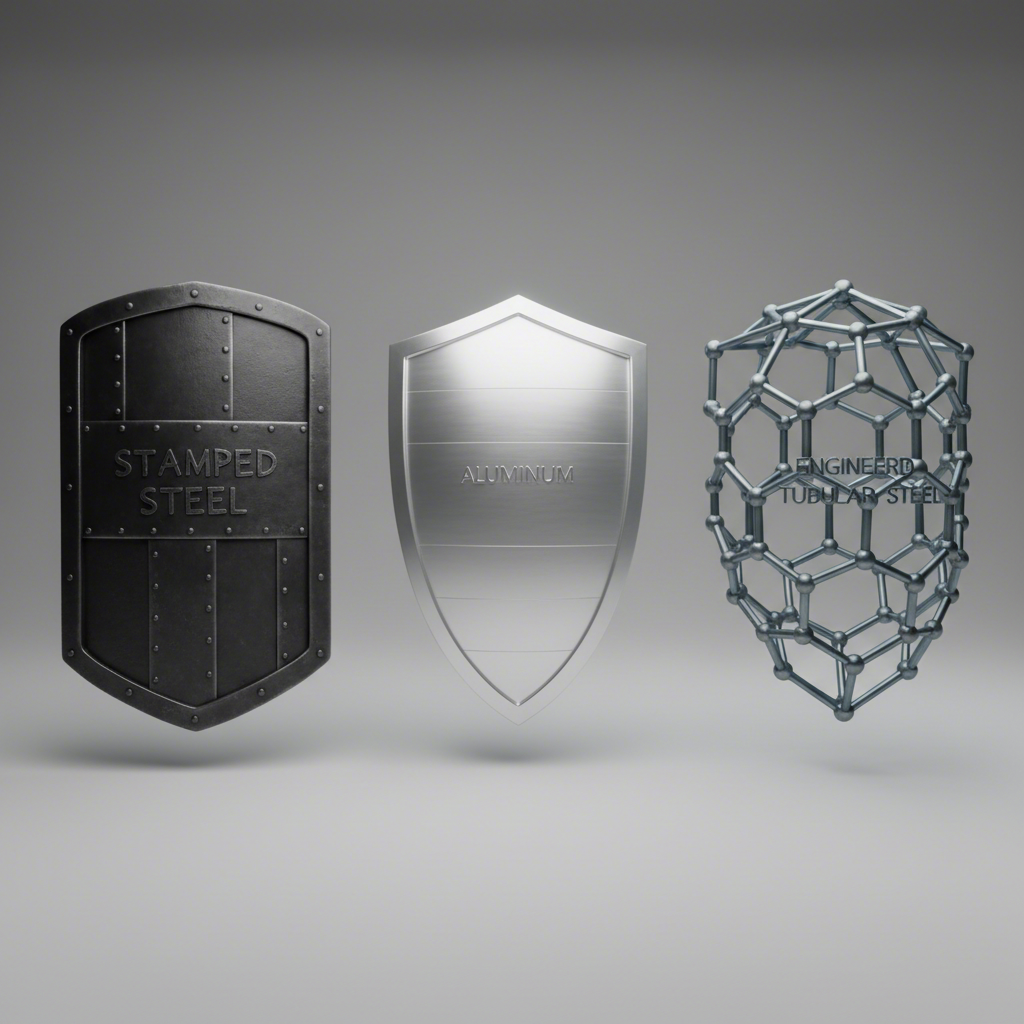

While perfectly adequate for the average driver, stamped steel is just one of several materials used for control arms. The main alternatives—cast iron, cast aluminum, and tubular steel—each offer a different balance of weight, strength, and cost. Understanding these differences is key to deciding if stamped steel is the right choice for your vehicle or if an alternative material would better suit your needs.

The Core Advantages: Cost-Effectiveness and Durability

The widespread use of stamped steel control arms in the automotive industry comes down to two primary, compelling advantages: low cost and impressive durability. These factors make them an incredibly practical choice for both manufacturers and vehicle owners focused on reliability and budget-conscious maintenance.

The most significant benefit is their cost-effectiveness. The stamping process is highly automated and optimized for producing large quantities of parts quickly and inexpensively. As noted by Metrix Premium Parts, steel is generally a less expensive raw material than aluminum. This combination of efficient manufacturing and affordable materials means that both producing and replacing stamped steel control arms is relatively inexpensive, keeping vehicle production costs down and making repairs more accessible for consumers.

Beyond price, steel offers inherent strength and durability. Steel control arms are robust and can withstand significant loads, impacts, and harsh road conditions more effectively than lighter materials like aluminum. This makes them particularly well-suited for heavy-duty applications, such as trucks and SUVs, or for vehicles frequently used on rough terrain. Their ability to endure stress without fracturing makes them a reliable choice for ensuring long-term suspension integrity.

These core benefits make stamped steel arms a default choice for a wide range of situations. For a daily commuter vehicle, they provide all the strength and performance needed for safe operation. When a control arm needs replacement due to wear and tear, a stamped steel part offers a dependable and economical solution. The key advantages can be summarized as follows:

- Low Production Cost: Efficient manufacturing processes make them the most budget-friendly option for OEMs and the aftermarket.

- High Strength: Steel's natural toughness allows it to handle heavy loads and absorb significant impacts without failing.

- Proven Reliability: As the long-standing industry standard, their performance and longevity in normal driving conditions are well-documented.

- Wide Availability: Due to their common use, finding replacement stamped steel control arms for most vehicles is simple.

Stamped Steel vs. The Alternatives: A Detailed Comparison

While stamped steel control arms are the workhorse of the automotive world, they are not the only option. Understanding how they stack up against alternatives like aluminum and tubular steel is crucial for anyone considering an upgrade or replacement. Each material offers a unique set of trade-offs in performance, weight, and cost.

Aluminum control arms are prized for being significantly lighter than steel. This reduction in weight lowers the vehicle's "unsprung mass"—the weight of components not supported by the springs. Less unsprung mass allows the suspension to react faster to bumps and dips in the road, potentially improving ride quality and handling. However, aluminum is generally not as strong as steel and can be more susceptible to damage from severe impacts.

Tubular steel arms represent a high-performance alternative. As explained by the experts at QA1, these are constructed from high-strength steel tubing, which offers a superior strength-to-weight ratio compared to stamped steel. More importantly, they are often engineered with optimized suspension geometry, providing improved caster and camber angles that can dramatically enhance steering feel, straight-line stability, and cornering grip, especially in classic or performance-tuned vehicles.

To clarify the differences, here is a detailed comparison:

| Feature | Stamped Steel | Aluminum | Tubular Steel |

|---|---|---|---|

| Weight | Heavy | Light | Medium (Lighter than stamped) |

| Strength | High to Very High | Moderate (Less impact resistant) | Very High (Engineered for performance) |

| Cost | Low | High | Very High |

| Corrosion Resistance | Low (Requires coating) | High (Naturally resistant) | Moderate (Typically powder-coated) |

| Best Use Case | Daily drivers, budget repairs, OEM applications | Luxury/performance vehicles, reducing unsprung weight | Classic car upgrades, racing, performance handling |

Choosing the right material depends entirely on your goals. For a daily driver, the durability and low cost of stamped steel are often the winning combination. If you're looking to enhance handling and responsiveness in a performance or luxury car, the weight savings of aluminum may be worth the extra cost. For classic car restorers or track enthusiasts seeking to modernize suspension geometry and gain a competitive edge, tubular steel arms are often the ultimate upgrade.

Limitations and Common Issues of Stamped Steel Arms

Despite their benefits in cost and strength, stamped steel control arms are not without their drawbacks. Providing a balanced view is crucial for making an informed decision. The primary limitations revolve around weight, susceptibility to corrosion, and less-than-ideal performance geometry.

One of the most significant disadvantages is their weight. As the heaviest option, they contribute to a higher unsprung mass, which can hinder the suspension's ability to react quickly to road surfaces. For most daily driving, this effect is negligible. However, in performance driving scenarios, this added weight can lead to a less responsive or "vague" handling feel compared to lighter alternatives that allow the wheel to maintain better contact with the road.

Corrosion is another major concern. Stamped steel parts are often made from multiple pieces of metal welded together, and these seams, along with any scratches in the protective coating, can become entry points for moisture. In regions with heavy rainfall, humidity, or road salt usage during winter, these control arms are susceptible to rust. Significant corrosion can compromise the structural integrity of the arm, eventually requiring replacement to ensure safety.

Finally, the design of OEM stamped steel arms is typically a compromise, prioritizing low cost and acceptable performance for a wide range of drivers. For enthusiasts, this one-size-fits-all approach is a limitation. The suspension geometry of factory arms, especially in older cars, may not be optimized for modern radial tires or aggressive driving styles. Upgrading to tubular arms with improved caster angles can provide a more stable, connected steering feel that simply isn't achievable with stock stamped steel components. Additionally, some factory-stamped arms are designed with non-replaceable ball joints, meaning the entire arm must be replaced when only the ball joint wears out, adding to long-term repair costs.

Frequently Asked Questions

1. What is the best material for control arms?

There is no single "best" material for all applications; the ideal choice depends on your priorities. Stamped steel is best for budget-conscious repairs and daily driving due to its high durability and low cost. Aluminum is an excellent choice for performance and luxury vehicles where reducing weight to improve handling and ride quality is a priority. Tubular steel is the top option for serious performance upgrades, classic car restoration, and racing, as it offers optimized geometry and a superior strength-to-weight ratio.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —